1. Introduction

Inconel 718 finds prime applications in defense, food processing equipment, automobile, marine, turbines, and aerospace industries (Asala et al., 2018). Although Inconel 718 is widely known for its high strength (Kim and Lee, 2019), creep resistance (Abdul Halim et al., 2020), and thermal stability (Ratnam et al., 2018), this material is difficult to cut (Kartheek et al., 2018). Low thermal conductivity (Fan et al., 2013), properties at elevated temperature (Venkatesan et al., 2016), work hardening (Ay et al., 2010; Alauddin et al., 1996), and tendency to adhere to cutting tools (Beer et al., 2014) adversely affects the machinability of Inconel 718. The heat generated between the tool-chip interface leads to poor tool life, low dimensional stability of the workpiece, and inferior surface finish (Pusavec et al., 2010a, Pusavec et al., 2010b).

To advance the machinability of Inconel 718 and promote cleaner machining, researchers are exploring earth-friendly machining alternatives to conventional machining. Dry machining is performed in the absence of cutting fluids, and hence it is more sustainable than wet machining. Dry machining using coated cutting tools improved the surface finish and tool life to a great extent. Coatings with superior properties like chemical stability, oxidation resistance, low thermal conductivity, high temperature, and hot hardness make it the most dependable option (Prengel et al., 2001). However, a vast amount of heat is disseminated through dry machining, which may cause a premature failure and shorten the tool life.

Cryogenic cooling is a viable and environmentally benign cooling technique. Cryogenic cooling rendered good results with regard to cutting forces, tool life and surface finish quality compared to conventional machining (Islam et al., 2017). Unlike conventional cutting fluids, liquid nitrogen (LN2) is a non-toxic, inert, non-corrosive, non-flammable and safe liquid that gets evaporated into the atmosphere, reduces clutter, and does not require costly disposal. Additionally, cryogenic cooling with CO2 resulted in significantly reduced cutting temperatures, forces, and better chip control (Kumar, 2013). Although cryogenic cooling using CO2 has several industrial applications (Biermann and Hartmann, 2012), LN2 is preferred in cryogenic machining due to its advantages like lower cutting tool wear and boiling point than CO2 (Kaynak and Gharibi, 2018; N Khanna et al., 2021). However, the handling costs involved in cryogenic machining are high due to the shallow temperature (below-1500C) of LN2 (Benedicto et al., 2017). There is a high chance of phase change while machining with LN2 owing to significant thermal losses that may be caused due to improper insulation.

Minimum quantity lubrication (MQL), also identified as near dry machining, has recently gained much prominence in research. This technique reduces friction, tool wear, and cutting forces drastically in contrast to conventional machining. The choice of cutting fluid determines the overall performance of MQL. The presence of solid lubricants in MQL gave high-grade results in decreasing cutting forces, increasing tool life and machined surface quality (Muaz and Choudhury, 2019). Hybrid cryogenic MQL is another variant of MQL where LN2 is applied simultaneously from different nozzles at the machining area for enhanced lubrication and cooling effect (Gajrani, 2020). Besides the above, the combination of MQL and cryogenic CO2 gave a high performance in machining superalloys like Inconel 718 (Bagherzadeh and Budak, 2018). Machining hard materials in cryo-MQL conditions improved the machinability performance with lower surface roughness, cutting forces, and temperatures (Pereira et al., 2021). Furthermore, recent studies indicate that nanofluid assisted MQL is an excellent option to promote sustainable machining of Inconel 718 (Haq et al., 2021). Nano-fluids assisted machining gives improved machining efficiency with lesser cutting forces, tool wear, better cooling, and cleaner production (Hegab et al., 2018). Promising results have been reported with nanofluid and MQL combinations, particularly in diminishing the cutting forces and tool wear.

Recently, hybrid machining techniques are gaining researchers' attention for their numerous advantages in machining hard-to-cut materials. Several hybrid machining techniques like nano and micro-particles based solid lubricant machining (Krajnik et al., 2016; Zahoor et al., 2020), high-pressure cooling system (Kubala, 2016; Xavior et al., 2017), ultrasonic-assisted machining (He et al., 2019; Azarhoushang and Tawakoli, 2011), and laser-assisted machining (Feng et al., 2019; Darwish et al., 2016) are critically studied for various superalloys. Results indicated that these techniques yield better results in improving the machinability of the workpiece in comparison with conventional machining.

The existing literature provides an origin to the path of sustainable machining of Inconel 718. Researchers are rigorously exploring modern lubricating and machining techniques to enhance the machining efficiency of difficult-to-cut materials like Inconel 718. The following vital aspects remain the topic of research.

-

•

Despite the availability of innumerable machining and cooling techniques, the machinability of Inconel 718 continues a subject of concern.

-

•

Research is confined to one or two machining strategies; there are limited reports concerning novel cutting and lubrication techniques.

-

•

Machining processes based on cryogenic and MQL cooling, despite being eco-friendly, present uncertain viability concerning its control in industries.

Therefore, the present study provides a valuable and comprehensive review of the progress of machinability during Inconel 718 machining. This study gathers the last two decades of research to explore the different machining processes, lubrication technologies, and improvement strategies for Inconel 718 to achieve sustainable and cleaner machining. This review is helpful to the researchers and industrialists and lays a strong foundation for further research on the topic.

2. Data collection and review methodology

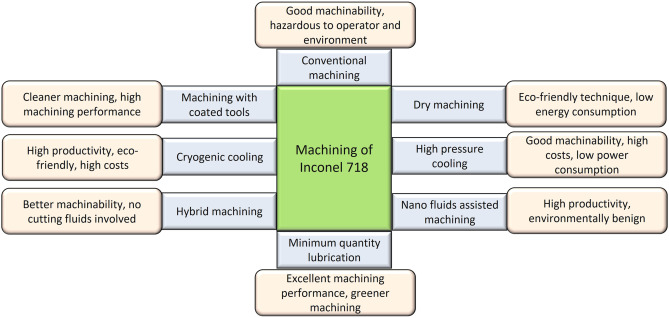

A systematic review is conducted to assess and evaluate various cooling and machining strategies for the good machinability of Inconel 718. Some of the important aspects covered in the present review are highlighted in Fig. 1. From Fig. 1, it is observed that the alternative machining techniques to conventional machining include dry machining, cryogenic cooling, machining with coated tools, solid lubricant-assisted machining, high-pressure cooling, hybrid machining, MQL machining, and nano-fluid assisted machining. In the present review, an attempt is made to analyze various lubri-cooling techniques by considering the questions presented in Table 1.

Fig. 1

Fig. 1Table 1. Research questions formulated in the review.

|

|

|

|

Record identification is carried out using research database sources like Web of Science (WoS) and Scopus. A detailed search methodology adopted for selecting research articles with distinct keywords and search strings is given in Table 2. The distribution of articles in terms of timeline, lubrication/cooling technology, machining processes, and scientific publishers are presented in Fig. 2. The pie chart reveals that most of the literature (69%) is referred from the last decade, which signifies the increasing research from the perspective of cleaner machining.

Table 2. Search methodology adopted in the review.

| Research database | Web of Science (WoS) and Scopus |

|---|---|

| Year of search | 1996–2021 |

| Keyword/search string | (“Inconel 718” OR “IN718” OR “Inconel superalloy”) AND (“eco-friendly machining” OR “sustainable machining” OR “green machining”) AND (“MQL” OR “nano cutting fluids” OR “cryogenic machining” OR “dry machining” OR “conventional machining” OR “flood cooling” OR “pressure cooling”) AND (“turning” OR “milling” OR “drilling” OR “grinding” OR “LAM” OR “EDM” OR “hybrid machining”) |

| Exclusion criteria |

|

| Inclusion criteria |

|

| Document type | Journals, Conferences, and Books |

Fig. 2

Fig. 23. Challenges in Inconel 718 machining

The machinability of Inconel 718 is not solely a material property; it is closely connected to the type of machining operation, lubricants, cutting tools, and machining parameters (Trent and Wright, 2000). The effectiveness of a machined component is directly correlated to surface integrity and mechanical properties like hardness, surface roughness, residual stresses, and metallurgical states of the work material. These performance parameters are directly impacted by cutting process input conditions like depth of cut, feed, machining speed and tool geometry. Also, the selection of cutting tools, machining method, tool geometry, and lubrication technique must be regulated and optimized to attain satisfactory surface integrity and tool life (Ezugwu and Tang, 1995). The challenges and post-machining effects encountered during Inconel 718 machining with various cutting techniques were reported in several studies, and critical observations are abstracted in Table 3.

Table 3. Critical challenges in the machining of Inconel 718.

| Author | Machining type | Challenges | Review remarks |

|---|---|---|---|

| Subhas et al. (1998) | Drilling | Dimensional instability | Surface deformation twinning occurs |

| Kawagoishi et al. (2000) | Bending | Poor surface integrity | Higher fatigue strength at elevated temperatures |

| Costes et al. (2007) | Finishing | High abrasive wear | Major wear mechanisms in CBN tools are adhesion, diffusion, and abrasion |

| Devillez et al. (2007) | Orthogonal cutting | High ductility and strong welding tendency leading to BUE | AlTiN coating provides optimal results in dry machining |

| Ibrahim et al. (2011) | Finish turning | Surface tearing, high surface roughness, and increased tensile residual stresses | MQL of 50 ml gives better surface roughness than dry and MQL of 100 ml |

| Touazine et al. (2017) | Hard turning | Work hardening tendency | Low cutting speed & high feed rate leads to higher cracked carbides. |

| Moufki et al. (2017) | End milling | Extreme thermo-mechanical loads | A predictive machining theory is used to determine cutting edge effect |

| Anthony et al. (2018) | Turning | White-layer formation | In MQL, at cutting speed of 100 m/min, small metallurgical damage, low microhardness, and compressive residual stresses are observed |

| Hua and Liu (2018) | Turning | High density and high melting point | Feed rate & tool nose radius majorly influence the surface roughness |

| Rakesh and Datta et al. (2019) | Turning | High chemical affinity with tool material | Helix angles of chips decreases with increasing cutting speed |

| Sharman et al. (2004) | Turning | Formation of microcracks | Tool life decreased with increasing cutting speed |

4. Conventional methods of Inconel 718 machining

4.1. Machining with cutting fluids

The application of cutting fluids or metalworking fluids is a conventional technique utilized to machining hard-to-cut materials. There are mainly three kinds of cutting fluids: water-based, non-water miscible, and water-miscible. The benefit of using cutting fluid is twofold: it acts as a lubricating catalyst and reduces the cutting zone temperature (Soković and Mijanović, 2001). In addition, it improved the dimensional accuracy (Inasaki et al., 1993), reduced friction between the tool-workpiece contact (Brinksmeier et al., 2015), and helped in the efficacious removal of chips and swarfs (Ali et al., 2020). The additives and lubricating oils existing in the cutting fluids form a shielding layer on the workpiece, machining equipment, and the cutting tool, which helps prevent corrosion and rust. Thus, the use of cutting fluids greatly affects the tool temperature, tool life, residual stresses, dimensional accuracy, workpiece surface roughness, and productivity. Despite its advantages, machining with cutting fluids harmed the environment and led to high production costs. Cutting fluid is one of the pre-potent effluents discarded into the environment (Kuram et al., 2011). The neat cutting oils and water-based emulsions produce an annual waste volume exceeding 20 billion litres worldwide (Cheng et al., 2005). Moreover, cutting fluids vaporize due to the extreme temperatures at the tool edge and do not reach the tool-workpiece interface (Varadarajan et al., 2002; Srikant and Rao, 2017).

4.1.1. Adverse effects on biodiversity

Large amounts of cutting fluids are liable as they cause a considerable menace to the environment and workers' health. Cutting fluids are loaded with hazardous additives, toxic metal particles, and biocides to control bacterial growth (Park et al., 2020). When inappropriately managed, cutting fluids can deteriorate water and other natural resources, leading to many ecological problems (Hong et al., 2001). Industrial workers suffer from respiratory problems like asthma, allergies, and respiratory illness through inhalation of aerosols (Sivaiah and Chakradhar, 2018). Physical contact with the cutting fluids causes hypersensitivity, allergic reactions, and cancer in the worst case (Diepgen, 2012). The National Institute of Occupational Safety and Health (NIOSH) calculated that 1.2 million operators (Marksberry, 2007) throughout the world had been exposed to the harmful influence of cutting fluids (Sanchez et al., 2010; Jegatheesan et al., 2009; Cetin et al., 2011). The cutting fluids are needed to be recycled multiple times before disposing them into the environment. Large production industries need to ensure proper disposal of gallons of waste cutting fluids which causes significant soil contamination, water and severe ecological damage if improperly treated before disposal (Vamsi Krishna and Nageswara Rao, 2008). Furthermore, life cycle assessment (LCA) has been performed and studied for several hard-to-cut materials to understand the impact of cutting conditions on natural resources, ecosystem, and human health (N. Khanna et al., 2021). A case study that analyzes the sustainability of various machining techniques with Inconel 718 states that besides causing adverse environmental and health effects, the cleaning process of cutting fluids is costly and time-consuming (Pusavec et al., 2010a, Pusavec et al., 2010b).

4.1.2. Economic challenges

In addition to the machinability concerns, economic analysis of hard-to-cut materials is an equally important element of sustainable machining. On the expenditure point, the handling cost of cutting fluids can go up to 17% of the manufacturing cost (Klocke and Eisenblätter, 1997; Goindi and Sarkar, 2017). It was noted that the expense of cutting fluids and cooling costs of the components constituted 20%–30% of the entire manufacturing costs, exceeding the overall tooling costs (Shokrani et al., 2012; Mia et al., 2018a, Mia et al., 2018b). The high amount of the cutting fluids resulted in storage and disposal issues, and more pumping power is required leading to a considerable rise in manufacturing cost (Maiyar et al., 2013; Makhesana et al., 2020; Kadam and Pawade, 2017). In a study (Tebaldo et al., 2017), the costs associated with Inconel 718 machining and the effect on productivity and machinability in terms of tool life and the surface finish has been analyzed. It is observed that the machining costs of Inconel 718 in dry, wet, MQL, and cryogenic MQL machining for distinct cutting speeds are 0.2154, 0.1739, 0.1781, and 0.2423 (€/cm3), respectively. The cost of acquisition, usage, and disposal of cutting fluids is two times greater than the other expenses, and hence it must be considered during the evaluation of machining economics. Furthermore, the overall cost of machining is prominently influenced by tooling and cooling costs (Fig. 3). The machining cost breakdown in conventional machining was reported in the literature. Dry machining and flood lubrication generally involve higher cooling and cutting costs than MQL machining (A.K. Singh et al., 2020).

Fig. 3

Fig. 34.2. Dry machining

Dry machining dismisses the use of cutting fluids to overcome the limitations associated with conventional machining. This technique can efficiently exterminate health risks like skin infections, respiratory ailments, and at the same time, improves the final cutting performance (Vollertsen and Schmidt, 2014). Dry machining is becoming increasingly popular in industries due to its advantages. Tools used in dry machining must have the ability to resist high stresses and retain hot hardness (Sreejith and Ngoi, 2000). Ceramic tools are usually used during dry machining of hard materials like Inconel 718.

In contrast to carbide tools, they offer a better abrasion, high-temperature resistance, hot hardness, corrosion resistance, minimal chemical affinity, better tool life, and an ability to perform at high speeds (Zeilmann et al., 2017). However, while machining hard materials like Inconel 718, surface quality decreases, and tool wear raises for greater feed rate and depth of cut (Krolczyk et al., 2019). Dry machining resulted in high tool wear and temperatures, leading to faster tool deterioration while machining difficult-to-cut materials at moderate and high speeds (Sasahara et al., 2008). Although the tool life can be regulated by selecting the cutting factors by the process specifications, tool wear is inevitable in any machining process. With the increase in friction at the tool-workpiece interface, the applied cutting force also increases (Wang et al., 2003).

A high-temperature gradient between surface and subsurface is generated, particularly at high cutting speeds, due to the lesser thermal conductivity of Inconel 718 (Le Coz and Dudzinski, 2014). High-temperature gradients induced surface integrity alterations like change in microstructure, plastic deformation, phase transformation, and high tensile residual stresses. A summary of the critical observations related to the machinability of Inconel 718 for various machining operations like grinding, milling, drilling and turning is presented in Table 4.

Table 4. Critical observations during dry machining of Inconel 718.

| Author | Machining type | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|

| Tso (1995) | Grinding | Wheel speed: 650–1320 m/min, table speed: 2–5 m/min, down feed: 5–15 μm | GC grinding wheel resulted in better surface roughness in case of dry grinding | CBN grinding wheel gave a better surface roughness than GC and WA types, for machining Inconel 718 |

| Heinemann et al. (2006) | Drilling | Speed: 26 m/min, feed: 0.26 mm/rev, machine power: 2.6 kW | Chips generated get jammed in the tool flank and hole surface, leading to tool deterioration | To reduce tool run-out, boreholes are centered with a pilot hole |

| Liao et al. (2008) | Milling | Max. speed: 24,000 rpm; side milling- depth of immersion: 12 mm, depth of cut: 1.0 mm | Steep rise in cutting forces after the speed of 124.4 m/min | High cutting temperatures and chip disposal issues |

| Imran et al. (2011) | Drilling | Feed: 0.5, 2, 5, 8 μm/rev, speed: 1000, 3000, 5000, 7000 rpm, peck depth: 0.1 mm | Increase in hardness attributed to rising in work hardening deformation | 5–10 μm white layer formation occurs under dry cutting |

| Devillez et al. (2011) | Turning | Depth of cut:0.5 mm, feed: 0.1 mm/rev, cutting speed: 40, 60, 80 m/min | Coated carbide tool gives high surface quality, residual stresses, and microhardness | Workpiece adheres to the tool surface, which leads to BUE formation |

| Bushlya et al. (2011) | Turning | Feed: 0.1, 0.15, 0.2 mm/rev, depth of cut:0.3 mm, speed: 100, 200, 300, 400 m/min | Refinement of grains occurs due to dynamic recrystallization | White layer formation |

| Umbrello (2013) | Turning | Feed:0.050–0.100 mm/rev, speed: 47–66 rpm | Surface roughness increase with feed rate from 0.15 to 0.25 mm/rev | High feed rate & cutting speed gives greater surface hardness in the material |

| Zeng et al. (2015) | Grinding | Wheel speed: 25 m/s, depth of cut: 0.005–0.04 mm, work-piece speed: 10 m/min | Rapid deterioration of grinding interface and high temperatures | Grinding burn may occur due to high temperatures |

| Shen et al. (2017) | Electric discharge Milling | Input current: 100, 400, 700 A, spindle rotation speed: 3000 r/min; servo speed: 2 m/s | Smaller surface roughness is attained with low input current | The thickness of the re-solidified layer is significantly thin |

| Zou al. (2019) | Turning | Speed: 40 m/min, depth of cut: 1.5 mm, feed: 0.1 mm | Minimal cutting forces and cutting temperature | Major wear mechanisms are adhesion, abrasion, and oxidation |

5. Ecological machining methods

5.1. Machining with coated cutting tools

The primary purpose of the coating material is to boost the resistance to abrasion, diffusion, adhesion, and oxidation wear processes (Pervaiz et al., 2014). Ceramic CBN and PCBN cutting tools effectively enhance the sustainability of machining processes, but due to high costs, these tools are not widely used. Therefore, researchers explored the application of coated carbide tools for improving machinability performance (Chinchanikar and Choudhury, 2013). Researchers performed several experiments in various cooling conditions. TiAlN coated tungsten carbide cutting tool-assisted machining reduced the cutting temperatures by 81% (183.6 °C to 34.9 °C) and 54.3% (76.4–34.9 °C) in case of cryogenic cooling compared to conventional cutting, respectively (Uçak and Çiçek, 2018). Also, TiAlN coatings decreased the surface roughness values under dry, cryogenic, and wet conditions, respectively. Low wear amount further resulted in lesser surface roughness of the workpiece surface. A study observed that the tool wear occurred primarily due to flank wear, plastic deformation, boundary wear, and rake face due to crater wear during micro-milling of Inconel 718 (Lu et al., 2016). During high-speed machining of Inconel 718 utilizing carbide tool inserts, the tool life decreased with increasing speed, i.e., a tool life of 357 s and 243 s is observed at 40 and 55 m/min, respectively (Thakur et al., 2009a, Thakur et al., 2009b). The effect of coated cemented carbide tools was investigated while machining Inconel 718, and it was deduced that the surface roughness decreased by 56% when single TiN coated RCMT 120400 type inserts were used (Nalbant et al., 2007). The machining performance of Inconel 718 is studied under dry machining using coated carbide tools (Rakesh and Datta, 2020). It was observed that coiled, continuous helical chips are generated, and the radius of chip curl decreases with rising cutting speed. Different types of coated tools are used in various machining processes, and their influence on the machinability performance of Inconel 718 under various cutting operations is summarized in Table 5.

Table 5. Machinability performance during coated tools assisted machining of Inconel 718.

| Author | Machining type | Cutting tool type | Cutting conditions | Review remarks |

|---|---|---|---|---|

| Ezugwu et al. (1999) | Turning | Single-layer and multi-layer PVD and CVD coated tools | Speed: 32, 42 m/min, feed: 0.13, 0.25 mm/rev, depth of cut: 1, 2 mm | Multi-layered PVD tool gives best performance in tool life. Single-layer TiN coated tool gave the improved surface finish |

| Bhatt et al. (2010) | Finish-turning | Multi-layer CVD coated tool | Speed: 50–100 m/min, feed: 0.075–0.125 mm/rev, depth of cut:0.25 mm | CVD coating (TiCN/Al203/TiN) gives the highest wear resistance at high speeds |

| Hao et al. (2015) | Turning | PVD coated tools | Speed: 20, 32, 45 m/min, feed: 0.1 mm/rev, depth of cut:1 mm | Tool wear varies with cutting speed |

| Grzesik et al. (2018) | Turning | Tools coated with heat isolating TiAlN/AlTiN layers | Speed: 65, 80, 95, 110 & 125 m/min, feed: 0.1 mm/rev, depth of cut: 0.25 mm | Coated tools enhanced the thermal resistance, resulting in longer tool-life |

| Sterle et al. (2020) | Milling | TiAlN coated carbide tool | Speed: 60 m/min, feed: 0.05 mm, depth of cut: 0.1, 12 mm | New end mills used for each sample |

| Thakur et al. (2012) | High-speed turning | TiN/Al2O3/TiCN (CVD) and TiN/TiAlN (PVD) coated tungsten carbide tools | For PVD and CVD tools, speed: 50–90 m/min, feed: 0.05–0.2 mm/rev, depth of cut: 0.5 mm, respectively | CVD tool outperformed the PVD tool with lower cutting temperatures and forces |

| Yazid et al. (2011) | Turning | MQL with PVD coated TiAIN tools | Speed: 90, 120, 150 m/min, feed: 0.10, 0.15 mm/rev, depth of cut: 0.30, 0.50 mm; Inconel 718 | Better surface roughness |

5.2. Cryogenic machining

Cryogenic cooling involves injecting liquefied gases for instance liquid nitrogen (LN2) or liquid carbon dioxide (CO2) into the cutting zone. LN2 is widely applied in cryogenic machining. It grants nearly zero pollution since it is colorless, odorless, tasteless, non-toxic, and non-flammable and has the greatest cooling capacity (−196 °C) (Abdul Halim et al., 2021). Also, CO2 procured as a contaminant from industrial and chemical processes is employed in cryogenic machining applications (Lu et al., 2018). In a study, a life cycle assessment is performed to compare liquid CO2 and LN2 in cryogenic drilling of Inconel 718 (Shah et al., 2021). The overall result indicated that although CO2 consumed less power during machining, it had a higher impact on the environment in 17 out of 18 impact categories of the LCA compared to LN2. Cryogenic machining enhances the machining performance by decreasing the tool wear, machining temperatures, cutting forces, and improving the surface quality (Dhar et al., 2002). Nevertheless, hard-to-cut material's hot strength and hardness remain high (Wang and Rajurkar, 2000). It is generally implemented as an option for cutting fluids. Researchers have investigated the benefits of cryogenic machining in various machining processes. A significant drop in flank wear of about 30% was observed while cryogenic turning of Inconel 718 with a speed of 310 m/min for a given cutting time (Pusavec et al., 2014). It was witnessed that there was almost a 50% drop in cutting temperature in the case of cryogenic cooling when contrasted to dry and flood-based cooling (Aramcharoen and Chuan, 2014). In the milling of Inconel 718, cryogenic LN2 aids to greatly lower the cutting temperature by approximately 70%, contrasted to dry machining (Musfirah et al., 2017). Cryogenic machining provides societal sustainability, along with operational safety and personal health (Lu et al., 2018a, Lu et al., 2018b). Even though cryogenic cooling is perceived as a sustainable strategy for machining hard-to-cut materials, its operational and capital costs are higher than other machining processes (Yıldırım, 2019). Cryogenic cooling is implemented with various machining processes resulting in good results in the machinability of superalloys. The effect of cryogenic cooling on the machinability of difficult-to-cut materials and its impact on various cutting operations is summarized in Table 6.

Table 6. The machinability of hard-to-cut materials in cryogenic cooling.

| Author | Machining type | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|

| Pereira and Delijaicov (2019) | Turning | Speed: 250, 275 & 300 m/min, feed: 0.1 mm/rev, depth of cut: 0.13–0.47 mm; Inconel 718 | Low surface roughness obtained (<0.3 μm) in LN2 cooling for high machining speed and lower feed and depth of cut | Improvement in fatigue life of workpiece for high cutting speeds |

| Sinha et al. (2018) | Grinding | Wheel speed: 10, 15 & 20 m/s, table speed: 3, 9 & 15 m/min, depth of cut: 10, 15 & 20 μm; Inconel 718 | Reduction in grinding forces and temperatures | Improved lubrication due to the formation of the thin lubricating layer around grinding wheel periphery |

| Chaabani et al. (2020) | Turning | Speed: 70 m/min, feed: 0.2 mm/rev, depth of cut: 0.2 mm; Inconel 718 | Higher strain in cryogenic cooling hardening than the conventional lubrication | Low tensile residual stresses |

| Khanna et al. (2020) | Turning | Speed: 60 m/min, feed: 0.05 mm/rev, depth of cut: 0.5 mm; Inconel 718 | Surface roughness in cryogenic machining is lowered by 20–37% when compared with dry and wet turning | Enhancement in tool life and reduced power consumption |

| Kaynak (2014) | Turning | Feed: 0.075 mm/rev, speed: 60 and 120 m/min, depth of cut: 8 mm; Inconel 718 | At high-level cutting speed, cryogenic machining gives superior surface roughness of 0.325 μm compared to 0.641 μm | Cryogenic cooling is best suited for machining of Inconel 718 at high speed |

| Kenda et al. (2011) | Turning | Speed: 60 m/min, feed: 0.05 mm/rev, depth of cut: 0.63 mm; Inconel 718 | Cryogenic cooling resulted in large compressive residual stresses, which resulted in better surface quality | Cryogenic machining out-performed conventional machining giving better wear resistance and fatigue life |

| Varghese et al. (2018) | Milling | Speed: 34, 22, 17 m/min, feed: 32, 52, 58 mm/min, depth of cut: 0.05, 0.1, 0.15 mm; Austenitic stainless steel AISI 304 | Cryogenic cooling gives reduced surface roughness values by 72.65% and 77.78% than dry & wet conditions | Chips formed in case of cryogenic cooling had low serrations when than dry and wet conditions |

| Zurecki et al. (2003) | Hard turning | Speed: 122, 213 m/min; feed: 0.102 mm; depth of cut: 0.381 mm, steel | Limits the development of white and dark layer compared to conventional machining | Increased surface hardness and residual stress distribution |

5.3. Solid lubricant assisted machining

Another research area, which likewise presents environment sustainability and is studied by several researchers, is solid lubricants assisted machining. Solid lubricants improved machining effectiveness in terms of surface finish, cutting force, and tool life. Various solid lubricants such as graphite, MoS2, CaF2, WS2, and barium fluoride are reported in the literature. In a study (Reddy Paturi et al., 2018), the effect of WS2 assisted turning resulted in considerable enhancement in the quality of the Inconel 718 machined surface. Graphite and MoS2 provide exceptional lubrication in critical conditions, where operational limits of contact pressures and temperatures are surpassed in the case of conventional cutting fluids (Marques et al., 2016; Sterle et al., 2018). In another study (Dilbag and Rao, 2008), MoS2 and graphite assisted hard turning are performed on bearing steel. It is observed that solid lubricant-assisted turning provided lower surface roughness values compared to dry turning. When used with other lubrication techniques such as cutting fluids and MQL, solid lubricants enhance the tribological properties of the base fluids. A study (Makhesana and Patel, 2021a, Makhesana and Patel, 2021b) compared solid lubricant assisted MQL machining of Inconel 718 to dry machining; tool life, energy consumption, and carbon emission reduction are observed to be improved 75%, 64%, and 79%, respectively. of Inconel 718 machining is performed with hexagonal boron nitride and graphite solid lubricants (Kumar et al., 2018). The results show that solid lubricants' performance is better in reducing surface roughness value by 10–18%. To summarize, solid lubricant-assisted machining is cleaner, greener and provides superior benefits in enhancing the quality of machining hard-to-cut materials compared to conventional techniques. The performance of solid lubricants in various machining operations investigated for hard-to-cut materials under different cutting conditions is presented in Table 7.

Table 7. The performance of solid lubricants in machining of difficult-to-cut materials.

| Author | Machining type | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|

| Suresh Kumar Reddy and Rao (2006) | Milling | Speed: 150, 200 and 250 m/min, feed: 200, 300 and 400 mm/min, AISI 1045 steel | Considerable reduction in specific energy and an improved surface finish | Lesser cutting force with an increase in radial rake angle |

| Marques et al. (2019) | Turning | Feed: 0.1 mm/rev, depth of cut: 0.5 mm, Speed: 250 m/min, Inconel 718 | Increase in tool life by 12% when compared to dry machining | MoS2 outperformed graphite in terms of better tool life (by 22%), cleaner machining |

| Darshan et al. (2019) | Turning | Speed: 80, 120, 180 m/min; feed: 0.16 mm/rev, depth of cut: 0.5 mm, Inconel 718 | Decrease in forces by an average of 12–14%, less energy requirement | Canola oil & MoS2 particles mixture enhances the cooling & friction in cutting zone |

| Paturi et al. (2016) | Turning | Speed: 150 m/min, feed: 0.2 mm/rev, depth of cut: 0.1 mm, Inconel 718 | The surface finish of workpiece rises sharply with an increasing feed value | Up to 35% improvement in surface quality WS2 solid lubricant assisted machining when compared to MQL machining alone, green machining |

| Sahoo et al. (2012) | Grinding | Speed: 15, 18, 21, 24 m/s, feed: 10, 20, 30, 40 μm, Ti–6Al–4V alloy | Cutting forces reduced from 5 to 20% compared to dry grinding | MoS2 gives surface finish than dry grinding |

| Agarwal and Rao (2007) | Grinding | Feed:10 m/min, depth of cut: 25 μm, grit size: 63 μm, SiC alloy | Significantly low surface roughness compared to dry conditions | High machinability compared to dry grinding |

| Rudnev et al. (2021) | Grinding | Sebacic acid and stearin mixture (1:1) is used, Alloy T15K6 | Better surface roughness, eco-friendly | Increase in productivity is 13.8%, diamond spark grinding, less waste |

5.4. High-pressure cooling

High-pressure cooling is a modern form of conventional lubricating technique that involves administering fluid jet onto the cutting zone at extremely high pressure, up to 80–360 MPa (Courbon et al., 2009; Öjmertz and Oskarson, 1999). Besides with the improved machinability characteristics such as high surface finish and lower cutting forces, high-pressure cooling has a superior capacity to induce breaking of chips, unlike dry and wet machining (Mia et al., 2018a, Mia et al., 2018b; Debnath et al., 2014). In addition, high-pressure cooling enables better diffusion of the cooling medium in the tool-chip and tool-work contact, thus giving a more cooling effect and reduced tool wear (Sharma et al., 2009; Naves et al., 2013). The cooling effect is higher in high-pressure cooling, majorly due to its enhanced convective heat transfer coefficient (Courbon et al., 2011).

In a study (Ezugwu and Bonney, 2004), high-pressure machining of Inconel 718 is analyzed and compared with conventional machining. In high-pressure cooling (203 bar and 50 m/min), tool life improved by 740% than conventional machining. A similar study on turning of Inconel 718 in high-pressure cooling (15 MPa and 250 m/min) indicated improved tool life by 71% compared to conventional machining conditions (Ezugwu et al., 2005). Furthermore, when machining Inconel 718 and Waspaloy during high-pressure jet cooling, it is observed that the flank wear notably reduced in high-pressure machining than conventional cooling (Polvorosa et al., 2017). In another study (Dahlman and Escursell, 2004), decarburized steel is machined under high-pressure cooling conditions; surface topography improved by 80% in high-pressure cooling compared to dry machining. For other difficult-to-cut materials like Ti–6Al–4V, it is noted that high-pressure water-based emulsion gives good quality results in terms of tool life than in the cryogenic coolant case (Bermingham et al., 2012). The performance of high-pressure cooling in Inconel 718 machining and its impact on machinability with various cutting operations is highlighted in Table 8.

Table 8. The role of high-pressure cooling in Inconel 718 machining.

| Author | Machining type | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|

| Ezugwu and Bonney (2005) | Finish machining | Pressure up to 20.3 MPa, PVD coated carbide tools | Reduced surface roughness, tool life increased by 350% than conventional technique | High cutting forces with rising cutting speed. |

| Sharman et al. (2008) | Turning | Speed: 3000 r/min, motor: 60 kW, pressure up to 450 bar | Surface roughness is between 0.7 & 1.0 μm, lower flank wear | Due to better cooling ability, lower tensile stress (900 MPa) is induced |

| Vagnorius and Sørby (2011) | Facing | Speed: 300 m/min, feed: 0.2 mm/rev, depth of cut: 1.0 mm | Improved chip breaking, increase in life of SiAlON ceramic tool | Economically sustainable |

| Hood et al. (2013) | End milling | Pressure: 70 bar, flow: 26 l/min | Lowest surface roughness obtained is 0.4 μm with horizontal downward cutter position | Reduction in cutting temperature from 320 °C to 175 °C in case of dry and high pressure cooling respectively |

| Cica, D and Kramar D. (2019) | Turning | Pressure: 150 MPa | Better surface roughness is obtained at lower feeds | Lesser energy consumption, eco-friendly |

| López De Lacalle et al. (2000) | Drilling | Drilling (Speed: 25, 35 m/min), Turning (Cutting speed: 120 m/min, doc: 0.5 mm, feed: 0.12 mm/rev) | Surface roughness: 0.3 mm | The tool performs well at the speed 25 m/min, TiN coating |

5.5. Hybrid machining

The hybrid machining process is based on the regulated interaction of machining processes or energy sources or tools to improve the overall machinability (Lauwers, 2011). Therefore, the development of a hybrid process must be such that it maximizes the benefits and results in minimal difficulties observed in the individual techniques. A few examples of hybrid machining are magnetic field-assisted finishing (Guo et al., 2017), ultrasonic-assisted vibration turning (Wang et al., 2016), abrasive powder mixed WEDM (Ranjan et al., 2019), rotary EDM (Aliakbari and Baseri, 2012) and ion-irradiation induced hardening (Hunn et al., 2001).

The ultrasonic vibration-assisted machining technique improved the machinability of nickel-based superalloy to a greater extent in grinding (Bhaduri et al., 2013), milling (Hsu et al., 2007), drilling (Baghlani et al., 2013) and turning processes (Mitrofanov et al., 2004). In an experimental study of cryogenic ultrasonic turning of Inconel 718, surface roughness is reduced by 25–33% compared to conventional turning (Khanna et al., 2020a, Khanna et al., 2020b). Ultrasonic assisted grinding is better than conventional grinding in terms of lower grinding force (40–60%), better material removal rate, low temperatures, enhanced surface quality, less thermal burn, and better tool life (G. Singh et al., 2020). During ultrasonic-assisted machining of Inconel 718, the tool vibrates in the feed direction, and it was noted that the ultrasonic method increases surface quality; surface roughness values of conventional turning and ultrasonic-assisted turning are 1.719 μm and 0.505 μm, respectively (Silberschmidt et al., 2014). In an investigation on micro-milling of Inconel 718 with laser-induced oxidation, the surface roughness of slot bottom, up-milling and down milling sides is 108.5 nm, 26.8 μm and 36.2 μm, respectively (Xia et al., 2020). In addition to that, the given hybrid process reduces the tool wear and improves the life of the micro-end mill compared to standard micro-milling. Research shows that the use of abrasive mixed surface electro-discharge diamond grinding enhances the overall performance of the process (Unune and Mali, 2017). A study observed that the workpiece surface machined using SiC powder combined EDM exhibited better surface morphology with regard to fewer surface irregularities (pockmarks, deposited globule of debris and cracks) than conventional EDM of Inconel 718 (Sahu et al., 2018). Despite high energy consumption and processing costs, hybrid machining is an environmentally benign process that offers promising results in improving the overall machinability of Inconel 718. The machinability of Inconel 718 is reviewed for different cutting operations under hybrid machining conditions and the differences and observations are presented in Table 9.

Table 9. The role of hybrid techniques in Inconel 718 machining.

| Author | Machining type | Hybrid machining technique | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|---|

| Feyzi and Safavi (2013) | Cutting | A combination of plasma enhanced cryogenic and ultrasonic assisted machining | Cutting speed: 5, 7.5 and 10 m/min; feed: 0.025–0.1 mm; depth of cut: 0.1 mm | Surface roughness values in hybrid and conventional method are 0.2 μm & 2.5 μm respectively | Only 7–14% of cutting forces are required in hybrid method, eco-friendly |

| Venkatesan and Ramanujam (2016) | Laser cutting | Laser assisted hybrid technique | Cutting speed: 60, 80, 100 m/min; feed: 0.06, 0.08, 0.1 mm/rev; approach angle: 60° | Laser assisted machining reduced tool wear by 2.5 times than conventional method | Low cutting forces with lower cutting speed |

| Bai et al. (2019) | Turning | Ultrasonic assisted hybrid method | Cutting speed: 20, 30, 40 m/min; feed: 0.08, 0.16, 0.25 mm/rev; depth of cut: 0.12, 0.2, 0.28 mm | Surface roughness reduced in ultrasonic method compared to conventional turning | Better surface topography |

| Wang et al. (2003) | Turning | A combination of plasma enhanced and cryogenic technique | Cutting speed: 5.2 m/s; feed rate: 0.127 mm/rev; doc: 0.76 mm | Surface roughness and cutting forces reduced by 250% and 30–50% than conventional machining | Tool life is increased by 170% compared to conventional machining, cleaner machining |

| Ahmed et al. (2020) | Drilling | Electric discharge machining with extra DC supply | DC supply: 50, 140 A; rotational speed: 100, 2000 rpm | Brass and copper tool electrode gave less surface roughness than CuW electrode. | Brass electrode generated highest MRR, eco-friendly |

| Novak et al. (1997) | Cutting | Plasma enhanced machining | Cutting speed: 5.45 m/s, depth of cut: 0.82 mm, feed: 0.124 mm | Surface roughness improved by a factor of 4, cutting forces reduced by 20% | Tool notching is significantly reduced |

5.6. MQL machining

The disadvantages of using conventional machining encouraged the researchers to develop a sustainable lubrication technique; MQL is introduced as a cleaner substitute to conventional machining (Brinksmeier et al., 1999; Javaroni et al., 2020). MQL uses only around 10–100 ml/h of cutting fluid compared to 20 l/min in case of flood cooling (Tai et al., 2014). Overall performance of MQL depends upon the choice of cutting fluid, machining process, and workpiece material (El Baradie, 1996). Researchers inferred that the MQL or near dry machining method provided more reliable results than other lubricating methods in improved tool life and surface characteristics (Rahim and Dorairaju, 2018). The tribological characteristics with the MQL technique can be enhanced by adding micro and nano dispersed particles of MoS2, CaF2, Al2O3, CuO, and graphite to the base fluids according to the process requirement (Pervaiz et al., 2016; Maruda et al., 2017). High vaporization and low wettability of the cutting fluids result in high tool wear and poor surface quality (Ajay Vardhaman et al., 2018). After thorough research of various machining operations with MQL and its combination with other lubricating techniques, it can be concluded that MQL is successful in terms of environmental sustainability.

5.6.1. Cryogenic assisted MQL

Cryogenic MQL is a hybrid technique that combines the advantages of MQL and cryogenic cooling, providing a sustainable balance between the machinability of Inconel 718 and environmental issues (Zhang et al., 2012). The mixed use of MQL with CO2-based cryogenic cooling is studied on a progressive level, significantly reducing the temperatures while using this technique in milling Ti6Al4V (Hanenkamp et al., 2018). Compared with other green alternatives, the internal cryogenic MQL technique effectively increased tool life in milling of Inconel 718; cutting forces reduced by 21%, and tool life increased by 57% compared to MQL alone (Pereira et al., 2020). Furthermore, during the turning operation of Ti6Al4V, the cryogenic MQL technique was implemented, and an enhancement in terms of lower surface roughness of about 29% is observed, compared to dry cutting (Sartori et al., 2017). The aerosol lubrication with CO2 provided sufficient lubrication under optimized conditions; this cooling technique is prevalent and finds a massive application in machining hard-to-cut material. Several machining operations including grinding (Manimaran et al., 2013), turning (Dhar et al., 2015; Venugopal et al., 2003), milling (Ravi and Kumar, 2011; Huang et al., 2014), and drilling (Dix et al., 2014) are studied in the cryogenic MQL environment. Additionally, in cryogenic machining of Inconel 718, an increase of 124% in tool life was observed (Su et al., 2010). An improvement in machining performance is reported during cryogenic machining in literature; lower cutting forces (Yuan et al., 2011) and better tool life (Su et al., 2007) are observed. The prime target of the researchers was to lower the tool wear, which could be implied by the enhancement in surface finish and reduction in crater wear was noted. The increase in tool service life and drop in cutting forces is reported in milling hard-to-cut material such as Inconel 718 while machining with cryogenic MQL using biodegradable vegetable oil (Iqbal et al., 2016). The important observations and differences in machinability reported in the literature for various cutting operations in cryogenic MQL lubrication machining of Inconel 718 are critically studied and summarized in Table 10.

Table 10. The role of cryo-MQL in Inconel 718 machining.

| Author | Machining type | Cutting conditions | Machinability | Review remarks |

|---|---|---|---|---|

| Danish et al. (2021) | Turning | Cutting speed: 60, 80, 100, 120 m/min; feed: 0.15 mm/rev; cutting depth: 0.5 mm | Cryo-MQL lessens temperature, surface roughness, and tool wear by 37%, 60.6%, and 19.5%, respectively than dry machining | Micro-hardness increases, ecofriendly machining |

| Pereira et al. (2017c) | Milling | Flowrate: 7 l/min; Speed: 60 m/min, feed: 0.02 mm/tooth, depth of cut:10 mm | Cutting forces reduced by 10% compared to wet machining | Reduces the consumption of CO2, leaner machining |

| Shokrani et al. (2017) | Milling | Cutting speed: 60 m/min, feed: 0.05 mm/tooth, depth of cut: 20 mm | Doubles the tool life and enhances surface quality by 18% compared to conventional technique | Delays chipping and low abrasion wear |

| Iturbe et al. (2016) | Turning | Cutting speed: 70 m/min, feed: 0.2 mm/rev, doc: 0.2 mm | Tool life is shorter compared to conventional in long run | Environment friendly |

| Pereira et al. (2017b) | Milling | Oil flow: 100 mL/h, Cutting speed: 120 m/min, feed: 0.12 mm/teeth, doc: 0.2 mm | Tool life increases up to 93.5% | Cleaner machining; Low cutting temperature |

| Halim et al. (2019) | High speed milling | Cutting speed: 120–140 m/min, feed: 0.15–0.25 mm/tooth, depth of cut: 0.3–0.7 mm | Tool life improves 70.8% relative to dry machining | Eco-friendly; 80% lower cutting temperature than dry machining |

5.6.2. Solid lubricant assisted MQL machining

Despite its advantages in improving surface integrity and providing environmental sustainability, the machinability of Inconel 718 remains a subject of concern in MQL due to the insufficient cooling capacity of air compared to liquids (Dureja et al., 2015). The micro/nano-sized solid lubricants (for instance hexagonal boron nitride, molybdenum disulfide, tungsten disulfide, and graphite) are applied to overcome this issue in a suitable base fluid. In addition to improving the machinability of the workpiece material in lowering friction and controlling heat generation at the tool-workpiece edge, processing costs in solid lubricant-assisted MQL machining are lesser than cryogenic assisted MQL machining (Sartori et al., 2018). Furthermore, solid lubricants can decrease the coefficient of friction by forming a lubricating film at the cutting interface and maintaining a constant thickness irrespective of changing load, speed, and temperatures (Sidik et al., 2017). In a study (Marques et al., 2017), the turning operation of Inconel 718 is performed in the presence of MoS2 and graphite assisted MQL. It is observed that MoS2 and oil mixture gave superior machinability, environmental sustainability, and cost-effectiveness. A variety of solid lubricants are used for machining Inconel 718 with various cutting operations, and their influence on machinability for each operation is discussed thoroughly in Table 11.

Table 11. The role of solid lubricant assisted MQL in Inconel 718 machining.

| Author | Machining type | Solid lubricants/mixture | Cutting conditions | Review remarks |

|---|---|---|---|---|

| Danish et al. (2021b) | Milling | Graphene-based sunflower oil | Speed: 80 m/min, feed rate: 0.2 mm/rev, depth of cut: 0.5 mm | Reduction in surface roughness, cutting temperature, cutting force and tool wear by 49%, 31%, 25%, and 20% respectively than dry machining; clean machining |

| Gutnichenko et al. (2018) | Turning | Graphite nanoplatelets dispersed in vegetable oil | Speed: 100 m/min, feed: 0.15 mm/rev, depth of cut: 1.5 mm | 0.2% GnP additives to vegetable-based oil substantially improved the performance in terms of process stability and surface finish; ecological machining |

| Makhesana (2021) | Turning | Nano-molybdenum disulphide dispersed in palm oil | Speed: 150 m/min, feed: 0.2 mm/rev and depth of cut: 0.5 mm | Decrease of tool wear and surface roughness with 1% nMoS2 and palm oil is observed; sustainable machining |

| De et al. (2019) | Grinding | Graphene dispersed in semi-synthetic oil | Worktable speed: 5 m/min, depth of cut: 5 μm | The presence of graphene reduced the number and size of cracks obtained; requires about 50% less grinding power and gives a better surface finish |

| Sivalingam et al. (2020) | Turning | 0.2 wt% of molybdenum disulfide and graphite powder with atomization-based cutting fluid | Speed: 250, 300, 350 m/min; feed: 0.1 mm/rev Depth of cut: 1.1, 0.3 mm | 50–65% less flank wear, 39–51% less surface roughness than dry conditions |

5.6.3. Nanofluid assisted MQL machining

A nano-fluid is prepared by dispersing nanoparticles in a base oil. Nano-cutting fluids have advanced lubricating properties due to their excellent heat extraction capabilities. Nano-additives can be primarily categorized into metallic, non-metallic, ceramic, and carbon types (Daungthongsuk et al. 2007). Nano-fluids exhibit excellent lubricating properties at different temperatures, proving their potential advantages for green machining (Sharma et al., 2015). The rolling and sliding impact of nanoparticles and the fatty acid matter in vegetable oils can appreciably increase the lubrication effect during the machining of hard materials (Gupta et al., 2019). The sliding mechanism reduces the friction coefficient, diminishing the surface roughness and refining the machining performance (Zin et al., 2018). Nanoparticles tend to readily form a protecting film on the workpiece surface (Sen et al., 2019). Many researchers have assessed the performance of nano-fluid based MQL to reach the goal of sustainable machining (Yıldırım, 2020). The nano-additives present in nano-fluids can easily seep through the rubbing interface of workpiece and tool. Thus, an electro-hydrodynamic lubricating property is provoked, which augmented the lubricating capability of the cutting fluid (Chein and Chuang, 2007; Wickramasinghe et al., 2020). Various mechanisms have explained the enhancement in lubricity of nano-fluids such as ball-bearing effect (Rapoport et al., 2002), tribo-film formation (Hu et al., 2002), mending (Liu et al., 2004), polishing effect (Raina and Anand, 2017), sliding, rolling, filming (Lee et al., 2009). The benefits of using nanoparticles dispersed MQL were reported in the literature. In the grinding operation of Inconel 718, lower temperatures, grinding forces, and surface roughness values are observed when machining with graphene nanoparticles compared to dry grinding and has a positive influence on both environmental and production costs (Pavan et al., 2019).

It is observed that the performance of silicon dioxide nanoparticles was better than other nanoparticles; it gave high hardness, high sliding effect, low cost, and high market availability (Sayuti et al., 2014). In another work (Paturi et al., 2020), eco-friendly turning of Inconel 718 is performed using a 0.6 wt % AgNP-GCF (silver nanoparticle green cutting fluid) supported MQL technique; 55% and 26% drop in surface roughness values are observed compared to dry and MQL machining without the presence of AgNPs, respectively. The better surface quality with AgNP-GCF assisted MQL is due to the solid inherent heat transfer property of AgNPs. In an experiment, internal-cooling assisted grinding of Inconel 718 is executed using nano-additive (Al2O3 in soyabean oil) assisted MQL. It was observed that the 2.0 wt% Al2O3/soybean oil nanofluid exhibited the best anti-wear and friction-lowering capability by diminishing the coefficient of friction and wear volume to 19.79% and 67.8%, respectively (Peng et al., 2021). According to another study (Azim et al., 2020), using eco-friendly nanofluids ended in improved characteristics like the decline in applied forces, coefficient of friction, and better surface integrity during grinding of Inconel 718. Overall, nanofluid-assisted MQL machining of Inconel 718 and other hard-to-cut materials like Ti alloys, steel, etc., gave positive results in terms of sustainable machining and improving the machinability under various cutting conditions (Table 12).

Table 12. The machinability of hard-to-cut materials in nanofluid-assisted MQL machining.

| Author | Machining type | MQL conditions | Cutting conditions | Review remarks |

|---|---|---|---|---|

| Behera et al. (2017) | Turning | MQL and nMQL | Speed: 40 m/min, feed: 0.04 mm/rev, rake angle: 10°; Inconel 718 | Low cutting forces and tool wear |

| Pereira et al. (2017) | End milling | MQL with high oleic and plain sunflower oil, castor oil and ECO-350 | Speed: 45 m/min, feed: 0.03 mm/tooth, depth of cut: 0.2 mm; Inconel 718 | Tool life is increased by 15% with high oleic sunflower oil |

| Bertolini et al. (2020) | Turning | Graphene nanoplatelets-assisted MQL | Speed: 100 m/min, depth of cut: 1 mm, feed: 0.3 mm/rev; Inconel 718 | Improved surface integrity and chip morphology |

| Gong et al. (2020) | Turning | MQL with GnP nanofluid | Speed: 100 m/min, depth of cut: 1 mm, feed: 0.3 mm/rev; Inconel 718 | Improved thermo-physical characteristics |

| Kamata and Obikawa (2007) | Turning | High-speed MQL with coated tools | Depth of cut: 0.1 mm, feed: 0.1 mm/rev, Speed: 1.0, 1.5 m/s; Inconel 718 | Better tool life & surface finish, tool life decreased with cutting speed |

| Khanafer et al. (2020) | Micro-drilling | Rapeseed oil is base cutting fluid, and Al2O3 is the nano-additive of MQL | Speed:5540 rpm, feed: 39.878 mm/min, depth of cut: peck depth: 0.1 mm; Inconel 718 | Reduced thrust forces, flank wear, and unexpected breaking of micro-drilling tool |

| Rahim and Sasahara (2011) | Drilling | Palm oil and synthetic ester assisted MQL | Speed: 30, 40, 50 m/min, feed:0.05: 0.1 mm/rev thickness: 20 mm; Inconel 718 | Surface roughness reduces with rising machining speed and feed |

| Kasim et al. (2016) | End milling | MQL with the plat-base oil Coolube 2210 EP | Speed: 100 m/min, feed: 0.15 mm per tooth, depth of cut: 0.2 mm; Inconel 718 | Optimized values are maximum material removal = 9.03 cm3 and minimum total cost = $11.03 per 100 cm3 |

| Virdi et al. (2020) | Grinding | Al2O3 nanoparticles, sunflower, rice bran based MQL | Wheel Speed:28 m/s, depth of cut:20 μm, traverse speed: 35 mm/s; Inconel 718 | Energy efficient and environment friendly process, lower coefficient of friction |

| Li and Chou (2010) | Micro-milling | Vegetable oil based MQL | Feed: 1.0, 1.5, 2.0 micro m/rev, depth of cut: 300 μm; SKD 61 steels (hardness: HRC38) | Tool flank wear increases in MQL than dry cutting by 60% |

| Tawakoli et al. (2010b) | Grinding | Mineral oil-MQL and fat alcohol-MQL | Wheel speed: 30 m/s, depth of cut: 30 μm, work speed: 3000 mm/min; 100Cr6 hardened steel | Low thermal deterioration and material side flow on the surface generated by grinding wheel |

| Filipovic and Stephenson (2006) | Drilling | MQL | Cutting speed: 80 m/min, spindle speed: 4130 rpm, feed: 0.13 mm/rev, penetration rate: 537 mm/min; 1038 Steel | Higher penetration rates and acceptable tool life |

| Fratila (2009) | Gear milling | Vegetable oil (fluid flow – 0.4 ml/min) in MQL and compressed air (5 bar) in MQCL | Cutting speed: 130 m/min, axial feed: 2.7 mm/workpiece rotation, 16MnCr5 of hardness (55–60 HRC) | Improvement in the chips recycling, better tool life, clean environment, less costs |

| López De Lacalle et al. (2006) | Milling | MQL | Speed: 942 m/min, depth of cut: 3 mm, feed: 5000 mm/min, 5083-H112 aluminum alloy | MQL helps in cooling, lubrication and chip removal from the tool and workpiece |

| Silva et al. (2005) | Grinding | LB 1000 lubricant assisted MQL | Wheel speed: 30 m/s, spark out time: 10 s, depth of cut: 0.1 mm; ABNT 4340 steel | Tangential cutting forces decreased, diametral wear reduced substantially |

| Fratila and Caizar (2011) | Face milling | MQL using Lubrimax oil | Depth of cut: 0.5 mm, feed: 0.08 mm/tooth, speed: 100.48 m/min, AlMg3 | Near-dry techniques are a successful alternative to conventional cutting fluids |

| Braga et al. (2002) | Drilling | MQL and diamond coated tool | For uncoated carbide K10 tool Speed: 300 m/min, feed: 0.1 mm per revolution; number of holes: 612 Aluminum–silicon alloy with 7% silicon (SAE 323) | Better quality holes obtained |

| Rahman et al. (2002) | Milling | Base oil BP CILORA 128 in MQL | Speed: 75 m/min, feed: 0.01 mm/tooth, depth of cut: 0.35 mm, ASSAB 718 HH steel | Reduction in cutting force, very efficient at minimal speed, feed rate & depth of cut |

| Rahman et al. (2001) | End milling | MQL | Speed: 75, 100, 125 m/min, feed: 0.01, 0.015, 0.02, 0.03 mm/tooth, depth of cut: 0.35, 0.50, and 0.70 mm; ASSAB 718HH steel | Fewer burrs formed during MQL |

| Davim et al. (2007) | Turning | MQL and flood cooling | Cutting speed:100, 200, 400 mm/min, feed: 0.05, 0.1, 0.15, 0.2 mm/rev, depth of cut: 2 mm; Brass | Surface roughness improves with a rise in feed |

| Tawakoli et al. (2011) | Grinding | Mineral oil, hydrocracked, fat alcohol, ester, white oil, carbon hydride, polymer, and synthetic oil based MQL | Wheel speed: 30 m/s, depth of cut: 30 μm, work speed: 3000 mm/min; Hardened (100Cr6) | Grindability of 100Cr6 hardened increase with MQL method |

| Tawakoli et al. (2010a) | Grinding | HAKUFORM 20–34 MQL oil | Depth of cut: 20 μm, speed: 30 m/s; Hardened (100Cr6) with 5072 HRC | MQL oil effectively penetrates the boundary layer |

| Tawakoli et al. (2009) | Grinding | Mixture of air and oil mist based MQL | Speed: 2.5, 5, 10 m/min, depth of cut: 5, 10, 15, 25 mm; Hard steel (100Cr6), Soft steel (42CrMo4) | Better surface roughness, low cutting forces and high MRR |

6. Economic concerns of machining Inconel 718

Manufacturing industries upgrade their working notions to lessen machining costs and adverse effects on biodiversity for sustainable manufacturing, thus shifting from conventional machining to its sustainable alternatives. In dry machining, the total machining cost of the workpiece reduces by 17%, mainly by eliminating coolant supply, maintenance, disposal, and cleaning costs (Dudzinski et al., 2004). However, despite negligible cleaning and maintenance costs, high tool wear leads to more extraordinary expenses due to the frequent replacement of the tools in dry machining (Cantero et al., 2013). In a study on the machinability of Inconel 718, it is observed that utilizing the carbide tool insert (K20 type) during high-speed turning is more economical compared to CBN or PCD tools (Thakur et al., 2009a, Thakur et al., 2009b). In cryogenic machining of Inconel 718, a minimal overall machining cost is reported due to no additional coolant disposal costs and the inert nature of LN2 (Courbon et al., 2013; Zindani and Kumar, 2020; Patil et al., 2014). Although cryogenic cooling is cleaner and more cost-effective than conventional machining, tooling costs constitute a large portion of total production (Pušavec and Kopač, 2011). MQL is an economically feasible technique for low set-up cost due to minimal cutting lubricants (Astakhov, 2010). Therefore, researchers emphasized the benefits of using nanofluid-assisted MQL in terms of machinability (Najiha et al., 2016). Furthermore, except for the overhead and material costs, the overall processing cost of nano-fluid assisted machining is minute (Khan et al., 2020). In addition to improving the machinability of Inconel 718, laser-assisted hybrid milling lowered the cost of fabrication compared to conventional milling (Tian et al., 2008). Additionally, the cost of 1 m length of Inconel 718 for laser-assisted machining is 66% and 50% lesser than conventional carbide and ceramic machining, respectively (Anderson et al., 2006). Economic aspects of various lubrication technologies are comprehensively studied in the literature (Skerlos et al., 2008; Bhushan, 2013) to obtain an economically sustainable machining process. Novel approaches are being implemented to present a realistic, accountable and robust solution to tackle the issue of high production costs in machining hard-to-cut materials. Waste minimization is one such management technique that involves five main steps, i.e., eliminate, reduce, re-use, recycle and disposal to identify and reduce unnecessary expenditure during industrial production (Kopac and Pusavec, 2009).

7. Conclusion

In the current study, the machinability of Inconel 718 is reviewed under various machining operations and lubrication technologies. Challenges in the machining of Inconel 718 concerning machinability, biodiversity, society, and production costs are discussed. The machinability performance during machining of Inconel 718 in a variety of machining operations, including turning, grinding, sliding, milling, broaching, and drilling is discussed. The effectiveness of different lubrication technologies like conventional cutting fluids, dry machining, machining with coated tools, cryogenic cooling, solid lubricant assisted machining, high-pressure cooling, hybrid machining, and MQL on machinability are comparatively reviewed.

This study's main objective is to review and analyze the machining of Inconel 718 from the perspective of environmental sustainability. Sustainable manufacturing is formed by contemplating the machining efficiency, ecological and economic factors. The sustainability of any machining process can be estimated by studying factors such as machining costs, operator safety and health, environmental impact, waste management, and energy consumption. Many researchers have performed life cycle assessment (LCA) of Inconel 718 for various machining techniques for better interpretation of the sustainability regarding environmental and costs related factors. Cutting fluids play an essential role in the machining of hard-to-cut materials like Inconel 718. However, due to the adverse effects of cutting fluids on the environment, and the high production costs, industrialists switched to other alternative lubricating techniques. The summary, including machinability, costs, and environmental impacts of various lubricating technologies for different machining operations, is presented in Table 13. In addition, the salient features of this review are listed below:

-

•

Dry machining is a reliable alternative to cutting fluids as it completely eradicates the use of cutting fluids and adverse effects associated with it. However, optimized cutting parameters and proper tool selection are critical as high-level cutting forces and temperatures are involved.

-

•

Solid lubricant assisted machining is an eco-friendly technique and that exhibited an excellent improvement in the machinability of Inconel 718 in terms of increased tool life and surface finish. Performance characteristics of various solid lubricants for example molybdenum disulphide, graphite, tungsten disulfide, calcium fluoride, and boric acid are reviewed in the machining of Inconel 718. When used with base fluids in the form of additives and combined with the MQL method, solid lubricants improved the surface integrity to a greater extent.

-

•

Cryogenic cooling is another potential alternative to conventional cutting fluids because of cleaner machining. This technique not only improved tool life and machinability but also ensured environmental safety. However, this technique involves high initial costs and a costly setup to handle LN2 and CO2.

-

•

Hybrid machining is a novel technique introduced by researchers to maximize the machinability of the workpiece while considering environmental sustainability. A variety of hybrid machining techniques such as ultrasonic-assisted grinding, electric discharge machining, grind hardening, and plasma-assisted milling are studied in this review. These techniques provide better machinability in terms of better material removal rate, surface quality, and tool life.

-

•

MQL method is environmentally benign and efficiently improves the machining performance by reducing cutting force, tool wear, cutting temperature, and surface roughness. Furthermore, when used as a compound technique with solid lubricants, nanofluids, and cryogenic machining, MQL enhanced the machinability of Inconel 718 in terms of its surface integrity, reduced tool wear, and cutting forces. Nevertheless, a careful selection of the working fluid is needed to maximize the performance of this technique.

Table 13. Summary of machining Inconel 718 with different lubri-cooling technologies.

| Lubri-cooling technologies | Machinability performance | Environmental impact | Cost analysis |

|---|---|---|---|

| Flood cooling/wet machining | Good lubrication and cooling, low contact friction, poor machinability at high-speed conditions | Hazardous to the environment and biological problems to operator | High coolant acquisition, handling, and disposal costs |

| Dry machining | High temperatures, more friction and adhesion between cutting tool and workmaterial | No pollution and ecofriendly technique | Reduced disposal and cleaning costs |

| Machining with coated tools | Self-lubrication, low contact friction, high wear, and resistance in low and medium speed conditions | Sustainable machining, eco-friendly | High machining costs |

| Cryogenic cooling | High cooling, high productivity, good tool life, better wear resistance, good surface quality | Eco-friendly, inert nature, non-toxic | High tooling and handling costs (uneconomical) |

| Solid lubricant assisted machining | Self-lubrication, low contact friction, improved surface finish, low cutting forces & tool wear | Operator-friendly, no hazardous fumes | Low equipment costs |

| High-pressure cooling | Improved chip control, low energy, reduced cutting forces, good surface finish, high productivity, low temperatures | Eco-friendly, low energy consumption | High initial costs |

| Hybrid machining | Good surface finish and low cutting forces | Environmentally benign process | High processing costs |

| MQL machining | Thermal stability, low flank wear in turning, good hole quality in drilling and better surface finish in grinding | Ecofriendly technique, lower power consumption | Economical solution, low cooling costs, minimal machining costs |

8. Future research direction

MQL is a green machining technique that has a tremendous potential of boosting the machinability of hard-to-cut materials. Moreover, to promote sustainable and cleaner machining, many industries are substituting conventional machining with the MQL method. Thus, nanoparticle/fluid based MQL finds the direction to meet the requirement of Industry 4.0. However, few areas in the literature indicate a scope of development, which are listed below:

-

•

Although researchers emphasized the use of hybrid nanoparticles to advance the performance of MQL, further research needs to be conducted in this field to maximize the benefits in terms of environmental viability and machinability of hard-to-cut materials like Inconel 718.

-

•

Considering the benefits linked to nanoparticle-based MQL, comprehensive research needs to be carried out to develop tribo-film formation models, suspension of nanoparticles, heat transfer in MQL, and the wetting ability of sprayed droplets.

-

•

Owing to its advantages in machining of hard-to-cut materials, the studies related to solid lubricants are increasing. With proper research and analysis, solid lubricants can become a potential option for industrial manufacturing and mass production.

-

•

Data science and advanced computational algorithms must be assimilated with the machining of Inconel 718 to study the machinability characteristics using mathematical models, manage data in experimentation with ease and provide the means to smart manufacturing in the vision of Industry 4.0.

-

•

Despite its adverse effects on the environment, high-pressure oil emulsion can make a potential alternative to conventional machining due to excellent results in the aeronautics sector.

-

•

With proper research and cost analysis, cryogenic MQL can be a potential alternative to cutting fluids owing to its better machining efficiency in hard-to-cut materials and eco-friendly nature.