1. Introduction

The idea of circular economy (CE) started from manufacturing counterparts which are now making inroads into the construction industry. Several authors define circular economy as the new future for sustainability concept through novel flexibility metrics of buildings (Cavalliere et al., 2019), a framework for near-future research, such as a comprehensive evaluation of the performance of construction and demolition waste diversion, human factors, and design and planning for waste diversion by Jin et al. (2019) and a proposal on flexible housing project that leasing the housing components and services that allow the company to retain possession of the housing modules and properties and thus contribute to its own future resource stock (Zairul et al., 2018). The idea of CE is also associated with the potential in the construction industry to reduce waste and to promote building resiliency (Cavalliere et al., 2019). In comparison to the conventional construction strategy, prefabricated buildings also have the potential to save both construction time and money (Mangialardo and Micelli, 2020). Studies on how prefabricated buildings have contributed to the green building literature were also promoted by Xu & Sun (2019) and Sáez et al. (2019). In some countries, prefabricated or industrialized building systems (IBS) have often been described as a potential sustainable construction process, moreover with the integration with a circular economy in the policy (Luo et al., 2021). Recent trends in CE publications have suggested that circular economy (CE) adoption in the built environment is the new future for the building industry (Munaro et al., 2020).

The circular economy (CE) is nothing new in the manufacturing sector. It provides the likeness of recycling to another level, or can be simplified as ‘rubbish is the new industry’ (W. Stahel, 2008). Many articles in the literature talk about how to move current conventional construction towards the direction of CE. However, the process so far has been in a deadlock since most of the materials used conventionally propos a linear economy rather than circularity (Zairul, 2017). On the other hand, prefabrication or Industrialized Building System (IBS) is defined as an innovative process of building components utilizing a mass production industrialized system, produced within a controlled environment (on or off-site) which include organized logistics and an on-site installation process with systematic planning and management (Zairul, 2020). Prefabrication and IBS advantages include shorter project plans, cost savings in the project, enhanced site protection, better product quality, and reduced waste. Current developments have increased accessibility to prefabrication technology, including: Building Information Modelling (BIM), 3D printing, green buildings demand and continuous pressures to shorten schedules of projects.

The ongoing practices in the building sector present various threats and influence the societal and economic environment, not to mentioned the climate and sustainability (Gencel et al., 2012). Therefore, the effort towards solving these impacts has rendered solutions from circular economy perspectives (Akanbi et al., 2018a). CE has been proven to increase economic productivity through the effectiveness of resource utilization, consumption, and allocation. From the social aspect, the CE framework provides more employment opportunities and improves the sustainability rating of companies that adopt this strategy (Su et al., 2013). The effort to apply CE principles in conventional buildings represent a monolithic effort in nature (Minunno et al., 2018). Therefore, prefabrication technology and IBS are the ideal solutions (Zairul et al., 2018) towards waste reduction and lean supply chain in the construction industry (W. R. Stahel, 2016). However, despite increasing publications on prefabricated buildings and the circular economy in the construction industry, no review paper has discussed recent trends on the prefabricated buildings with the integration of circular economy (CE) and what the future holds. Hence, this article will highlight selected literature from 2015 to 2021 on the discussions that relate to prefabricated buildings with CE strategy and to answer the following questions:

RQ 1

What are the current trends on prefabricated buildings with CE strategy?

RQ 2

How to formulate a new framework on prefab buildings with CE for the future direction of this strategy?

2. Methodology

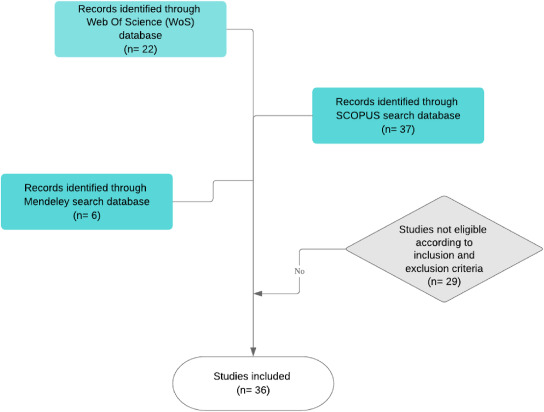

The term thematic review using ATLAS.ti 8 as the tool introduced by (Zairul, 2020, Zairul, 2021) was applied as this research method applies thematic analysis procedure in literature review. Clarke and Braun (2013) defined thematic analysis as a process of identifying the pattern and construct themes over thorough reading on the subject. The following step is to identify the pattern and construct themes to understand the trend of prefabricated building with a CE strategy. The tenets of the research are to analyse and interpret the findings for the recommendation of future research in both domains (prefabricated buildings OR IBS OR modular OR off-site OR pre-assembly buildings and Circular Economy aka CE). The selection of literature was performed according to several selection criteria: 1) publication from 2015 to 2021; and 2) have at least the keyword(s) IBS or Industrialized Building System or IBS, Prefabricated buildings, modular construction, pre-assembly building and off-site construction coupled with the keyword Circular Economy or CE. Review papers were excluded from this review due to contradiction with the objective of this paper.

The sources of literature were the research databases from Web Science of Clarivate Analytics and Scopus of Elsevier and Mendeley. The Network of Science was chosen because it will hit all indexed journals with a measured impact factor in the Journal Citation Report (JCR) (Carvalho et al., 2013); Mendeley, owing to the multidisciplinary nature of research and multiple sources, and Scopus was chosen as it has the largest collection of peer-reviewed publications. A filter was applied in the Web of Science using “type of documents”, articles types, and proceedings papers, NOT reviews. The analysis criteria were contained in the other datasets: “Title, Keywords, and Abstract”. The following keywords were used as search terms: prefabricate*, build*, industriali*ed building system OR IBS OR modular building OR pre-assembly and construction projects associated with circular* econom*.

The articles were uploaded in the Mendeley for data crunching. Data crunching involves removing duplicated articles, updating the authors' names, and ensuring the metadata are correct. Next, from Mendeley, all 36 articles were exported to ATLAS.ti 8 for analysis of the current trends in the literature. From the documents' list, several bibliometric data were established which include the article title, year, author, author's country, periodical, keyword used and subject area. The results of this paper are divided into two parts, Quantitative and Qualitative. The quantitative part will report the data that was obtained from the numerical points of view, while the qualitative part will establish themes that were established from the selected articles, and formulate a conceptual framework on integration of CE in prefabricated buildings.

The study found that the prefabricated building with CE approach was still in its infancy, with just a few suggestions on how the approach could extend to the built environment. The exploratory nature of research related to circular economy comprises predominance with quantitative and mathematical experiments, along with data collection techniques, experiments, and mathematical model assessments. The focus of literature in the last 6 years shows the trends and patterns on the revised subjects.

3. Results

The results are divided into two parts: i) Quantitative and ii) Qualitative. The results in the quantitative part generated the word cloud below based on the analysis of 36 documents in the primary documents. The biggest words that appear in the word cloud signify high frequency in the articles, which are ‘construction’ and ‘building’. As mentioned at the beginning, the focus of this paper is on CE adoption in prefabricated buildings.

Despite the increasing trend, there are no review papers that talk about the integration and constructing framework for the future of prefabricated buildings and circular economy. A study protocol was developed whose data collection, preparation and results interpretation were based on previous research and defined in a logical sequence. From the analysis in the word cloud, the word ‘buildings’ was mentioned 1469 times, followed by construction at 1255 times, while design and circular are mentioned 693 times and 622 times, respectively. The trend of publications has seen an increase over the years. From only 1 article in 2015, although missing in 2016, the publications increased annually to 3 in 2017, 10 articles in 2019, and15 in 2020. As of 2021, 3 articles have been written at the time this article is being written. The reason why the literature for this study starts from 2015 is basically to focus on the latest publications within the last 5–6 years, and to see the trends towards 2021. The authors would like to point out that this analysis does not appear to be excluded from any restrictions or to be comprehensive, as it was focused on search strings, indexes, and exclusion criteria. The authors, however, claim that it reflects the literature based on the research question (see Table 1).

3.1. Quantitative results

From our analysis below, there are several varieties of journals chosen by prefabricated buildings and CE researchers. According to the list, the IOP Conference Series: Earth and Environmental Science and the Journal of Cleaner Production are the top two popular choices for circular economy researchers. As mentioned earlier, if the keyword used in this search only uses “Circular Economy,” the result of the number of articles found will be a few thousand. However, after focusing the search strings to prefabricated OR IBS OR modular OR pre-assembly OR off-site construction coupled with circular economy (CE), the results show a significant drop and are more focused, thus providing evidence that the subject is still new, and that more exploration can be conducted in the future. Nevertheless, the growing interest indicates that the terms ‘circular economy’ and ‘prefabricated buildings’ have increased. This can be seen in the evolutionary development of articles as illustrated in the following Table 2(see Table 3).

Table 1. Search strings.

| SCOPUS |

(TITLE-ABS-KEY (( prefabricated AND buildings AND circular AND economy) ) OR TITLE-ABS-KEY (( industriali*ed AND building AND system AND circular AND economy) ) OR TITLE-ABS-KEY (( modular AND buildings AND circular AND economy) ) OR TITLE-ABS-KEY (( preassembly AND buildings AND circular AND economy) ) OR TITLE-ABS-KEY (( off-site AND construction AND circular AND economy) )) Year: 2015 to 2021 |

37 results |

| Web of Sciences |

TITLE: (((prefabricated building) OR (industrialized building system) OR (modular construction) OR (modular construction))) AND TITLE: ((circular economy) OR (CE)) Timespan: 2015–2021. Indexes: SCI-EXPANDED, SSCI, A&HCI, CPCI–S, CPCI-SSH, BKCI–S, BKCI-SSH, ESCI. (((prefabricated building) OR (industrialized building system) OR (modular construction) OR (modular construction) OR (off-site construction)) AND TOPIC: ((circular economy) OR (CE)) Timespan: 2015–2021. Indexes: SCI-EXPANDED, SSCI, A&HCI, CPCI–S, CPCI-SSH, BKCI–S, BKCI-SSH, ESCI. |

22 results |

| Mendeley |

“Prefabricated buildings” AND “circular economy” year:[2015 TO 2021] “Modular buildings” AND “circular economy” year:[2015 TO 2021] “IBS” AND “circular economy” year:[2015 TO 2021] “off-site construction” AND “circular economy” year:[2015 TO 2021] |

2 results 2 results 1 result 1 result |

Table 2. No. of articles according to periodical.

| 2015 | 2017 | 2018 | 2019 | 2020 | 2021 | Totals | |

|---|---|---|---|---|---|---|---|

| A + BE Architecture and the Built Environment | – | 1 | – | – | – | – | 1 |

| Automation in Construction | – | – | – | 1 | – | – | 1 |

| Buildings | – | – | 1 | – | – | – | 1 |

| Construction and Building Materials | – | – | – | – | 1 | – | 1 |

| Design + Built | – | – | – | 1 | – | – | 1 |

| EG-ICE 2020 Workshop on Intelligent Computing in Engineering | – | – | – | – | 1 | – | 1 |

| Environmental Sciences Proceedings | – | – | – | – | 1 | – | 1 |

| Facilities | – | – | – | 1 | – | – | 1 |

| Frattura ed Integrita Strutturale | – | – | 1 | – | – | – | 1 |

| Green Energy and Technology | – | – | – | – | 1 | – | 1 |

| ICCREM 2019: Innovative Construction Project Management and Construction Industrialization | – | – | – | 1 | – | – | 1 |

| International Journal of Life Cycle Assessment | – | – | – | – | 1 | – | 1 |

| International Journal of Sustainable Development and Planning | – | – | – | – | 1 | – | 1 |

| IOP Conference Series: Earth and Environmental Science | – | – | – | 3 | 2 | – | 5 |

| Journal of Cleaner Production | – | – | – | – | – | 2 | 2 |

| Journal of Economic Structures | – | – | 1 | – | – | – | 1 |

| Journal of Facade Design and Engineering | – | – | – | 1 | – | – | 1 |

| Journal of Materials in Civil Engineering | – | – | – | 1 | – | – | 1 |

| Malaysia Architecture Journal | – | – | – | 1 | – | – | 1 |

| Open building | 1 | – | – | – | – | – | 1 |

| Polymers | – | – | – | – | 1 | – | 1 |

| Procedia Environmental Science, Engineering and Management | – | 1 | – | – | – | – | 1 |

| Research for Development | – | – | – | – | 1 | – | 1 |

| Resources, Conservation and Recycling | – | – | 1 | – | 1 | – | 2 |

| Science of the Total Environment | – | – | – | – | 1 | – | 1 |

| Steel Construction | – | 1 | – | – | – | – | 1 |

| Sustainability | – | – | – | – | 1 | 1 | 2 |

| Sustainability (Switzerland) | – | – | – | – | 1 | – | 1 |

| Journal of Basic Science and Engineering | – | – | 1 | – | – | – | 1 |

| Totals | 1 | 3 | 5 | 10 | 15 | 3 | 36 |

Table 3. Authors according to themes.

Next, in terms of geographical dispersal, CE-related studies have become popular and are trending in China. This can be seen from Yanya (2018), who talked about blending ratio in the recycled aggregate; Xu & Sun (2019) reported analysis of prefab in the green construction; while Wuni & Shen (2020) discussed the barriers in adopting prefabricated or modular integrated construction. Several studies from Italy reported research with several focused on BIM-based assessment as proposed by Cavalliere et al. (2019) and a proposal for hydroponic greenhouses using BIM based software by Cumo et al. (2020). Several authors discussed the validation of push-out test as part of prefabricated system (Pavlović and Veljković, 2017) and implementation of wood to reduce carbon footprint by (Licciardello et al., 2017). Another pertinent study by Ginelli et al. (2020) focused on modular building systems and construction approach experiments and constructive, structural and plant engineering techniques for OFF-GRID housing. Next in line is the Netherlands, which contributed 3 papers. Some of the discussions talked about designing a composite floor (Nijgh and Veljkovic, 2019), and a discussion on business model by Heesbeen and Prieto (2020) and Zairul and Geraedts (2015).

Most experiments that demonstrate the principle of CE first differentiate neoclassical, stable state economy and circular economy. A linear economic trend is believed in conventional economics (neo-classic), which until recently was the fundamental framework for economic growth. Neoclassical economics focuses mainly on efficient market resource allocation, and fails to include analytical instruments which take account of the restricted and exhaustive existence of the natural resources. The solution to the state-constant economy would appear to fill this void by attempting to hold the economic operations under the limits placed by design (same rate for use of energy and resource utilization) (networks of interacting components, exchange of material and energy flows, recycling patterns and, environmental mimicry) (Ghisellini et al., 2016). (see Fig. 1).

The patterns on regional dispersion indicate that prefabricated patterns of CE methods have been applied for quite some time in Europe: Italy, the Netherlands, the United Kingdom, Germany, Spain, Finland, and Luxembourg. Recently, in Asia both China and Malaysia have begun to adopt it (Fig. 5). Several authors talked about sustainable strategy by Sáez et al. (2019) and Plevri et al. (2020). The recent trends in 2020 and 2021 show that the focus of the papers were mainly on the application in construction, and how this strategy can be implemented as a policy (Luo et al., 2021). Several authors highlighted the application of prefabricated construction with BIM technology as suggested by Akanbi et al. (2018b) for appraising the salvage performance of structural components of buildings right from the design stage through BIM, and coupling Building Information Modelling (BIM) and Visual Programming Language (VPL) tools (Cavalliere et al., 2019), Hao et al. (2020b) develop a BIM-based approach to measuring carbon emission reduction during the materialization stage of a prefabricated building project. Further, a BIM model for architecture, a life cycle cost analysis model, energy-saving analysis model, and a value analysis model were developed by (Yuan et al., 2020). It should also be pointed out that the trends on Prefab and CE in the Europe and America are mainly on the application, while in Asia, especially China and Malaysia, the studies revolve around on the policy and framework in its operation (see Fig. 3) (see Fig. 4) (see Fig. 6) (see Fig. 2).

Fig. 1

Fig. 1 Fig. 2

Fig. 2 Fig. 3

Fig. 3 Fig. 4

Fig. 4 Fig. 5

Fig. 5 Fig. 6

Fig. 6In the following table, this paper formulated the trends and patterns of the selected publications. The original coding resulted in 15 attributes, but after merging and renaming, the coding came to just five themes. The following themes will be discussed at length in the qualitative section.

3.2. Qualitative results

In the qualitative section, this paper will discuss in detail the themes that were derived to answer the research question. Five themes were established based on the directions and subject of the articles. The following are the themes established from the selected publications: Assessment (5); Building materials (8), Business model (4); Framework (9); and Technology (11). The main themes are not independent, but rather overlap between articles presented in this review. It is common for some articles to adopt several themes and vice versa. In the following section, the themes will be discussed separately and more in depth to answer research question no 1 (What are the current trends on prefabricated buildings with CE strategy?) and followed by the next section on the formulation of the framework Fig. 7.

Fig. 7

Fig. 7What are the current trends on prefabricated buildings with CE strategy?

3.2.1. Assessment

The potential of BIM in prefabricated buildings through circular economy principles was discussed by Hao et al. (2020). The study elaborated on the potential of CE to reduce the execution stage in the construction phase. The framework on BIM-based CE projects proposed carbon-emission reduction through life-cycle assessment approach. However, Cavalliere et al. (2019) suggested that the flexibility of the building functions are necessary to be assessed by metrics on the functional flexibility. Both studies elaborated on two different phases; the first one during the construction phase, and the latter on the functions of the spaces, which is during post-construction stage. Several authors proposed building assessment to evaluate the potential on waste reduction by applying CE in the prefabrication buildings. For instance, Hao et al. (2020a) developed a BIM-based framework for assessing the potential for CE reduction through prefabrication during the materialization stage of a construction project. The BIM approach to the estimates of the use of materials and energies makes them more project-specific and simplifies the definition of the evaluations. Results from this study provide a better understanding of the potential on waste reduction through prefabrication and CE approach in materials production, transportation, and conventional construction phases.

Subsequently, Akanbi et al. (2018) developed a BIM-based Whole-life Performance Estimator (BWPE) to evaluate the performance of the structural components of buildings right from the design stage. The results of the evaluation show that building design with modular and prefabricated assemblies generate reusable materials that are mostly reusable (i.e. 93% reusable, 07% recyclable), whereas, building design with concrete structure generates recoverable materials that are mostly recyclable. The design with timber structure generates recoverable materials that are largely reusable (i.e. 65% reusable, 35% recyclable). Nevertheless, estimating salvage performance of a complete building system varies according to building life cycle and environmental context.

On the other hand, the study approach taken by Cavalliere et al. (2019) was to implement the suggested metrics in the BIM setting in order to automatically verify the versatility of buildings during simulation activities. The metrics requires engineers and architects to be aware of flexibility problems relevant to design choices. However, the application is focused on a specific domain of a building, thus is not to be generalized in a different context. Similarly, there are no standard test methods available for prefabricated buildings, especiallyon the composite facade panels. Therefore, Frankovič et al. (2020) suggested up-scaling and performance assessment of facade panels produced from demolition waste.

From this theme, it can thus be inferred that there are many developments in the application to create a mathematical estimation of the building efficiency based on the CE adoption in prefabricated buildings. More future research may propose evaluations of the usability of the idea in a realistic context and how it could help to minimize waste and enhance building efficiency and productivity Fig. 8.

Fig. 8

Fig. 83.2.2. Building materials

Green building material meets not only the core elements of sustainable growth, but also contributes to the development of the circular economy, which is required to constantly and extensively promote the development of circular economy (CE) Fig. 9. Xu and Sun (2019) mentioned the environmental benefits of prefabricated buildings in terms of carbon emissions, noise pollution and environmental pollution in specific engineering cases to explore the degree to which manufactured buildings represent the principles of green construction. In terms of construction and demolition (C&D) works, a framework has been proposed for near-future studies, such as a systematic assessment of the efficiency of C&D waste diversion, human factors, and the design and preparation of waste diversion (Jin et al., 2019).

Fig. 9

Fig. 9More green approaches in the construction materials were proposed to cause less impact to the environment. One of the materials for prefabricated buildings is a gypsum composite with an addition of glass waste by (Villoria Sáez et al., 2019). The author suggests the composites may be used in the manufacture of prefabricated gypsum elements or as inner coatings requiring special surface hardness, enhanced water behaviour and mechanical strength properties. The idea of composite as a circular economy product was extended by Nijgh and Veljkovic, (2019b) through his experiment on the detachability and reusability of the composite flooring system consisting of steel beams and prefabricated concrete decks. Composite action was accomplished by resin-injected bolted shear connectors rather than by traditional welded head studs. The advantage of the resin-injected shear connectors is that the composite action is instantaneously accomplished under live loading. Concentrating the shear connectors near the supports of a simple beam has been shown to improve the rigidity of the composite beam (Nijgh and Veljkovic, 2019).

Green buildings are paying more attention to the environment in addressing global warming. Since envelope optimization can greatly minimize energy usage in green buildings, Value Engineering (VE) and Building Information Modelling (BIM) technologies are frequently used to configure the green building envelope, considering both energy conservation and life cycle costs. Green building materials and their energy-saving problems are paying more attention to the environment in the light of the increasingly serious energy crisis and global warming. Since envelope optimization can dramatically reduce the energy consumption of green buildings, Value Engineering (VE) and Building Information Modelling (BIM) technologies are used to optimise the green building envelope, considering both energy saving and life cycle costs. Responding to this, Yuan et al. (2020) proposed a theoretical optimization system for the green building envelope based on BIM-VE. The results and recommendations would provide useful feedback and guidance for the architectural design industry in maximising the green building envelope in terms of both energy conservation and life cycle costs (Yuan et al., 2020). Yuan (2020) further proposed a mathematical formula (F) in the energy-saving analysis model for green building envelopes to measure the energy savings of each envelope scheme.

Circular economy is also concerned with building energy in exchange for renewable energy. The use of computational thermal simulation demonstrated that the properties of the prefabricated block influenced the annual thermal demand of the building for heating and cooling (Briones-Llorente et al., 2020b). Improvements to the thermal inertia of the building envelope have also been confirmed by the incorporation of polyurethane foam (PF) waste, giving the mortar an energy output like traditional materials, in such a way that its use in facade construction can be justified. In return, this will contribute to the sustainability and the circular economy principles (Briones-Llorente et al., 2020b).

As controversial as it may sound, plastics need a good waste management strategy. The selected papers collected in this review paper by Chen et al. (2020) offered a broad overview of the research required to achieve sustainability in plastic cycles and management, for which material focused on accounting techniques, eco-design and life-cycle assessment and enhancement of human behaviour have been described as essential and complementary methodologies for achieving the objectives. Nevertheless, this effort will be nothing without a proper policy. Principles of the CE literature still need to be adapted to the construction, and more formal terminologies need to be added. The centralization of work in European countries and China shows the outcome of the introduction of public policies and underlines that the expansion of research needs political and government support (Munaro et al., 2020).

3.2.3. Business model

In recent years, several authors suggested economic gains and the operationalization of the value propositions. Several CE business models have been established (Heesbeen and Prieto, 2020; Zairul, 2017). The three core concepts of the Ellen MacArthur Foundation in the field of circular economy illustrate the following definitions: (i) utilizing waste for production; (ii) extending the life cycle of the product (iii) and the restoration of natural systems. The BMC provides organisations a shared language for exchanging understanding and creativity on business models. There are basically nine main components in the business model canvas (BMC) by Osterwalder et al. (2002). The building blocks include: the value creation, target customer and how to hold customer relationships, key activities, key resources, and partnerships and the pricing structure (cost structure and revenue streams). The alignment of taxonomy indicates that the models derived from (Heesbeen and Prieto, 2020; Zairul, 2017) are an inclusive construction representation.

The circular business model theory is thus related to industrial construction practise. The translation enables progress in the business model to be predicted and geared towards realistic scenarios of a potential circular economy (Heesbeen and Prieto, 2020). Previously, Zairul (2016) suggested a new business model to integrate flexible housing by employing circular economy a part of his business model. However, to turn the business model into plausible business propositions, it is crucial to roadmap the existing innovation as a benchmark Fig. 10.

Fig. 10

Fig. 103.2.4. Framework

Several frameworks have been proposed by several authors Fig. 11. A circular economic framework for prefabricated construction is used to analyse the environmental benefits of prefabrication in terms of its component to ensure that CE principles will be adhered to. Minunno et al. (2018) highlighted seven strategies to improve CE for prefabricated building: 1) to provide lean construction; 2) the use of recycled or remanufactured products; 3) the use of replacement parts; 4) adaptation of repurposed products; 5) designing for disassembly with BIM; 6) attention to recyclable materials; and 7) the application of tracking technologies to track the product lifecycle. Despite the long discussion and debate on environmental sustainability in the building industry, the building industry also consumes the highest amount of natural resources (Wong and Zhou, 2015). Therefore, alternatives in the construction industry to reduce more waste are required.

Fig. 11

Fig. 11The more durable a building is and adaptable to changes rather than producing waste, the more sustainable it is. The resistance to buildings can be defended as the attitude of the building to easily recover from or adapt to an unfortunate situation, event or transition, such as changes in building use (Cavalliere et al., 2019). Flexibility in the construction industry can be defined as the ability to change the usability according to changing needs (Zairul, 2017). Therefore durability and resilience are parts of flexibility in nature (Cavalliere et al., 2019). Recently, the need for flexibility in space and building design has become apparent (Geraedts, 2016). The need for adaptability and flexibility in design can be materialized with the application of Building Information Modelling (BIM) (Cavalliere et al., 2019).

The future of building industry is moving towards industrialization (Acerbi and Taisch, 2020) or manufacturing (Zairul, 2019). However, the cost of adding CE in the current building's fabric has always been a pain in the neck. Therefore, a theoretical framework on green architecture based on BIM and value engineering was proposed to calculate the life cycle cost and to make the product more energy saving (Yuan et al., 2020). In the experiment, Yuan et al. (2020) proved that a lot of financial exercise can be conducted using BIM, which includes an energy-saving model, life cycle cost, value analysis, and BIM model for architecture. The simulation tested a prefabricated project case to see how the building corresponds to the green building strategy and cost saving (Yuan et al., 2020). Nevertheless, all of this effort must be supported by a good policy from the government (Luo et al., 2021).

3.2.5. Technology

The innovation and technology solutions through engineering calculation have also been discussed by several authors as a CE tool in the prefabricated buildings Fig. 12. Prefabrication of concrete slabs decreases the construction time and overall life-cycle costs of composite steel-concrete structures and bridge decks. The use of bolts as shear connexions embedded in prefabricated concrete slabs enables the re-use and easy replacement of slabs as structural components suitable for a circular economy design (Pavlović and Veljković, 2017). Alternatively, recycled pervious concrete as environmentally friendly and material-saving building material will meet the current demands of the circular economy and environmental conservation in China (Yanya, 2018). The results of the experiments by Yanya (2018) showed that the pervious concrete recycled strength and water permeability matched the regulations. The test results were superior to the former concrete produced in the same proportion using natural aggregates.

Fig. 12

Fig. 12Several studies incorporated BIM as the study design. The BIM simulation by Akanbi et al. (2018) shows that construction design with a steel frame, demountable connexions and prefabricated assemblies produces mainly recyclable materials. The study shows that BWPE is an objective way of assessing how much recoverable content in buildings at the end of their productive lives is reusable and recyclable. The solution in terms of technology also suggests the way prefabricated buildings are to be manufactured. Several authors suggest volumetric IBS (Zairul et al., 2019; Bin Mohd Noor, 2017) and the use of the thermo-physical and mechanical properties of the new prefabricated material plate (Briones-Llorente et al., 2020b).

4. A proposed conceptual framework for prefabrication buildings with circular economy approach

The thematic review led to the proposal of new studies to continue the development of information in the field. These propositions are pointed out by reading and reviewing studies and defining, according to the conceptual framework in Fig. 13. Fig. 13 provides 36 research directions to guide the implementation of circular practises in the construction scenario so that new research opportunities can be discovered, policy-makers' strategic success can be contributed and an approach to business reality can be promoted. In view of the present scenario of research and the planned structure, future studies can be clustered into:

-

1)

Engineering & Technology studies- Focus on alternative, low carbon, BIM-related activities to implement technology enablers in the idea of circular economy in prefabricated buildings.

-

2)

Framework- A new framework on government policy, site management, management in general, supply chain and business model of prefabricated buildings using CE approach

-

3)

Green building materials- More studies on construction materials that are sustainable and to utilize the waste and performance economy as part of the agenda.

-

4)

Business model- New value creation in the model development to support the idea of a circular economy into a prefabricated building business model.

-

5)

Assessment- To assess building performance that has already adopted the CE approach in prefabricated buildings in practice.