1. Introduction

Both hard coal and lignite have a long tradition in Germany. The Prosper Haniel mine in the Ruhr area was closed at the end of 2018 after 150 years, which signalled the end of hard coal production in Germany. Lignite mining still takes place in the Central German, Lausitz and Rhineland districts. However, lignite mining in Germany is expected to be phased out gradually by 2038 [1]. With the closure of these mines, however, mining damage is not over. The long-term consequences of mining, which extend far beyond the closure of the mines, are associated with the liability and responsibility of the individual mining companies. The so-called eternity burdens on the mining company continue to apply. In the field of lignite production, the discontinuation of dewatering and the resulting possible elevations of the surface will be a relevant topic for the future of mine surveying. The same applies to the hard coal mines, which are partially flooded in Germany and therefore require extensive monitoring of soil movements in the future.

The discontinuation of energy from hard coal and lignite calls for a change in the energy mix. With the renewable energy revolution in Germany, the focus is on a sustainable and environmentally compatible climate and energy policy based on renewable energies. Sustainable use of the subsoil, both natural and anthropogenically produced cavities, will play an essential role in the objectives of this policy. For example, disused mine cavities can be used to store electricity from renewable energy sources [2]. These functions will again cause classical ground movements such as subsidence and uplift, but will also bring new challenges for the mine surveyor. Challenges can be underground cavity exploration in inaccessible areas or legal aspects of underground competition.

Various existing and future uses of the underground spaces are described in this paper. Subsequently, the resulting challenges and opportunities for mine surveying are identified.

2. Current challenges in subsidence research

Due to the slow closure of lignite mines in Germany, the issue of discontinuing dewatering is currently the subject of much debate. Up to now, groundwater has been pumped off extensively in lignite mining areas in Germany. The result was subsidence at the surface. Uniform subsidence was mostly unproblematic or hardly noticeable. Different subsidence rates in geological fault zones, on the other hand, often cause major subsidence damage to buildings or cellars at the surface. Federal Chancellor Dr. Angela Merkel and the Federal Government decided on the 5th of February 2019, that lignite mining in Germany will be finally abandoned until 2038 [3]. Sump measures, which so far amount to around 3 × 109 m2 around the opencast mines in the Rhine mining area, will be reduced and then discontinued. The groundwater horizons then rise to the original level, resulting in hydrogeological processes that can in turn have an impact on the surface. In the areas where subsidence of the surface has been the main problem so far, the surface will return to its original level and may continue to rise [4].

The rising of mine water not only has an effect on surface heaving, but also on the following aspects: mine gas leaks, ground and drinking water, shafts and abandoned mines, which are located near to the surface.

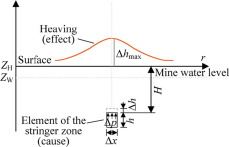

The method of Sroka shown in Fig. 1 allows the calculation of the maximum heaving on the one hand and the dynamic prediction of ground elevations for any points of the subsurface on the other hand. The method is based on the Ruhr coal method for the prediction of surface subsidence. Under the influence of mine water, each element causes an infinitesimal heaving bell of the surface, whose shape corresponds to a parameterized Gaussian distribution function. By summing up, a total movement of the surface can be predicted. The stringer zone comprises all parts of the mountain body above the mining area in which at least a loosening of the structure takes place [5].

Fig. 1. Heaving prediction model (after [5]).

Fig. 1. Heaving prediction model (after [5]).3. Underground spatial planning: possibilities of sustainable re-use of subsurface openings

In the past, the economic use of the deep underground of the earth's crust in Germany consisted mainly of the extraction of raw materials such as energy and mineral raw materials (lignite, hard coal, salt, oil, gas, etc.), the extraction of drinking water, the use of thermal water, the extraction of groundwater, the storage of waste in landfills or disposal sites, tunnel construction or geothermal resources exploring. In some cases, this has created artificial cavities or opened up natural cavities, e.g. caused by leaching. The sustainable use of these cavities is increasingly of ecological and economic interests. The storage of energy sources from renewable energies such as compressed air, methane or hydrogen is important for sustainable development and climate change. In contrast, fossiland nuclear energies are to be replaced as completely as possible in the future. This corresponds to the ecological demands of modern society and counteracts the increasing scarcity of resources with an ever-growing population. The necessary energy storage can be ensured by using cavities like caverns. Other possible uses of the underground include the final storage of (highly) radioactive waste and the storage of crude oil and natural gas. These possible uses are shown in Fig. 2 [6], [7].

Fig. 2. Scheme of different underground usage possibilities (after [8]).

Fig. 2. Scheme of different underground usage possibilities (after [8]).Storage is becoming an increasingly important topic in the energy revolution, as renewable energies such as solar/wind energy are cyclically dependent on the supply of the sun or wind. Feed-in into the power grid is therefore highly variable.

The aim of these largely new or developed utilisation variants is to meet the requirements of a sustainable and environmentally compatible climate and energy policy. This requires an early integration of the mine surveying system into this process of change [9].

3.1. Pumped storage hydropower plant

Pumped storage power plants are one of the possibilities for energy storage. These are already being used in many different ways on the surface today. One plant that has been used in practice since 2003 is the “Goldisthal” pumped storage power plant in Thuringia. The capacity is 1060 MW with a drop height of 350 m and is therefore currently the most powerful plant in Germany. The world's most powerful plant is located in the USA. This pumped storage power plant “Bath County” has a capacity of 3 GW and a head of more than 380 m. The plant is located in the USA [10].

In Germany, however, there are no such natural differences in altitude as in Austria or Norway. In addition, pumped storage power plants are always a form of landscape consumption and an encroachment on nature that is not always welcomed by the population.

A suitable solution to these problems is to relocate the pumped storage power plant underground. The University of Duisburg-Essen and the Ruhr University Bochum are currently planning the world's first pumped storage power plant in a mine. Fig. 3 schematically shows this pumped storage power plant in the Prosper Haniel mine of RAG.

Fig. 3. Scheme of the pumped storage hydropower plant in the Prosper-Haniel mine in Bottrop, Germany [11].

Fig. 3. Scheme of the pumped storage hydropower plant in the Prosper-Haniel mine in Bottrop, Germany [11].The pumped storage power plant works according to the following principle: it can supply electricity on demand by draining available water to a lower level via locks at a higher potential level through turbines. These power plants can be switched on as required to cover peak loads and are “black-start” capable. This means that power generation can be started without external auxiliary power in the event of a blackout (short-term power failure). This makes such storage power plants particularly important for securing the power supply at peak times or in the event of a blackout [10].

The theoretical calculation of the possible power output () of such a pumped storage power plant is listed below [12]:(1)where is the rate of flow; the density of liquid; the gravitational constant; and the potential elevation difference.

In the case of the Ruhrkohle AG mine, there is a head of about 600 m, so that an output potential of 360 MW or a working storage capacity of 900 GWh per year can be achieved [13].

Within the framework of scientific investigations at the institute, a potential study on coal seam gas deposits in the Bavarian Faltenmolasse was carried out based based on data from closed coal mines. In this abandoned pitch coal district, the possibility of a pumped storage power plant was investigated using the Hausham mine as an example. The results of the study are explained below: the old tunnels and shafts in the Hausham mine are in principle also suitable for the use of an underground pumped storage power plant. The rock is largely impermeable and many of the tunnels have not yet been filled. The Klenze shaft () of 5.1 m, which has a usable height difference of approximately 370 m, could be used as a drop shaft. The possible storage volume is estimated as follows: the open stretches are 77,000 m long; assuming an average cross-section of 15 m3and only one tenth in the bottoms can be used for storage, and the storage volume is therefore approximately 115,000 m3. Due to the large height difference of approximately 370 m, a pumped storage power plant would be useful here.

The theoretical rate () of fall of the water for the stated potential difference of 370 m is approximately 85 m/s and is calculated as follows [14]:(2)

Due to the hydraulic line losses in the supply and discharge lines in the tunnel and the downpipe, as well as the danger of cavitation at the turbine outlet and the triggering of surges downstream of the turbine in the discharge lines, the maximum practical drop speed is reduced to at least half, which can be achieved by means of throttling measures. In addition, a surge lock must be provided to prevent pressure surges. Assuming that pipes with a total free cross-section of 3 m2 are drawn in, and this results in a maximum flow rate of = 127.5 m3/s in the downpipe. The output in the downpipe results from this to approximately = 462 MW. The actual achievable electrical output is reduced by the turbine efficiency of 50% and the electrical conversion efficiency of 80%. This results in a usable output of approximately 183 MW.

The Clausthal University of Technology estimates the described potential of pumped storage power plants in abandoned mines at around 20 GWh and speaks of approximately 100 suitable mines [15].

3.2. Storage in salt caverns

Compressed air energy storage (CAES) uses electricity to compress air to 40–120 bar with a compressor and cools it with cooling elements. Converted electrical energy is stored in 700–900 m deep cavities in the form of pressurized gas. The re-conversion takes place through decompression, in which the air has to be heated and flows through modified gas turbines. Salt caverns, in particular, are suitable for such storage facilities due to their low permeability [15].

Proven salt domes with great potential are located in Lower Saxony, Schleswig-Holstein, Mecklenburg-Western Pomerania and other European regions (e.g. Poland and Spain). In Germany, caverns for natural gas storage with a geometric volume of approximately 1.5 × 108 m3 are in operation and under construction and planning. According to estimates, under technical and ecological restrictions there is an expansion potential in Germany of approximately 2 × 108m3. An example of such a CAES is shown in Fig. 4.

Fig. 4. Scheme of a CAES in a salt cavern [16].

Fig. 4. Scheme of a CAES in a salt cavern [16].4. Future topics in German subsidence research and potential risks

The future of underground spatial planning naturally brings with it familiar but also new challenges for the mine surveyors. Fig. 5 shows the core competencies of underground mine surveying.

Fig. 5. Core competences of mine surveyors.

Fig. 5. Core competences of mine surveyors.The mines were built at the time of development only for the purpose of extracting raw materials. The mine surveyor will therefore be an integral part of the assessment of the suitability of abandoned mines for subsequent use. Some mines require a great deal of securing work. These include above all mines in loose rock, pitch or hard coal, where explosive gases are to be expected, salt mines due to their temperature dependency and flooded mines or mines in connection with large aquifers. In the case of mines that have been flooded, swamping is necessary in the event of possible subsequent use. Changing the filling columns can in turn lead to subsidence damage at the surface. As soon as the mine has been pumped empty, storage reservoirs can be built, for example. This can cause rock layers to lose their stability, resulting in subsidence that can lead to building damage or even fall hazards. This can also lead to the remobilisation of pollutants in soil and water sediments, which in turn can lead to drinking water pollution [17].

In addition to the risks mentioned above, such as subsidence and heaving, further risks may arise. These include, for example, the release of methane into the atmosphere or legal challenges, which will be explained in more detail in the following chapters.

In conclusion to this chapter, the mine surveyor will continue to play an important role in the future energy supply and is indispensable for determining stability [17].

4.1. Monitoring of gas exhalation

Another challenge following the closure of coal mines is the uncontrolled diffuse escape of gas into the atmosphere. The enrichment of mine gas in old mining cavities is a natural consequence of the intervention in the upper layers of the earth's crust, especially in the extraction of hard coal. Coal seam gases are natural gases that are often absorbed in coal at the time of coalification or have accumulated underground in free gas bubbles. During mining, these gases were released as a result of mining activities. Sufficient ventilation of the underground mine was and is necessary for underground mining work, as the gas entering the mine causes possible firedamp explosions, deflagrations or other similar incidents. In the past, the gas was often released uncontrolled into the atmosphere due to a lack of technological and economic possibilities of use and a lack of understanding of the ecological effects. At the end of the lifetime of each mine, both ventilation and possible mine gas extraction were stopped, while natural gas production can continue underground. This enables a continuous accumulation of methane concentrations in old mining cavities, mountain cracks and natural fissures. These natural and anthropogenic migration pathways allow the gas to reach the surface. As a result, methane-rich gas can also escape into the atmosphere diffusely and uncontrollably for years after decommissioning and accumulate in above-ground buildings and cellars. The rising of mine water can also lead to a displacement of the gas phase within the mine [18].

A number of dangerous consequences of mine gas have already occurred in the closed coal mines in Germany. On June 6, 2018, for example, there was a mine gas leak from an old mine in Hamm, which presented a high risk of explosion. During this event, several roads had to be closed and residential buildings had to be evacuated [19].

Within the potential study in the area of the Bavarian Faltenmolasse mentioned in the previous section, such possible mine gas and seam gas deposits in the abandoned pitch coal area were investigated. A total of around 250 archived mine documents such as weather analyses or recorded firedamp events from this area were viewed and evaluated. In this area, so-called pitch coal was mined in 8 mines for more than 175 years. With the help of the study, gas deposits in the area could be confirmed. These are present in the form of accompanying gas, which is distributed regularly in the coal, and in the form of blowers, which is a long-lasting outflow of a gas accumulation. The average methane exhalation in the area was determined to be 2.60 m3/t or 5000 m3/d with a daily production of usable coal of 1870 t/d. With the help of the coal stock quantities and the exhalation, a total gas stock for the entire pitch coal area of approximately 700 m3 was calculated. This would mean a carbon dioxide CO2 saving of about 1.1 × 1010 kg. Especially the blowers are interesting for further consideration. For over 30 years, gas with methane values of up to 37% has been flowing out of one of the blowers found there [10], [20].

The decision of the Renewable Energy Law in 2000 created the economic and political conditions for the commercial use of mine gas in Germany [21]. A decisive point for the inclusion of mine gas and its subsequent energetic use in the EEG is the obligation to comply with limits on the release of environmentally harmful greenhouse gases, since methane (CH4) has a 28 times higher greenhouse effect than, for example, carbon dioxide (CO2) [21]. This means that it is imperative to avoid uncontrolled release. On the other hand, the energetic use of mine gas is an important contribution in relation to the agreed energy turnaround in Germany [21].

Companies such as BP are already using drones to locate and measure potential gas leaks into the atmosphere. This would be a suitable way to locate, measure and monitor methane leaks from abandoned mines. Edinburgh Sensors has developed a sensor that the drone can easily carry for such measurements. The sensor can measure gas concentrates such as CO, CO2 and CH4. The Gascard NG infrared gas sensor is sensitive enough to measure methane concentrations between 0 and 1560 mg/m3 [22].

In the future, it will be an important task for the mine surveyor to monitor and control the methane leaks in the abandoned coal fields and to use them for energy production if necessary.

4.2. Underground reconnaissance

With the closure of the mines, the task of the mine surveyor cannot be stopped. Long-term monitoring measurements must continue to be carried out. On the one hand, it is indispensable for underground spatial planning that the underground cavities, some of which have been closed for more than 100 years, are examined for their suitability for rehabilitation. An inspection of tunnels, shafts and other mining areas can be dangerous or partly impossible at the present time. Therefore, the surveying by humans often turns out to be complicated or impossible. A possible solution for it is explained in the following:

At the Institute for Mine Surveying, Mining Subsidence Engineering and Geophysics in Mining (ifm) at RWTH Aachen, experiments are currently being carried out on underground cavity exploration using photogrammetric methods[23]. In this method, cavities are generally captured in images using a camera, and the image material is then evaluated with software and further generated into a three-dimensional model of the cavity. In order to test and optimize this method, measurements were first taken at the institute itself. The aim was to represent the entire institute complex in three dimensions and to measure its size and volume. For this purpose, a total of 73 images were first captured with a commercially available smartphone camera. The images were then processed with the Agisoft PhotoScan Professional software. There, a three-dimensional model is created which is connected to a local coordinate system. The local coordinate system is spanned by four targets so that three coordinate axes are perpendicular to each other as seen in Fig. 6.

Fig. 6. Cartesian coordinate system (picture from IfM).

Fig. 6. Cartesian coordinate system (picture from IfM).The identified corner points are then exported, and the floor plan is created. The results are 3D models as shown in Fig. 7. These models can also be used for documentation purposes such as geoinformation systems, for visualization (orthophotos, 3D PDF, etc.) or for volume and mass calculations (CAD).

Fig. 7. Three-dimensional model of IfM.

Fig. 7. Three-dimensional model of IfM.In addition, a digital elevation model was created to determine the base area. The advantage of this method would be that measurements could be carried out remotely in inaccessible areas using a chain-driven robot or air-supported drone, for example. This method could also be more cost-effective and faster than laser scanning. The coding of the target marks is easily detected, and the total error of the model is less than 0.01 m. Nevertheless, this method must be further developed. A texture that is too homogeneous, such as white walls, leads to significant gaps in the model. In addition, point clouds are sometimes blurred due to deep scattering in planar surfaces. Further investigations and optimizations will be carried out next in the form of a measurement of the entire mining building.

This method of photogrammetry can be used not only for space exploration but also for monitoring ground movements on the surface. So far, ground movements in opencast mines have been measured and monitored over large areas, mainly with the aid of small aircraft and photogrammetry. Embankments and dams are mainly monitored with laser scanners. This method is very expensive; it is only worthwhile in large opencast mines and extensive planning is required then. Nowadays the drones offer further possibilities. The advantage of drones is that they have low investment costs and low flight altitudes and short and fast measurements are possible. An example of such a three-dimensional reconstruction of a topography measured by drones as shown in Fig. 8.

Fig. 8. Three-dimensional reconstruction with the help of drones [24].

Fig. 8. Three-dimensional reconstruction with the help of drones [24].An alternative method of photogrammetry is called light detection and ranging(LIDAR) or LADAR (laser detection and ranging). The basis is the measurement of the reflected intensity of a laser beam as a function of the time elapsed after its emission. With the help of the speed of light, distance profiles of the reflection properties of the sounded objects, e.g., an altitude profile of the atmosphere, can be measured. Modern LIDAR devices record the atmosphere up to altitudes of about 100,000 m [25].

4.3. Legal challenges

An essential problem in underground spatial planning is the emergence of several competing uses within the subsoil, which arise due to identical demands on the depth or rock properties. Systematic and precautionary planning of the use of underground space in the future is essential for a functioning coexistence of different possible uses. A legally regulated spatial planning of the German underground has not yet taken place and is only partially taken up in mining or water law. In addition, acceptance problems arise within society with some use options, which in some cases lead to a lack of planning security.

It is also questionable whether an examined subsequent use of the underground cavities and the possible resulting damage can be described as mining damage. It must also be clarified whether the damage was caused by the former mining company or by the operator of a pumped storage power plant, for example [26].

5. Conclusions

Hard coal and lignite mining cause seismic events and ground motions like subsidence and heaving. Due to the fact that, in Germany, hard coal mining is already shut down and lignite mining will only take place until 2038, there will be new possibilities of re-use of abandoned cavities like pumped storage hydropower plants. Such a facility was theoretically researched in an abandoned mine in the Bavarian pitch coal district, where a power of 183 MW could be generated.

With the subsurface spatial planning, there will be new challenges but also chances for the subsidence experts. Measuring old mine cavities for energy storages or the ground motion with the help of photogrammetry methods, drones or robotics will be an important topic in the future.

Acknowledgements

The authors would like to thank Ralf Schulte and Malte Jan Michael Gurgel for providing the pictures for the 3D model of the Institute for Mine Surveying, Mining Subsidence Engineering and Geophysics in Mining.