1. Introduction

Electricity and thermal energy for electrical utilities, heat, deep cooling, or food preservation are very important in commercial, industrial and domestic uses [1,2]. The energy demand is expected to accelerate significantly in the coming years [3,4]. Most electric power generation systems use fossil fuels followed by biomass. Is applicable over a long period at a high calorific value [5,6]. Consumption of fossil fuels for future energy production has negative consequences on the economy, global warming, and degradation of resource availability [[7], [8], [9]]. According to the International Energy Agency (IEA) statistics, the global CO2 emission is estimated to be about 65 Gt of CO2 per year in 2030 [10,11]. To respond to the world's rising energy demand and to reduce GHG emissions, developing a sustainable energy supply with multiple-output systems are good options [7,12]. Hence, trigeneration is introduced after cogeneration. Such a system yields higher overall efficiency and provides significant financial and environmental benefits than conventional power plants [13]. Different authors define the term trigeneration differently based on its final service of delivering power, heating (drying), cooling (air conditioning), and water distillation applications [13,14].

Currently, electricity production using trigeneration accounts for more than 24% of the electricity produced in the top global economic power countries and is set as a goal to reach around 840 GWe in 2030 [16]. Due to the shortage of conventional energy resources, concern for increasing energy demand, and global warming issues, the energy supply switching from conventional towards renewable resources: solar, biomass, wind, hydro, geothermal, and biogas, among those options biomass is a highly investigated and most promising energy source in the place of fossil fuel, this will mitigate the global warming problem [[16], [17], [18], [19], [20], [21], [22]]. But still, further research and development efforts should be taken to develop a system for a sustainable, efficient, and environmentally friendly solution. Similarly, other renewable energy systems such as solar and/or wind turbine power generation systems are intermittent and fluctuate significantly depending on weather and season, but they are effective as a renewable energy source [17]. Also, biogas seems to be a very promising alternative energy source for supplying electric and thermal energy through a trigeneration system where biogas resource is available [6,16]. Therefore, the main objective of this paper is to present an organized structural review of biogas-based trigeneration systems.

2. Biogas based trigeneration systems and their performance

Table 1 indicates the concept for large, medium, small, and micro-scale power generation ranges, and typical applications. So far, fossil fuel-driven, medium-large scale trigeneration systems have been successfully proven and commercialized in the last decades and their interest is increased due to showing advantages of multiple generations [6]. Most installed trigeneration systems are involved centralized facilities for consumers, however, losses due to transfer for long-distance and higher security risks are mentioned as a disadvantage [[23], [24], [25]]. However, sustainable energy-based, small-scale and decentralized systems for local electricity and thermal energy demand can be a more profitable and efficient alternative [16,26]. While, the micro-small scale trigeneration system's main components are of course developed but, still in investigation to commercialize more stably and efficiently [27,28].

Table 1. Micro, Small, Medium, and Large-Scale Power Generation, and typical application.

| Power systems | Range | Typical application | Ref |

|---|---|---|---|

| Micro/Pico scale | <20 kW | Domestic (individual) appliances. | [7,29] |

| Small scale | 20 kW – 1 MW | Office building, domestic building, small scale sectors (farm, hotel, school). | [29,30] |

| Medium-scale | 1–10 MW | Hospitals, universities, data centers, commercial complexes | [12,31] |

| Large scale | >10 MW | Large industrial premises. | [29,32,33] |

To design an ideal trigeneration system, which is environmentally friendly, highly efficient, and economical, the components have to be carefully evaluated related to consumers' electrical and thermal energy demand [27]. The power generating unit has a big impact on the system design [34,35]. Operation strategy is another option to optimize trigeneration systems by adjusting the required power load [16,33,[36], [37], [38], [39], [40]]. Several studies indicated that a power generating unit is the principal equipment for a trigeneration system. Its behavior is investigated based on the fuel type, economic, and energy performance. It could be the fuel cells [[41], [42], [43], [44], [45], [46]], internal combustion engines [[47], [48], [49]], Stirling engines [47,[50], [51], [52]], conventional steam/gas turbines and organic Rankine cycle [12,24,[53], [54], [55], [56], [57]], microturbines [58,59].

In recent years, the lower impact on the environment and higher efficiency are the objectives, and several studies [37,41,54,58,[60], [61], [62], [63], [64], [65], [66], [67], [68], [69], [70]] were conducted and analyzed to evaluate the thermodynamic, environmental, and economic viewpoint of trigeneration systems using the energy and exergy index. Some studies developed a method to prioritize power generation unit selection and suitable type prime moverswere discussed in Refs. [34,35,71,72]. Most recently, Jingzheng [35] employed multicriteria decision-making (MCDM) for selecting thirteen (13) sustainability criteria and three (3) principles in technological, economic, environmental, and social dimensions for evaluating the power generation units for the trigeneration system. These were used to rank different power generation units. The most suitable four prime movers were considered and the sustainability study shows that internal combustion engines, fuel cells, microturbines, and gas turbines are ranked from the most sustainable to the least order.

Several research efforts are being undertaken to improve the performance of trigeneration systems [41,[73], [74], [75]]. Ebrahimi and Derakhshan [42] proposed a combined trigeneration system for cooling, heating, and electricity application using a plate heat exchanger, fuel cell, and adsorption chillerrespectively. Thermodynamic, environmental, and economic evaluation analysis was presented and new thermal damping tanks are developed. The study concludes that the cycle can avoid the production of 15.4 tons of CO2 per year, and the trigeneration system operational cost is economical if the H2 price of less than 2 US$ and overall efficiency and fuel-saving is 75% and 39% respectively. Abbasi et al. [74] analyzed the performance of trigeneration systems using a combined arrangement of a gas engine, diesel engine, and gas turbine as power generating units. The analysis is conducted separately and simultaneously for comparison of its performance. The result showed that the system with combined prime movers increases the efficiency by 10% compared with a single prime mover. Ishaq et al. [76] presented an investigation of a biomass gasification-based trigeneration system, in which an organic Rankine cycle with thermoelectric generators was proposed. In the same study, the overall energy and exergy efficiencies improved by 58.03% and 32.78% respectively.

Some works of literature [48,[76], [77], [78], [79], [80], [81], [82], [83], [84], [85], [86]] have evaluated the performance and cost of trigeneration systems using hybrid systems (combined fuel utilization). Cacua et al. [49] investigated the experimental evaluation of micro trigeneration systems for power, drying, and cooling applications. Dual fuel (diesel and biogas) engine was proposed. From the result, 50% maximum diesel substitution was achieved, and at full load, the efficiency was 40%. Wegner et al. [77] proposed a biomass-based, solar-assisted trigeneration system for cooling, heating, and power. The proposed system was modeled with HOMER simulation software to compare their economic, energetic, and ecological performance. The result reveals that the proposed system has an economic saving of more than 500,000 USD over 20 years, it could also decrease CO2 emissions by 365 t per year. Wang et al. [79] investigated the performance comparison of the trigeneration system fueled with pure diesel and mixed with jatropha oil using ECLIPSE software. A diesel engine generating set is used as a prime mover, and the system consists of waste heat recovery and an absorption refrigerator for heating and cooling purpose. The results of the study show that the thermal efficiency of trigeneration is higher with lower CO2 emissions than that of a single generation. Mohammadi et al. [80] also studied the integration of wind energy coupled with compressed air energy storage systems for cooling, heating, and power cycle using gas turbine, organic Rankine cycle, and absorption refrigeration system. The energy and exergy analyses are applied for the cycle. The result showed that the system can generate 33.67 kW of electricity, 2.56 kW of cooling, and 1.82 tons of hot water per day with an energy efficiency of 53.94%. Sanaye and Sarrafi [81] presented energy, exergy, and economic optimization analysis of solar-powered trigeneration systems. The highest exergy efficiency and relative net annual benefit (RNAB) were the objectives to be achieved. The system consists of concentrated photovoltaic/thermal (CPVT), conventional photovoltaic (PV), and evacuated tube (ET) collectors. Non-dominated Sorting Genetic Algorithm (NSGA-II) multi-objective optimization technique was used to decide the number of CPVT, ET, and PV collectors as well as the capacity of batteries and hot water storage tank size. Wang and Yang [82] analyzed hybrid biomass and solar energy-based trigeneration system to improve efficiency. The system is composed of biomass gasification, an internal combustion engine, a solar evacuated collector, and a mixed-effect absorption chiller. The results show that the exergy efficiency and the primary energy ratio are 16.1% and 57.9% respectively, and the ratio of carbon emission was reduced by about 95.7%. Fani and Sadreddin [83] studied solar-assisted trigeneration systems in office buildings in Iran. System performance, economic analysis, and CO2 emission are calculated. The results of the study concluded that overall system efficiency increases to 89% and CO2 emission can be reduced by 2217 kg/day considering the optimization model. Jiang et al. [84] evaluate the performance impact of incorporating energy storage units (ESUs) in trigeneration systems. And from the study, reported that thermal energy storage reduces the total installed cooling capacity by 15.8% and total installed heating capacity by 37.5% of the CCHP system. Same time trigeneration system with thermal energy storage enables more cost savings of up to 40% compared with trigeneration systems ESUs. Gholamian et al. [85] biomass gasifier and solid oxide fuel cell-based trigeneration system are investigated. The result shows an exergy efficiency of 37.92% with a CO2 emission of 20.37 t/MWh. Uche et al. [88] conducted an experimental and simulation model of a micro-wind turbine and a photovoltaic/thermal collector's based trigeneration system aimed to operate in off-grid conditions. Electricity provides by solar photovoltaic collectors and wind turbines, hot water is produced from the solar photovoltaic and evacuated tube collectors, and the freshwater is produced using membrane distillation and reverse osmosis technique. The result of the study showed that the overall system efficiency is 49.83%. Soheyli et al. [89] evaluated wind and solar renewable energy resources based novel trigeneration system, natural gas is considered the system's primary fuel. In the study, solid oxide fuel cells (SOFCs), wind turbines, and photovoltaic (PV) modules are considered prime movers. Intermittent/fluctuating energy production by wind and solar systems is minimized by deploying heat storage tanks (HSTs) and battery banks. The result of the study showed that, fuel consumption and pollution are reduced up to 154 and 207 times more than a separate production system.

Researchers argue that the extension of solar and wind with other main fuel sources is the best alternative where to respond the performance improvement, environmental pollution, and accelerating energy demand [55]. Rostami et al. [90] investigated the performance of a wind turbine-driven trigeneration system found in a wind farm, in Iran. The waste heat is recovered from a wind turbine (Enercon 70 Model) and applied for freshwater production and cooling applications. In the meantime, studied three types of nanoparticles (Cu, CuO, and TiO2) with water as a base fluid to increase the rate of the cooling process in the wind turbines, resulting in more cooling and freshwater production. Thermodynamic and thermo-economic modeling is used to determine the performance of the system. The results show that Cu/water nanofluid gives the highest performance in terms of freshwater production and cooling capacity compared with other options. If the proposed system run at a wind speed of 12 m/s 7.135 kW of power can be saved for a cooling capacity of 56.6 kW in comparison with the reference system. Increasing Cu concentration from 0.5% to 7% increases cooling load from 5.1 kW to 5.8 kW, supply air volume rate from 9.27 m3/min to 10.56 m3/min, freshwater rate from 126.9 L/day to 144.5 L/day, energy efficiency from 45.47% to 51.68%, and exergy efficiency from 11.04% to 12.12%. Gholizadeh et al. [91] studied the performance of a geothermal heat source at 170 °C based trigeneration system for power, cooling, and freshwater production. Different optimization modes are defined and the genetic algorithm (GA) method is used to optimize the performance of the devised system. The optimization result showed an increase in the system output power of 77.08%, overall cooling load to 87.01%, trigeneration-based gain-output ratio (TGOR) to 8.18%, and exergy efficiency to 46.36%. Khaliq et al. [92] presented energy and exergy investigations of trigeneration systems. The system comprises an organic Rankine cycle, an ejector-absorption chiller, a heat exchanger, and the heliostatfield. The result showed that the propane-based system exergy output raised from 1203 kW to 2028 kW and the isobutane-based system exergy output raised from 2562 kW to 4314 kW whereas normal irradiations are raised from 600 to 1000 W/m2. Therefore in isobutane operated system 65.42% can be produced as energetic output out of 100% solar energy supply, the rest 34.58% is lost as thermal exhaust. Bellos and Tzivanidis [34] conducted multi-objective optimization of a parabolic trough solar-driven trigeneration system. The prime mover proposed was a steam turbine. The result showed that the proposed system gives 87.39% and 11.26% energy and exergy efficiency respectively. Eisavi et al. [55] conducted energy and exergy analyses of solar-powered trigeneration systems to determine the efficiencies and losses. Double effect absorption cooling, organic Rankine cycle, and heat exchangers were incorporated. The proposed system is compared with a similar system that differs by having a single-effect cooling. The result showed that, when comparing a double effect absorption with a single effect absorption system, it can raise the cooling and heating power to 48.5% and 20.5% respectively for the same amount of input energy. Askari et al. [93] investigated the reliability, economics, and emissions of micro trigeneration system applied for cooling, heating, and power demand of 50 kW, 100 kW, and 48 kW respectively. Implemented a 5-story-high residential building having a total of 1000 m2 floor area. The analysis focuses on the techno-economical procedure and optimizes the effects of solar collectors, solar PVs, and fuel prices. The study concluded that the renewable base trigeneration systems and an increasing number of solar collectors the system economical and have less environmental emission results.

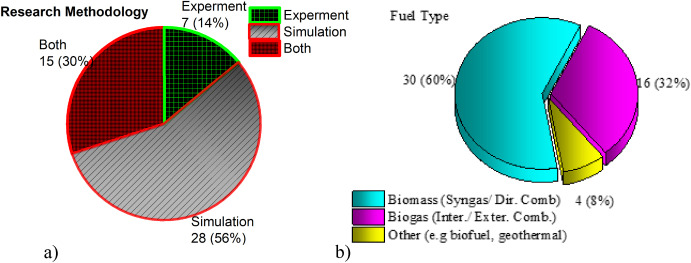

Based on the above-presented literature, considering 50 scientific published data, it could be concluded that most studies were simulation models, seen in Fig. 1a, which were more focusing on sustainable energy-based systems, the reason for this may require a high cost to set up the experiment of such a complex system. As shown in Fig. 1b, biomass looks widely employed fuel alternative in the place of fossil fuels, and biogas also seems repeatedly investigated and promising fuel source for electric power generation applications. Other renewable energy resource-based trigeneration systems are investigated, such as optimization of trigeneration system with combined wind & solar energy system [88], a geothermal source for trigeneration system [94]. However, those energy resource potential availabilities are limited with a location and season, but they are a very good option as an energy extension with a base fuel source.

Fig. 1. Considering 50 scientific publications to prepare the synthetic data for comparison a) Research methodology b) Fuel type employed.

Fig. 1. Considering 50 scientific publications to prepare the synthetic data for comparison a) Research methodology b) Fuel type employed.This paper presented the success story of the performance of the trigeneration system powered by biomass, biogas, and other renewable energy resources in Fig. 2.

Fig. 2. Success story assessment of trigeneration system fueled with biomass and biogas

Gt = Gas Turbine, ICE=Internal Combustion Engine, ORC=Organic Rankine Cycle, SOFC=Solid Oxide Fuel Cell, MGT = Micro-Gas Turbine, HT-PEMFC=High Temperature Proton Exchange Membrane Fuel Cell, SE=Stirling Engine, TEG = Thermoelectric Generator, EFMT = Externally Fired Microturbines, ηen = Energetic Efficiency, ηex = Exergetic Efficiency, ηs = System Efficiency, ηel = Electrical Efficiency.

As discussed in the literature above, power generations are well proven for fossil fuel cases, but in other biofuel sourced technologies it is under investigation to improve the performance and commercialization. Hence the integration of different prime movers gives higher efficiency, for example deploying fuel cells, ORC, and parabolic trough together sourced with biomass gives about 85% of system efficiency for the cooling, heating, and power generation application. Biomass-fueled gas turbines, internal combustion engines, and ORC also has good performance and they are available at a lower price and longtime service than advanced technologies like fuel cells. The combination of different fuel sources also makes the system more economical and efficient. It is observed that when the system works with biomass, biodiesel, solar, and wind combination gives about 73% energy efficiency. Biogasand solar-based systems incorporating fuel cells, and waste energy recovery systems (TEG) give about 75% of electrical efficiency. And all possible prime mover alternatives are suitable to implement biogas as fuel and give good results.

3. Biogas based trigeneration systems

The history of biogas technology traced back to the 17th century, Count Alessandro Volta 1776, develops a correlation between decaying matter and the produced gases [95]. The first application of biogas as fuel was recorded in 1859 in England and used for lighting [96]. Over the year, after the development of microbiology science in 1930, Buswell and other scientists discovered anaerobic bacteria and promote suitable conditions for methane production [97]. Therefore, biogas is a methane-rich renewable gas produced by popular biochemical conversion of organic material passing through hydrolytic, fermentative, acetogenic, and methanogenic stages [97,98]. Then producing methane at the composition of 50–70%, 30–50% CO2 while 2–8% are water vapor and traces of O2, N2, NH3, H2, H2S, and organic remains as a waste [97,98]. Biogas has a caloric value of 21–24 MJ/m3 and 1 m³ of biogas is equivalent to 0.5–0.6 L of diesel fuel or 6 kWh [[99], [100], [101]].

In the modern world, biogas production is well established and rapidly growing technology, targeting waste recycling, from an economical point of view and to ensure environmental sustainability [104,105]. Countries like India and China are into using biogas extensively [106,107], in Germany, biogas technology is advanced to produce electricity in the Mega-Watt range [97]. Ethiopia, like many other developing countries, is in the early stage of implementing policies to promote sustainable use of energy resources. Such technologies specifically biogas technology was introduced in early 1979 [104,105] in Ethiopia. Due to the interest in biogas, concerning the country's Energy Policy and Environmental Protection Strategy and address the energy demand for local households, a biogas feasibility study was conducted in 2015 by Ethiopian Rural Energy Promotion and Development Centre (EREDPC) and Netherlands Development Organizations SNV/Ethiopia partnership [110]. The report reveals that there is a biogas potential, and offers an attractive option to replace fuelwood and charcoal in Ethiopia. Biogas can be designed to fit nationwide, regional, urban even rural energy need applications [108]. The National Biogas Programme, Ethiopia (NBPE) was launched to construct over 18,000 biogas digester plants in two phases ran from 2008 to 2017 to reach 10,678 households in the selected Woredas of four regions of the country, namely, Oromia, Amhara, Tigray, and SNNPR [105,106]. And envisions upscaling construction of up to 100,000 biogas plants in phase to cover more areas [110]. After the complete implementation of both phases of the NBPE project, the achievement rate was 70%. Lack of exploiting awareness, success stories, biogas negative image, lack of project monitoring, poor ownership, policies, and finance issues (subsidies) of the planned target are reasons for the result. The produced gas utilizes for lighting and cooking, still, there is no technology to use the gas advanced [[107], [108], [109], [110]]. As the NBPE report, the effect of the installed biogas digester plant confirmed that about 8,732 tons of charcoal 27,162 tons of fuelwood, and 5,336 ha of forest were saved. Moreover, about 66,463 tons of biomass and 485 tons of fossil fuel will substitute with the total implementation of plants, this leads to the reduction of 64,684 tons of CO2 per year. Besides, 43,662 kilotons of organic matter (fertilizer) can be produced [106,111]. However, in the Ethiopian context, no technology is involved producing electricity from biogas. But electric power is a backbone of economic development, therefore, thinking to produce electric power can be economically useful to society. Literature indicates that raw biogas can be supplied to generate electricity and thermal energy through cogeneration, trigeneration, and even polygeneration technology [[134], [135], [136]]. Biogas to biomethaneupgrading at the approximate natural gas quality of 75–98% is a promising alternative using membrane separation, chemical absorption, pressure swing adsorption, and pressure water scrubbing technologies [120,126]. Sweden and Germany have more invested in biomethane infrastructure [117,118]. Biogas biochemical conversion and upgrading technology development are not included in this review.

Previous reviews [7,13,16,25,71,[93], [94], [95], [96], [97]] on trigeneration technology have provided a discussion, covering, prime mover technologies, system configurations, cooling technologies, heat exchangers, and fuel type supplied. This paper presents a review of scientific study outputs; aiming to cover biogas supplied trigeneration systems are presented and covers from 2009 to the present in chronological order.

3.1. Prime mover technologies

This section presents biogas-based trigeneration system power generation unit alternatives from Table 2 to Table 5. Their performance, capacity, suitable cooling technology used, reliability, instability, fuel flexibility, heat recovery, initial and lifetime economic issues, commonness in practice, and operating condition are compared and presented in Table 6. Fig. 3, shows all possibly considered fuel types and prime mover alternatives.

Table 2. Case studies on biogas trigeneration system with an internal combustion engine.

| Power generation unit | Fuel | Cooling unit | Analysis | Application, Output/key findings | Ref |

|---|---|---|---|---|---|

| one-cylinder, air cooling, 4 strokes Motor-Generator. | Biogas, Compressed natural gas (CNG) | – | Experiment | Generate 2 kWel. The efficiency of separated & combined heat & power was 27.6% & 65.3%. Nanofluids enhance the efficiency using Al2O3nanofluid is 73%. | [127] |

| Internal combustion engine | Biogas | – | Case study | Electricity and heat production. | [128] |

| The payback period is 2.5 years. | |||||

| Internally combustion engine | Biogas | Pink Chiller PC19 absorption refrigeration | A case study |

The final services are biogas, electricity, cooling & fertilizer. Electrical efficiency is 37%. coefficient of performance is 0.65. Lower cost, payback 7.8 years. |

[129] |

| Internal combustion engine | Biogas | Absorption refrigeration |

Simulation Aspen Plus |

Produce power, heating, and cooling. Electricity & system efficiencies is 25.7% and 74.5%. The power output of around 72 kW. Payback periods are 2.5 and 4.7 years. |

[130] |

| The internal combustion engine and Stirling engine | Biogas, Solar energy | Absorption chiller |

Lhasa for simulation Experimental research |

For electricity, cooling, and heating. Biogas & solar integration improve annual electric productivity and refrigeration by 8.70% and 2.57%. Natural gas consumption and emissions were reduced by 8.66% and 8.20%. | [48] |

|

Internal combustion engine (CAT engine) |

Biogas | Absorption refrigeration system |

Aspen Plus® thermodynamic performance simulation. Economic analysis. Manufacturing. |

Generating power, cooling, drying. System efficiency raised from 25.66% to 76.02%. 2.313 MT, 20.35 MT, & 3.75 MT of maize, cassava tubers, & tomato have dried respectively per year. While 3.75 MT of tomato is also preserved. | [70] |

| Internal combustion engine | Biogas, Natural gas | Absorption cooling system | Case study | Produce 1.25 MWel. Less CO2 emissions. Energy-saving improves from biogas. | [131] |

| Internal combustion engine | Biogas, solar PV | Absorption chiller | Primary energy savings |

Generate power, cooling & heating. 64.7% electrical efficiency, 8.9% PV compared to the total. Annual total heat production per year is 21172.4 GJ/a. |

[132] |

| Internal combustion engine | Biogas | H2O–NH3absorption system. | Energetic and economic comparison b/n natural gas & biogas fuel used for cogeneration. | Generating power and cooling. The global efficiency of the system for natural gas is 63.14% and biogas is 63%. Using biogas as fuel is more economical. Payback period of 5 years. Produces cold water at 7 °C | [15] |

| Internal combustion engine | Biogas | – | Economic analysis | Generating electricity, cooking energy, and safe drinking water for 30 households. The payback period is between 2.6 and 4 years. Electricity cost per kWh is lower than 12 times that of solar and wind turbines. | [133] |

Table 3. Case studies on biogas trigeneration system with fuel cells.

| Power generation unit | Fuel | Cooling unit | Analysis | Application, Output/key findings | Ref |

|---|---|---|---|---|---|

| Solid oxide fuel cell | Biogas | Absorption refrigeration | Simulation PROMS Model Builder | Produce power and cooling. | [134] |

| Exergy efficiency 56.69%. | |||||

| System efficiency without intake cooling is 45.24%. The power output of around 180 kW. | |||||

|

High-temperature proton exchange membrane fuel cell (HT-PEMFC) Microturbine (gas) |

Biogas | Li–Br absorption chiller | Simulation by applying exergy analysis | Generation of power, heat, cooling. Electrical power output 5 kW. | [43] |

| Electrical efficiency is about 36% | |||||

| System efficiency achieved 74% | |||||

| Solid oxide fuel cell | Biogas | – | Simulation GAMS® software solved with CPLEX | Produce power and heating. | [135] |

| SOFC becomes interesting if implemented in a thermally optimized wastewater treatment plant. | |||||

| Solid Oxide Fuel Cell, small gas turbine | Biogas | – | MATLAB and Aspen Plus® modeling. | Gas turbine integration improves system efficiency. | [44] |

| Solid oxide fuel cell | Biogas | – | Simulation Aspen Plus | Produce power and heating. | [136] |

| Electrical efficiency 51.6%. | |||||

| System efficiency 87.5%. |

Table 4. Case studies on biogas trigeneration system with steam/Gas turbine, ORC.

| Power generation unit | Fuel | Cooling unit | Analysis | System application and key findings | Ref |

|---|---|---|---|---|---|

| Gas turbine cycle, Organic Rankine cycle | Biogas | Ejector cooling cycle (ECC) | Exergoeconomic optimization of system | For electricity, refrigeration, and potable freshwater generation. Performance increases in electricity by 2.58%, and refrigeration by 22.69%. While the cost of trigeneration is decreased by 6.71%. | [54] |

| Chemically Recuperated Gas Turbine (CRGT) | Biogas | – |

Simulation Aspen Plus software |

Power and heating. The system increases the power generation | [106] |

| Gas turbine | Biogas | bi-evaporator electricity/cooling system | Simulation Engineering Equation Solver (EES) software |

Produce electricity and cooling. Generate overall cooling load & net electricity of 505.2 kW & 1168 kW. Energetic & exergetic efficiency of 54.54% & 36.83%. |

[137] |

| 1 gas cycle and 2 steam cycles | Biogas | LiBr–H2O absorption cycle | Mathematical modeling by Engineering Equation Solver (EES) |

Produces 1460 kW of electrical energy, 280.8 kW of cooling, and 122.6 L/min of hot water. Energy and exergy efficiency is 64% and 34.51%. |

[138] |

| A gas turbine, organic Rankine cycle | Biogas | Absorption chiller | Energy and exergy analyses | For 1078 kWel, 198 kW heating & 87.54 kW cooling & 40 kg water production daily. System energy & exergy efficiency is 72.5% & 30.44%. | [139] |

| Steam turbine | Biogas | Absorption chiller unit (ACU) |

ChemCad 6.3® simulation. Enviro-economic analysis. |

Electricity, cooling, and heating. Generate 2523 kW heating, 925 kW electricity, and 473 kW of cooling from combusting 3280 kW of biogas. | [13] |

Table 5. Case studies on biogas trigeneration system with microturbines.

| Power generation unit | Fuel | Cooling unit | Analysis | Application, Output/key findings | Ref |

|---|---|---|---|---|---|

| Externally fired microturbine (gas) | Biogas | Absorption refrigeration system |

Aspen Hysys V8.4 simulation. Experiment |

Electricity, refrigeration, and hot water production. Primary energy savings of up to 37%. | [2] |

| Microturbine (gas) | Biogas | – | Simulation |

600kWel production and biomethane upgrading. Results show that the biogas system can be versatile for polygeneration. |

[116] |

| Micro Gas turbine | Biogas | – | Simulation modeling |

For cooling, heating, and power generation. Electrical efficiency is 46.6%. CHP efficiency of 81.2%. Net power output 500 kW |

[140] |

|

Microturbine (gas) Capstone C30 model |

Biogas | Double effect H2O–LiBr Abs. Chiller | Aspen Hysys modeling | Identified biogas and microturbine integration are best for trigeneration systems. | [141] |

Table 6. Assessment and comparisons of power generating units for trigeneration system.

| Power generator unit | Internal combustion engine | Fuel cells | Steam/Gas turbine/ORC | Micro Turbines |

|---|---|---|---|---|

| Maximum Achieved Capacity | Up to near 1.25 MW [125,126] | Up to 180 kW [134] | Up to 1.168 MW [13] | Up to 600 KW [142] |

| Cooling Technology Used | Single/Double Stage, LiBr–H20, NH3–H2O Absorption Chiller [15] |

LiBr–H20 Absorption Chiller, and liquid desiccant cooler [7] |

Silica gel–water and Zeolite–water Adsorption system [137] | LiBr–H2O single-effect Absorption system [140]. |

| Advantages | Very good reliability (for clean fuels) [127], Rapid start-up [129], Low investment cost [129], Electrical efficiency 45% [48] |

Excellent performance [131], Very high electric Efficiency, Low noise [44,131], No combustion, Low GHG [44] |

Operate at low grade heat [137], High reliability [56,137], Low maintenance costs [106] | Used low-quality fuels (external fired), Very few moving parts & compact [2]. Fuel flexibility (bio/syngas) [102]. High temperature exhaust, less thermal loss and Low emissions [141] |

| Disadvantages | Short maintenance interval, High noise [69,124], Instability with bio & syngas/limited fuel flexibility [99,126], High GHG [132]. Using waste heat is difficult [130], Quickly damage by low-quality gases [133] |

Very high investment costs [135] Long start-up times [131] Need very high quality, energy-intensive fuels [131]. Low heat recovery [44] |

High investment costs [139] Low electric efficiency [137] Low heat recovery for low-grade heat applications [13] |

High investment costs [140] Difficult Start-up [2]. Low electric efficiency [143] |

| Practice commonness and potential | Common and very high [128] | Rare and high [43] | Common and high [54] | Rare and very high [141] |

Fig. 3. Considered prime movers and fuel alternatives.

Fig. 3. Considered prime movers and fuel alternatives.