1. Introduction

Large amounts of waste have accumulated because of urbanization and population growth, with much of it coming from residential, commercial, and industrial operations, as well as quarrying activities (Adeboje et al., 2022). Because of the population's continued growth and the rate of consumption growth, landfills are the primary method of disposal (Adeboje et al., 2022). Agricultural output has increased more than threefold in the last 50 years due to soil extension for pastoral use, technological advances in agricultural operations, and demographic change (Duque-Acevedo et al., 2020). Agriculture has evolved to be one of the most powerful and valuable sectors of the economy in various nations, as well as the world's leading employer. Globally, it produces 23.7 million tonnes of food per day on average (Jagaba et al., 2021b). It is responsible for 21% of global carbon dioxide emissions, so it places a high priority on developing sustainable agriculture and reducing environmental impacts through novel technological systems (Harun et al., 2019). Farming is one of the most biologically important industries, generating a large amount of agro waste, which is an important component of the green economy. These waste materials are abundant, sustainable, and affordable, and their application has the potential to be environmentally responsible (Ukanwa et al., 2019). These agro wastes were only disposed of to comply with the available environmental policies and laws. Due to the prevalence of sustainable and ecological components in the waste composition, illegal disposal or incineration alternatives are offered as available landfill area becomes scarce (Bui et al., 2022; Moh, 2017). One of the key issues in road engineering has always been the durability of asphalt pavement, especially against harsh conditions (Long et al., 2022; Xiong et al., 2019). However, the shortage of conventional materials and the demand for an eco-friendlier system have prompted waste conversion instead of essential disposal and management in recent decades. The global nation's punitive regulation has redirected the construction industry's research interest to using biomass waste and industrial by-products for construction (Yaro et al., 2022b). Furthermore, because the quantity of waste, particularly agricultural waste, is growing exponentially worldwide every year, finding a strategy to reuse or minimize it is imperative (Adeboje et al., 2022; Alawa et al., 2022). As the world's focus has shifted to alternative energy and sustainability in recent years, biomass from agricultural by-products has gained recognition. In addition, to mitigate improper waste management while researching environmentally friendly low-cost resources as alternatives to conventional materials (Jikol et al., 2022; Rashidi et al., 2022).

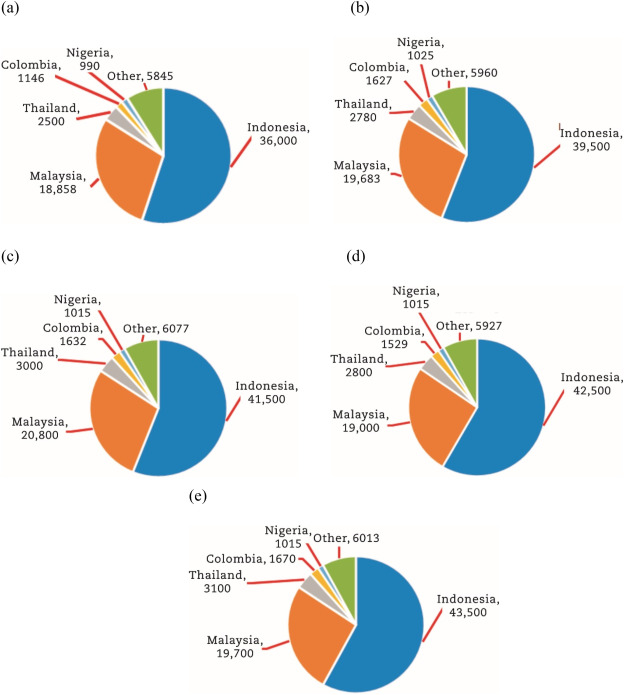

Elaeis quineensis, or palm oil, has grown in popularity as a global commodity, and the industry is rapidly expanding and establishing itself as a major agriculture-based industry. As shown in Fig. 1, the total amount of palm oil output has increased almost every year since 2016. The palm is one of the most common crops that thrive in hot, humid climates such as those found in Equatorial Africa and Southeast Asia (Jagaba et al., 2021b; Mba et al., 2015). Palm oil is regarded as one of the most self-sufficient agricultural products due to its adaptability. Apart from the root, the entire palm tree can be used to make one or more items; the branches and leaves can be used to make baskets, and the palm nut can be used to make palm kernel oil. While the stem is used to make lumber, the fruit bunches can be used to make palm oil and soap. A conventional palm oil mill's main outputs are crude palm oil/kernels and biomass. The tree is naturally brown, and the seed is crimson due to a high betacarotene content (Jagaba et al., 2021c). The palm shell, palm fronds, oil palm trunks, mesocarp fiber, and empty fruit bunches are all considered significant sectors providing copious biomass in various forms (Yaro et al., 2021a). Palm oil producers confront considerable hurdles in complying with increasingly severe waste disposal punitive environmental laws (Jagaba et al., 2021c; Yaro et al., 2021e). With the global population expected to exceed 9.7 billion by 2050, palm oil is one of the primary sources of fats and vegetable oils required to sustain the planet's growing population. China and India are two recent examples of large-population countries that import a significant amount of palm oil (Al-Sabaeei et al., 2022; Tan et al., 2009).

Fig. 1. World palm oil output in thousand metric tonnes for the years. (a) 2016–2017. (b) 2017–2018. (c) 2018–2019. (d) 2019–2020. (e) 2020–2021 (Saad et al., 2021).

Fig. 1. World palm oil output in thousand metric tonnes for the years. (a) 2016–2017. (b) 2017–2018. (c) 2018–2019. (d) 2019–2020. (e) 2020–2021 (Saad et al., 2021).As a result, if the vast amount of waste generated is not managed and properly repurposed, it poses an environmental risk and disrupts the stability of the ecosystem. To address this challenge, it is critical to address the existing issue without jeopardizing future generations' access to appropriate resources (Al-Hdabi, 2016; Lindsey, 2011). As a result, waste reduction, recycling, and reuse (RRR) is a widely used strategy for fostering a sustainable environment all over the globe (Hasan et al., 2019; Jamshidi and White, 2020; Zhang et al., 2016).

Malaysia and Indonesia produce significant palm oil worldwide and generate the most waste (Hosseini and Wahid, 2014; Yaro et al., 2021a). Also, the nation's green strategy strives to foster a sustainable economy while preserving the environment (Chua and Oh, 2011; Hezri and Nordin Hasan, 2006; Keong, 2005).

Furthermore, the extensive production of palm oil-related goods produces a nearly equivalent amount of biomass residue, which must be addressed appropriately (Yaro et al., 2021a). The use of waste as a construction material replacement or modifier has become more common among researchers. Furthermore, the potential for various palm oil wastes to be transformed or used as surrogate or secondary materials is expected to drive up demand soon. Furthermore, the long-term viability and environmental consequences of these waste materials must be considered. The palm oil industry has exploded in the last few decades. The number of active palm oil mills and oil palm planting areas has increased because of this development. Palm oil accounts for about 25% of the total weight of the materials, with the remaining 75% made up of dry waste biomass (Amran et al., 2021). Palm oil is divided into two types: crude palm oil (CPO) and palm kernel oil (PKO). PKO is derived from the seed or kernel, whereas CPO is derived from the mesocarp. On the land and at palm oil mills, the palm oil industry produces a significant amount of biomass waste. After the commercial service life of the palm oil plantation has expired, waste such as palm oil fronds (POF) and palm trunks (PT) are produced in the field (Jafri et al., 2021).

Massive amounts of liquid and solid waste have been generated in palm oil mills because of the conversion of fresh fruit bunch (FFB) into crude palm oil (CPO). The liquid waste generated is the palm oil mill effluent (POME), whereas the five most abundant wastes generated by the mill are palm fronds (PF), palm mesocarp fiber (PMF), palm kernel shells (PKS), empty fruit bunches (EFB), and palm trunks (PT), as shown in Fig. 2. FFB wastes account for about a quarter of this, with trunk and frond debris accounting for the other two-thirds (Dungani et al., 2018; Jafri et al., 2021). The PT is a waste product that is easily accessible throughout the year during replanting. Massive amounts of POT biomass wastes are gathered as plants that have successfully completed their valuable lives are felled. Palm oil frond (POF) fibers, on the other hand, are made up of vascular bundles with varying diameters (Aris et al., 2022; Jafri et al., 2021). The palm fibers are composed primarily of natural and non-hazardous, biodegradable, and eco-friendly (Yaro et al., 2021g). Furthermore, PKS is a waste product of palm oil mills, and the shape of PKS varies depending on the extraction procedure or shattering of the nut. The shape of PKS can be uneven, round, angular, flaky, or irregular. PKS with a relatively smooth shell surface texture is also available (Abd Majid et al., 2012; Jafri et al., 2021). PKS is the shell fractions that remain after the nut has been crushed in the palm oil mill. PKS refers to fibrous materials that are processed in bulk from the factory to the end user. Dusty fractions and tiny fibers were mixed in with large clusters of tiny shells. PKS absorbs water at a lower rate, ranging from 11% to 13% (Jafri et al., 2021; Otti et al., 2014). The pyrolysis of POS and palm fibers, which are used to create energy-elevated-temperature boilers in the oil mill, produces palm oil fuel ash (POFA) and palm oil clinker (POC) chunks. Table 1 shows the palm oil waste composition from processing FFB and their percentage total weight.

Fig. 2. Wastes produced by the palm oil mill (Abnisa et al., 2013).

Fig. 2. Wastes produced by the palm oil mill (Abnisa et al., 2013).Table 1. Palm oil waste composition from the processing of fresh fruit bunches (Abdullah and Sulaiman, 2013b).

| Palm oil waste | FFB constitution as a percentage of total weight on a dry weight basis (%) |

|---|---|

| Palm oil shell | 6 |

| Palm oil fiber | 15 |

| Empty fruit bunches | 23 |

| Palm kernel | 72 |

| Crude palm oil | 21 |

| Palm oil mill effluent | 28 |

As a result of combustion, significant amounts of POC and POFA waste are produced and deposited near palm oil mills (Jagaba et al., 2021c; Yaro et al., 2021e). An estimated 2.6 million metric tonnes of POC have put environmental sustainability and energy conservation at threat (Yaro et al., 2021e). POC produced by the boiler is transported from the incineration boiler and dumped on industrial grounds (Nayaka et al., 2018). It's a waste product with little to no commercial value that pollutes the environment, degrades the land, and contaminates the aquifer (Karim et al., 2018; Yaro et al., 2021a). It has recently been disposed of in landfills and contaminates the soil (Jagaba et al., 2021c). Every year, over 4 million tons of POFA and POC are generated as unwanted waste (Abdullah and Sulaiman, 2013). POFA is the mill's most common ash by-product substance (Khankhaje et al., 2016; Tangchirapat et al., 2007). The amount of this residual waste is increasing in tandem with the development in palm oil output around the world, which now exceeds 10 million tons per year (Awal and Hussin, 2011; Safiuddin et al., 2011). POFA is a geopolymer material that is both ecologically benign and biodegradable (Jagaba et al., 2021c; Yaro et al., 2021d). POFA and POC are two essential biomass wastes commonly utilized in construction (Ahmad et al., 2007). The pyrolysis of PKS at 600 °C–1000 °C produces PKSA, a different form of ash residue (Nnochiri et al., 2017). Most of these wastes are usually discarded, with little usage in other areas (Yaro et al., 2021c). Ongoing dumping would lead to waste building up at the dump, prompting the creation of more dumping areas. Thus, an assessment and review of the primary uses of different palm oil mill wastes as green waste materials in the asphalt sector is vital. Because of the outstanding mechanical properties and environmental advantages of palm oil waste materials. They are regarded as emerging and future sustainable industrial materials with a wide range of applications in the asphalt pavement industry. In this article, we investigate various palm oil waste physicochemical properties and their effects on asphalt pavement performance, with the goal of providing a thorough understanding of palm oil waste's current and future uses. Its application in a variety of asphalt pavements is critically examined, as is how it can affect the physicochemical and mechanical properties of asphalt binder and mixtures, as well as soil properties. The use of palm oil wastes in various forms or composites is a promising prospect with limited literature.

The primary objective of this study is to provide a systematic review, a scientometric investigation, to assist in highlighting and comprehending works of literature relating to the sustainable use of various palm oil waste in the asphalt pavement industry, as well as to help identify future research gaps and challenges in the literature that need to be explored by future studies.

2. Palm oil mill waste properties

2.1. Physical properties

Because the physical properties of agro-waste can be complex, assessing the physical properties of palm oil waste can aid in determining its suitability. Table 2 lists the physical properties of palm oil waste. Even though the particle sizes were within the limits of the pozzolan materials requirement, it was discovered that palm oil waste has lower specific gravity than ordinary Portland cement (OPC). Furthermore, the size distribution of the particles of some palm oil waste material is depicted in Fig. 3 in comparison to OPC, indicating its potential for use as a substitute material. The physical and chemical properties of palm oil waste are heavily influenced by the boiler's temperature and time (Hamada et al., 2020; Yaro et al., 2021a).

Table 2. Physio-chemical properties of selected palm oil waste.

| Physiochemical parameter | POF (Evbuomwan et al., 2013; Yaro et al., 2021g) | POCP (Hamada et al., 2020; Kanadasan et al., 2015) | POCF (Sooraj, 2013; Yaro et al., 2021a) | PKS (Evbuomwan et al., 2013) | OPC (Yaro et al., 2021g) |

|---|---|---|---|---|---|

| Colour | Yellowish-brown | Blackish grey | Grey | Brownish yellow | Grey |

| Density (kg/m3) | 0.70–1.55 | – | – | 1429.00 | |

| Specific gravity | <1.00 | 2.53 | 1.81–2.60 | 1.27 | 3.14 |

| Porosity (%) | 57.9 | – | – | 63.6 | – |

| Ash content (%) | 6.7 | – | – | 6.1 | – |

| Tensile strength (MPa) | 50–400 | – | – | 50–400 | – |

| Median particle size (μm) | – | 37.97 | 17.62 | – | 22.47 |

| Retained on 45 μm | – | 29.00 | 11.62 | – | 11.16 |

| Surface area (m2/g) | 1030 | – | – | 1080 | – |

| Moisture content (%) | 3.43 | 0.96 | 1.12 | 2.15 | 0.11 |

| Bulk density (%) | 0.56 | 0.64 | |||

| pH | 6.74 | 6.10 | 6.40 | – | – |

Fig. 3. Agro waste materials particle size distribution (Alengaram, 2019).

Fig. 3. Agro waste materials particle size distribution (Alengaram, 2019).2.2. Chemical composition

Table 3 shows some of the chemical oxides of some selected palm oil waste. As can be seen, most palm oil wastes contain a significant percentage of SiO2, indicating that they are pozzolanic material. Several variables influence the composition. Some of the factors are the fiber-to-shell ratio, combustion temperature, palm oil tree species, and soil properties (Jagaba et al., 2021b; Karim et al., 2016).

Table 3. Palm oil waste chemical constitution (weight %) compared to OPC.

| Material | Reference | Al2O3 | SiO3 | Fe2O3 | MgO | K2O | P2O5 | CaO | SO3 | SAF |

|---|---|---|---|---|---|---|---|---|---|---|

| PKSA | Tangchirapat et al. (2007) | 4.56 | 57.10 | 3.30 | 4.23 | – | – | 6.55 | – | 64.96 |

| Adeyemi and Joseph (2015) | 11.40 | 54.80 | 0.36 | 6.11 | 6.52 | 0.250 | – | 1.14 | 66.56 | |

| Sylvester and Lukuman (2018) | 2.40 | 42.60 | 5.60 | 2.20 | 0.50 | 0.005 | 4.30 | 0.02 | 50.60 | |

| POCP | Nayaka et al. (2018) | 4.71 | 60.29 | 5.83 | 4.20 | 7.24 | 3.780 | 3.28 | 0.31 | 70.83 |

| Kanadasan et al. (2015) | 3.11 | 74.29 | 2.09 | 1.72 | 6.22 | 2.790 | 5.10 | 0.15 | 79.49 | |

| Ibrahim and Razak (2016) | 3.89 | 59.90 | 6.93 | 3.30 | 5.82 | 3.470 | 6.37 | 0.39 | 70.72 | |

| POFA | Ranjbar et al. (2014) | 6.30 | 64.20 | 3.70 | 4.80 | 5.18 | – | 5.80 | 0.72 | 74.20 |

| Awal and Shehu (2013) | 2.54 | 59.62 | 5.02 | 4.52 | 7.52 | 3.580 | 4.52 | 1.28 | 67.18 | |

| Alnahhal et al. (2021) | 2.07 | 50.00 | 6.70 | 3.22 | 12.8 | – | 4.00 | 1.40 | 58.77 | |

| OPC | Yaro et al. (2021a) | 5.90 | 21.00 | 3.40 | 2.50 | 0.50 | 0.280 | 64.70 | 2.40 | 30.30 |

Moreover, to address waste dumping issues, incorporating economical and eco-friendly sustainable waste materials into the development of innovative and eco-friendly materials would aid in reducing contamination, proper land usage, and sustainability (Kanadasan and Razak, 2015a, Kanadasan and Razak, 2015b). As a result, reusing palm oil waste for various purposes would aid in the conservation of natural resources and the reduction of carbon dioxide emissions, paving the way for efficient utilization and a sustainable future. With the advancement of technology, it is becoming increasingly necessary to abandon the use of antiquated, out-of-date materials in industrial applications. Because the raw materials used by industries have a huge environmental impact, it is critical to change the current scenario, particularly for emerging nations (Yaro et al., 2021c). Several attempts have been made to develop low-carbon products or processes using sustainable technology. Waste palm oil wastes are emerging as prospective sustainable industrial materials with applications in a variety of industries, particularly the construction industry, due to their remarkable mechanical properties and environmental benefits. Its goal is to thoroughly understand the current and future use of palm oil waste in the pavement industry. Its use and modification in various fields of pavement engineering are discussed.

3. Methodology

Based on prior research on the use of palm oil waste in asphalt mixtures, we discuss a thorough systematic review of the published literature using the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) technique, as well as a scientometric study using VOS viewer software. Because it improves the chances of accurately accessing the area of research, the synergistic use of review methodology and software as assistance for performing a systematic review (Barbosa et al., 2019). Also, scientometric assessment of scientific development is becoming more common (Al-Sabaeei et al., 2022; Barbosa et al., 2019; Boloy et al., 2021).

3.1. PRISMA method for qualitative analysis

To effectively identify scientific research on palm oil waste, a comprehensive systematic review of the literature was conducted, along with a scientometric analysis. When these two methodologies are combined, they can help scientific investigations progress by providing quantitative analysis via scientometrics and qualitative analysis via a systematic literature review (SLR) which is a comprehensive research method. It is structured and accurate to aid article selection and filtering of acceptable published studies (Boloy et al., 2021; Jagaba et al., 2021b). It is a form of secondary assessment in which all accessible information relevant to a specific field of study, research question, or research approach is identified, selected, analyzed, and interpreted. Early April 2022 marked the commencement of the SLR mentioned here. Fig. 4 depicts the PRISMA pattern that was employed in this study. This can only be feasible if the research questions linked to the study objective are well established.

Fig. 4. PRISMA flowchart for article selection for the review process.

Fig. 4. PRISMA flowchart for article selection for the review process.3.1.1. Study question

The increased use of palm oil trees for palm oil production has resulted in waste accumulation and environmental contamination, prompting research into the application of various waste products generated during the palm oil milling process. Thus, the primary goal of this research was to determine the viability of palm oil waste applications in the asphalt pavement industry. In a typical SLR, study questions are used to aid in the development of the review process. As a result, the most important aspect of any SLR is establishing the questions and selecting the best approach to answer them. The primary goal of this SLR was to address concerns about the feasibility and performance of palm oil waste in various aspects of asphalt pavement engineering applications. As a result, Table 4 shows the study questions developed exclusively for this research.

Table 4. SLR's objectives and questions.

| Item | Description |

|---|---|

| Objective | To determine the most potential uses of palm oil waste in the asphalt pavement sector and assess their performance in various forms when used for different purposes. |

| Questions | What properties define palm oil waste, their main uses in asphalt pavement engineering, and how do the properties of palm oil waste influence and improve the asphalt pavement performance design. |

During the literature-gathering phase, reputable publications were obtained to identify research papers related to the study's topic. As a result, to find the necessary peer-reviewed publications, the search method used in this review focused on three electronic repositories: Scopus, Web of Science, and ScienceDirect. The databases were chosen because they are among the most comprehensive, extensive, and accurate scientific databases available, with significant data collection and relevant bibliometric analyses. Additional records were obtained from a variety of sources, including “ResearchGate” and “Google Scholar”.

Because various palm oil waste is still being researched for use in asphalt pavement engineering to increase waste utilization and sustainability, this study covered the years 2009 through March 2022, and data collection was completed on March 7, 2022. The next step in the literature review was to use two keywords in the document search to find palm oil waste studies from the scientific community. Initially, “palm oil waste in asphalt mixtures” were used for the TITLE-ABS-KEYS. Finally, the authors of this paper agreed and used the “Title” search to find articles on palm oil waste usage in asphalt pavement. However, there are few SLR articles and studies evaluating the potential for palm oil waste in asphalt pavement engineering and applications. The next stage is the sorting stage, the elimination of repetitions. At this stage, book chapters, only abstracts, retracted articles, editorial papers, corrigendum conference proceedings, and no access to full text, dissertations, and other materials were all eliminated. Since numerous duplicates were detected due to the use of four (4) online databases and two (2) additional sources, the remaining documents were re-examined for content relevance after the repetitions were eliminated. The last analysis was done to compile the most relevant topics for use in this analysis. The investigation focused on a selection of journals with significant contributions, credible research, and results. The inclusion and exclusion process were used to locate relevant research, retrieve data, and compile it. Several of the papers were first collected for review from the specified repository. The quality and well-known relevance of papers considered for the full review following filtering were used as inclusion criteria. This study evaluated 984 documents discovered using the predicted time lapse between 2011 and April 2022. However, with the application of the previously indicated criteria for all categories. The result was reduced to 62 as the only articles of relevance to the study. This shows that researchers are increasingly focusing on employing palm oil waste materials in the asphalt pavement industry. The data was then imported in tabulated form with the whole document and cited references for further use in Microsoft Excel to generate charts and maps. The document was stored in suitable mode and processed with the Open Refine application, which is ideal for, unclear data, removing junk, format conversion, and eliminating duplicates.

3.2. Scientometric review for quantitative analysis

Bibliometrics refers to scientific, quantitative, and analytical approaches to analyzing and developing scientific activity and progression indices, with a focus on fields, regions, groups, or nations. The information is derived from a number of well-known databases that stores articles from scholarly papers and periodicals (Soares et al., 2016). The VOSviewer software was used to assess the findings of the acquired data. VOSviewer is a free and easy-to-use program that lets you create and explore precise scientometric maps in an easy-to-understand format. The diagrams show a network of elements in the shape of circles, with circle shapes varying according to the importance of the component and network connections indicating the closeness of the relationship between elements. The components are grouped together based on the spacing between the circles and the colours used (Van Eck and Waltman, 2010).

To aid in evaluating the quantitative research technique of large amounts of bibliometric data, a suitable software tool was used for scientometric analysis. Traditional review studies' ability to link different components of the literature thoroughly and correctly is inadequate. Co-occurrence, co-citation, and science mapping are some of the more challenging aspects of modern research (Amin et al., 2022; Yang et al., 2022). For this study, recognized search engines were used to analyze articles published on the subject. The scientometric analysis identifies the sources with the most publications, keyword co-occurrence, the most active researchers in journals and citations, and current research fields for palm oil waste usage in asphalt pavement. In asphalt pavement. As listed for the SLR, various customization options were used to eliminate unnecessary articles. The reputable database was used to retrieve scientometric data for pertinent papers, and the data were stored in Comma Separated Values (CSV) format for further examination using the VOSviewer software for the scientific visualization and evaluation of the literature were generated. Fig. 5 shows the scientometric approach flowchart.

Fig. 5. The VOSviewer scientometric approach flowchart.

Fig. 5. The VOSviewer scientometric approach flowchart.The current state of investigation on the usage of palm oil wastes in the asphalt pavement industry will be summarised in this systematic review with scientometrics. Using the PRISMA approach, essential findings were identified, checked for validity, leading to data acquisition, and evaluated for methodological quality, scientometric variables, gaps, and research potential. For this study, the listed scientometric variables were chosen as unit analyses: country contribution, co-occurrence with author keyword, co-citation with cited sources, and publication source. The various features, interactions, and co-occurrence were depicted graphically, with statistical data presented in tables.

4. Results analysis

The data obtained were plotted in Microsoft Excel to determine and analyze the annual publication trend for the current study from 2009 to 2022. Since the first article on the subject was published in 2009, it has been noted that research on the use of palm oil waste for construction applications in the asphalt sector has expanded in tandem with technological advancements all the way up to the present year 2022. The number of publications on palm oil waste in asphalt industry studies has steadily increased, with an average of one paper published each year. However, it is worth noting that a wide range of applications was investigated during the time under consideration. This was possible because these materials were characterized before use, revealing their properties. According to Fig. 6, the year 2022 had the most articles (22), followed by 2018 and 2020 (Nine and seven, respectively). It's also worth noting that 2009, 2010, and 2011 each had only one minor publication. Furthermore, as shown in Fig. 7, the type of publications was examined in the databases. According to this study, journal articles, conference papers, journal reviews, conference reviews, and book chapters currently contributes 45%, 26%, 22%, 5%, and 2% of total publications, respectively.

Fig. 6. Articles published by year relating to palm oil waste utilization in the asphalt industry.

Fig. 6. Articles published by year relating to palm oil waste utilization in the asphalt industry. Fig. 7. Type of publication in the study area.

Fig. 7. Type of publication in the study area.The geographical location and sectoral specialization of the articles were determined by the content strategy. Even though both terms appeared in the keywords, descriptive and content analysis was used to classify the articles by region. The number of papers published by the regions must be used to assess their interest in various topics. According to Fig. 8, Asia, Africa, and the Middle East had the most publications on palm oil waste, with 57, 14, and 12 papers, respectively. It was discovered that South America has only one minor publication, whereas North America, Europe, and Australia have three, four, and four papers, respectively. This can be attributed to two factors: population density and the palm oil industry. Indonesia and Malaysia are the primary producers of palm oil in the world, accounting for more than 80% of global demand, followed by Thailand, Colombia, and Nigeria. Because of their high palm oil production, these countries generate a lot of waste. As a result, they must devise strategies to mitigate the negative effects of this massive amount of waste, such as recycling or repurposing it into alternative materials.

Fig. 8. Regional representation of studies on palm oil waste utilization in the asphalt industry across the world.

Fig. 8. Regional representation of studies on palm oil waste utilization in the asphalt industry across the world.4.1. Palm oil mill waste applications in the asphalt pavement industry

Road construction is critical for every nation's well-being as populations grow. As a result, the natural resources and materials used in the asphalt pavement industry are being depleted. Many of these materials have immediate socioeconomic and environmental ramifications. The global palm oil industry's activities increase year after year, resulting in a massive amount of waste that is simply discarded in landfills. Because of the ongoing waste accumulation, researchers have devised a strategy to use palm oil waste material in the asphalt pavements industry to help harness sustainability and improve performance.

4.1.1. Utilization of POFA and POCP as an asphalt binder and mixtures modifier

Because of the growing interest among researchers and the pavement industry in developing a sustainable alternative to traditional modifiers for asphalt binder and mixtures. One of the preferred options for exploring as a sustainable alternative was the utilization of palm oil waste. The physicochemical and rheological characteristics of the POFA-modified asphalt binder were examined in a study conducted by Rusbintardjo et al. (2013). In the study, POFA was found to stiffen the asphalt grade and to make up 5%–7% of the overall weight of the asphalt when added to the asphalt binder. According to rheological studies, 5% POFA with fine size can withstand permanent deformation at 70 °C, fatigue cracking at 20 °C, thermal cracking at −15 °C, moisture resistance test, and drain-down test. Finally, its use in SMA-14 increases Marshall Stability values. The study discovered that using POFA as an asphalt binder modification is feasible. Another study examined the use of POFA to increase bitumen aging resistance because asphalt binder aging changes the binder's structural network, which affects bitumen properties (Hainin et al., 2014). The study discovered that using POFA reduced the temperature sensitivity of binders while increasing the rutting resistance of asphalt. The results show that POFA-modified asphalt has better aggregate coverage and adhesive failure resistance than control asphalt. In a study conducted by Yaro et al. (2021c), the high-shear mixer was used to characterize the material and conduct conventional testing to determine whether palm oil clinker fine (POCF) was suitable for use as an asphalt binder modifier. The impact of changing the blending factors was also investigated. The results of its characterization supported its pozzolanic property, implying that it could be used as an additive in asphalt binders. The optimum mixing conditions were 900 rpm at 160 °C for 30 min with a content of 6.3% POCF. The results show that adding POCF to control asphalt improves its conventional properties.

Abdulrahman et al. (2019) investigate the warm mix asphalt performance of asphalt modified with POFA, using 5% POFA and 0.75% Evotherm asphalt binder with penetration grade 60–70. Penetration and ductility have both decreased, while viscosity has increased by 40%, according to the asphalt test results. According to the results of the asphalt pavement analyzer test and dynamic creep, WMA-modified POFA mixes have a 30% higher resistance to permanent deformation than conventional bituminous mixes. Also, a recent study by Yaro et al. (2021b) investigated the effects of short-term aging on the volumetric and mechanical properties of a modified asphalt mix containing POCF. The modified asphalt contained 4.9% POCF by weight of asphalt. When compared to unaged mixtures, aged blends had better volumetric characteristics and Marshall stability. POCF-modified mixes were found to have a better mechanical performance during and after short-term aging than base asphalt mixes. The response surface methodology (RSM) approach was applied to optimize the conventional properties of the unmodified asphalt binder at different content and blending conditions of POCF (Yaro et al., 2021e). POCF was found to increase asphalt binder stiffness by improving softening points and viscosity and reducing penetration values. The RSM optimized conditions were evaluated to be 7.75% POCF by weight of binder for 52 min at a blending speed of 1000 rpm at a temperature of 140 °C.