1. Introduction

Over the last few decades, metabolic engineering approaches, ranging from very simple manipulations to sophisticated designs, have greatly expanded the number of industrially-relevant compounds that can be accessed via whole-cell biocatalysis (Nielsen and Keasling, 2016, Park et al., 2018, Woolston et al., 2013). However, the most successful histories of metabolic engineering of microorganisms have been often confined to an assortment of genetic and genomic manipulations that lead to over-production of natively-synthesized metabolites in a handful model microbial cell factories (Smanski et al., 2016), such as Escherichia coli and Saccharomyces cerevisiae. Along the line, only a very limited number of structurally simple metabolites (e.g., the diols 1,4-butanediol and 1,3-propanediol) and a few natural active compounds (e.g., artemisinin) have found their way towards industrial-scale production (Chubukov et al., 2016, King et al., 2016). Actual commercialization and bioprocesses account today for merely ca. 3.5% of the total production volume of commodity and specialty chemicals (Campbell et al., 2017). A major reason underlying this state of affairs has been the emphasis of contemporary metabolic engineering (and, in particular, approaches aimed at engineering the core metabolism) of individual components in the microbial cell, which resulted into a collection of elegant demonstrations rather than generalizations. In contrast, systematic practices through the adoption of reliable, generalizable tools in standardized microbial chasses aimed at developing biosustainable production processes have been rather scarce. During the three decades that followed the establishment of metabolic engineering as a discipline on its own merit (including the period that is often referred to as the post-genomic era), a staggering volume of omics data has been accumulated and more precise analytic techniques for studying cellular metabolism have been established. Empowered by these rapid developments, the focus of metabolic engineers has gradually shifted away from perturbing individual pathways and single metabolic nodes to the manipulation of the entire cell itself, giving rise to the concept of systems metabolic engineering (Lee and Kim, 2015, Nielsen, 2017). At the same time, the cost of oligonucleotides and de novo DNA synthesis has declined exponentially, and the emergence of a number of tools, afforded by contemporary synthetic biology, has made possible to access the metabolism of non-traditional microbial platforms. In this sense, soil bacteria are a group of microorganisms that have attracted attention as microbial platforms since they are often exposed to extreme environmental conditions, which correlates with a remarkable metabolic and physiological robustness. Among them, the intrinsically high metabolic diversity characteristic of Pseudomonas species, has emerged in recent years a solid basis for designing and creating novel pathways for bioproduction.

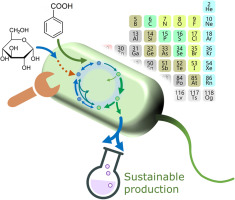

In this review, we present the most relevant advances in the field of metabolic engineering using the non-pathogenic soil bacterium Pseudomonas putida as the functional chassis—highlighting a number of synthetic biology approaches that made these manipulations possible. The discussion is focused on what we perceive as the frontiers in the field of engineering P. putida and other environmental bacteria beyond the canonical manipulations of the extant biochemistry towards complex designs aimed at re-writing metabolism and the very microbial lifestyle. As indicated in Fig. 1, we argue that the purposeful combination of (i) enabling technologies, such as novel synthetic biology tools, (ii) alternative feedstocks that cannot be processed by other microbial platforms (including man-made waste streams), and (iii) the wealth (if fairly disorganized) of omics data will strengthen the value of P. putida as the platform of choice for the synthesis of new-to-Nature products compatible with biosustainable industrial production. The establishment of an authentic systems metabolic engineering of P. putida is needed to fulfill this purpose, and specific examples are entertained as a step into this direction. The leitmotiv of these examples is that the rational exploitation of the native metabolic architecture is expected to uncover unique biochemistries (which we collectively refer to as «trans-metabolisms») that enable the expansion of the biochemical network of P. putida towards unusual elements and chemical structures, thereby generating highly valuable compounds that could not be accessed otherwise.

Fig. 1. P. putida as a functional chassis for developing novel biochemistriesleading to new-to-Nature bioproducts. The adoption of specific synthetic biology tools (enabling technologies), along with the knowledge brought about by omics data, will help re-purposing the rich and flexible central carbon metabolism of P. putida to nest trans-metabolisms (with reactions and connectivities alien to the extant biochemistry) leading to the synthesis of completely new chemical structures from alternative substrates. Note that the whole process has a cyclic nature (echoing the design-build-test cycle of synthetic biology), which benefits from further manipulations to boost bioproduction.

Fig. 1. P. putida as a functional chassis for developing novel biochemistriesleading to new-to-Nature bioproducts. The adoption of specific synthetic biology tools (enabling technologies), along with the knowledge brought about by omics data, will help re-purposing the rich and flexible central carbon metabolism of P. putida to nest trans-metabolisms (with reactions and connectivities alien to the extant biochemistry) leading to the synthesis of completely new chemical structures from alternative substrates. Note that the whole process has a cyclic nature (echoing the design-build-test cycle of synthetic biology), which benefits from further manipulations to boost bioproduction.2. Pseudomonas putida, primus inter pares among soil bacteria

A quick search in the relevant literature reveals that several microbial hosts have been considered and used for applications in metabolic engineering (Beites and Mendes, 2015, Liu and Deutschbauer, 2018). However, to date, no single, naturally-isolated bacterial strain seems to possess all the characteristics that would be desirable in an optimal host. Although the emerging picture indicates that the selection of an adequate bacterial platform will largely depend on the application intended, the adoption of a flexible and robust bacterium as the basis for developing a functional chassis, amenable to geneticand metabolic manipulations and endowed with high catalytic performance across a variety of operating conditions is definitely desirable. As hinted in the Introduction, soil bacteria in general, and P. putida in particular, could satisfy many of these requirements because of the physicochemical conditions they face naturally in the niches in which they thrive. These conditions include a somewhat continuous exposure to environmental contaminants, often together with all sorts of physicochemical stresses and competing as well as predatory microbial species. Many environmental bacterial species are widely recognized by their versatile, flexible metabolic lifestyles, which allow them to adapt to rapidly changing conditions (e.g., contact with oxidative stressors, temperature challenges, and sudden osmotic perturbations). As indicated in the section below, P. putida serves as a prime example of these qualities.

2.1. The roadmap from soil to the laboratory

The name «Pseudomonas» was coined in 1894 by Migula, who described the genus as a group of cells with polar organs of motility and, in some special cases, the formation of spore-like structures (Migula, 1894). This short, unclear description of the genus prevailed until the publication of the doctoral thesis of den Dooren de Jong in the late 20s (den Dooren de Jong, 1926). This publication revealed one of the features that would define (and classify) the entire genus more accurately: a remarkable capacity to degrade a large variety of organic compounds as part of the process of carbon mineralization. The den Dooren de Jong's thesis was, however, not widely used by contemporary scientists (perhaps because it was written in Dutch), but held out an inspirational vision for Stanier, Palleroni, and Doudoroff, who went on creating the first accurate description of the Pseudomonas genus some forty years later (Stanier et al., 1966). A set of differential tables was proposed for the classification of the most relevant Pseudomonas species known by then (including P. putida), based on nutritional characteristics and morphological features. Upon obtaining the sequence of the 16S rRNA gene of several Pseudomonas species in 1973, the bacterial genus was redefined by Palleroni et al. (1973) to encompass the previously described RNA-I group within the subclass of Gram-negative, aerobic γ-Proteobacteria (Palleroni, 2003, Palleroni, 2010). Fig. 2 identifies these milestones in a timeline depicting historical developments in the field of Pseudomonas biology.

Fig. 2. Schematic timeline of the main findings on the isolation and characterization of P. putida. This non-extensive representation of the milestones in the field includes the dates of publication of key articles. Further information on historical developments can be found in the text and references therein.

Fig. 2. Schematic timeline of the main findings on the isolation and characterization of P. putida. This non-extensive representation of the milestones in the field includes the dates of publication of key articles. Further information on historical developments can be found in the text and references therein.P. putida is a ubiquitous rhizosphere saprophytic specimen and soil colonizer that belongs to the wide group of fluorescent Pseudomonas species. In particular, P. putida KT2440 strain is the best-characterized saprophytic member of the group, as it has become with time a model laboratory species which also retains its ability to survive and thrive in natural soil environments (Regenhardt et al., 2002, Timmis, 2002, Wackett, 2003). This P. putida strain is a derivative of P. putida mt-2, which was isolated from a soil sample in Japan in 1960 as a degrader of 3-methylbenzoic acid (actually, «mt-2» stands for «meta-toluate degrader, isolate 2») (Nakazawa, 2002). This remarkable metabolic property was later traced to the presence of the catabolic TOL plasmid pWW0, which encodes dedicated metabolic activities that enable P. putida mt-2 to grow on various aromatic substrates as sole carbon and energy sources, e.g., toluene, m-xylene, and p-xylene (Wong and Dunn, 1974, Worsey and Williams, 1975). Thus, the metabolic potential of P. putida and some closely related Pseudomonasspecies was recognized early on for applications in biodegradation of aromatic compounds. Once the catabolic plasmid pWW0 was eliminated from strain mt-2, the plasmid-less variant was designated as strain KT2440 (Bagdasarian et al., 1981) and it soon became the subject of a series of genetic studies in the laboratory, which resulted in the assignment of the generally recognized as safe(i.e., GRAS) status as a microbial host for recombinant DNA constructs (Federal Register, 1982, Nikel, 2012, Poblete-Castro et al., 2017, Timmis, 2002). This strain also exhibits remarkable resistance to oxidative stress (Kim and Park, 2014, Lemire et al., 2017, Nikel et al., 2013, Nikel and de Lorenzo, 2014), a remarkable feature closely associated with its capacity to degrade compounds that, on themselves, are sources of stress.

The in silico analysis of the 6,181,873-bp long genome sequence of P. putidaKT2440, which became available first in 2002 (Nelson et al., 2002) and was later revisited in 2016 (Belda et al., 2016), confirmed the lack of any conspicuous virulence factor in the 5592 coding sequences present in the genome. The core and pangenome of P. putida has been likewise identified (Udaondo et al., 2016). The updated genome annotation of strain KT2440 generated a list of novel biochemical functions (e.g., the assimilation of alternative carbon sources) that were not previously identified in P. putida and resulted in a total of 1256 degradation reactions—including newly-identified catabolic pathways for 32 carbon sources, 28 nitrogen sources, 29 phosphorus sources, and 3 carbon and nitrogen sources. As indicated in the next section, the extremely rich secondary metabolism of P. putida KT2440 is wired to a robust core biochemistry characterized by a very distinct architecture.

2.2. The unique core metabolic architecture of P. putida: Reshaping the connectivity of sugar assimilation

In addition to its ability to use a wide variety of carbon and nitrogen sources indicated above, rapid growth and low nutrient demand are some of the added advantages of adopting P. putida as a chassis (Loeschcke and Thies, 2015, Nikel et al., 2014a, Nikel et al., 2014b, Poblete-Castro et al., 2017). Most of these properties arise from (or are intimately connected to) a robust central carbon metabolism (Nikel et al., 2016). How is central carbon metabolism fueled by sugars in P. putida? Many Pseudomonads are known to have peripheral pathways for oxidation of sugars (e.g., to gluconate and 2-ketogluconate) in addition to the canonical, phosphorylation-dependent routes for assimilation of hexoses (del Castillo et al., 2007, Lessie and Phibbs, 1984, Sánchez-Pascuala et al., 2017). Interestingly, only one phosphoenolpyruvate-dependent sugar transport system is present in P. putida, and it is connected to fructose uptake and phosphorylation (Pflüger-Grau and de Lorenzo, 2014)—an architecture that has been recently shown to conform a complex regulatory device, which senses the availability of fructose via the regulatory Cra protein and the intracellular redox status (Chavarría et al., 2016).

Glucose is incorporated either via oxidation of the sugar to gluconate or 2-ketogluconate (either oxidized product follows a dedicated catabolic pathway for further processing) or the direct phosphorylation by glucokinase. Irrespective of the first steps in sugar processing (either oxidation or phosphorylation, although the former seems to be preferred over the later in strain KT2440), these pathways converge at the key intermediate 6-phosphogluconate—a metabolite that serves as precursor of the Entner-Doudoroff pathway and the interphase between the oxidative and non-oxidative branches of the pentose phosphate route. As recently reviewed by Udaondo et al. (2018), the regulation of all these catabolic pathways for carbohydrate processing is orchestrated by a versatile set of transcriptional regulators in Pseudomonas species. Additionally, the combined activity of enzymes from the Entner-Doudoroff pathway, the pentose phosphate pathway, and the incomplete Embden-Meyerhof-Parnas route form a cyclic metabolic architecture in P. putida KT2440 known as EDEMP cycle (Fig. 3A). When growing on hexose sugars, the operativity of this metabolic architecture endows P. putidawith high NADPH regeneration rates via partial recycling of triose-phosphates (Nikel et al., 2015a)—a metabolic property that is in turn regulated by the presence and extent of oxidative stress conditions. Furthermore, the EDEMP cycle enables different ATP and NADPH formation rates depending on the amount of triose-phosphates recycled, a circumstance that reflects the specific stoichiometry of the Entner-Doudoroff pathway and the Embden-Meyerhof-Parnas pathway. The former yields half the ATP per molecule of glucose than the later, but produces, at the same time, one NADH and one NADPH equivalent. In particular, and assuming that the core metabolic pathways of P. putidaKT2440 (i) use a NAD+–dependent glyceraldehyde-3-phosphate dehydrogenase (an activity represented by no less than five isozymes, i.e., GapA, GapB, Epd, PP_0665, and PP_3443) and a NADP+–dependent glucose-6-phosphate dehydrogenase (represented by the three isozymes Zwf, ZwfA, and ZwfB) under homeostatic physiological conditions, (ii) yield pyruvate as the main triose end product (that is further processed to acetyl-coenzyme A), and (iii) the fluxes through the peripheral oxidative loop leading to 2-ketogluconate formation are very low, the net flux of NADPH formation stemming from the activities in the EDEMP cycle (vNADPH) increases linearly with the overall recycling flux from glyceraldehyde-3-phosphate upwards (vR), as indicated in Fig. 3A.

Fig. 3. The EDEMP cycle of P. putida KT2440 and two possible uses of this specific metabolic architecture for metabolic engineering purposes. (A) Glucose catabolism occurs mainly through the activity of the Entner-Doudoroff (ED) pathway and part of the trioses-phosphate thereby generated are recycled back to hexoses-phosphate by means of the cycle, that also encompasses activities from the Embden-Meyerhof-Parnas (EMP) and pentose phosphate (PP) pathways. A set of peripheral oxidative reactions, which convert glucose to gluconate and 2-ketogluconate before any phosphorylation of the intermediates occurs, is not shown in the diagram for the sake of simplicity. Each metabolic block is indicated with a different color along with the relevant enzymescatalyzing each step, and the EDEMP cycle is shaded in blue in this illustration. The overall stoichiometry of the ED and the EMP routes from glucose is indicated, along with the rate of NADPH regeneration (vNADPH) as a function of the overall recycling flux of trioses-phosphate (vR, which depends on the combined activities of Fda, Fbp, and Pgi), assuming that there is no formation of 2-ketogluconate through the peripheral oxidation loop. Further processing of the C3 intermediates is indicated with a gray arrow. The abbreviations used in the figure are as follows: G6P, glucose-6-phosphate; 6PG, 6-phosphogluconate; KDPG, 2-keto-3-deoxy-6-phosphogluconate; GA3P, glyceraldehyde-3-phosphate; FBP, fructose-1,6-bisphosphate; DHAP, dihydroxyacetone phosphate; F6P, fructose-6-P; and Pi, inorganic orthophosphate. (B) Synthetic metabolic circuit for a generic NADPH-dependent reaction that would transform a substrate S into a product P in a positive feedback loop wired to the EDEMP cycle. The formation of P is gauged by two separate sensors connected to individual actuators (e.g., an activator A and a repressor R) that will, in turn, boost trioses-phosphate recycling and restrict downwards catabolism of C3 units, respectively. (C) Implantation of the Bifidobacterium shunt onto the upper metabolic architecture of P. putida would allow for the direct C6 to C2 conversion via phosphoketolase (Xfp). Note that the spectrum of products P that could be potentially obtained by using this strategy encompasses virtually any metabolite derived from acetyl-coenzyme A as the precursor. Acetyl-P, acetyl-phosphate; E4P, erythrose-4-phosphate.

Fig. 3. The EDEMP cycle of P. putida KT2440 and two possible uses of this specific metabolic architecture for metabolic engineering purposes. (A) Glucose catabolism occurs mainly through the activity of the Entner-Doudoroff (ED) pathway and part of the trioses-phosphate thereby generated are recycled back to hexoses-phosphate by means of the cycle, that also encompasses activities from the Embden-Meyerhof-Parnas (EMP) and pentose phosphate (PP) pathways. A set of peripheral oxidative reactions, which convert glucose to gluconate and 2-ketogluconate before any phosphorylation of the intermediates occurs, is not shown in the diagram for the sake of simplicity. Each metabolic block is indicated with a different color along with the relevant enzymescatalyzing each step, and the EDEMP cycle is shaded in blue in this illustration. The overall stoichiometry of the ED and the EMP routes from glucose is indicated, along with the rate of NADPH regeneration (vNADPH) as a function of the overall recycling flux of trioses-phosphate (vR, which depends on the combined activities of Fda, Fbp, and Pgi), assuming that there is no formation of 2-ketogluconate through the peripheral oxidation loop. Further processing of the C3 intermediates is indicated with a gray arrow. The abbreviations used in the figure are as follows: G6P, glucose-6-phosphate; 6PG, 6-phosphogluconate; KDPG, 2-keto-3-deoxy-6-phosphogluconate; GA3P, glyceraldehyde-3-phosphate; FBP, fructose-1,6-bisphosphate; DHAP, dihydroxyacetone phosphate; F6P, fructose-6-P; and Pi, inorganic orthophosphate. (B) Synthetic metabolic circuit for a generic NADPH-dependent reaction that would transform a substrate S into a product P in a positive feedback loop wired to the EDEMP cycle. The formation of P is gauged by two separate sensors connected to individual actuators (e.g., an activator A and a repressor R) that will, in turn, boost trioses-phosphate recycling and restrict downwards catabolism of C3 units, respectively. (C) Implantation of the Bifidobacterium shunt onto the upper metabolic architecture of P. putida would allow for the direct C6 to C2 conversion via phosphoketolase (Xfp). Note that the spectrum of products P that could be potentially obtained by using this strategy encompasses virtually any metabolite derived from acetyl-coenzyme A as the precursor. Acetyl-P, acetyl-phosphate; E4P, erythrose-4-phosphate.The distinct metabolic architecture in strain KT2440 when the cells grow on sugars has two remarkable sides that offer an interesting starting point for synthetic metabolic designs. Firstly, the connectivity that underlies the cyclic assembly of glycolytic activities in strain KT2440. Among other peculiarities, this architecture is characterized by the functional redundancy of at least four key activities: glucose-6-phosphate dehydrogenase (Zwf, three isozymes), glucose-6-phosphate isomerase (Pgi, two variants), and fructose-1,6-bisphosphate aldolase (Fda, four potential isozymes catalyzing this gluconeogenic reaction). Second, the existence of the EDEMP cycle (Fig. 3A) enables new strategies for engineering entirely novel biochemistries (Aslan et al., 2017). The ability of P. putida to sustain high NADPH formation rates is a requisite for implantation of what we could call redox-expensive metabolic pathways (Akkaya et al., 2018). In this sense, different engineering strategies can take advantage of the inherent layout of the EDEMP cycle. One attractive possibility for metabolic re-wiring could involve implantation of a metabolic circuit for coupling the activity of orthogonal NADPH-dependent reaction(s), leading to the target product, with two output signals, i.e., (i) increased flux through Fbp (and thus, a higher vR flux that will further boost NADPH recycling), and (ii) decreased fluxes downwards glyceraldehyde-3-phosphate (e.g., by blocking the Gap activities around this metabolic node), which would prevent further catabolism into acetyl-coenzyme A (Fig. 3B). This synthetic metabolic design would offer the twofold benefit of enhancing the catalytic output of a redox-demanding bioreaction leading to the desired product viawhole-cell biocatalysis while decoupling bacterial growth from the synthesis of the target molecule.

Besides playing with the fluxes through the native reactions within the core metabolic architecture, the gluconeogenic branch of the EDEMP cycle could be also harnessed as a source of fructose-6-phosphate for directly shunting the natural C6 → C2 conversion via the phosphoketolase-catalyzed Bifidobacteriumshunt or fructose-6-phosphate pathway (Fig. 3C). The reaction executed by phosphoketolase (e.g., Xfp from B. bifidum or B. animalis) merges ketol cleavage, dehydration, and phosphorolysis to split fructose-6-phosphate into erythrose-4-phosphate (which can be then transformed via the non-oxidative branch of the pentose phosphate pathway) and acetyl-phosphate (Henard et al., 2015). Importantly, Xfp also catalyzes the formation of glyceraldehyde-3-phosphate and acetyl-phosphate from xylulose-5-phosphate. If the split of fructose-6-phosphate between the reactions catalyzed by Xfp and Pgi is balanced, the cycle could in principle continue providing NADPH, which has been a limitation on the use of the Bifidobacterium shunt in metabolic engineering. The C2-unit acetyl-phosphate can be easily converted into acetyl-coenzyme A (bypassing decarboxylation via pyruvate dehydrogenase and thus increasing final products yields)—and from there into a plethora of acetyl-coenzyme A-derived, added-value products.

The two scenarios entertained above represent rather simple manipulations aimed at harnessing the potential of the native biochemistry of P. putida via the introduction of a limited number of modifications. Nevertheless, it is possible to further rewire what we could call «cis-metabolism», i.e., the enzymatic parts and devices present in the extant metabolic architecture of this bacterium. Predictably, by just reconnecting existing endogenous reactions one could expand the portfolio of products derived from central carbon metabolism. The practical realization of these synthetic metabolic designs is heavily dependent on the access to dedicated synthetic biology tools for genome and genetic engineering—the scope of which is surveyed in the next section.

2.3. Enabling technologies for metabolic engineering of P. putida: Tools for genome engineering and regulated gene expression

As indicated above, the entire field of metabolic engineering is experiencing a transition from being a mostly trial-and-error exercise to become an authentic branch of rational engineering thanks to the tools and approaches brought about by contemporary synthetic biology. A clear indication of this transformation is our capacity to manage long DNA molecules, which has evolved from the handling of a few genes at a time up to synthesizing long sequences de novo and complete prokaryotic genomes—and soon eukaryotic chromosomes and entire genomes as well. A further example of our capability of handling genetic information includes the use of 3'→2'-phosphonomethyl-threosyl nucleic acid as a xeno-genetic material for in vivo applications (Liu et al., 2018). In all, this dynamic situation opens up possibilities for adoption of truly engineering-based approaches for manipulating metabolic pathways of non-traditional microbial platforms. The development and availability of such enabling technologies is essential for the design and implantation of veritable synthetic designs in cell factories.

Dedicated tools for gene expression have been developed for P. putida over the years and, not surprisingly, this bacterial species has also served as a treasure trove of functional parts (e.g., specific transcriptional regulators and their cognate promoters) that have been harnessed for the construction of novel expression systems. Table 1 presents a recompilation of these gene expression systems and platforms, highlighting those cases in which novel expression platforms have been used for metabolic engineering purposes. Building on the wealth of catabolic pathways in P. putida, many transcriptional regulators that respond to complex molecules (e.g., the regulatory proteins that rule aromatic degradation pathways) have been used to design expression systems that could be considered orthogonal when implanted in any surrogate host. In some other cases, expression systems developed for E. coli (Dvořák et al., 2015) have been implanted in P. putida. For example, strain KT2440 lacks the catabolic pathway needed for lactose processing and breakdown, therefore the LacI regulator along with Plac and associated promoters are known to exhibit an orthogonal (if scarcely titrable) response in P. putida. The erratic behavior of the LacI/Placsystem (and, in reality, that of virtually any other expression platform) when placed in a heterologous host does not come as a surprise: the internal environment of growing cells is highly variable and dynamic (Goñi-Moreno et al., 2017), making it difficult to knock-in and manipulate reliable genetic parts. Additionally, most genetic systems have been thoroughly characterized only in laboratory E. coli strains, making extrapolations on their quantitative behavior in alternative hosts almost impossible. An elegant alternative to tackle this issue has been recently proposed by Segall-Shapiro et al. (2018), applying control-theoretic ideas to design promoters that would maintain constant levels of expression at any copy number in E. coli. This approach may significantly improve expression systems in P. putida, especially considering that the plasmid copy number of well-established origins of replications is different (on average, higher) in P. putida and E. coli (Cook et al., 2018), which in turns impacts the catalytic capacity of engineered P. putida in a strain- and regulatory system-dependent fashion (Jahn et al., 2014, Lindmeyer et al., 2015). Besides plasmid-based gene expression and manipulation, assembly and handling of large DNA segments has been also incorporated to the toolbox recently (Domröse et al., 2017).

| Expression system (inducer)a | Source of regulatory elements | Characterization and examples of uses in metabolic engineeringb | Reference(s) |

|---|---|---|---|

| XylS/Pm (3-methylbenzoic acid) | P. putida mt-2 | Extensively characterized in E. coli and P. putida; p-coumaric production in engineered P. putidastrains; heterologous expression of genes for fermentation under low oxygen availability in P. putida | de Lorenzo et al. (1993a); Gawin et al. (2017); Calero et al. (2016); Nikel and de Lorenzo (2013b) |

| XylR/Pu (3-methylbenzyl alcohol) | P. putida mt-2 | Extensively characterized in E. coli and P. putida; expression of phosphoglucomutase (celB) from Acetobacter xylinum in recombinant E. coli and Xanthomonas campestris strains | Ramos et al. (1997); Marqués and Ramos (1993); Blatny et al. (1997) |

| AlkS/PalkB (short-chain alkanes) | P. putida GPo1 | Characterized in E. coliand P. putida; production of (S)-styrene oxide and heterologous proteins in recombinant E. coli strains | Panke et al. (1999); Makart et al. (2007) |

| NahR/Psal (salicylic acid) | P. putida NCIB 9816-4 | Characterized in E. coliand P. putida; surface reporter of catabolic promoter activity; gene expression cascade with XylS variants | Cebolla et al., 1996, Cebolla et al., 2001; Becker et al. (2010) |

| TodST/PtodX (4-chloroaniline) | P. putida T-57 | Characterized in E. coli | Vangnai et al. (2012) |

| CymR/Pcym (4-isopropylbenzoic acid) | P. putida F1 | Characterized in E. coli | Choi et al. (2010) |

| ClcR/PclcA (3- or 4-chlorocatechol) | P. putida PRS2015 | Characterized in P. putida | Guan et al. (2000) |

| HpdR/PhpdH (3-hydroxypropionic acid) | P. putida KT2440 | Characterized in E. coliand Cupriavidus necator | Hanko et al. (2017) |

| MmsR/PmmsA (3-hydroxypropionic acid) | P. putida KT2440 | Characterized in E. coliand Cupriavidus necator | Hanko et al. (2017) |

| NagR/PnagA (salicylic acid) | Comamonas testosteroni | Production of 3-methylcatechol by P. putida | Hüsken et al. (2001) |

| ChnR/PchnB(cyclohexanone) | Acinetobacter johnsonii | Characterized in E. coli; regulation of biofilm formation in engineered P. putida strains | Benedetti et al., 2016a, Benedetti et al., 2016b |

| CprK/PDB3 (3-chloro-4-hydroxyphenylacetic acid) | Desulfitobacterium hafniense | Characterized in E. coliand P. putida | Kemp et al. (2013) |

| MekR/PmekA (methyl-ethyl ketone) | P. veronii | Characterized in E. coliand P. putida; expression of cre for recombineering in P. putida | Graf and Altenbuchner (2013); Luo et al. (2016) |

| MtlR/PmtlE (mannitol) | P. fluorescens | Characterized in E. coliand P. putida | Hoffmann and Altenbuchner (2015) |

| AraC/ParaB (arabinose) | E. coli | Characterized in E. coliand P. putida; p-coumaric production in engineered P. putida strains | Calero et al. (2016) |

| RhaRS/PrhaB(arabinose) | E. coli | Characterized in E. coliand P. putida; p-coumaric production in engineered P. putida strains | Calero et al. (2016) |

| TetR/PtetA(anhydrotetracycline) | E. coli | Synthesis of myxochromide S (mchSbiosynthetic gene cluster from Stigmatella aurantiaca), epothilone (epo biosynthetic gene cluster from Sorangium cellulosum), and tubulysin (tub biosynthetic gene cluster from Cystobactersp.) in engineered P. putida strains | Fu et al. (2008); Chai et al. (2012) |

| LacIQ/Plac, Ptac, Ptrc(isopropyl β-D-1-thiogalactopyranoside) | E. coli | Extensively characterized in E. coli and P. putida; biological containment of P. putida; production of long-chain rhamnolipids and vanillin in engineered P. putida strains | de Lorenzo et al., 1993a, de Lorenzo et al., 1993b; Pérez-Martín and de Lorenzo (1996); Ronchel et al. (1995); Wittgens et al. (2018); Graf and Altenbuchner (2014) |

| PT5 | Bacteriophage T5 | Expression of 6 × His-tagged proteins (pfrAsiderophore regulatory gene) in P. putida | Bertani et al. (1999) |

| PT7 | Bacteriophage T7 | Characterized in P. putida; containment of P. putidastrains by conditional expression of the streptavidin gene | Herrero et al. (1993); Szafranski et al. (1997) |

| PEM7 | Synthetic, constitutive | Characterized in P. putida; CRISPR-Cas9—based counter-selection for genome manipulations in P. putida | Aparicio et al. (2018) |

| PoprL | Synthetic, constitutive | Characterized in P. putida; expression of a bacterial laccase gene from Shigella dysenteriae and surface display in P. putida | Llamas et al. (2003); Wang et al. (2012) |

| Pgro, Ptuf, Ptufs | Synthetic, constitutive | Tailor-made for calibrated gene expression in P. putida; production of cis,cis-muconic acid | Kohlstedt et al. (2018) |

| PJE | Synthetic, constitutive | Tailor-made for calibrated gene expression in P. putida | Elmore et al. (2017) |

| PSynP·BG | Synthetic, constitutive | Tailor-made for calibrated gene expression in P. putida | Zobel et al. (2015) |

- a

-

In some cases, more than one inducer can activate the expression system. Only the typical inducers are listed in the table (usually selected because they are the cheapest and/or the most effective).

- b

-

Only the first example(s) of uses in practical applications are indicated, and also those studies that have adopted the corresponding expression system for approaches beyond the customary characterization experiments in a surrogate host using fluorescent proteins.

The lack of well-established standards, which used to afflict not only engineering efforts using P. putida but essentially the entire field of synthetic biology, has only recently been tackled systematically. The hallmark brought about by the Standard European Vector Architecture (SEVA; a user-friendly, open-source toolbox platform in constant expansion) has helped to standardize the use of genetic parts that can be applied for metabolic engineering of P. putida(Martínez-García et al., 2014a, Silva-Rocha et al., 2013). Besides many of the gene expression systems listed in Table 1, other functionalities have been formatted and added to the SEVA collection, including Tn5- and Tn7-based transposon vectors (Martínez-García et al., 2011, Martínez-García et al., 2014a, Martínez-García et al., 2014b, Martínez-García et al., 2017, Nikel and de Lorenzo, 2013a)—and the list of novel parts and devices therein continues to expand practically by the month. Needless to say, the inception of technologies based on clustered regularly interspaced short palindromic repeats (CRISPR) and Cas9(Jakočiūnas et al., 2017) resulted in novel tools for targeted genome manipulations in P. putida, including counter-selection strategies for targeted genome mutagenesis (Aparicio et al., 2018, Mougiakos et al., 2017), gene down-regulation (i.e., CRISPR interference) using catalytically deactivated Cas9 (Sun et al., 2018, Tan et al., 2018), and precise plasmid curing (Lauritsen et al., 2017). The impact of CRISPR/Cas-based gene editing techniques is expected to reach genetically intractable microbial species (Shapiro et al., 2018), and would be instrumental to harness the metabolic potential of non-traditional Pseudomonasstrains. For a recent update on many of the currently available P. putida genetic toolbox, the reader is referred to the recent review published by Martínez-García and de Lorenzo (2017). Alas, given the relentless publication of more and more genetic tools for P. putida and other non-E. coli microbial platforms, chances are that their compilations become obsolete by the time they are published.

Therefore, at the time of writing this article, the challenge is not so much a dearth of synthetic biology tools. Instead, the task is about pushing the boundaries of what P. putida can do towards biosynthesis of compounds through importing and nurturing other microorganisms' genes, and the «biologization» of otherwise purely chemical bonds and structures. In other words, the frontier in the field is moving from cis-metabolism towards trans-metabolism. Some avenues to make progress in this direction are discussed below.

3. From extant (cis) metabolism towards orthogonal (trans) metabolism in the P. putida chassis

3.1. Design and construction of microbial cell factories afresh: Extant biochemistries and synthetic metabolisms

The textbook definition of metabolism (from the Greek μεταβολή, transformation or, more literally, change) could be summarized as «the collection of life-sustaining chemical transformations within individual cells of living organisms». The canonical definition implies an enumeration of components of metabolism from a rather reductionist point of view; something that does not come as a surprise since reductionism has dominated biological research for over a century. Central carbon metabolism provides energy and biomass precursors to the entire cellular network, and its fine regulation is essential to ensure optimal use of substrates and proper allocation of resources to the metabolic pathways that make up for the extant biochemistry of any cell. Overcoming this fine regulation has been the ultimate goal of traditional metabolic engineering. From a broader perspective, a key challenge for biology in the 21st century is to understand the structure and the dynamics of the complex intercellular web of metabolic interactions that contribute to the structure and functioning of the bacterial cell. This has led to the realization that the relational logic of metabolic networks within a cell is shared (to a large degree) by other complex systems, e.g., computer chips and even modern society. This organizational universality indicates that similar laws may govern most complex networks in Nature, which allows the expertise from large and well-mapped non-biological systems to be used in characterizing the intricate interwoven relationships that govern metabolic functions. Systemic biology is the view of live systems through the optics of such quantitative perspective, relational logic and analysis tools of bona fide engineering being its core tenets by merging systems and synthetic biology with metabolic architectures and multi-scale organization of biological objects.

The process of moving from the study of individual components in central carbon metabolism to re-purposing the whole biochemical network implies that there should be a distinction between the extant (cis) biochemistry and the implanted (trans) metabolism. This operational definition indicates that, for some metabolic engineering purposes, re-wiring the components of the cis-metabolism would result in the formation of the target product(s), whereas the synthesis of new-to-Nature compounds would require the design and incorporation of trans-metabolic reactions into the bacterial chassis, e.g., involving novel biochemical transformations. Accordingly, this description of cis- and trans-metabolism conveys four categories of potential products, as proposed by Lee et al. (2012) and as indicated in Fig. 4: (i) natural and endogenous (metabolites that can be produced through native pathways of P. putida), (ii) natural, exogenous (natural metabolites produced by introducing an heterologous pathway that uses native precursors), (iii) non-natural (and therefore, exogenous; metabolites not found in Nature that can be produced by combining metabolic pathways, either native or heterologous), and (iii) completely new-to-Nature (for which a completely synthetic pathway is needed, including novel enzymes and reactions). In the next sections, we discuss examples of these two types of engineering operations in P. putida.

Fig. 4. The cis- and trans-metabolism realm, highlighting the role of synthetic biology and metabolic engineering in bridging the gap with P. putida as the functional chassis. Four categories of products are distinguished in either domain, depending on the metabolic pathways needed to synthesize them, and typical examples are provided in each case. Note that entirely new-to-Nature products are indicated in white lettering, as there are no cases reported for their synthesis in P. putida.

Fig. 4. The cis- and trans-metabolism realm, highlighting the role of synthetic biology and metabolic engineering in bridging the gap with P. putida as the functional chassis. Four categories of products are distinguished in either domain, depending on the metabolic pathways needed to synthesize them, and typical examples are provided in each case. Note that entirely new-to-Nature products are indicated in white lettering, as there are no cases reported for their synthesis in P. putida.3.2. Engineering of the cis-metabolism in action: Pseudomonas putida as a host for efficient degradation and production of aromatic compounds

The capacity of P. putida strains to degrade aromatic compounds was recognized early on as a key signature of the species. The late 1980s and early 1990s witnessed the golden era of research in the biodegradation of xenobioticcompounds, and the literature reflects the numerous attempts that followed the pioneering work by Chakrabarty while he was working at the Research and Development Center of General Electric Co. At the time, four species of oil-metabolizing bacteria were known to exist, but when introduced into an oil spill, they would compete with each other, thereby limiting the amount of crude oil that they could degrade. Chakrabarty and co-workers described the preparation of recombinant P. putida strains (which they called «multi-plasmid hydrocarbon-degrading Pseudomonas») by means of plasmid-assisted molecular breeding, i.e., propagation of novel catabolic capabilities through directed bacterial conjugation and plasmid transfer (Chakrabarty et al., 1975). The resulting strains were able to break down two-thirds of all the hydrocarbons typically found in a crude oil spill at rates one or two orders of magnitude faster than the previously described individual strains of oil-eating bacteria, a set of results which lead to the first USA patent granted for a genetically modified organism (Chakrabarty, 1981).

3.2.1. Biodegradation of aromatic compounds as a source of added-value metabolites

The huge potential for biodegradation of aromatic compounds written in the cis-metabolism of P. putida was exploited for transformations beyond the customary bioremediation approaches in the context of which they were discovered (Dvořák et al., 2017). The practical demonstration of this metabolic capability is represented by several engineering strategies developed for the production of cis,cis-muconic acid [(2E,4E) 2,4-hexanedioic acid]. This dicarboxylic acid is a relevant platform chemical that is currently recognized for its high industrial value (Xie et al., 2014)—cis,cis-muconic acid provides synthetic access to terephthalic acid, 3-hexenedioic acid, 2-hexenedioic acid, 1,6-hexanediol, ε-caprolactam, and ε-caprolactone, all of which are important building blocks of commercial plastics, resins, and polymers (e.g., Nylon-6,6 viaadipic acid). The traditional chemical processes for its production rely on non-renewable, oil-based feedstocks and high concentrations of heavy metal catalysts—and a mixture of the cis,cis- and cis,trans-muconic acid isomers is obtained. The synthesis of cis,cis-muconic acid in P. putida mt-2 takes place as an essential part of the upper catabolic pathways dealing with the degradation of aromatic compounds. All of these catabolic segments ultimately converge at the level of catechol (1,2-dihydroxybenzene) as a central metabolic intermediate, which then undergoes intradiol ring ortho-cleavage by the action of catechol-1,2-dioxygenase to yield of cis,cis-muconic acid.

The inactivation of muconate cycloisomerase was one of the first attempts to enhance the production of cis,cis-muconic acid, given that this enzyme would lactonize the target product and thereby reduce yields. Such strategy enabled the production of cis,cis-muconic acid via the catechol branch of the β-ketoadipate pathway directly from benzoic acid and toluene (Chua and Hsieh, 1990). In addition, the expression of phenol hydroxylating enzymes in P. putidaKT2440 (i.e., the dmpKLMNOP-encoded phenol monooxygenase from Pseudomonas sp. strain CF600) enabled efficient cis,cis-muconic acid synthesis from phenol (Vardon et al., 2015). More recently, the entire protocatechuate branch of the β-ketoadipate pathway was successfully connected to the catechol node, thereby allowing for cis,cis-muconic acid formation from an even greater number of precursors, including coniferyl alcohol, p-coumarate, vanillate, ferulate, and protocatechuate itself (Johnson et al., 2016). As a result, the upper pathways of P. putida for aromatic compounds degradation were rendered a metabolic funnel to convert heterogeneous mixtures of aromatics with catechol as a central intermediate (Linger et al., 2014)—a circumstance that was adopted to reconstruct efficient modular pathways for cis,cis-muconic acid synthesis in engineered E. coli (Thompson et al., 2018).

3.2.2. From complex alternative feedstocks towards added-value metabolites

Some of the most recent instances on the production of cis,cis-muconic acid also offer an example of the use of alternative substrates by metabolically engineered P. putida, e.g., plant biomass containing lignin. Extensively found in terrestrial plants, lignin is the second most abundant biopolymer on Earth. With the advent of biorefineries that use plant biomass as a source of sugars, lignin has become a common by-product with an enormous potential to be used as raw material in the fuel and chemical industries. However, lignin remains the most under-utilized lignocellulosic biopolymer (Rinaldi et al., 2016). The catalytic potential of P. putida in taking part of this endeavor has not passed unnoticed.

As indicated in the previous section, the catechol node plays a central role in the production route leading to cis,cis-muconic acid production since (i) all the upper segments of the catabolic pathways for degradation of aromatic compounds ultimately yield catechol as the central intermediate, (ii) catechol itself is frequently generated during pre-treatment of lignin, and (iii) catechol is directly converted to the target product by means of catechol-1,2-dioxygenase. However, one of the main problems to overcome in production processes from lignin-based feedstocks is the high toxicity of catechol. First, these raw materials can themselves contain significant fractions of catechol. Second, the conversion of crude mixtures of aromatic compounds requires the engineering of heterologous catabolic pathways into the microbe, all of which additionally contribute to catechol accumulation, potentially leading to forced self-poisoning. These factors could explain why the conversion of complex lignin liquors to cis,cis-muconic acid by engineered P. putida strains has so far resulted in the accumulation of significant amounts of toxic upstream pathway intermediates (which lower final yields, and can altogether hamper the process) and in the production of the target metabolite at only the milligram scale.

In an attempt to overcome this state of affairs, Kohlstedt et al. (2018) designed an entire genealogy of engineered P. putida KT2440 strains endowed with enhanced catechol tolerance and high conversion efficiency, and having a wider substrate spectrum than other production platforms. Different metabolic configurations were tested in the engineered strains, and cis,cis-muconic acid was produced from benzoate, catechol, mixtures of catechol and phenol, and from a lignin hydrolysate liquor (obtained via base catalysis and hydrothermal conversion) in bioprocesses tested both at the laboratory- and at the pilot-scale (50 L). When grown under fed-batch conditions using glucose as the main carbon source, some of the engineered strains were able to achieve a cis,cis-muconic acid titer of ca. 65 g L−1 and 13 g L−1 from externally added catechol and from the lignin hydrolysate, respectively. More importantly, these engineered cis,cis-muconic acid producers were successfully applied to provide the first case example of lignin-to-Nylon-6,6 production via a cascaded biochemical and chemical integrated process. The bulk of the acid obtained in the process designed by the authors was subsequently hydrogenated to adipic acid via a chemical, Pd-assisted hydrogenation process, and the product was directly reacted with hexamethylenediamine to yield Nylon-6,6.

The dependence of these processes on sugars somehow compromises the value of using lignin-derived substrates at the industrial level that, as indicated above, are usually utilized as a co-feed. Novel metabolic engineering strategies are being tested to overcome this problem, and shift to lignin hydrolysates as the only carbon source fueling the process. In a recent example of this sort, Sonoki et al. (2018) engineered a P. putida KT2440-based strain to produce cis,cis-muconic acid from a mixture of vanillic acid (i.e., a guaiacyl-lignin model) and 4-hydroxybenzoic acid (i.e., a p-hydroxyphenyl-lignin model) with a yield of ca. 20% (mol mol−1) without the need of glucose supplementation.

3.2.3. Production of aromatic compounds in P. putida

In the same way that P. putida is naturally equipped with the metabolic machinery needed for the degradation of aromatic compounds, this bacterium can be used as the functional chassis for the synthesis of aromatic compounds—a situation that could lead to sustainable production of some of them (used as building blocks for commodities), since the industrial synthesis of aromatics currently relies almost exclusively on petrochemical-based processes from benzene, toluene, and xylenes (Lee and Wendisch, 2017). Several examples from the literature indicate that P. putida has been engineered for the production of aromatic compounds that are often extremely toxic to be handled by other microbial hosts, e.g., cinnamate, p-coumarate, p-hydroxybenzoate, and phenol (Calero et al., 2018, Molina-Santiago et al., 2016). Although it is not the purpose of this article to survey all these examples, a recent addition to the literature of engineering the cis-metabolism of Pseudomonas for phenol production deserves attention considering its elegance and simplicity (Wynands et al., 2018). Phenol is an aromatic commodity chemical with a multitude of applications in the chemical industry, and its biological production from tyrosine has been achieved by introducing genes encoding tyrosine-phenol lyase from Pantoea agglomerans or Pasteurella multocida in P. putida or E. coli strains (Wierckx et al., 2005). However, the P. putida variants capable of producing 1.5 mM phenol from glucose with a yield < 7% C-mol C-mol−1 were obtained by non-rational strain engineering techniques, i.e., random mutagenesis followed by extensive high-throughput screening. Building on the knowledge stemming from those early studies, P. taiwanesis (a relative of P. putida) was forward- and reverse-engineered (22 modifications in total) to finally yield a strain that bears no plasmids (all relevant activities were integrated into the chromosome), and has no auxotrophies (a problem that plagued the engineered P. putida strains constructed thus far). The product titer and yield of phenol on glucose reached by the best engineered candidate after 96 h of batchwise shaken-flask cultivation was ca. 3 mM and 16% C-mol C-mol−1, respectively, which are the highest reported in the absence of any additives (e.g., yeast extract) to the culture medium. Considering the high performance of these engineered P. putida strains in producing phenol from sugar substrates, it would be interesting to connect this metabolic architecture with the catabolic segments discussed in the preceding section leading to the synthesis of cis,cis-muconic acid to enable the forward design of a high-yield cis,cis-muconic acid P. putidaproducer from hexoses.

An entirely new chapter in the synthesis of aromatic compounds is likely to arise from the recent discovery and identification of enzymatic activities for the synthesis of toluene (Beller et al., 2018). Microbial sources of biogenic toluene were first reported more than three decades ago; however, the underlying biochemistry and specific enzymes that catalyze toluene biosynthesis had never been elucidated until now. Phenylacetate decarboxylation is catalyzed by the glycyl radical enzyme PhdB together with its cognate activating enzyme PhdA, a radical S-adenosyl-L-methionine enzyme, and the activities were discovered in two distinct anoxic microbial communities known to produce toluene—most likely by a non-cultivated microbial member (strain TolSyn) of the Acidobacteriaphylum. The unconventional process of enzyme discovery from a complex microbial community (> 300,000 genes) undertaken by the authors involved metagenomics- and metaproteomics-enabled biochemical analysis, as well as in vitro confirmation of activities using recombinant enzymes. Yet, the strictly anoxic nature of these glycyl radical enzymes might hinder the design of a trans-metabolism for aromatic compounds in P. putida KT2440, an obligate aerobe—but there are emerging strategies at hand to overcome this issue, as indicated in the next section.

3.3. Trans-metabolisms engineered in the P. putida chassis: Exploring the untapped metabolic potential of environmental bacteria

The few examples presented in the preceding section are, in a nutshell, the practical demonstration of how flexible the metabolism of P. putida is, being able to host complex biochemistries that range from the degradation of complex aromatic substrates down to simple, low-molecular-weight metabolites—and potentially back. This aspect is the subject of the present section, in which we discuss some of the examples available in the literature on the engineering of trans-metabolisms in P. putida.

3.3.1. Engineering the oxygen-dependent lifestyle of P. putida

As diverse as the natural environmental niches inhabited by P. putida and other Pseudomonas are, they all share a physicochemical characteristic: oxygen does not usually represent a nutritional limitation. This feature is not surprising, as microbial activity in soil is known to be spatially heterogeneous, and individual species often forming spatial hotspots that differentially contribute to overall biogeochemical processes. Mounting evidence had suggested that spatial organization of bacterial species contributes to the persistence of anoxic hotspots in soils—a hypothesis that has been recently confirmed experimentally with a soil-like system that includes both the obligate aerobe P. putida and the facultative anaerobe P. veronii (Borer et al., 2018). The strictly aerobic, highly oxidative cis-metabolism of P. putida, however, hampers its broad application under micro-oxic and anoxic conditions, which in turn excludes the utilization of oxygen-sensitive proteins and metabolites. This situation also leads to complications when it comes to industrial-scale applications. On one hand, the operation of oxic bioprocesses it increases the capital cost, as scaling-up of these processes is significantly limited by the oxygen transfer rate and, due to this, both the maximum and average scales of commercial oxic bioreactors are much smaller in comparison with anoxic bioreactors (Ruiz et al., 2012). On the other hand, oxygen-dependent bioproduction bring about some degree of substrate loss in the form of CO2, while some anoxic processes can achieve carbon yields close to theoretical yields. Against this background, it is no surprise that engineering an anoxic P. putida chassis has been the subject of intense research over the last few years, including the quantitative study of the responses of P. putida to different agitation rates and oxygen availability in shaken-flask cultures (Rodríguez et al., 2018).

Three types of engineering approaches can be distinguished, which are based on (i) a trans-metabolism for mixed fermentation, (ii) a trans-metabolism for nitrate-dependent respiration, and (iii) the adoption of bioelectrochemical systems. In the first type of engineering approach, the genes encoding the acetate kinase from E. coli and the ethanol biosynthesis pathway from Zymomonas mobilis were introduced in strain KT2440, which resulted in an extended survival in the absence of oxygen (Nikel and de Lorenzo, 2013b). This anoxic-tolerant bacterial chassis was further engineered by recruiting two haloalkane dehalogenases from P. pavonaceae, which conferred the ability of degrading 1,3-dichloprop-1-ene (a recalcitrant xenobiotic that neither wild-type P. putida nor P. pavonaceae can degrade under anoxic conditions). In a different study, Steen et al. (2013) constructed two cosmids encoding all the structural, maturation-related, and regulatory genes needed for nitrate reductase and nitrite- and nitric oxide reductase from P. aeruginosa in order to establish nitrate-dependent respiration in strain KT2440. The resulting engineered strains efficiently reduced nitrate or nitrite, which in turn sustained an extended anoxic lifespan. Finally, the utilization of bioelectrochemical systems was exploited to develop bioprocesses under conditions with limited oxygen supply. Schmitz et al. (2015) engineered a P. putida KT2440 derivative able to synthesize phenazine redox-mediators by expressing the seven-gene cluster phzA1-G1 together with phzM and phzS from P. aeruginosa PAO1. Formation of the redox-active pyocyanin allowed for partial redox balancing with an electrode under micro-oxic conditions, and the biomass yield on glucose of the engineered P. putida was doubled as compared with the wild-type strain. Lai et al. (2016) used [Fe(CN)6]3− or [Co(2,2′-bipyridine)3]3+ as the high midpoint potential redox mediator when culturing P. putida F1 in the anodic compartment of a bioelectrochemical system ran under anoxic conditions in the presence of glucose as the carbon source. Under these conditions, most of the glucose was converted into 2-ketogluconate (with a yield of ca. 0.9 mol mol−1), and overexpression of the endogenous gluconate dehydrogenase in strain KT2440 boosted 2-ketogluconate formation under similarly anoxic culture conditions by > 600% (Yu et al., 2018).

Despite all these valuable efforts, no metabolically engineered P. putida strain was able to actually grow in the absence of oxygen thus far, which opens up the question of what are the factors missing in the picture that need to be manipulated in order to accomplish the task. It is likely that an authentic genome scale metabolic model-driven design of an anaerobic trans-metabolism will help filling the knowledge gap that currently limits the adoption of an oxygen-independent lifestyle by P. putida—a situation that will soon be remediated by exploiting the information of the five genome-wide metabolic models currently available for strain KT2440 (Belda et al., 2016, Nogales et al., 2008, Puchałka et al., 2008, Sohn et al., 2010, Yuan et al., 2017), including the latest update by Nogales et al. (2017), in which the in silico metabolic potential of P. putida has been fully evaluated in the most comprehensive metabolic reconstruction built to date. Meanwhile, and in some cases with the support of such metabolic reconstructions, the already rich cis-metabolism of P. putida has been used to incorporate new substrates for bioproduction, as disclosed in the section below.

3.3.2. Expansion of the range of carbon substrates

What makes a carbon source into a good substrate for P. putida? Hintermayer and Weuster-Botz (2017) attempted to answer this question by estimating the growth parameters of strain KT2440 in silico using 57 individual carbon sources, and experimentally validated the results in batch cultures carried out on six of them (i.e., acetate, glycerol, citrate, succinate, malate, and methanol). Glycerol was the carbon source that promoted the highest biomass yield on substrate (0.61 C-mol C-mol−1) with a very good fit between the in silico prediction and the experimental validation. The use of glycerol has been explored from a biochemical and genetic point of view in other studies (Nikel et al., 2014a, Nikel et al., 2015b), and it has been also used as a substrate to design bioprocesses for the cost-efficient production of polyhydroxyalkanoates by P. putida (Beckers et al., 2016, Gomez et al., 2012, Prieto et al., 2016). In fact, biopolymers constitute one of the main products of the cis-metabolism of P. putida that has been exploited for commercial production, and the reader is referred to the key literature in the domain for further information on polyester production in engineered P. putida strains (Arias et al., 2013, Li et al., 2011, Liu et al., 2011, Meng and Chen, 2018, Tripathi et al., 2012).

All these studies indicate that the nutritional landscape of typical P. putidaniches in Nature (including plant rhizosphere and polluted soils) has pushed its metabolic specialization towards the use of organic acids, amino acids, and aromatic substrates (Martins dos Santos et al., 2004). Considering that glucose and xylose are the two most abundant monosaccharide building blocks of the abundant polysaccharides cellulose and hemicellulose in plant cell walls, both of them are attractive sugars to be used as substrates in bioprocesses. Expansion of the cis-metabolism of sugars in P. putida to assimilate industrially-relevant hexose and pentose substrates is thus an important topic in the field of metabolic engineering since carbohydrates are not the preferred carbon sources of environmental bacteria.

The carbohydrates on which P. putida KT2440 can grow are confined to some hexoses (glucose and fructose), but this strain is unable to metabolize disaccharides or C5 sugars (Köhler et al., 2015), thus limiting the number and nature of sugars that can be used in bioprocesses. Dvořák and de Lorenzo (2018)expanded the cis-metabolism of a genome-reduced variant of strain KT2440 to include disaccharides and xylose as the carbon substrates by (i) plugging-in a β-glucosidase from Thermobifida fusca (i.e., the enzyme needed for intracellular hydrolysis of cellobiose), (ii) and three separate activities from E. coli (i.e., a xylose transporter, a xylose isomerase, and a xylulokinase), and (iii) blocking the oxidative branch of sugar utilization by eliminating the endogenous glucose dehydrogenase. When implemented together, these manipulations enabled co-utilization and total utilization of both cellobiose and xylose in minimal medium by the engineered strain.

Sucrose is another disaccharide alien to the extant catabolic potential of P. putida. Being the main sugar component of molasses, thus an interesting feedstock for bioproduction, Löwe et al. (2017a) engineered a reduced-genome variant of strain KT2440 to acquire sucrose permease and invertase activities by delivering the cscAB genes from E. coli strain W into the chromosome via mini-Tn5 transposons. The resulting P. putida variant not only grew on sucrose as the carbon source, but it was also used as a platform strain for photoautotrophic polyhydroxyalkanoate production in a co-culture system along with cyanobacteria. In this setup, a mutant strain of Synechococcus elongatus fixes CO2 and converts it to sucrose, which is in turn used as the main carbon source by the engineered P. putida strain to accumulate the intracellular biopolymer with an overall productivity of ca. 24 mg L−1 day−1 (Löwe et al., 2017b).

Other substrates beyond individual sugars are likewise relevant for industrial production. Lignocellulose, for instance, can be decomposed to cellulose (25–55%), hemicellulose (11–50%), and lignin (10–40%). As most biomass conversionschemes for bioproduction employ a high-temperature processing step, sometimes in the presence of an acid, sugar dehydration products are inevitably formed (Ravindran and Jaiswal, 2016). C5 and C6 sugars can be dehydrated into furfural and 5-(hydroxymethyl)furfural, respectively, and these two compounds are commonly formed during the thermochemical pretreatment, liquefaction, or pyrolysis steps of lignocellulose processing. These aldehydes are considered major inhibitors in microbial conversion processes, but some microorganisms are known to convert these compounds to their less toxic, dead-end alcohol counterparts, furfuryl alcohol and 5-(hydroxymethyl)furfuryl alcohol. P. putidaKT2440 was engineered to utilize both furfural and 5-(hydroxymethyl)furfural as sole carbon and energy sources via genomic integration of the 12-kb hmfgene cluster, encoding the eight enzymes previously characterized in Burkholderia phytofirmans that transform the two substrates in the common metabolic intermediate 2-furoic acid (Guarnieri et al., 2017).