1. Introduction

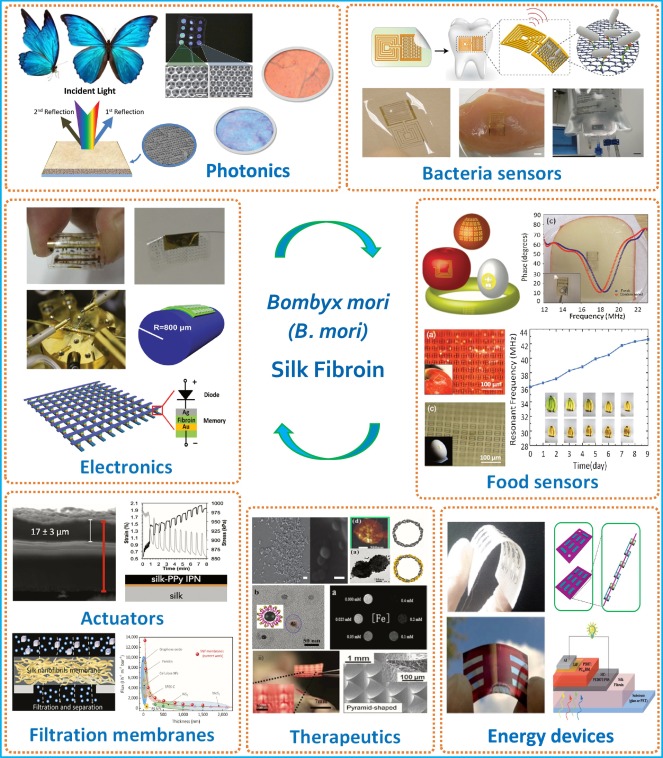

In the recent year, sportswear mega brand Adidas revealed its business plan to manufacture eco-friendly biodegradable shoes made of silk, and promised to start retailing them by early 2018 [1]. Such splendid incorporation of silk into contemporary lifestyles reflects the growing acceptance and high-value opportunities for the ‘seemingly ancient or obsolete’ material in modern-day settings. Plentiful amounts of silk can be obtained from domesticated Bombyx mori (B. mori) silkworms, or via more costly extractions from cannibalistic spiders, such as Nephila clavipes (N. clavipes), Nephila edulis (N. edulis), Araneus diadematus (A. diadematus). Both the silkworm and spider (dragline) silks bear great resemblance in their molecular structures and mechanical properties, and they are among the strongest and toughest fibers obtainable in nature [2]. Both types of silks are estimated to be five to six times lighter than steel while having the same strength. Furthermore, they are also tougher than all existing synthetic fibers, including high-performance polyethylene or Kevlar (both of which are used to build bulletproof vests) [[3], [4], [5], [6]]. B. mori silk (i.e. silk fibroin) has been rapidly developed in recent years for novel applications in surgical sutures and fashion textiles, as well as demonstrating promising advanced applications in electronics, optoelectronics, photonics, energy-harvesting/storage, laser-induced/wirelessly-activated drug delivery carriers, smart edible food coatings/sensors, high performance water filters, and consumer products (Fig. 1) [[7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22]]. In particular, silk fibroin is especially highly valued in biomedical and related devices with rapidly increasing emphasis on seamless human integration and environmental sustainability.

Fig. 1. Advanced uses of Bombyx mori (B. mori) silk fibroin. B. mori silk fibroin is applied in electronics, optoelectronics, photonics, biohazard/bacteria sensors, edible food coatings/sensors, energy-harvesting/storage devices, therapeutics/drug delivery carriers, high-performance water filtration membranes and actuators.

Reproduced with permission from [[7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22]].Even in the 21st century today, it remains extremely difficult to find natural or synthetic materials which exhibit the numerous attractive properties of B. morisilk fibroin, such as aqueous processability, biocompatibility, controllable biodegradability, ease of functionalization and patterning, flexibility, natural abundance, optical transparency, strength, thermal stability, toughness, ultra-thinness, and ultra-smoothness. With these properties, silk fibroin has emerged as the top material candidate of natural origins for advanced utilities in electronics and energy-harvesting/-storage devices (hereafter simply referred to as electronics and energy devices), and a multitude of related bio-applications, remarkably outperforming synthetic materials and also many other materials found in nature (such as collagen, chitin, chitosan, alginate, dextran, shellac, and hard gelatin). Silk fibroin is actively being developed as a “green” component to replace or complement conventional materials, especially those which are deemed unsuitable, especially for advanced bio-applications where biocompatibility or sustainability is crucial [23,24].

As society progresses towards a more sustainable future, a ‘green’ approach is increasingly sought after to viably meet the advanced technological requirements for manufacturing next-generation wearable, implantable, self-resorbable electronics and energy-devices. This is also to curb the surging amounts of electronic waste (e-waste) generated [25] which poses severe environmental and health concerns worldwide. Astonishingly, almost 60 million kilograms of e-waste is generated every year even in a small city-state like Singapore [26], which exceeds the combined weight of approximately two hundred and twenty Airbus A-380 aircrafts. On the other hand, the world's most populous country, China, discernibly holds the largest share of the world's total amounts of e-waste, accounting for >70% which is mainly in the forms of discarded smartphones, computers, laptops, refrigerators, televisions, and digital music/photo devices [27]. These alarming figures compellingly call for ‘green’ materials in electronics and energy-devices. Up to this point, the realization of electronics and energy-devices made entirely from ‘green’ materials (i.e. materials that are nontoxic, biocompatible, biodegradable, and renewable) remains an ambitious technological dream worldwide. Such ‘green’ electronics and energy-devices will also be highly applicable for next-generation applications (e.g. artificial intelligence-driven cosmetics, skin-like electronic bandages) and are of utmost importance especially for advanced biomedical or related biological applications.

Among the concerted efforts towards a ‘green’ future for electronics and energy devices, Muskovich and Bettinger, as well as Torculas et al. provided exceptional reviews on biologically-derived materials for semiconductors and insulators for use in electronics [28], essentially exploring flexible electronic technologies and the fabrication methods of protein materials for biomedical applications [29]. Some examples of these materials are pigments, peptides, proteins, and deoxyribonucleic acid (DNA). Tan et al. recently provided a highly comprehensive coverage on the various biodegradable materials for use in electronics (along with their printing technologies) intended for medical, drug delivery, and tissue engineering applications [25]. Meanwhile, Zhu et al. gave an exceptional review on the use of silk fibroin for flexible electronics and energy-devices, with great emphasis on its unique material properties for these applications [30].

Here, we introduce the fundamental concepts of silk-based electronics/optoelectronics to provide a more general and well-rounded understanding across the various research hotspots. We will provide an updated review of the latest technological advances on the use of silk in combination with other functional components, with the goal of improving the performance of next-generation silk-based materials for futuristic biomedical devices, wound dressings or related biological applications. Preparation of silk fibroin that is patterned with micro/nano-scale features will be highlighted, as well as the functionalization of silk fibroin to impart antimicrobial (i.e. antibacterial) properties. Collectively, the various sections serve as a guide to lead the synergistic development of silk-based materials towards such futuristic/advanced applications. Some of the patterning/printing techniques which are also used to produce tissue scaffolds (as described in Section 4) will serve as a guide or a starting point for producing more complex silk-based structures for futuristic electronics in addition to the simple film morphology. Through this review and our proposed areas of future growth, we hope to spur continued efforts to advance the scientific frontiers of silk fibroin in electronics/optoelectronics and other bio-related applications and expedite its translation into commercially competitive high-performance products with standards that match or, more crucially, exceed existing technology.

2. Electronics and optoelectronics

Electronics are ubiquitous in today's life – we encounter the use of electronics in a river of daily activities sometimes without even realizing them (e.g. when texting or making calls using smartphones, accessing the entrances of train stations/offices, withdrawing cash from an automated teller machine (ATM), working/gaming on a laptop, or navigating an unfamiliar route with a global positioning system (GPS) unit). Moving forward, electronics are expected to take over almost every aspect of our life and become increasingly inseparable with the human world. A glimpse into the future of electronics suggests a trend towards a hybrid of technology and fashion, with society progressively moving towards futuristic ideals of new and enhanced consumer experience. This will be reflected as a series of high-end technologies such as electronic papers (e-papers), electronic skins (e-skins), robotic systems with human-like sensing capabilities, smart wearables (i.e. tech gadgets/devices integrated into clothing or human body), autonomous (i.e. self-driving) cars, non-invasive health monitoring and critical care, and radio-frequency identification tags [[31], [32], [33], [34], [35], [36], [37], [38], [39]]. Inevitably, commercial attractiveness and usefulness of these technologies depend greatly on the introduction of novel or enhanced features to achieve unprecedented device functionalities and performance advantages, while being eco-friendly (i.e. safe for human use and gentle on the environment). Here, we review the use of B. mori silk fibroin (i.e. an FDA-approved biomaterial) as ‘green’ components in electronics and optoelectronics (i.e. optoelectronics refers to those electronics that source, detect and/or control light), which have promising utilities in advanced bio-related applications as e-skins, e-cosmetics, edible food sensors, next-generation wearable displays, implantable devices and bio-actuators, etc. Futuristic silk fibroin-based electronics may also provide an alternative (also as a complement) to tissue engineering to provide stimulation and feedback loop for enhanced wound healing and monitoring in the convenient forms of electronic bandages (e-bandages or skin-like bandages), electronic sutures (e-sutures), etc. In this review, we primarily focus on the use of silk fibroin in transistors, electrodes, antennas, diodes and memristors, actuators, and as exfoliators for electronics, mainly because these electronic components are the basic building blocks of an electronic circuit, system, or device (which are also referred to as electronics in short).

2.1. Transistors

Silk fibroin can be applied as a dielectric layer (an electrically insulating layer that is polarizable by an applied electric field) in transistors, which is an electrical component that switches on/off or amplifies an electrical signal in a circuit. Organic field-effect transistors (OFET) have highly promising applications in e-skins [30,37,40], biosensors, flat panel displays radio frequency identifications tags, and e-papers [13,41]. In OFET, silk fibroin can be applied as a dielectric layer sandwiched between the gate and semiconductor layer as an organic alternative to the commonly used inorganic silicon dioxide dielectrics in transistors.

2.1.1. Silk fibroin as dielectric layer for improved semiconductors

Owing to its high dielectric constant which confers high capacitance, the use of silk fibroin as dielectric layers in OFET required only a low operating voltage of −3 V or lower [13], in contrast with operating voltages as high as 100 V in traditional OFET. Besides, silk fibroin dielectric layers (Fig. 2A) had remarkably smooth surfaces (i.e. low surface roughness RMS of 0.3 nm) which ensured good interfaces with the upper semiconducting pentacene layer (i.e. above the silk dielectric layer). This contributed to reduce the charge trap density at the dielectric/semiconductor interface. More importantly, silk fibroin dielectric layers also greatly improved the crystal qualities of the semiconductor layers above it by enhancing their molecular order (Fig. 2B), where the amounts of crystalline orthorhombic phase and thin-film phase of pentacene increased by approximately three and four times, respectively (Fig. 2C). These dramatic improvements contributed to an unprecedented high charge carrier mobility (μ) of 23.2 cm2 V−1 s−1 and an on/off current (Ion/off) ratio of 3 × 104 in the silk-based OFET [13] (OFET is typically benchmarked to that of amorphous silicon (a-Si) thin-film transistors which have μ = 0.5 to 1 cm2 V−1 s−1; Ion/off = 106–108 [42]). Progressively, silk-based OFET has to demonstrate the following characteristics for it to be attractive for commercial use in advanced applications: 1) low operating voltage (between 0 to −3 V to be compatible with the voltage level being used in the electronics industry [43]), 2) high field-effect charge carrier mobility (μ), which will provide higher device speeds (e.g., >1 cm2 V−1 s−1) to greatly reduce ‘reading’ and ‘programming’ time [44], 3) good electrical (i.e. stress-bias) stability as this is currently an obstacle to commercial use of OFET [45], and 4) high Ion/off ratios of ~105 or greater for practical applications [46], depending on the field of applications. For instance, OFET for use in a liquid crystal typically demands a high Ion/off ratio of 106 and a minimum μ of 0.1 cm2 V−1 s−1 for good performance [47].

Fig. 2. Silk fibroin as a dielectric layer in organic field-effect transistor (OFET). A dielectric is an electrically insulating layer that is polarizable by an applied electric field. (A) Left: Photograph showing silk fibroin/pentacene transistor (OFET) in a rolled-up configuration. Right: Atomic force microscopy (AFM) image showing the surface topology of silk fibroin dielectric layer. Bottom: Schematic showing the OFET with the 420 nm-thick silk fibroin dielectric layer. Inset: Field emission scanning electron microscopy (FESEM) image showing a cross-section of silk fibroin dielectric layer on Au gate electrode. (B) Schematics showing the growth modes of pentacene on silk fibroin (left), and on SiO2(right), respectively. (C) Grazing incidence X-ray diffraction (GIXRD) spectra of (001) peak of the pentacene thin-film phase (70 nm), and the pentacene orthorhombic phase (25 nm), grown on silk fibroin (SF) and on SiO2, respectively. Silk fibroin serves as a better substrate than SiO2 for the growth of the pentacene orthorhombic phase at the beginning of pentacene deposition. When the pentacene film thickness is larger than 30 nm, a prominent X-ray peak at 2θ = 5.7° appears, indicating that the pentacene molecules are tilted towards a higher angle normal to the surface normal. The pentacene phase is called the thin-film phase. (D) Schematic structure of silk fibroin/pentacene transistor (OFET) with dielectric layer prepared from silk fibroin/poly(vinyl alcohol) (silk/PVA) blend. Inset: The molecular structure of PVA.

Reproduced with permission from [13 and 41].2.1.2. Silk fibroin/PVA as dielectric layer for reduced dielectric surface roughness

In another study, Zhuang et al. reported that blending silk fibroin with poly(vinyl alcohol) (PVA) at a silk/PVA blend of weight ratio 7:5 helped to further smoothen the surface of the dielectric layer for use in OFET (Fig. 2D) [41]. The roughness RMS decreased from 0.31 nm to 0.19 nm, thus greatly reducing the charge trap density at the dielectric/semiconductor interface. It also permitted a near-zero operating voltage of −1 V, and this was a dramatic improvement compared to the operating voltage of −11 V with the use of pure silk fibroin as dielectric in the same study. Moreover, it gave an enhanced μ of 0.22 cm2 V−1 s−1 (an increase from 0.14 cm2 V−1 s−1 with the use of pure silk fibroin) and a higher Ion/off of 9.4 × 103 (an increase from 2.4 × 103 with the use of pure silk fibroin). Zhuang et al. attributed this smoother surface of the silk/PVA dielectric layer to the interaction between  OH (in PVA) and

OH (in PVA) and  C

C O (in silk fibroin) [41], since PVA is a surfactant that lowers the surface energy of the dielectric layer, resulting in a reduced surface roughness. However, Zhuang et al. mentioned one downside with regards to the use of PVA in silk dielectric: it reduced the quality of the semiconductor crystals (by resulting in more grain boundaries) and diminished the crystals' stability when compared with the same device using pure silk fibroin as the dielectric layer. It is noted that the dielectric layer from the silk/PVA blend had only slightly lower capacitance (5.09 nF cm−2) than that of pure silk fibroin (5.34 nF cm−2) [41]. Besides the use of PVA to reduce surface roughness, blending silk fibroin with tropoelastin also reduced the surface roughness of silk fibroin films [49]. Tropoelastin is the precursor to elastin protein which is responsible for the stretch properties of skin, arterial walls and ligaments [48]. It was also noted that factors such as the molecular weight, molecular weight distribution, chain branching, and molecular orientation influenced the surface roughness of polymeric materials [50].

O (in silk fibroin) [41], since PVA is a surfactant that lowers the surface energy of the dielectric layer, resulting in a reduced surface roughness. However, Zhuang et al. mentioned one downside with regards to the use of PVA in silk dielectric: it reduced the quality of the semiconductor crystals (by resulting in more grain boundaries) and diminished the crystals' stability when compared with the same device using pure silk fibroin as the dielectric layer. It is noted that the dielectric layer from the silk/PVA blend had only slightly lower capacitance (5.09 nF cm−2) than that of pure silk fibroin (5.34 nF cm−2) [41]. Besides the use of PVA to reduce surface roughness, blending silk fibroin with tropoelastin also reduced the surface roughness of silk fibroin films [49]. Tropoelastin is the precursor to elastin protein which is responsible for the stretch properties of skin, arterial walls and ligaments [48]. It was also noted that factors such as the molecular weight, molecular weight distribution, chain branching, and molecular orientation influenced the surface roughness of polymeric materials [50].

2.1.3. Secondary structure of silk fibroin and future OFET

The secondary structure of silk fibroin critically influenced the performance of OFET [40,51]. Various silk processing strategies may be explored to enhance the performance of silk dielectric-based OFET or organic light-emitting field-effect transistors (OLET). For instance, according to Park et al. [40], a more crystalline silk structure led to better performance of OFET. Silk fibroin was demonstrated to be feasible as dielectric layers in both n-type and p-type OFETs [30,51]. (Note: the difference between the two is that n-type semiconductors have more electron carriers than hole carriers, while p-type semiconductors have more hole carriers than electron carriers.) As transistors are important components in almost all modern digital electronics/optoelectronics, it is highly desirable to produce commercially attractive high performance silk-based OFETs, ideally at low-cost and high production speed, with the device having a near zero operating voltage, high device speed, high on/off current ratio, air/moisture stability, flexibility, and even stretchability (i.e. >50–80% strain) for use in cutting-edge applications such as smart wearable electronics [53]. Here, it is also noted that vacuum-deposited pentacene layers were superior to their solution-prepared counterparts as pentacene has poor solvent solubility. Thus, vacuum deposition conferred a much higher charge carrier mobility [53]. Interestingly, silk fibroin were also applied in OLET for the added functionality of light generation in a single device [51,52] to produce nanoscale light-emission with intensities of 100 nW [51].

2.2. Electrodes and antennas

In electrodes, silk fibroin was used as a charge-selective coating, or as an electrically conductive substrate that is embedded with conducting elements such as silver nanowires (AgNWs). As an electrical conductor, an electrode allows electrical current to enter or leave a non-metallic medium (e.g., skin, electrolyte, vacuum, air) and it can be used to detect electrical activity. (Note: an electrode is used as part of a sensor, i.e. a device which senses and measures changes in physical quantities, such as temperature, pressure, humidity, strain, and loudness.) Besides being used as electrodes, conductive silk-based substrates are also used to produce antennas for use in antenna-based sensors. An antenna allows conversion of electromagnetic signal into electrical current, and vice versa.

2.2.1. Silk fibroin as coating with charge-selective recognition

Silk fibroin was used to coat the surface of graphite and carbon-fiber electrodes for charge-selective recognition of anions/cations. For instance, silk fibroin-modified carbon-fiber electrode became negatively-charged when used in a solution where the pH was greater than the isoelectric point (pI) of silk fibroin (4.5) (Fig. 3A). With the negatively-charged silk fibroin coating, the electrode attracted cations and rejected anions. This enabled the selective detection and measurement of cationic neurotransmitter dopamine in vivo for bioanalysis or sensing purpose [54,55].

Fig. 3. Silk fibroin as a coating with charge-selective recognition, or as a transparent substrate with surface electrical conductivity. (A) Dependence of silk fibroin membrane (coating) potential on pH of test solutions. The isoelectric point is approximately pH 4.5, which allows the membrane to be an anion exchanger below pH 4.5, and a cation exchanger above pH 4.5. (B) Schematic diagram showing a patterned, optically transparent, flexible, and biocompatible surface conductor prepared from silk fibroin and silver nanowires (AgNWs). The patterned AgNWs network was embedded (i.e. buried) at the surface of the free-standing silk film and exhibits optical transparency and good electrical conductivity. The electric current could flow through the embedded AgNWs surface conductor, and this setup can be used as an electrode and a radio-frequency (RF) antenna. Inset: Scanning electron microscope (SEM) images showing the morphology of AgNWs on bare silicon (1) and AgNWs embedded at a density of 21.3 mg m−2 at the surface of a silk film (2). The scale bars in (1) and (2) correspond to a length of 5 μm. (C) Operation of a light-emitting diode (LED) chip on AgNWs line electrodes. The dashed rectangular boxes indicate the patterned AgNWs electrodes. (D–E) Schematic showing the application of a silk-AgNWs line resistor and with a silk-AgNWs RF antenna as food sensor. Spoiled (i.e. rancid) food was used to emit the foul odor. (F) Experimentally measured reflections of the RF antenna applied to a slice of rancid food and (G) time-dependent resistance of the line electrode. An increase in electrical resistance of a silk-based electrode was observed with increasing exposure time to the odor of the rancid food (the resistance is almost tripled after 1 h of exposure when compared with control, i.e. exposure to fresh food).

Reproduced with permission from [54 and 56].2.2.2. Silk fibroin embedded with AgNWs as transparent surface-conductor

To confer electrical conductivity to silk fibroin for applications as conductive substrate of an electrode, electrically conductive material such as AgNWs (~20 μm in length, ~40 nm in diameter) were patterned and embedded into a silk fibroin film just beneath the surface (Fig. 3B), as reported by Min et al. [56]. The conductive silk fibroin film was achieved by casting a silk solution over the patterned AgNWs on a silicon surface. Subsequently, it was dried in air and peeled off from the silicon (Fig. 4A) [56,57]. This free-standing, flexible, biocompatible, and surface-conductive silk fibroin film exhibited an optical transparency of ~80% transmission (at 550 nm). It also had highly stable electrical conductivity independent of the film's thickness with a low sheet resistance of ~15 Ω sq.−1 [56]. The surface-conductive AgNWs-silk fibroin film was applied as an electrode for a light-emitting diode (LED) chip (Fig. 3C), or as a radio-frequency (RF) antenna for food sensors that could detect food spoilage in conjunction with a silk-based resistor, similarly constructed from silk and patterned AgNWs (Fig. 3D–G) [56]. Being permeable to gases, the AgNWs-silk fibroin sensor worked by having the silver component served as a poison indicator which detected the presence of sulfur (S) found in the odor of spoiled or rancid food. Sulfur reacts with silver to form Ag2S which greatly decreases silver's electrical conductivity [56]. After exposure to rancid food for 1 h, the resistance almost tripled (Fig. 3G) as compared with exposure to fresh food. Tao et al. also reported that silk-based food sensors, functionalized with an array of micro-metamaterial wireless passive antennas that spanned the megahertz to terahertz regions of the electromagnetic spectrum, were applied on the curved surfaces of fruits or perishables such as dairy products to monitor fruit ripening or food spoilage through conformal surface contact (Fig. 5). For liquid food samples, these sensors served the same function through immersion [11].

Fig. 4. Silk fibroin/metal nanowires conductive substrate, types of inter-wire junctions, and silk fibroin stretchability (i.e. patterned and non-patterned, with and without prestretching) (A) Schematics showing the preparation of silk fibroin/silver nanowires (SF/AgNWs) transparent conductive substrate. (B) Schematic of junctions between solution-processed Ag nanowires (upper) and electropsun Cu nanowires/nanofibers (down). (C) Representative stress-strain curves of silk fibroin films before and after being stretched along the prestretching direction. (a) RSF-E film, (b) RSF-E-2, and (c) RSF-E-3. The silk fibroin film with a thickness of ∼200 μm was submerged in an ethanol/water solution (80/20, v/v) for 24 h to be water-insoluble and named RSF-E. To carry out prestretching, the RSF-E films were swollen in water for ∼30 min and then were mounted on an Instron 5565 tensile testing machine and stretched to a total strain of 100 or 200% at a pulling speed of 500% min−1. This corresponded to a draw ratio (the ratio between specimen length after stretching and before stretching) of 2 or 3. To fix this extension, the prestretched films were dried on the machine under the stress at 25 °C and 50 ± 5% relative humidity (RH) for at least 3 h. The strips were further dried under vacuum for >48 h and were labelled as RSF-E-2 and RSF-E-3, respectively. (D) Scanning electron microscopy (SEM) images of stretched silk film with stripe pattern, and with grid pattern (F), respectively. (E) Dark-field image of stretched silk film with stripe pattern. To prepare the patterned silk fibroin films, silk fibroin solution was first spin-coated and dried on PDMS template to form patterned silk films, which were then transferred to soft and tacky PDMS substrates.

Reproduced with permission from [57,71,75,76].

Fig. 5. Silk-based conformal, adhesive, edible food sensors with patterned wireless passive antennas across multiple regions (MHz, GHz, THz) of the electromagnetic spectrum. (A) A GHz resonant coil on silk fibroin film, (B) a THz resonant metamaterial array (i.e. split ring resonators) on silk fibroin film, and (C) an Au nanoparticle plasmonic array on silk fibroin film. (D) For rapid transfer of the silk antennas onto curved substrates, water vapor is applied to the back of non-crystalline functionalized silk films, yielding (E) a functionalized film in which the back surface of the film has been partially melted (i.e. moisturized back surface). (F) The melted back surface of silk fibroin film is conformally applied to arbitrary surfaces, yielding (G) applied functional sensors on a variety of surfaces; background shows an egg attached to a lab glove with a moisturized thin silk fibroin film. (H) Cross-sectional view of the silk/eggshell interface. (I) Experimentally measured reflection spectra of the eggs with (red solid) and without (blue dash) the THz split ring resonators(SRRs) sensor, respectively. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

Reproduced with permission from [11].