1. Introduction

Infrastructure systems are the backbone of modern societies by providing essential services such as energy, water, waste management, transport, and telecommunications. Infrastructure development without proper planning can harm human communities and their surrounding environment, make them more vulnerable to natural disasters, and leave them with an unsustainable debt burden (Thacker et al., 2019). It is projected that the urban areas where most of the infrastructures are concentrated will be expanded by more than two times (Ramaswami et al., 2016). An unprecedented amount of investment is being made in global infrastructure; therefore, decisions are being made now that will determine future development patterns (Thacker et al., 2019).

With the increase in demand for infrastructure services due to demographic and economic growth, urbanization, and climate change, infrastructure systems must evolve and adapt to meet society's needs effectively, efficiently, and sustainably (Morozova et al., 2019, Ramaswami et al., 2016). Several definitions of sustainability have been used, but the most general one is a development that meets the needs of current generations without compromising the ability of future generations to meet their own needs (Garren and Brinkmann, 2018). Generally, sustainability is viewed and evaluated in terms of trade-offs among three aspects: economic (generating a net positive return on investment); social (enhancing well-being); and environmental (preserving, restoring, and integrating the natural environment while ensuring resilience to climate change) (Ramaswami et al., 2016). Almost every development has been considered sustainable in the past few years; sustainability has been a key factor in design, construction, and implementation (Roostaie et al., 2019). The construction and building industry are not an exception; in recent years, civil engineers have attempted to provide a more sustainable urban life by designing green buildings and roads using environmentally friendly approaches (Ogunmakinde et al., 2022; Shani et al., 2021).

In nature, living species can be found that were formed or evolved with unique qualities to survive in their habitat or with natural processes that promote their longevity. Engineers have examined these creatures and their characteristics to create products with novel properties. For instance, mechanical engineers have used birds' bodies to improve the aerodynamics of aircraft and high-speed trains, and worms has inspired the design of machines for boring tunnels (Snell-Rood, 2016; Wang et al., 2019a, Wang et al., 2019b, Wang et al., 2019d). Architects have been inspired by termite nests to design mega buildings with sustainable ventilation, and the form of the structure of abalone nacre has inspired the production of highly durable construction materials (Fu et al., 2020; Rosewitz et al., 2019). The science and art of copying nature's time-tested patterns and strategies to solve human problems is called biomimicry (MacKinnon et al., 2020).

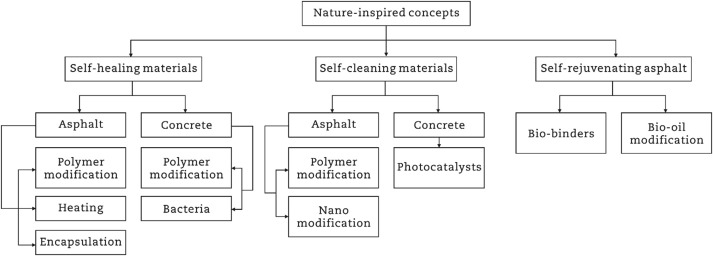

Biomimicry has affected the evolution of conventional construction materials; civil engineers have been inspired by nature to produce more sustainable and durable materials for buildings and other infrastructures. This paper aims to review the state-of-the-art studies of bio-inspired solutions for improving the built environment that focus on modifying construction materials such as concrete and asphalt. Self-healing, self-cleaning, and self-rejuvenating are the novel bio-inspired features that are reviewed throughout this paper.

To provide a comprehensive review of bituminous or cementitious materials with self-healing, self-cleaning, or self-rejuvenating properties, over 500 journal articles were collected. These journal articles were then screened based on their publication status and the journal's ranking. Only journal articles published in English in high-ranked journals (with a peer-review system) were selected first. To the extent that it did not disrupt the review's integrity, only recently published journal articles (during the last decade) were chosen for review; this was done to study the recent advances in construction materials. Fig. 1 shows the breakdown of the topics covered in the review.

Fig. 1. Breakdown of conducted reviews.

Fig. 1. Breakdown of conducted reviews.2. Self-healing materials

Self-healing is common in living species; it helps them continue their lives after an injury. In nature, self-healing can be done either at the molecular level (e.g., DNA repair) or on a large scale (e.g., reconstruction of broken bones, or closure and healing of blood vessel wounds) (Li et al., 2019b; Scheckenbach et al., 2021).

A self-healing material is one that can heal (recover/repair) damage automatically and autonomously, that is, without external assistance. Self-healing, autonomic healing, and autonomic repairing are all common terms used to define this property (Ghosh, 2009). This unique feature inspired scientists to produce materials with autonomous or semiautonomous self-healing properties. According to the literature, the initial attempts in this regard were made using polymeric materials. These polymeric materials had the ability to regenerate broken bonds through time and special conditions (Hager et al., 2010). Since then, this feature has been extended to metals, glass, and other materials (Wool, 2008).

As a highly used material in road construction, asphalt has inherent self-healing ability due to its polymeric nature. However, its self-healing ability is too slow and inefficient to call it a self-healable material on its own (Kazemi et al., 2022b). As the other popular material in construction, concrete is exposed to many distresses such as cracking. Producing self-healable construction materials would benefit society with a longer service life of roads and buildings and a lower depletion rate of natural resources (Garces et al., 2021). Thus, many civil engineers have been inspired to make the construction and building industry more sustainable by inventing mechanisms either to make asphalt and concrete self-healable or to accelerate the healing. The following is a brief review of the factors that influence the self-healing of asphalt and concrete, followed by a review of recent advances in the self-healing technology of these materials.

2.1. Self-healing asphalt

From the earliest research on asphalt self-healing in the 1960's through 2009, there was only limited research investigating the self-healing of asphalt. However, research on factors affecting asphalt self-healing has become popular in the last decade, especially in the pavement industry (Abejón, 2021; Nalbandian et al., 2021).

In the literature, factors that affect the self-healing of bituminous mixtures can be categorized into internal factors and external factors. Fig. 2 lists these factors.

Fig. 2. Factors that influence asphalt self-healing.

Fig. 2. Factors that influence asphalt self-healing.Increases in temperature or length of rest period (a period when no external loading applies to the asphalt) have a direct positive effect on the rate of asphalt healing by increasing the opportunity for asphalt to flow and fill the cracks (Li et al., 2021c; Tan et al., 2012). In contrast, higher loading intensity with larger crack width or more aging negatively affect healing by decreasing the healing efficiency of asphalt (García, 2012; Menozzi et al., 2015; Wu et al., 2019). Moisture basically has a negative effect on asphalt self-healing. Its effect varies during the healing period by temporarily increasing the healing speed at first. But it can ultimately disrupt the healing process by decreasing the surface free energy of asphalt due to the generation of hydrogen bonds between water's hydrogen atoms and some of asphalt's components (Lyu et al., 2017a, b). Grossegger and Garcia (2019a, b) reported that the presence of water in a crack prevents asphalt from flowing into the crack. In addition, the presence of water in a crack causes a change in crack geometry.

The physical properties of asphalt such as asphalt stiffness and softening point are directly related to the asphalt's viscosity and significantly affect the asphalt's healing. Higher viscosity leads to lower healing (Xiang et al., 2019a, b). Also, it was found that the thermal expansion of asphalt is a primary contributing factor in asphalt self-healing. The extra pressure created by asphalt's thermal expansion reduces the activation energy required for asphalt to flow through a tiny crack (Grossegger and Garcia, 2019a, b). Furthermore, asphalt with a higher aromatic-to-amphoteric ratio has higher molecular mobility and a higher diffusion rate due to the lower molecular weight of aromatics compared to amphoterics (Bhasin et al., 2011). Asphalt modifiers are typically polymers, and their effect on self-healing is highly dependent on the polymer type. Lyu et al. (2017a, b) investigated the bond-healing performance of asphalt modified at different polymer dosages with either styrene-butadiene-styrene (SBS), high-density polyethylene (HDPE), crumb rubber (CR), terminal-blend CR, or gilsonite. Results indicated that the HDPE, crumb rubber, and gilsonite at proper dosages could enhance asphalt's self-healing property; the others showed adverse effects (Huang et al., 2016; Lyu et al., 2017a, b; Zhou et al., 2020). Qiu et al. (2012) also reported the negative effect of polymer modification of mastics in crack closer and strength recovery. However, Fakhri et al. (2021) found that SBS-modified asphalt maintains its healing function and shows higher healing after multiple healing cycles. In addition, molecular dynamic simulation of SBS-modified asphalt showed a higher preexponential factor of SBS-modified asphalt than the neat asphalt and improvement in the diffusion rate of asphalt molecules; thus, SBS improved the self-healing of asphalt (He et al., 2020; Sun et al., 2016). This contrasting result on the self-healing of commercial polymer-asphalt could be due to two factors: the presence of an elastic polymeric network in the asphalt matrix, which promotes asphalt healing especially around the medium-temperature range; and the absoption of light components of asphalt by SBS polymer, which reduces the flowability and crack healing (Sun et al., 2020). Cheng et al. (2021) used nano-montmorillonite (MMT) to improve the self-healing of SBS-modified asphalt. They indicated that the presence of nano-particles enhanced the interaction between polymer chains and asphalt, which improved the viscosity and surface free energy of asphalt. However, they recommended the MMT-modified polymeric asphalt only for healing of micro-cracks (Cheng et al., 2021; Zhang et al., 2021b).

Due to contradictory findings on the self-healing functionality of polymers commonly used in the pavement industry (such as crumb rubber, SBS, and SBR), producing reliable self-healing asphalt pavement with these polymers is not guaranteed. So, researchers have recently produced polymers to accelerate the self-healing of bituminous mixtures in addition to improving their durability. These polymers typically have a supramolecular structure. Supramolecular polymers are polymeric arrays of monomeric units connected by reversible and highly directed non-covalent interactions, such as hydrogen bonds, resulting in polymeric characteristics in solution and bulk (Qin et al., 2020). These polymers are favorable for self-healing purposes, since they can regenerate its broken hydrogen bonds in ambient conditions (Cordier et al., 2008).

Polyurethane is one of the popular polymers synthesized for improving asphalt's self-healing. These polymers are more eco-friendly and more healable because they can use bio-oils such as castor oil, soybean oil, or palm oil as a polyol, which is a main component of polyurethane (Kazemi et al., 2021b; Vural Vural Kök et al., 2021). It was found that polyurethane bio-modified with castor oil has good compatibility with asphalt and improves the self-healing of asphalt. An increase in temperature or healing period increased the healing index of modified asphalt compared to neat samples. Higher temperature accelerates the regeneration of hydrogen bonds in polyurethane (Kazemi et al., 2021b). Polyurethane was shown to slow the aging in asphalt, which ultimately would improve asphalt's self-healing at higher ages (Shirzad et al., 2020). Polyurethane modified with castor oil showed 72% and 50% lower increases in the content of carbonyl and sulfoxide (known aging products in asphalt) after aging compared to neat asphalt, resulting in a 3.5 times higher healing index (Kazemi et al., 2022b). Lyu et al. (2021) found that the self-healing efficiency of polyurethane-modified asphalt on macroscopic fatigue cracks was due to promoting the formation of dynamic covalent bonds.

Besides polymer modification, two healing technologies have been used to intensify the self-healing function of bituminous mixtures: heating, and rejuvenator encapsulation (Fig. 3). These techniques have been used to control damage levels, reduce viscosity, and accelerate the flow, resulting in a better recovery capability of the asphalt (Ayar et al., 2016). In the encapsulation technique, rejuvenators are stored in capsules or hollow fibers and then placed in the bulk of asphalt (Shu et al., 2019; Tabaković and Schlangen, 2015). If the asphalt cracks, the crack breaks capsules, releasing the rejuvenator into the crack. The rejuvenator helps the aged asphalt to soften, flow to the crack, and close it (Gonzalez-Torre and Norambuena-Contreras, 2020). In the heating technique, the flow of asphalt would happen by healing the asphalt. Commonly, asphalt has been heated by microwave irradiation or by subjecting bituminous samples containing conductive materials to an electromagnetic field, known as induction heating (Grossegger and Garcia, 2019a, b; Norambuena-Contreras and Garcia, 2016). While these two techniques have a similar theory, they have individual advantages and disadvantages, as shown in Table 1.

Fig. 3. Technologies for self-healing asphalt.

Fig. 3. Technologies for self-healing asphalt.Table 1. Advantages and disadvantages of two asphalt-healing techniques.

| Advantage | Disadvantage | |

|---|---|---|

| Heating | ||

|

|

|

| Encapsulation | ||

|

|

|

The following two sections summarize recent advances in encapsulation technology and heating technology.

2.1.1. Encapsulation technique

As mentioned, the use of microcapsules for healing purposes can affect the mechanical function of asphalt pavements (Micaelo et al., 2020; Norambuena-Contreras et al., 2019a). So, Su et al. (2021) investigated the effects of the empty microcapsules remaining after the healing process on the mechanical responses of asphalt pavement. Results showed that broken microcapsules became filled with asphalt after rupture, and no holes were detected in the microcapsules’ original locations. Due to microcapsules' micron-size range, the influence of probable micropores on asphalt pavement is negligible (Su et al., 2021). Also, microcapsules can cause a slight reduction in the air-voids content of asphalt pavement by occupying the space in the voids of the aggregate skeleton (Ruiz-Riancho et al., 2021). Furthermore, microcapsules with relatively larger sizes were found to decrease the fatigue durability and the rutting resistance of asphalt pavement more than small-size microcapsules (Ruiz-Riancho et al., 2021). Ruiz-Riancho et al. (2021) found a direct linear relationship between an increase in self-healing and a worsening of the rutting performance by the number of capsules and the amount of oil that the capsules release. Also, the researchers found that crack healing with the encapsulation technique can delay the occurrence of reflective cracks in the pavement, but it marginally reduces the skid resistance of asphalt pavement (Norambuena-Contreras et al., 2019b; Ruiz-Riancho et al., 2021). The effectiveness of the encapsulation technique was found to be greater in an open-grade asphalt mixture like porous asphalt or stone mastic asphalt; this was due to the amount of mastic in the asphalt mixture, which influences how the asphalt gets deformed under cyclic loading and the flow of mastic (Garcia-Hernández et al., 2020; Xu et al., 2019a).

Recently, the focus of studies has been on green, sustainable approaches for producing microcapsules. Scientists have used various green rejuvenators (bio-oils) or waste oils to recover fractured bituminous pavements. Using waste vegetable oil and waste mineral oil as the core materials of sodium alginate capsules showed that changes in the water-to-oil ratio can affect the compressive strength of microcapsules; an oil-to-water ratio of 5 was the best ratio for producing microcapsules with 17.5 g sodium alginate. While both types of oils improved the self-healing of asphalt, encapsulation of waste mineral oil was more effective on asphalt mastic self-healing than encapsulation of waste vegetable oil due to higher rupture rate compared to that of capsules with vegetable oil (Yamaç et al., 2021). Among the oils (sunflower oil, engine oil, and waste cooking oil) tested by Shu et al. (2021), sunflower oil showed the best capacity for capillary flow, the best reduction in viscosity, and the highest rate of infiltration. The capillary length and wetting rate of sunflower oil at 15 °C were 2.61 cm and 2.145 m/s, respectively, and 3% wt. of encapsulated sunflower oil reduced asphalt's viscosity by 49%. An increase in temperature and the aging of asphalt increased the diffusion rate of sunflower oil. However, engine oil exhibited the best wetting and fatigue recovery. Its wetting rate at 15 °C was 43.61 mJ/m2, and it recovered up to 83.8% of the fatigue life of asphalt (Shu et al., 2021). The application of waste repair plant oil as the core material in urea-formaldehyde microcapsules was found to have negligible healing efficiency after a 1-h rest period, and an extension of the rest period had a marginal effect on its efficiency (Wang et al., 2020c). The pyrolytic oil from waste tire rubber was found to have a self-healing efficiency close to 100% at a time of 300 min of evaluation. However, due to the low stability of the pyrolytic oil-in-water emulsion over long periods, its encapsulation should happen in less than 2 h (Norambuena-Contreras et al., 2021). Li et al. (2020b) used a bio-material called “bio-asphalt” as the core material in polyurea-formaldehyde microcapsules. It was produced from soybean oil, methanol, and zeolite. Adding only 0.4% wt. of these microcapsules to asphalt improved its ductility healing by about 30%, which was twice the ductility healing of SBS-modified asphalt (Li et al., 2020b).

Apart from the contents of microcapsules, scientists have attempted to produce durable microcapsule shells; urea-formaldehyde (Li et al., 2020a; Zhang, 2020), polyurethane (Tian et al., 2020), and polyvinylidene fluoride (Guo et al., 2019) are common polymers that have been used for the encapsulation of rejuvenators. However, scientists have focused on greener materials to produce microcapsules. Calcium alginate has been used extensively in recent years as an environmentally friendly material for the production of microcapsules and hollow fibers. Calcium alginate is the insoluble form of alginate with a high swelling capacity (15–20 times more than its initial weight); it is made from salts of alginic acid obtained from algae (Kordestani, 2019).

Calcium alginate was selected not only because of its mechanical and chemical durability but also because calcium alginate helped scientists to create sponge-like microcapsules; this allows capsules to maintain oil inside the inner cavities and release it partially by the compressive pressure of vehicles. Microcapsules are prepared using high-speed mixers to disperse small droplets of rejuvenator into calcium alginate. As a result, microcapsules with multiple small cavities containing rejuvenators are formed. Having a thin shell thickness on each droplet enables the rejuvenators to release into the cracks caused by vehicle loads. This mechanism addresses the drawback of shell/core microcapsules (conventional microcapsules with a hard shell surrounding core material) that have the capability only of single-time healing. This results in an adequate release of rejuvenators into the crack proportionate to crack size and consequently better healing outcomes. Fig. 4 compares the sponge-like microcapsules and single-wall microcapsules. For calcium alginate microcapsules, the number of compression-loading cycles or their intensity increases the number of times the capsule is compressed and deformed; each cycle causes more oil to be released, with a consequent higher healing level of asphalt pavements. According to Bao et al. (2021), calcium alginate capsules showed sufficient mechanical strength at 160 °C and survived asphalt mixtures' mixing and compaction process. Nevertheless, approximately 7% of the oil was released during mixing and compaction, so it was lost before the loading cycles. These capsules returned to their original shape after compression. In addition, samples subjected to 30,000 loading cycles recovered about 45% more fracture energy and 22% more strength than samples subjected to 10,000 loading cycles (Bao et al., 2021). The researchers also modified their microcapsules with attapulgite to avoid the fast release of oil. The reinforcement enhanced the mechanical resistance of the capsules and prevented the leakage of oil during the processing of the capsules. The best capsules made of calcium alginate and attapulgite were produced with a sodium alginate solution concentration of 1.875% wt. and an attapulgite content of 12 g (Bao et al., 2020). The best ratio of alginate to oily rejuvenator was reported to be 30:70; a higher content of oil results in microcapsules with a larger diameter, larger internal pores, higher thermal resistance, and less compressive strength (Xu et al., 2019b).

Fig. 4. SEM images of different microcapsules. (a) Exterior of sponge-like microcapsule. (b) Cross-section of sponge-like microcapsule. (c) Exterior of single-wall microcapsule. (d) Cross-section of single-wall microcapsule (Bao et al., 2021; Wang et al., 2019b).

Fig. 4. SEM images of different microcapsules. (a) Exterior of sponge-like microcapsule. (b) Cross-section of sponge-like microcapsule. (c) Exterior of single-wall microcapsule. (d) Cross-section of single-wall microcapsule (Bao et al., 2021; Wang et al., 2019b).2.1.2. Heating technique

Heating of asphalt pavement is generally performed using microwave irradiation or by inducing heat using an electromagnetic coil. The electromagnetic field heats conductive particles in the body of the asphalt; microwave irradiation heats the pavement substances at an atomic level and is effective even in thick pavement layers. The studies related to heating techniques focused mostly on the effects of adding waste conductive materials or on using them as recycled aggregate in place of normal aggregate. Table 2summarizes the studies of self-healing using induction or microwave heating.

Table 2. Studies of self-healing using the heating technique.