1. Motivation

Injection of CO2 to oil reservoirs is one of the most utilized methods for enhanced oil recovery (EOR). In addition to increasing the total oil production from a field, CO2 EOR can be used in combination with CO2 storage to mitigate CO2 emissions. The method is widely used in the United States and Canada. InflowControl AS has developed an autonomous inflow control valve, AICV, which can avoid direct reproduction of CO2 to the well in fields using CO2injection. A vertical well with AICV completion is installed in the Midale field, Canada. The field has CO2 injection, and the functionality of the AICV regarding closing for water and CO2 is tested. Many CO2-EOR projects are reporting problems with breakthrough and reproduction of CO2. This results in a poor distribution of CO2 in the reservoir, and parts of the field will not be exposed for CO2. Choking back the breakthrough zones where the reproduction of CO2occurs will give a better distribution of CO2 in the reservoir and increase the oil recovery. Closing the breakthrough zones, will contribute to reduce the required amount of injected CO2, reduce the demand of separation systems and thereby reduce costs and energy demand.

2. CO2 EOR

The efficiency of CO2 injection for EOR is dependent on the miscibility of CO2 in oil (U.S. Department of Energy, 2015). When CO2 is injected into an oil reservoir, light hydrocarbons from the oil dissolve in the CO2 and CO2 dissolves in the oil. This occurs most readily when CO2 is compressed and when oil is containing a considerable volume of light hydrocarbons. When CO2 dissolves in oil, the viscosity of the oil decreases significantly. The reduction of oil viscosity is highly dependent on the initial viscosity of the oil. Less viscous oil will be less affected by the CO2, while for more viscous oils, the effect of viscosity reduction is more pronounced. The reduction in oil viscosity will cause an increase in the oil relative permeability and mobility. This will reduce the residual oil saturation in the reservoir and improve the oil recovery (Zhang et al., 2015). CO2 interacts with the oil in the reservoir and dissolves in the oil at certain reservoir conditions. The dissolution of CO2 in oil causes the oil to swell. Reservoir characteristics, as pressure and temperature as well as oil composition, determine the strength of the oil swelling effect (Zhang et al., 2015). Swelling plays an important role in achieving better oil recovery. Variations in the swelling factor influences on the residual oil saturation, which is inversely proportional to the swelling factor. Residual oil saturation, in turn, affects the relative permeability, which plays a crucial role in oil recovery (Zhang et al., 2015). Swollen oil droplets force fluids to move out of the pores and oil that initially was unable to produce will now be forced to move towards the production well. Hence, oil swelling causes drainage effect that decreases the residual oil saturation (Zhang et al., 2015). An oil reservoir also contains disconnected pores. Swelling of the oil can contribute to additional oil recovery by reconnecting the disconnected pores (Zhang et al., 2015). Swelling of oil is assumed proportional to the solubility of CO2 in the oil. Experimental research has been performed with 821 and 9.7 cP oils to investigate the swelling of oil saturated with CO2. It was found that the saturated swelling factors were 1.12 and 1.25 for the 821 and 9.7 cP oil respectively (Optimization of CO2).

Mobility ratio, M, is the ratio between water/oil volumetric flow rates. It depends on viscosity and permeability of water and oil phases. The mobility ratio is expressed by:(1)where μ is the dynamic viscosity, kr is the endpoint relative permeability and the subscripts o and w indicate the oil and water phases respectively. The endpoints are the residual oil saturation and the irreducible water saturation. Injection of CO2 changes the relative permeability curves by changing the endpoints and the shape of the curves. In addition, the viscosity of oil will decrease, and all together, this results in reducing the mobility ratio. The oil recovery efficiency increases with decreasing water-oil mobility ratio.

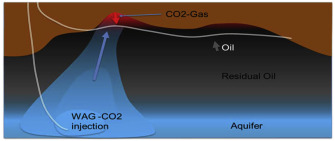

CO2 injection is often used in carbonate reservoirs. Carbonate reservoirs has usually low permeability, but very often, the reservoirs contains zones with high permeability and fractures. Due to high permeability zones and fractures, EOR schemes utilizing CO2 alternating water injection often experience significant problems and challenges with short circuiting of CO2 gas and water between injectors and producers, and thereby significant amounts of oil is left behind. This is illustrated in Fig. 1. Choking back the breakthrough zones where the reproduction of CO2 occurs will give a better distribution of CO2 in the reservoir (Fig. 2), increase the oil recovery and reduce the required amount of injected CO2. The redistribution of the injected fluid after choking back the breakthrough zone are dependent on the zonal isolation along the well. Packers are used to avoid crossflow in the annulus. If the reservoir has a major crossflow between the different layers, the fluid will bypass the packers through the reservoir and the zonal isolation will be difficult and result in a poorer redistribution of the injected fluid.

Fig. 1. Illustration short circuiting of CO2 gas and water between injector and production well.

Fig. 1. Illustration short circuiting of CO2 gas and water between injector and production well. Fig. 2. Illustration of improved distribution of CO2 in the reservoir by choking back the breakthrough zone.

Fig. 2. Illustration of improved distribution of CO2 in the reservoir by choking back the breakthrough zone.Fig. 3 shows the production history of the Midale field, and the increased oil recovery due to CO2 injection. In 2014, efforts were done to improve the oil recovery further, and the efforts succeeded by reducing oil declines, increasing oil production and reducing costs associated with injection quantities. However, further improvements were possible by utilizing inflow control technology, and the world's first field trial of the AICV in a water and CO2 injection scheme, and the world's first comparison with conventional ICD technology in the same well were started (Kais et al., 2016). The AICV technology opens up for increasing the drawdown and thereby increasing the production rates if wanted. The AICV has to be designed based on the properties in the specific reservoir. Closing off the flow of CO2 or carbonated water to the production well and getting a better distribution of CO2 in the reservoir, also contributes to storage of CO2 in the reservoir during the period of oil production. To choke back the breakthrough zone the AICV technology need to have some difference in viscosity or density in order to differentiate the flow through for the different fluids. However, water has usually lower viscosity than oil. CO2 gas has always lower viscosity than oil and water. For oil and water with equal viscosity the density difference is sufficient for the technology to differentiate between the phases. The installation of an AICV well is usually done with sand screens and packers, the same way as for ICD well. The packers in the AICV well will be exposed to higher differential pressure than the ICD well, due to the choking of the breakthrough zone. This requires packers that can resist the high-pressure differences.

Fig. 3. Midale production history and production response since the 2014 integrated approach (Kais et al., 2016).

Fig. 3. Midale production history and production response since the 2014 integrated approach (Kais et al., 2016).3. AICV technology and design for CO2 EOR in Midale

The AICV has the feature to distinguish between fluids, based on fluid viscosityand density, and the AICV design is adapted to the conditions and requirements in the relevant field. The functionality of the AICV, which is to keep open for high viscous fluids like oil, and to close for fluids like water and gas, is based on the difference in the pressure drop in a laminar flow element compared to a turbulent flow element as illustrated in Fig. 4. The main flow enters a conduit, A, at inlet pressure P1 (reservoir pressure). The pilot flow is passing through a laminar flow element where a pressure drop occurs and the pressure is reduced to P2. The flow is further flowing through the turbulent flow element before it exits the flow conduit at the well pressure, P3. The fluid properties and flow rate of the pilot flow determine the pressure, P2, which is the pressure controlling the valve functionality. The AICV is designed to let approximately 99% of the total flow go through the main flow and the rest through the pilot flow. When the valve is closed, the minor pilot flow represents the total flow rate through the valve.

Fig. 4. The pressure drop through a combination of laminar and turbulent flow restrictors in series.

Fig. 4. The pressure drop through a combination of laminar and turbulent flow restrictors in series.The laminar flow element (LFE) can be considered as a pipe segment and the pressure drop is expressed as:(2)where is the laminar friction factor , is the fluid density, is the fluid viscosity, ν is the fluid velocity, and is the length and diameter of the laminar flow element respectively. The pressure drop through the pipe segment is proportional to the fluid viscosity and the velocity. The turbulent flow element (TFE) can be considered as a thin plate orifice. The pressure drop through an orifice is given by:(3)where k is a geometric constant. The pressure drop through the turbulent restrictor is proportional to the fluid density and the velocity squared. The lower plot in Fig. 4 shows the pressure at different positions along the pilot flow path for oil, gas and water, respectively. When the pressure drop through the laminar flow element is high, as for oils, P2 is low and the valve will stay in open position producing oil. When low viscous fluids flow through the LFE, the pressure drop is low, and the pressure in B is high. The high pressure will actuate a piston, and the valve will close. Fig. 5 illustrates the AICV in open and closed position.

Fig. 5. AICV in open and closed position.

Fig. 5. AICV in open and closed position.The force balance around the piston is controlling the piston position, as shown in Fig. 6. The force, F1, on the upper part of the piston (P1∙A1) is acting downwards and the force F2 below the piston (P2∙A2) is acting upwards. Ffric is a friction force, which will work against the direction of fluid flow. Ffric will mostly be normal to F1, F2 and F3. F3 is acting downwards on the outer part of the piston. Most of the pressure drop of the main flow is located at the smallest passage, between the piston and the seat. The size of this opening will define the ICD strength of the AICV. When the net force (F1-F2+F3±Ffric) is positive, the valve is in open position and if the net force is negative, the valve closes. The ratio between A1 and A2 is a design parameter and the optimum ratio is dependent on the properties of the oil, gas and/or water.

Fig. 6. The areas and forces acting on the AICV piston.

Fig. 6. The areas and forces acting on the AICV piston.The AICV technology is described earlier (Mathiesen et al., 2014; Aakre et al., 2013a, 2013b, 2014; Kais et al., 2016).

A vertical well with AICV completion is installed in the Midale field in Saskatchewan. The reservoir is perforated in three sets at three different depths. The vertical well includes two AICVs in each of the three perforated zones, i.e. totally six AICVs. The Midale field is a heterogeneous field, and due to differences in permeability, the production rates from the three zones differ significantly. One of the perforated zones has high production rates whereas the other two have low rates. The advantage of AICV is that the same design can be used for all the three production zones, as long as the valves are designed to close or choke for unwanted fluids. Packers are installed to isolate the zones and avoid annulus flow from one zone to another. Fig. 7 shows an AICV mounted in a base pipe with sand-screen.

Fig. 7. AICV mounted in the base pipe with sand screen.

Fig. 7. AICV mounted in the base pipe with sand screen.The AICV used in this project, is designed to keep open for oil and choke for supercritical CO2 and water. Water has a higher viscosity than CO2, which implies that if the valve is designed to choke for water, it will also close for CO2. The most important design parameter for the AICV functionality is the oil/water viscosity ratio. The viscosity ratio in the near well area for the actual field is about 6.5, which is an acceptable ratio to give a good oil/water/CO2 separation. The higher viscosity ratio there is the easier to design an AICV to close for water and CO2 and keep open for oil. The design is also based on flow rates as a function of pressure drop over the AICV. The flow rates are specified by the customer and are based on the reservoir and fluid properties. An AICV for the Midale field is constructed and tested.

4. Production data from the Midale field

Kais et al. (2016) have published the results of the world's first field trial of the AICV in a water and CO2 injection scheme, and a selection of the results from the trial well with AICV are presented here. The focus was to increase the oil production as much as possible, and therefore the total liquid flow should be kept high. The average liquid and oil production rates before the recompletion of the well were 1100 bpd and 5 bopd respectively. The production had to be run with a low drawdown to avoid the total flow to exceed the capacity of the production and separation system. Table 1 presents the performance data for the trial candidate well before installation of inflow control completion.

Table 1. Well performance summary of trial well (Kais et al., 2016).

The well with ICD and AICV completion was tested and the results were compared to the results without inflow control. When using AICV completion, the drawdown can be increased and more oil can be produced from the low permeability zones M1 and M2. The tubing head pressure (THP) was decreased from 7100 kPa to 4400 kPa, which provides a corresponding increase in drawdown. The average oil rate increased from 5 to 39 bodp, which is an improvement of 690% on the oil rate. The summary of the results from the AICV and ICD completed wells is presented in Table 2. However, these results were poorer than expected for AICV most likely due to a damaged plug below the zone M3. Fluid from M3 was bypassing the AICVs and flew into the well via the damaged plug. Due to this, the main advantage of AICV (closing off the water production zone) did not appear in the results. However, the production from the low permeability zones can be assumed realistic.

Table 2. Well performance summary – AICVs, data from (Kais et al., 2016).

| Result summary | Highest rates | Averages | ||||||

|---|---|---|---|---|---|---|---|---|

| Liquid | Oil | Liquid | Oil | GOR | THP | Oil cut | WC | |

| bdp | bopd | bdp | bopd | Scf/bbl | kPa | % | % | |

| Base line, no ICDs or AICVs | 2050 | 10 | 1100 | 5 | 32,000 | 7100 | 0.4 | 99.6 |

| ICD completion | 3500 | 72 | 3500 | 45 | 10,500 | 3500 | 1.3 | 98.7 |

| AICV completion | 4800 | 57 | 3100 | 39 | 12,500 | 4400 | 1.3 | 98.5 |

| Improvement | 130% | 460% | 180% | 690% | −60% | −40% | 180% | −1.1% |

5. Near well simulation of the trial well in the Midale field

The vertical trial well in the Midale field in Saskatchewan is simulated using the near well simulation tool NETool. NETool is a steady state near well simulation tool, and can be used to analyse the effect of different completion components, near-wellbore effect on productivity of the well, modelling of completion components in the production and injection interval, design of inflow control devices to delay water and gas breakthrough, etc. NETool can be linked with reservoir simulators such as Eclipse and Nexus, but this link is not used in this study. The Black-oil model is implemented in NETool, and is used in the simulations carried out in this study. The Black-oil model was used in this work, and is often used when limited specification about the reservoir fluids are available. The basic modelling assumption for the Black oil is that the gas may dissolve in the liquid oil phase, but no oil will dissolve in the gas phase. This implies that the composition of the gas phase is assumed to be the same at all pressures and temperatures (dwsim).

NETool can run simulations for various well completion designs, and one of the most important benefits of NETool is the ability to design and evaluate completion designs in a timely manner (NETool). This includes the evaluation of different types of passive and autonomous inflow control devices (ICDs and AICDs). NETool allows the user to modify the functions for ICDs and AICDs, and in that way, it is possible to adjust the functionality of the implemented types of AICD to also fit the functionality of AICV.

In this study, the reservoir conditions have been considered as steady state for the particular cases, and NETool has modelled the wellbore and completion hydraulics in detail. The input to NETool is reservoir conditions, fluid properties, and well design including annulus, pipeline, inflow control devices, screens and packers. The reservoir is specified by depth, porosity, saturation of the phases, permeability and relative permeability. The phase saturation, permeability and porosity can be specified for each zone.

There is no option to calculate relative permeability curves in NETool, so the user has to implement the current values. In this work, the Corey and Stone II correlations were used to calculate the relative permeability curves for water and oil. The Corey model is derived from capillary pressure data and is a good approximation for the relative permeability curves for water in a two-phase system. The relative permeability for water, , is given by:(4)where is the water saturation, is the irreducible water saturation, is the residual oil saturation, is the end point relative permeability for water at maximum water saturation, and is the Corey exponent. (Tiab and Donaldson, 2012).

The Stone II model is used to calculate the relative permeability of oil. The Stone II model estimates the relative permeability of oil in an oil-water system based on the following equation:(5)where Krow is the relative oil permeability for the water-oil system, is the endpoint relative permeability for oil in water at irreducible water saturation and is a fitting parameter for oil. (Tiab and Donaldson, 2012) The irreducible water saturation is the maximum water saturation that a rock can have without producing water. Residual oil saturation represents the oil that cannot be produced by primary and secondary oil recovery. The exponents, and , are functions of the pore size distribution in the reservoir, and typical values are nw = 2–3 and now = 6–8. (Ghoodjani and Bolouri, 2011) The oil and water saturation in the reservoir was specified for each zone. In addition fluid properties as viscosity and density are specified and used in combination with the Black-oil model.

Fig. 8 shows a principle sketch of the simulated vertical well and the location of the different production zones. The production zones are located below 1410 m depth. The sketch including well and production information are used as basis for NETool simulations. The different production zones (M1, M2 and M3) have different permeability, and most of the oil and water are produced from the high permeability zone, M3. In the simulations, the horizontal permeability is set to 5 mD in zone M1, 50 mD in M2 and 2000 mD in M3. The vertical permeability is 1/10 of the horizontal permeability. Since M1 and M2 have low permeability compared to M3, it is assumed that these two zones have still high saturation of oil, whereas M3 is almost 100% saturated with water. The oil saturation is set to 1.0, 0.9 and 0.0 for zone M1, M2 and M3 respectively. Table 3presents the data used as input to NETool. The relative permeability curves are estimated based on Corey and Stone II, and is assumed to be influenced of the CO2 injection. There are no available data on the relative permeability in the appropriate field. The Midale field is a carbonate field, and few data are available for this rock type. However, the rock type does not influence significantly on the relative permeability other than through the wetting preference (Schneider and Owens, 1970). In the simulations, the reservoir is assumed to be water-wet, and the relative permeability curves used are presented in Fig. 9. As zone M3 is 100% saturated with the water, the permeability will be the permeability for water and the relative permeability is 0.175. In zone M2, the reservoir is 90% saturated with oil, and regarding the relative permeability curves presented in Fig. 4, the permeability of oil will not be influenced by the water as long as the water saturation is lower than 0.3. This means that both in M2 and M3 the relative permeability of oil is 1. When CO2 is injected into the reservoir, the permeability of oil and water changes as described in the introduction. The residual oil decreases, which means that more oil can be produced from the reservoir. This is taken into account by the relative permeability curves used in the simulation. The water phase is assumed as carbonated water, and the injection rate and mode of CO2 injection are therefore not considered in the simulations. The simulations are steady state simulations, and the saturation of oil and water in the different zones is constant.