1. Introduction

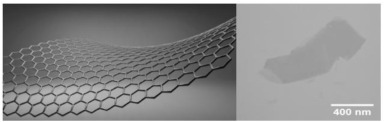

The isolation of graphene was first demonstrated in a repeatable manner in 2004 by Novoselov (2004). Novoselov and Giem later earned a Noble Prize in Physics for this work (Kungl. Vetenskaps-Akademien, 2010). Graphene, a single atom thick planar monolayer of graphite, is composed entirely of sp2 hybridized carbon atoms that are covalently bonded in a two-dimensional (2D) honeycomb lattice (Slonczewski and Weiss, 1958). The unique properties of graphene and its derivatives has made it the focal point for extensive research. Graphene exhibits high electrical conductivity as well as mechanical strength (Dreyer, 2009). The electrical conductivity has been measured to be approximately 7200 S/m while the thermal conductivity has been recorded in the range of 1800–5800 W/mK at room temperature (Kuilla, 2010) (Balandin, 2008). With a tensile or intrinsic strength of 130 GPa, Young's modulus of 1.0 TPa, and breaking strength of 42 N/m, graphene can be considered one of the strongest materials ever measured (Lee, 2008). To put it in perspective, graphene is 50 times stronger than steel in terms of mechanical strength, yet has one-half the density of aluminum (Ciriminna, 2015). Other properties that add to the utility of graphene include a resistivity of 10-6Ωcm, electron mobilityof 20,000cm2/Vs (at 300 K), and theoretical surface area of 2620 m2/g (Craciun, 2010). Graphene has been studied for its applicability in a many different fields including biodegradation, flexible electronic devices, spintronics, photonics, optoelectronics, sensors, energy storage and conversion, and biomedical to make a few (Ferrari, 2015) (Liang, 2009). Its robust electrical properties along with high optical transparency and flexibility makes graphene a potential candidate in the applications such as touch-screens, liquid crystal displays(LCD), photovoltaic cells, or organic light-emitting diodes (OLED) (Geim and Novoselov, 2007). Graphene has potential in nano-applications in many scientific and industrial fields including the study of nano-electronics, molecular separation, composite additives, catalysis, nano-sensors, and transport (Wang, 2011) (Gaikwad, 2012). While graphene has been studied extensively for applications in many fields, its presence in the oil and gas industry is still developing. Fig. 1 shows an image on graphene.

Fig. 1. Structure of graphene sheet and actual microscopic image (Advincula, 2014).

Fig. 1. Structure of graphene sheet and actual microscopic image (Advincula, 2014).The oil and gas industry is a multi-billion dollar market that effects the lives of any person who has ever driven a car, used electricity, walked on asphalt, or used polymeric products like plastics (Matar, 2001). With the world liquid fuelconsumption projected to increase in the coming years and the amount of easily obtainable oil decreasing, applying new technology to this industry will be crucial to fulfilling the world's energy needs in the future (US Energy Informatin Administration, 2016). Nanotechnology including graphene and graphene derivatives have shown potential in the oil and gas industry in the areas of drilling, shale inhibition, rheology modification, wellbore strengthening and stabilization, sensing, coatings, hydraulic fracturing, lubricity, emulsion stabilizers, desalination, and oil spill cleanup just to name a few (Genorio, 2012) (Hoelscher, 2013) (Aftab, 2016). Graphene derivatives, such as graphene aerogels, foam, sponges, modified membranes, and graphene oxide (GO) membranes have shown promising application in oil spill cleanup technology, desalination processes, and emulsion stabilization. The characteristic superhydrophobicity and superoleophilicity of graphene derived products allows for efficient oil-water separation (Bi, 2012). Desalination using graphene membranes could be a viable alternative to traditional desalination techniques because of the thickness, high mechanical strength, high water flux, and efficient ion rejection rate as well as a lower energy consumption and operating cost (Tellez, 2002) (Feng, 2016).

The purpose of this paper is to discuss the technology of graphene and graphene derivatives and their applicability to the oil and gas industry. The paper will briefly discus the major synthesis methods then it will introduce some of the main topics that are directly relatable to current oil field processes such as drilling, as well as larger industrywide issues like desalination needs, oil-spill cleanup, and emulsion stabilization. As interfacial phenomena is the scope of the paper, those topics pertaining to graphene will be discussed at length. While the oil and gas industry has been a late adopter of nanotechnology, including graphene and graphene derivatives, there has been an increase in graphene related research in recent years as it pertains to the industry.

2. Graphene synthesis

There are multiple ways to synthesize graphene. The majority can be classified into four categories; exfoliation and cleavage, chemical vapor depositiontechniques, chemically derived techniques, and other synthesis methods.

Very simplistically, exfoliation and cleavage methods involve the physical peeling of layers off pure graphite. This method was first attempted and explored by the Viculis group (Viculis, 2003). It was later perfected by Novoselov by using highly oriented pyrolytic graphite sheets that were dry etched in oxygen plasma, stuck on a photoresist, and peeled off using ordinary scotch tape (Novoselov, 2004). For this reason, the main exfoliation and cleavage method is sometimes termed the “scotch tape method”. Since graphite is comprised of layers of uniformly stacked graphene bonded by van der Waal forces, it is conceptually feasible that those graphene layers can be separated and isolated. Fig. 2 shows an example of the scotchtape method.

Fig. 2. Mechanical exfoliation of graphene from highly oriented pyrolytic graphite (HOPG) (Singh, 2011).

Fig. 2. Mechanical exfoliation of graphene from highly oriented pyrolytic graphite (HOPG) (Singh, 2011).Chemical vapor deposition (CVD) methods include thermal CVD, plasma enhanced CVD, as well as thermal decomposition on substrates to name a few (Singh, 2011). The first CVD growth of planar few layer graphene on a metal surface was reported in 2006 (Somani, 2006). Of the graphene methods currently being used, CVD methods are very common and seem to be the most promising for future large scale production of mono-layer and few-layer graphene films (Singh, 2011). CVD techniques can be very complicated processes, but at their core theory they involve first chemically etching a metal substrate. Various substrates have been successfully utilized (Stankovich, 2017). After the chemical etching, the graphene layers are isolated, removed, and transferred to another substrate. The graphene is then obtained from the second substrate in high quality layers and in larger quantity than some of the other methods provide.

Chemically derived techniques for graphene synthesis refers to the conversion of graphite into a graphite derivative and then through a viable chemical process, convert the derivative into isolatable graphene. By far the most researched and most popular chemically derived technique involves converting graphite to graphene oxide (GO) and then using GO to obtain graphene or using the GO directly. The major GO synthesis method, known as “Hummers method” involves the oxidation of graphite using sulfuric acid, nitric acid, and potassiumpermanganate (Hummers and Offeman, 1958). Graphene Oxide is then converted to a pure graphene through a variety of different routes, or the graphene oxide is utilized as a standalone substance for experimentation. Due to its similar properties to graphene, GO is just as popular as graphene in scientific research and experimentation.

Other synthesis methods is a broad class used to categorize the other graphene synthesis techniques that cannot be classified in the previous three sections. The most common technique appearing in this category is unzipping carbon nanotubes (CNT). By using CNTs as a starting material, it is possible to open or “unzip” them in the vertical direction using intercalation of lithium and ammonia and then sequential exfoliation in acid and heating (Cano-Marquez, 2009). This process produces multi-walled carbon nanotubes, nanoribbons, and pure graphene flakes. Plasma etching of nanoribbons is also a common nanotube treatment method to produce graphene (Jiao, 2009).

3. Graphene applications in the oil and gas industry

As previously mentioned, graphene and its derivatives have been vigorously studied for many years. However, graphene as it pertains to the oil and gas industry is a more recent topic of interest. Despite its relativity short record, there has already been many applications of graphene and graphene derivatives to the energy industry with a future outlook that is promising. Some of the main applications include drilling, cementing, enhanced oil recovery, desalination, oil spill cleanup, and emulsion stabilization, as well as others such as improvement to coatings and elastomers.

3.1. Drilling

Drilling is a crucial step in the recovery of hydrocarbons from the earth. A key factor in drilling is the use of drilling fluids. Some of the functions of drilling fluids include carrying the formation cuttings to the surface, lubricating the drill bit, and controlling pressure in the well by maintaining hydrostatic pressure. The use of graphene and graphene oxide can improve fluid loss control, rheology, lubrication, and shale stability. Traditional drilling fluid is not simply circulated water. It is a dense solution, usually bentonite based that contains additives. Even though the bentonite solution is denser than the wellbore fluid, due to its particle size it is not dense enough to completely control fluid loss. Nanoparticles, such as graphene or graphene oxide are much smaller and far more dense than bentonite. For this reason, graphene has been studied as a viable option for drilling fluid in the use of fluid control loss. One study concluded that even though graphene is small enough, its lateral size leads to flocculation and poor dispersion in well fluids (Xuan, 2013). However, modified graphene oxide maintains its morphology as well as resists permeation allowing it to act as a superior fluid loss control additive. The same study by Xuan and Li showed that by using a graphene oxide additive, fluid loss levels that are better than bentonite could be achieved with 10 times less additive.

Not only is fluid loss control important, but the rheological properties of the drilling mud in general must be considered. Poor rheology will result in a lower penetration rate, hotter drill bit, and potentially more downtime. A study by Aftab and Ismail investigated the effects of using graphene nanoplateletscompared to other additives in water based drilling mud (Aftab and Ismail, 2016). The results showed that graphene had the best results on enhancing rheological performance especially in high temperature high pressure situations (Aftab and Ismail, 2016). It was hypothesized that the reason for the better performance was due to the low friction between the nanoplatelets, other additives, and the fluid.

A factor directly intertwined with rheological properties is shale stability. When drilling in a shale formation, it is common for water in the drilling fluid to interact with clay materials in the shale and cause swelling. This swelling affects the flow of the drilling fluid and causes the penetration rate to decrease. For this reason, it is not uncommon for shale inhibitors to be added to drilling mud to try to reduce or eliminate the swelling. Graphene derivatives have been tested for their applicability to shale inhibition. Graphene oxide was found to serve as an excellent transport vehicle for the improvement of inhibition as well as an effective shale inhibitor for high temperature high pressure applications (Friedheim, 2012).

Graphene and graphene derivatives have been considered a viable option as a drilling fluid additive by industry leading oil field service companies. M-I SWACO, a subsidiary company of Schlumberger, has been working in conjunction with Rice University to explore graphene oxide as an additive to water base drilling mud (Kosynkin, 2012). In 2011 and 2012, Baker Hughes (currently Baker Hughes, a GE Company) filed for two United States patents for graphene containing fluids used in oil and gas exploration, production, drilling fluids, and completions fluids (United States Patent No. 0245058A1, 2012) (United States Patent No. 8822386B2, 2011).

3.2. Lubricant

A major contributing factor to the applicability of graphene derivatives to drilling fluids is the impermeable membrane properties as well as its lubricating properties. However, graphene shows promise as a lubricant for many other things aside from drill bits. The very thin structure of graphene and its ability to be evenly distributed on a micro-scale and nano-scale by simply using graphene flakes in solution allows graphene to be applied to much more than just drilling applications (Berman, 2014). In multiple studies, computational methods were used to determine the changes in friction properties of graphene at a nano-scale level. The studies showed that as the number of graphene layers increases the friction between the layers and the medium decrease and that as the number of graphene layers increased the friction between each graphene layer increases (Xu, 2011) (Lui and Zhang, 2011). A micro-study of graphene yielded similar results. The study conducted by Kim et al. found that adhesion and friction properties were reduced by using graphene deposited on Ni and Cu substrates and fused silica and polydimethysiloxane lenses (Kim, 2011). When considering modified graphene, friction tends to increase while adhesive properties are reduced or remain the same as a result of reduction in van der Waal's contact area (Balandin, 2008).

3.3. Desalination

Reservoirs usually contain petroleum hydrocarbons in the form of liquid, gas, or both along with varying amounts of water. It is generally believed that rock in the majority of oil-bearing formations were originally saturated with water prior to the introduction and trapping of petroleum through drainage or imbibition mechanisms (Amyx and Bass, 1960). Water, either produced or injected, is used in the many oilfield production applications including gas and liquid natural gas (LNG) operations, oil sands, steam assisted gravity drainage(SAGD), conventional, and unconventional (Adham, 2015). The amount of water that is utilized varies from application to application. For example, when dealing with oil sands, water is used as a lifting solution for the oil (Clariet, 2013). This water intensive process requires around 4.5 barrels of water for each barrel of oil produced (International Desalination Association, 2013). SAGD operations require approximately 4 barrels of water to produce a barrel of oil. When considering produced water as opposed to injected water, usually 3 to 4 barrels of water are produced for each barrel of oil for conventional operations (Adham, 2015). In unconventional operations, this ratio can be 7:1 or higher (Burnett, 2004). Generally the longer a well is being produced through primary recovery methods (conventional), the more water will be produced.

Produced water is the largest waste byproduct in the oil and gas industry (Veil, 2004). Besides the cost of lifting water out of a reservoir, the water must be processed, treated, reinjected, or disposed. Depending on the toxicity and composition of the produced water, it must be treated for oil contamination, organic materials, particles, and/or salts; with salts being the major contributor of toxicity (Ahmandun, 2009). Discharging large volumes of contaminated water to the environment has become a growing concern and has resulted in more strict regulations and permitting by governments (Tellez, 2005) (EPA, 2017). The oil and gas industry represents 14% of the desalination market share, a multibillion dollar market (Adham, 2015). Advancement in desalination technology will allow produced water to be transformed from an environmental and economic burden on energy companies to a valuable byproduct that can be used for reinjection, irrigation, industrial uses, fire control, or in aquifers (Veil, 2004).

Graphene and graphene derivatives have had the focus of study in recent years for its application in desalination. Graphene based materials and membranes have proven to be extremely effective in salt rejection (You, 2015). Developments in desalination using graphene have the potential to help solve some of the wastewater issues that currently burden the oil and gas industry. The fact that graphene in its pure form is strongly impermeable to liquid and gases makes it a prime candidate for desalination technologies. The two main areas of graphene desalination research are the use of a nanoporous grapehene membrane and the use of stacked graphene oxide sheets.

The general concept of using a nanoporous graphene membrane for desalination is as follows. Since graphene is impermeable to liquid and gases, even though it is extremely thin, it should be possible to create nano-pores in the single layer graphene that allows the passage of water, but blocks the passage of larger ions. This concept arose from research on carbon nanotubemembranes and their permeability to water using unique structures (Alexiadis, 2008). The pore selectivity would be two toned. First off, it is size selective and secondly by electrostatic repulsion between the salt ions and the pore. This concept is summarized in Fig. 3.

Fig. 3. Nanoporous graphene membrane selectivity (Perrearult, 2015).

Fig. 3. Nanoporous graphene membrane selectivity (Perrearult, 2015).Tests have shown that using nanoporous membranes for water treatment can produce purification rates of 400–4000 Lmˆ2/hbar; a rate that substantially higher than reverse osmosis membranes (Cohen, 2012). The nanoporous membrane can also reject salts at a comparable or higher efficiency than the osmosis membrane even with higher water volumes. More efficient membranes can result in overall higher water treatment volumes or smaller facilities can be utilized to achieve the same volume as current production. The largest issue to overcome with nanoporous membranes is controlling the pore size in a consistent, reproducible manner. In addition, pure graphene is expensive especially in large quantities.

The stacked graphene oxide method was first used by the Nair group when they realized that stacking graphene oxide membranes allows water to pass through while blocking permeation of gases and non-aqueous solutions (Nair, 2012). Unlike graphene, graphene oxide is much cheaper to purchase or synthesize. By stacking graphene oxide membranes, hydrophobic “channels” are created from unoxidized regions of each membrane. The stacked membranes have been showed to reject salts and other organic molecules in a similar fashion to a nanoporous graphene membrane (Nair, 2012). Fig. 4 is a pictorial representation of this process.

Fig. 4. Stacked GO membrane selectivity (Perrearult, 2015).

Fig. 4. Stacked GO membrane selectivity (Perrearult, 2015).Tests have shown that using stacked GO membranes can achieve water treatment rates of 22–71 Lmˆ2/hbar (Cohen, 2012). These rates are much lower than pure graphene but GO membranes are also less expensive. Since the main mechanism of separation is pore size, there are issues with GO membranes that are currently being studied. The main issues are that channel widths are larger and have less selectivity than nanoporous membranes and the decreasing quality and quantity of filtered water overtime using the GO membranes. A joint issue with nanoporous and GO membranes is being able to upscale the desalination processes from a laboratory size to an industrial size.

3.4. Other uses

Another use for graphene oxide is as an additive for cement. As a well is being drilled, casing must be inserted in order to add structural stability and prevent an inward collapse. Each section of the casing must be cemented into place. Having solid reliable cementing jobs is critical for the success of the well. A study on cement additives researched the effects of using graphene oxide as an additive to enhance the properties of cement. The study results were positive, showing that adding quantities as low as 0.05% GO can result in an increase of 41%–59% in flexural strength, 13%–33% in compressive strength, and an increase in ductility (Mangadlao, 2014). The study also presented that GO may help prevent microbial induced corrosion, which is an issue in production wells over time.

Corrosion has been a major issue in the oil and gas industry since its inception. It affects pipelines, production tubing, casing, and just about any type of downhole equipment that is not made of plastic. Graphene and its derivatives have been investigated for their application as a corrosion resistant coating for downhole metal equipment. The advantages of using graphene as a coating include its strong mechanical and electrical properties, its impermeability to gases and liquids, low chemical reactivity, as well as the fact that the coating could be substantially thinner than a traditional coating while in theory having superior performance. In one study, a 200 nm thick graphene oxide hybrid coating was applied to stainless steel. The study concluded that the GO coating by itself did not provide much corrosion resistance, but as part of the hybrid blend, it provided excellent results (Mondal, 2015). A second study utilized an oil-based graphene oxide base as a coating for cold-rolled steel in a seawater environment (Singhbabu, 2015). The study concluded that in a high salt environment, the use of their graphene oxide coating was highly effective and reduced the corrosion rate by over 10,000 times when compared to the non-coated control group steel. In a final study conducted by the Dumee group, pure graphene nano-flakes were grown directly on a stainless steel substrate (Dumee, 2015). The group successfully grew between 3 and 15 layers on the steel which resulting in enhanced corrosion resistant and electrical properties without affecting the properties of the stainless steel substrate. The experimental growth can be seen in Fig. 5.

Fig. 5. Graphene growth on stainless steel as a function of time (Dumee, 2015).

Fig. 5. Graphene growth on stainless steel as a function of time (Dumee, 2015).Just as graphene and graphene derivatives have proven to be worthy additives in cements and coatings, they can also be used to enhance the properties of elastomers. Elastomers are used for a variety of different things in the oil industry. The most common use for elastomers are on downhole equipment such as packers, plugs, or components of artificial lift systems. Regardless of their role, the elastomer must be able to withstand rigorous downhole conditions including high temperature and high pressure situations. With the increase of SAGD operations, there is constantly a need for enhanced elastomer properties. In a study by Wei and Jacob, graphene oxide and reduced graphene oxide (RGO) was used to enhance a fluoroelastomer at standard and high temperatures (Wei and Jacob, 2013). The study concluded that by using GO and RGO as enhancements, stress resistance increased by 28% at room temperature and 49% at elevated temperatures and the aspect and modulus ratios both greatly increased. Similar to coatings, graphene oxide and reduced graphene oxide function better as enhancement to elastomers additives as opposed to standalone additives.

3.5. Oil spill cleanup and separation

One of the largest critiques of the oil and gas industry are its potential effects to the environment. Normal oilfield operations such as drilling, fracking, and pipeline expansion are constantly the target of environmental groups, personal activists, and government lobbyist. However, the largest environmental issueassociated with the oil and gas industry will always be oil spills, and more specifically oil spills in bodies of water. The BP oil spill, which was the largest spill in US history, resulted in over 200 million gallons of crude oil being dumped into the Gulf of Mexico and damaging over 16,000 miles of coastline (Jarvis, 2010). After this major spill, oil cleanup technology and oil-water separation technology has become a hot topic both in the United States and abroad. Graphene and its derivatives has been identified as a viable option for both separation and cleanup. Graphene membranes, foams, and aerogels are among the major areas of research for their applicability to this topic.

One application of oil-water separation in the oil and gas industry is the separation of oil-water emulsions. Emulsion separation, also known as demulsification is the process of breaking crude oil into the oil and water phases. This is commonly used in refineries where the crude oil is processed into its constituent parts. Besides membrane filtration, other technologies exist to treat oil-water emulsions including; coagulation, ultrasonic separation, and flocculation (Stacka, 2005) (Bensadok, 2007). It has been studied that the use of graphene oxide to modify filtration membranes can result in better separation of the emulsion. In a study by the Hu group, an Al2O3 microfiltrationmembrane was modified using graphene oxide (Hu, 2014). The group prepared graphene oxide using the Hummers method and modified the membrane by transferring the graphene oxide via a vacuum method which resulted in average pore sizes of 200 nm (Chen, 2012). The experimental results showed that the modified membrane had a flux that was almost 28% higher than the unmodified membrane and the oil rejection rate was 0.6% higher at 98.7% (Hu, 2014). The paper and experiment support the idea that graphene oxide can act as a membrane modifier for oil-water separation.

Instead of using graphene oxide as a membrane modifier, it is also possible to simply modify the graphene oxide by the addition of functional groups in order to obtain a material suitable for oil-water separation. In a study from the Carbon journal, a group altered graphene oxide into a superhydrophobic material by using esterification with epoxy-functionalized polyhedral oligomeric silsesquioxane (ePOSS) (Lui, 2014). EPOSS is an organic-inorganic hybrid material with applications in biomedicine, catalysis, and stability enhancements that is hydrophobic (Kannan, 2005). Through esterification, a graphene oxide membrane can be altered to a GO/ePOSS membrane. Impurity free graphene oxide is characteristically hydrophilic with an air-water contact angle of less than 20° while ePOSS is characteristically hydrophobic with an air-water contact angle of around 115°. However, after the esterification of the two, the resulting GO/ePOSS membrane exhibited even more hydrophobic properties and an air-water contact angle of 145° (Lui, 2014). The study concluded that as long as the oil is less dense than the water than this method of separation is effective for at least 10 cycles of membrane use.

Graphene foam, which is a reduced derivative of graphene oxide with a variety of different agents, is a topic of considerable research due to its applicability for oil as well as organic liquid recovery. Graphene foam can be altered for absorption of gas, water, or oil because of changing the selectivity of the foam membrane. Graphene foam can be created in multiple ways but it is commonly synthesized by first making a metal foam (commonly Ni), then applying CVDgrowth to the metal foam and freeze drying it to form a graphene foam (Sha, 2016) (Ping, 2017). Graphene foam is interesting because it has been shown to exhibit switchable wettabilites (and switchable superoleophilic and superoleophobic properties) in response to changes in pH (Zhu, 2014). The changes in properties, coupled with very high absorption capacities as well as high cycle lifespans, makes graphene foams effective for oil recovery and cleanup as well as organic solvent recovery. The key to the switching wettabilityproperties is to first coat the graphene foam with an amphiphilic copolymercontaining poly (2-vinylpyridine) and polyhexadecyl acrylate which effectively results in a surface that can absorb oil when the surface is at a pH of 7 and can release the adsorbents at pHs lower than 3 as a result of protonation and deprotonation (Zhu, 2014). When testing the absorbency of the graphene foam, it was shown gain between 40 and 196 times its own weight which is higher than non-graphene foams and consistent or higher than other nanotubematerials (Li, 2014) (Jai, 2012).

Another large class of graphene foam are ones synthesized using magnetic polymers. In this approach, the graphene foam is produced by depositing Fe3O4 nanoparticles on graphene sheets and transferring it to a polyurethane sponge via physical absorption (Lui, 2013). The advantage of a physical absorption method versus the freeze-dried method is that the resulting foam is more sponge-like instead of brittle and coal-like. The sponge-like texture improves the mechanical properties of the foam and creates a new viable option for releasing the collected oil from it during the cycling process (Wu, 2013). The magnetic polymer foam has superhydrophobicity properties with a water contact angle of around 152°, oil contact angle of 0° (see Fig. 6), and contact angle hysteresis of 85° resulting from the hydrophilicity of the Fe3O4 nanoparticles (Lui, 2013). Sponge-like foams generally have a lower absorption capacity when compared to their freeze-dried counter parts but they do offer potential advantages when considering how to apply this technology to large scale industrial oil spills.

Fig. 6. Example of superhydrophobic properties (Gupta and Tai, 2016).

Fig. 6. Example of superhydrophobic properties (Gupta and Tai, 2016).An important consideration to remember is that even though the theoretical oil spill application must work on a nanoscale, it ultimately needs to be applied to a macroscale. Transferring graphene based technology from something that is hypothetical to practical (on both a size and cost basis) is one of the most challenging obstacles for scientists and industrialists today. Because having the best oil cleanup technology in the world is useless if it can only be created on a microscale. One research group is applying the graphene technology to a large-scale oil clean up vessel that not only cleans up the oil, it stores it for hypnotical future use.

The Kim group has applied reduced graphene walls to all sides of a cubical structure that will suck oil through the wall membrane while blocking water. However, since only the outside of the vessel contains the graphene membrane it serves as a one way “check valve” (Kim, 2015). The prototype vessel created by the group floats in water, requires no energy source, collects oil with a purity of over 99.9%, and has a scaled up collection rate of over 20,000 L per square meter per hour. The prototype can be seen in Fig. 7.

Fig. 7. Working prototype of graphene vessel (Kim, 2015).

Fig. 7. Working prototype of graphene vessel (Kim, 2015).The simplistic design could have huge implications in the oil and gas industry. For example, when oil is spilled in the ocean it would be possible to deploy a few of these vessels in the area of the spill. The oil will naturally collect and be contained inside the vessel until it was full. Later the vessels could be picked up, emptied, and reused. What is interesting about this concept is that since the oil is collected in a very pure state, it would actually be possible for the oil company to sell the oil. It would also be possible for the oil company to quantify how much of the spilled oil was recovered. This would reduce the fine from the government and possibly reduce litigation amounts. The main issue with the vessel is the price of producing graphene or graphene derivatives in large quantities. Until graphene synthesis becomes more affordable on the large scale, these new technologies will not be feasible for industrial use.