1. Introduction

Hunger is a worldwide socioeconomic problem that has been faced even today with technological advances. One of the main objectives of the United Nations' 2030 sustainable development agenda is to act with strategies that can contribute to eradicating the effects of this problem with negative consequences worldwide. Among existing initiatives, aquaculture can be mentioned, whose objectives are the production of high-quality food for human consumption with a low environmental impact (Fao, 2018). Even with these goals, the aquaculture industry still deals with some problems such as labour-intensiveness, environmental pollution, diseases and lack of traceability of products. Approaches using the most modern types of technologies are being developed for the aquaculture industry to deal with the mentioned problems and to achieve a sustainable and profitable production (Yue and Shen, 2022). One of the main contributions of the aquaculture industry to sustainable development lies in the reuse of water that is part of the fish farming by using mechanical and biological filters metabolic to remove wastes of stock before recirculation into the system (Ahmed and Turchini, 2021). This process is carried out through the so-called Recirculating Aquaculture System (RAS) and it can reduce environmental impacts in the food industry, as water has become a limited resource around the world (Bregnballe et al., 2010). Some parameters such as temperature, oxygen, pH, ammonia, nitrite and nitrate levels, which are directly related to water quality, need to be controlled as a way to achieve good fishing management and an appropriate growth of the animal under culture (Dupont et al., 2018). Salmonids are subject to manifestation of problems such as reduced growth, reduced condition factor and nephrocalcinosis when they are exposed to high concentrations of dissolved carbon dioxide (Summerfelt et al., 2015). Another possible problem indicator is the concentration of the hormone cortisol in water which has relation to the level of stress in the fish and with production quality losses (Mota et al., 2014).

Many of these issues can be properly controlled using RAS. Biofiltration process is applied for the conversion of ammonium cation and ammonia excreted by the fish organism into nitrate (Stickney et al., 1994). Ammonia in high concentrations can be toxic to fish metabolism, and its transformation into nitrate facilitates its removal by a denitrifying biofilter or by replacing water. Another important point to control using RAS is the pH level in the water. If the pH of the water reaches low values, there tends to be an increase in the level of carbon dioxide, which is toxic to the development of animals and can lead to their death (Summerfelt, 1996). Some ways to deal with it is making the water more alkaline by adding calcium carbonate or sodium hydroxide or by degassing carbon dioxide. A temperature control done using submerged heaters, heat pumps, coolers and heat exchangers (Lekang, 2020) is also relevant, as temperature can affect the concentration of dissolved oxygen, some species of fish tend to experience negative health effects within a specific range of temperatures and high temperature values increase the biochemical activity of the microbiota (Dupont et al., 2018). Reoxygenating the water of the aquaculture system is crucial considering that fish require oxygen for food metabolization of food and growth. The methods used to increase the level of oxygen are aeration and oxygenation. Finally, mechanical filtering is the strategy applied for the solid waste removal, essential to reduce bacterial growth, disease proliferation, and oxygen demand. Typical removal of solids in RAS involves sand or particle filters where solids are trapped and can be periodically removed (Chen, 1994).

In front of this scenario, the use of RAS allows the fish farmer to control environmental conditions, promote successful waste management and provide a suitable habitat for stable, better growth and development of fish (Silva et al., 2021). Nevertheless, in these situations it is still not possible to achieve a fully optimized production due to the inabilities related to human characteristics. Many steps of the process require human direct intervention and depend on farmer experience and intuition for correct decision and action based on the data collected over long time intervals (O'donncha and Grant, 2019). To improve process results, modern techniques are being applied to automate process components (Wang et al., 2021) to make it possible to collect, process and analyze a large volume of data.

Industry 4.0, also called the Fourth Industrial Revolution, consists of the most recent stage of industrialization in which smart devices are used to ensure the physical-digital connection of the components that make up the production flow in order to guarantee a fully optimized and integrated process. Some technological trends in this phase that can act as key tools for the production of more sustainable food are the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), computer vision (CV), and optimized sensors (Vaidya et al., 2018). The feedback to an automated system of the quantitative values of process’ key parameters, collected using sensors, enables an optimized performance that guarantees a high-quality product. Some sensors are of limited use underwater due to the salinity of the water and the aggressiveness of this type of environment. Sensors based on optical fibers are an advantageous approach to monitor chemical/biological parameters in this type environment due to their compact size and chemical stability (Peters, 2010), safety in aquatic environment, lightweight (Zhang et al., 2018), immunity to electromagnetic noises (Kersey et al., 1997), multipoint and multiplexed elements in one fiber (Leal-Junior et al., 2019) and in-situ monitoring (Zhao et al., 2019). Functional sensors based on surface plasmon resonance (SPR) using plastic and silica optical fiber (Leitão et al., 2021) are technologies developed to measure the cortisol level in fish. In addition, ammonia (Leal-Junior et al., 2020) and dissolved carbon dioxide (Mendes et al., 2019) detection, critical parameters in RAS, have been explored with optical sensors.

There are other critical parameters whose monitoring is still not easy so far. The plastics present in water can be defined as deleterious components and work as a way of transporting toxins to water such as industrial processes residuals. Those toxins ingested indirectly by fish consumption can have many harmful effects to humans (Li et al., 2018). There is evidence that the ingestion of plastics can inflame the immune system or damage internal organs (Seo, 2021). The detection of plastics with sizes down to the micrometer range, called sub-microplastics/nanoplastics (sub-MP/NP), is still facing some difficulties. For example, estimation of these residues by microscopic counting requires their sampling with nets and filters, and the sampling methods and instruments available on the market are only for particles larger than 0.1 µm (Ali et al., 2021). If the cut-off size of the particles to be detected is in the range of a few micrometers, Raman spectroscopy is the only possible technique for detection (Li et al., 2018) and cannot be performed in situ and in real time. Nitrogenous products in water are also problematic since they can be incorporated into the animal food chain causing ecological imbalance via eutrophication and hyper nitrification (John et al., 2020). The nitrite detection has problems such as low sensitivity and interference from other ions in commonly used approaches such as Griess method (Wang et al., 2017a).

In addition to the above, data collected from implemented commercial solutions are commonly stored manually by human operators. Due to human behavior, this approach can lead to errors and missing values in the process and this can make it difficult to make assertive decisions in the production process. An intelligent data acquisition system can be a proper substitute for manual data monitoring since it can provide a real-time sampling process with high precision and repeatability. A low-cost fog computing technology aligned with embedded systems can be an automatic data acquisition and processing solution to support decision making in aquaculture. The small size, low cost, lightweight, portable, high efficiency and low power consumption of the embedded systems combined with cloud computing service are promising characteristics of this type of strategy (Al-Hussaini et al., 2018). Allied to this, friendly interfaces can be developed through the integration of hardware and software packages to provide insights for the operator's decision making in a more assertive way from the data processed with computational algorithms.

Data collected with camera devices and digitally processed consist also of smart technologies to support humans and to achieve a more sustainable smart aquaculture. These devices can be applied in tasks usually performed with the aid of human vision, but their advantage lies in the fact that their efficiency is always the same as they are not influenced by external factors such as illness, emotional state and fatigue related to the human factor. Some applications related directly to the aquaculture industry are counting fish numbers in tanks, detecting the species of the fish (Yang et al., 2021), size measurement and mass estimation, gender detection and quality inspection (Zion, 2012).

In view of the above, this paper aims to present components, tools, and strategies, based specifically on Industry 4.0, which jointly has the objective of improving the aquaculture sector’s productivity and sustainability. It is intended to present state-of-the-art technologies that have certified that this type of industry has reached the current scenario of development and innovation.

The remaining sections of the paper are divided as follows. Section 2summarises what is meant by Industry 4.0 and how this new concept improved the quality and efficiency of industries processes in general. Section 3 presents a general overview of recent data on global results achieved by the aquaculture sector, the definition of basic principles and characteristics of the aquaculture industry and the relevance in applying modern intelligent technologies to achieve better results. Section 4 presents the main advantages and some applications using camera systems associated with stereo vision, image processing, computer vision and machine learning techniques to obtain relevant information and produce insights for management of the fish farm. Section 5presents the basic structure, main used technologies, the information flowchart and applications of wireless communication systems in the aquaculture industry. Section 6 presents types of robotic devices commonly used to support smart aquaculture and some applications from the literature for which they have been used. Section 7 presents the contributions of different algorithms and user-friendly interfaces to help the fish farmers with management and decision making in some types of tasks. Section 8 presents the most modern sensing technologies to monitor and quantify hard-to-measure elements and contaminants in water that are directly related to the quality of aquaculture products. Finally, Section 9 presents the conclusions and final remarks.

2. Industry 4.0: main concepts and technologies

Industry 4.0 can be defined as a most modern and automated degree of industrialization when compared to the third industrial and characterized as a group of technologies which provides a bridge between the physical and digital worlds through cyber-physical systems. It is important to highlight that the centralized control of processes predominant from the previous phase of the industry was changed to a control through data feedback and with the smart products defining the production steps. The main objective of this new type of approach is to achieve autonomous decision making, real-time monitoring of processes critical parameters, facilitate the establishment of real-time networks that enables values creation by engaging stakeholders early on and fostering both vertical and horizontal integration (Industry 4.0, 2017).

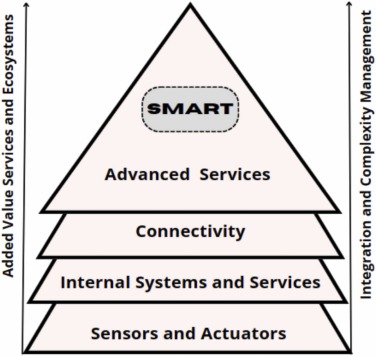

Fig. 1 presents the pyramid that guides the transformations from traditional to smart industry. The initial level of the automation pyramid deals with sensors and actuators. Products and manufacturing assets as well as components that serve as information carriers are included in this layer and can be addressed, localized, and identified through sensors. This layer serves as the basis for the others due to its function of connecting, in the physical and digital environment, the components which make up the production system. In the second layer are the systems and services that can change the organization and way of dealing with the value chain. Items included in this layer are energy monitoring, supervising and management of systems and conditions of machines, buildings and infrastructure. At the third layer, IoT service models lead with connectivity between assets as well as between data and monitoring systems, enabling new capabilities of smarter applications such as predictive maintenance, asset tracking and others. The top layer encompasses capabilities and services to truly transform the business model. Included in this category are applications that enable consumers to personalize the products they buy and sell, and advanced services to create new revenue streams. In addition, there is also the development of new services that significantly change the core business, adding data and intelligent systems, as well as third parties with complementary approaches that explore entirely new customer segments (Santos, 2021).

Fig. 1. The transformation pyramid associated with the Industry 4.0 concept.

Adapted from (Industry 4.0, 2017).The current state of mankind’s evolution made it possible to implement this evolutionary stage of industrialization and to achieve the various benefits arising from it such as reduction of production time and better management of inventory. The use of machines and robots that can perform production steps for many products updates the flexibility of the manufacturing processes. Another benefit is the possibility of faster intervention in case of errors found, monitoring production in real time through sensors and actuators in order to increase product quality. Finally, it is relevant to mention the possibility of accelerating the production line from the beginning to its end (Machado and Davim, 2020).

Some authors tend to call a machine that works under input signal, comparison between signal and ranges, triggers and output as a smart system, however it is just an automated system. The smart concept is directly related to Industry 4.0 and is not limited to basic logical operators but involves complex logical processes and algorithms (Romero et al., 2020). Smart systems primary objective is to enhance production efficiency through the utilization of state-of-the-art information, communication, and computing technologies and the possibility of developing this type of technology came along with studies in the field of AI (Ahmad et al., 2017). Reducing the distance between physical and cybernetic components by integrating operating systems and Information and Communication Technologies (ICT) is an important characteristic of this type of technology that came strongly with Industry 4.0 (Dalenogare et al., 2018).

The smart systems have the capacity to exchange data, communicate their capabilities, and inform about the state of their surroundings. They have the ability to learn from human experience and extract information from the environment. The previous ability enables adaptive behaviour to deal with new situations and contexts and allows it to use this acquired knowledge to make decisions (Kumar and Hancke, 2014, Sarkar et al., 2019) based on fuzzy logic, neural networks, or other techniques. Their interaction with the environment is done through sensors to perceive the state of the environment and through actuators to carry out actions that modify this state. Finally, it is important to highlight that these smart systems are mainly developed to improve aspects of human life (Ahmad et al., 2017).

3. Aquaculture sector: current scenario and future trends

3.1. Global population statistics and worldwide consumption of aquatic food

According to the United Nations World Population Prospects 2022, the world global population is expected to grow to 8.5 billion in 2030 with an increase of 1.18 billion over the next two decades, reaching a value of 9.7 billion by 2050. These results demonstrate that despite the decline in the average fertility rate from approximately 5 births per woman in 1950–2.3 births per woman in 2021, the global population growth rate remained positive. This happened due to the declining in population mortality, related to specific interventions in the health sector and improvements in medical infrastructure (Soares, 2007), and enabled the world population to sustain its growth in recent years (U. Nations And D. Of E. And S. A. P. Division, 2022). Fig. 2 shows the increase in the number of people in the world and the population growth from 1950 to 2022, along with projections until 2050 represented by the mean value accompanied by a 95% confidence interval.

Fig. 2. Global population size and growth rate from 1950 to 2022 and estimation until 2050. Adapted from (U. Nations And D. Of E. And S. A. P. Division, 2022).

Fig. 2. Global population size and growth rate from 1950 to 2022 and estimation until 2050. Adapted from (U. Nations And D. Of E. And S. A. P. Division, 2022).Between 1965 and 1970, the global population experienced an average annual increase of 2.1%, representing the peak of its growth rate. However, in the following years, the rate of growth gradually decelerated, falling below 1.1% per year from 2015 to 2020. However, according to the projections depicted in Fig. 3, it is anticipated that the global population will continue to experience growth in the upcoming decades even with a lower growth rate. Thus, a large increase in global population must be met with an even greater increase in the food supply.

Fig. 3. Worldwide per capita consumption of aquatic food.

Adapted from (Fao, 2022a).Global consumption of aquatic foods has increased at an average annual rate of 3.0% since 1961, which is higher than the average population growth rate of 1.6%. Fig. 3 presents the growth over the years of the worldwide annual consumption per capita of aquatic foods. The average value was equal to 9.9 kg in the 1960 s, 11.4 kg in the 1970 s, 12.5 kg in the 1980 s, 14.4 kg in the 1990 s, 17.0 kg in the 2000 s and 19.6 kg in the 2010 s. The record value happened with an average of 20.5 kg in 2019 (Fao, 2022a).

A 15% increase in aquatic food consumption is projected for 2030 and is expected to be driven by factors such as rising incomes, urbanization, improvements in post-harvest practices and changing dietary trends. Based on the above, this means that with the increase in world population, there will be an increase in fish consumption that will grow above the actual production capacity of the oceans and seas.

3.2. Status of world fisheries and aquaculture production

Over the past three decades, one of the fastest growing sectors of animal food production was the aquaculture industry (Ottinger et al., 2016), with an increase of approximately 5.1% per year over the period 2000–2020, with a record value of 87.5 million tonnes in 2020 (Fao, 2022b). Aquaculture can be defined as the industrial process of growing aquatic animals and plants for human consumption through farming that is coming to dominate seafood production globally (Fao Fisheries Department et al., 2019). The growth in popularity of aquaculture in recent years is related to its potential for production of sustainable seafood thereby reducing pressure on wild fish stocks and it stands as one of the rapidly growing sectors in animal food production globally. The types of aquatic organisms that can be included in the aquaculture farming process are fish, crustaceans, molluscs and aquatic photosynthetic organisms. Furthermore, aquaculture has a crucial purpose in combating global hunger and malnutrition by providing a valuable source of protein, essential fatty acids, vitamins, and minerals through the supply of fish and other aquatic products.

Fig. 4 shows the percentage of participation of capture and aquaculture in the production of aquatic foods in the years 2000–2020 and it can be seen that there was a loss of space in capture fisheries production when compared to the one from the aquaculture industry.

Fig. 4. World capture fisheries and aquaculture production from 2000–2020 by production mode (Fao, 2022a).

Fig. 4. World capture fisheries and aquaculture production from 2000–2020 by production mode (Fao, 2022a).Since the 1990 s, aquaculture production has experienced exponential growth, and in 2014, it surpassed fisheries in terms of providing food for human consumption for the first time (Report, 2013). Moreover, it can be observed that since 2010 the production of wild-caught fish presents only a slight decrease along the years while aquaculture production showed an exponential growth from the year 2000.

Aquaculture production aims to meet the targets of the Food and Agriculture Organization for 2030, whose objective is for the sector to provide 62% of the total fish consumed by humans (Report, 2013). Therefore, this industry tends to play a crucial role in reducing the seafood supply deficit and meeting the protein needs of humans (Luo et al., 2022).

Together, the capture and aquaculture production reached a value of 214 million tonnes in 2020, comprising 178 million tonnes of aquatic animals and 36 million tonnes of algae, of which 97% originated from aquaculture. From these 178 million tonnes of produced aquatic animals, 89% were used for human consumption, proving that the aquatic food production sector can play an increasingly significant role in providing food and nutrition in the next years (Fao, 2022a).

3.3. Precision aquaculture: an overview

The sharp growth in aquaculture production, in the worldwide consumption of seafood and a greater demand for food as a result of population growth have raised the need for better management of resources aiming for greater productivity and reduction of environmental impacts (O'donncha and Grant, 2019). In traditional aquaculture, some difficulties are faced in the water quality management process, since the plant operator is able to monitor the water characteristics in a few discrete and distant intervals. Collecting water manually for quality assessment is a time-consuming process and prevents the farmer from acting in cases of sudden changes that occur between sample capture intervals. Another problem faced is the impossibility of detecting fish diseases in their early stages. That way, they can only be treated when they come to the surface and many of them end up dying. In parallel to this, recent technological advances have allowed that large volumes of data can be collected and stored and that relevant information can be extracted from them through processing.

Within this aquaculture industry scenario, precision aquaculture can be defined as a recent initiative that uses different types of advanced strategies and technologies to reduce the environmental impact and to enhance the process efficiency and quality. The connection between digital and physical devices, such as image capture devices, sensors, communication protocols, embedded systems, to record, monitor, and control the main variables related to the aquaculture plant operating in real time characterizes precision aquaculture. The main requirements related to precision aquaculture are to monitor parameters related to behaviour and physiological state of the fish continuously with data acquisition tools, develop predictive models to assess the influence of external variables in the dynamic variations of animal characteristics and use online systems with integrated information of observations and predictions to support more assertive and less subjective decision or control (Føre et al., 2018).

Fish feeding activity corresponds to 50–70% of the farmer’s production costs in some types of fish cultures (Salger et al., 2020) and fish growth is directly related to feed composition and supply time. Minimizing waste with a more appropriate management of these tasks and resources is a way to increase the productivity, profitability and sustainability of the fish farm. Many tasks related to management of the plant are done manually by humans based on their observations of the environment and on their subjectivity and experience to make decisions. The use of integrated intelligent platforms of sensors with high degree of reliability and repeatability to support these activities guarantees a treatment process with high precision, either through manual actions by the farm operators or by an automatic control system (Lindblom et al., 2017). Accurate control of process variables makes the ideal environment for the healthy growth and development of fish and for obtaining high quality food (Berckmans, 2014).

The integration between advanced technologies, data analysis and automation that characterize precision aquaculture enables the use of the systematic framework OODA (Observe, Orient, Decide, Act) cycle to provide insights into the operational aspects of the industry. This cycle is a concept developed by a military strategist to assist decision-making (John, 1986). Precision aquaculture was implemented seeking a transition from current state-of-the-art tools, characterized by monitoring, interpretation and action based on the human operator experience, to technological solutions and automated principles based on knowledge (Føre et al., 2018). Fig. 5 presents the traditional and precision based tools which make up the OODA cycle applied in the aquaculture sector.

Fig. 5. Representation of operational processes which makes up the aquaculture industry. The transition process goes from experience-based tools to knowledge-based tools.

Adapted from (Føre et al., 2018).For the observation process, data is generated on modern aquaculture farms using in situ sensors to monitor a large number of environmental variables such as temperature, dissolved oxygen, salinity and turbidity (Oppedal et al., 2011). The sampling of variables related to the animals such size, clustering behaviour and movement is done using underwater technologies such video monitoring, hydroacoustic technology, and aerial drone imagery. However, there are some features that are almost impossible to be measured directly.

A common approach to dealing with this problem is to implement dynamic models that can often predict how the system responds to a specific set of inputs. These strategies, which are part of the interpret step of the OODA cycle, are important to structure the acquired knowledge and provide relevant information for the processes that occur on the farm before the moment of decision making. Some research carried out in the area of aquaculture has proposed mathematical models to estimate growth (Bar et al., 2007, Dumas et al., 2010) and behaviour (Føre et al., 2009) of the fish.

Experience-based decision-making cannot occur without the risk of unforeseen and potentially undesirable side effects present. In the case of the aquaculture industry, one possible effect is suboptimal feeding due to limited data on fish responses and behaviors. Decision Support Systems (DSS) are tools developed based on artificial intelligence and information technology, which emerged with the aim of providing the user with information that can facilitate making an appropriate decision. In DSS-oriented research in fish farming from (Føre et al., 2013), the proposed mathematical model predicts the potential utilization of depth variations in submerged artificial lights for guiding the swimming depth of salmon.

In the acting stage, centralized feeding systems are designed to convert the inputs obtained from the decision level into electrical signals necessary to achieve the desired response of the system. Some types of equipment that can support humans in performing underwater tasks are the Remotely Operated Vehicles (ROVs) and the Autonomous Underwater Vehicles (AUVs) (Føre et al., 2018).

4. Camera systems-based applications and solutions

4.1. Image collecting devices

The inherent challenge of using direct observation to assess the conditions of underwater animals in fish farms leads farmers to need technological solutions for monitoring the individual and population states. Camera systems can be used to monitor the behavior of fish in aquaculture farms during production. The computational analysis of images is a useful and promising strategy for extracting information from fish farms due to its non-invasive, automatic and remote monitoring of the environment. Fig. 6 presents some common commercial devices and solutions used to capture images for posterior application of automatization techniques. Equipment such as surface and acoustic cameras, underwater stereo video systems, sonar systems and others are installed in ponds, tanks and transport systems to observe the fishes (Føre et al., 2018).

Fig. 6. Camera systems applied in aquaculture (a) cages/ponds/natural environments, (b) fish tanks, and (c) fish transport systems in the CV systems are installed. (1) are the surface camera; (2) are the underwater stereo video systems; (3) is the sonar system; (4) is LiDAR; and (5) is the acoustic camera.

Adapted from (Føre et al., 2018).Together with the cameras, the hydroacoustic devices are the most commonly used equipment for research related to aquaculture. Conventional echosounders have the capability to generate echograms that depict the vertical arrangement and density of fish schools within a cage. The majority of modern variants of these devices can be used to gather some variables from fishes’ populations in cages (Oppedal et al., 2011). Aquaculture farmers can gain information on fish feeding patterns, growth rates and indications of disturbances in the aquatic environment and risks to animal health by tracking fish positions and movements within ponds using the equipment mentioned (Eguiraun et al., 2014).

4.2. Stereovision techniques

A widely used strategy to investigate these positions and movement patterns of the animals in the ponds is the stereovision-based technique, in which a group of different devices operate together to collect images and extract information about the position of a point in space from the processing of images through trigonometric formulas. The 2D positions of the point on the planes of the cameras together allow you to identify the position of that point in 3D space. The fish length estimation is obtained by knowing the distance between the points which represent its head and tail. Fig. 7 shows a scheme of working principle of the stereovision method.

Fig. 7. Head and tail points of fish projected onto camera planes.

Adapted from (Ruff et al., 1995).The fish’s dimensions and positions were obtained in (Ruff et al., 1995) with a stereovision approach in a tank full of fishes. All the fish that were visible to the cameras could be analyzed simultaneously and the method provided highly detailed position and movement information at a high sampling rate. The length of real fish could be measured with an error of 3–5% without removing the systematic error. A culture of Pacific bluefin tuna (Thunnus orientalis) swimming freely in a net cage was monitored in 3D using a digital stereo-video camera. The fork length and length frequency distribution of individual fish was estimated using the direct linear transformation (DLT) method. For animals moving at a distance < 5.5 m, 99% of the estimates were considered valid with an error ratio of < 5% (Torisawa et al., 2011).

An underwater stereo-vision system was developed by (Harvey et al., 2002) and it was used to estimate length of reef fish in comparison to the estimation of three experienced diver scientists under field conditions. The results of the experiments showed that the divers scientists have a lower statistical power to identify changes in relation to the mean length when compared to the stereo-vision system and for this reason the measurements related to specialists’ presented high standard deviation.

The study of (Costa et al., 2006) introduced a dual camera-based system designed to extract information about fish shape and size automatically. To achieve this goal, an image analysis algorithm was created to pre-process the images in order to eliminate the ones without fish and extract the contours of the fish from the rest. Subsequently, the three-dimensional coordinates of significant landmarks were reconstructed by utilizing the two-dimensional coordinates from a pair of stereo images and the proposed vector algorithm. The effects of the lens characteristics were compensated using an Artificial Neural Network (ANN) which receives as input the uncorrected positioning data, distance between cameras and focal length of the lenses to return as output the corrected positioning data. Images of tuna moving from a fishing net to a floating cage were collected at a rate of two images per second using an underwater dual camera system connected to a waterproof computer in (Costa et al., 2009). The distance between pixels in the pair of images is converted into distance between points in the real objects using an ANN to estimate the size of the fishes. System tests during a real tuna transfer were successful in counting and classifying fish as small or large according to their size with errors as low as 3.0%. The choice of the ANN-based method was due to its ability to correct problems with asymmetries and automatically correct the camera aspect distance estimates and distortions.

More recent work (Silva et al., 2023) developed a low-cost and easy-to-use stereo vision system to deal with the refraction of light in water that can affect stereo reconstruction using the traditional methods. The camera pair was installed inside a solid acrylic chamber that is immune to underwater conditions. Their proposed direct method produces an initial estimate using an out-of-water calibration, and subsequently the estimate is transformed to compensate for the refraction effect. The underwater 3D reconstruction is calculated without the need to do the difficult underwater calibration of the camera pair.