1. Introduction

Global warming was first predicted in 1896 by Swedish chemist Svante Arrhenius, and has been a hotly debated topic among scientist, politicians, and environmental experts alike. It might be a slow and gradual process, but the long-term consequences could be catastrophic, including elevated sea levels, crop failure and famine, changes to plant and animal populations, and serious health effects. (Khasnis and Nettleman, 2005)

Today, environmental protection is one of the main concerns of our society, and one of the best-known causes of environmental risk is greenhouse gas (GHG) emissions, especially CO2. The most common source of this gas is as a by-product of combustion reactions, and most transportation systems today use internal combustion engines, including the maritime sector. International shipping accounts for about 78% of global trade in metric tonnes, while emissions from this sector contribute about 2,4% of global GHG emissions in international trade. While it might seem small, if nothing is done these emissions will continue to grow with the sector, rising from 50% up to 250% of CO2 emissions from 2012 to 2050 (HÜFFMEIER & JOHANSON, 2021). (Wang, 2018)

A solution to some of these problems is not only to try to use alternative energy sources, but also to increase energy efficiency within ship systems, not just in the sense of reducing emissions, but also increasing the performance of the ship. An improved performance means both a smaller ecological footprint in the sector and a non-negligible economic saving by making better use of each unit of fuel. The possible fuel savings that could be achieved range from 25% up to 75% via more efficient operations of existing ships and designing of new ships efficiently (Beşikçi, 2016). And so, over the last few decades, several projects and organizations have been created by various governments worldwide to minimize the consumption and pollution in the sector. The most prominent of these is the International Maritime Organization (IMO), responsible for the introduction of the Energy Efficiency Design Index in 2011 (Ančić et al., 2018)

Despite being named as an “energy efficiency index”, the EEDI is primarily a CO2 emission measurement, which is usually related to the energy efficiency, but it only evaluates a part of the ship's power system and in only one operating point, meaning that its usefulness as an energy efficiency measure is questionable (Ančić et al., 2018). This is a problem shared by other regulations, which almost exclusively keep track of the energy efficiency from the perspective of the CO2 emissions, making a study of the energy efficiency by itself a complex and difficult affair.

There are some long standing efforts to increase the efficiency of the ships independently of their CO2 emissions, due to the increasing price of the fuel which can account for 50–60% of the overall costs in ship operations. Reducing it by just 1% can mean hundreds of thousands of dollars saved every year in large vessels. (Ang, 2017) These measures range from reducing power required for propulsion (Hochkirch and Bertram, 2010), both in design (Lützen and Kristensen, 2012) and during operations (Moustafa et al., 2015), to more efficient employment of fuel energy by alternative engine systems (Dedes et al., 2012a), to the partial substitution of fuel power by renewable energies (Mckinlay et al., 2021)

Some studies have also been done regarding the energy efficiency itself from several different perspectives (Baldi, 2013) along with the potential problems and factors that might hold back the industry from realizing the potential of most of the cost-effective energy efficiency measures. (Johnson and Andersson, 2016) (Rehmatulla and Smith, 2015)

However, the lack of a normative directly dedicated to the examination and enforcement of energy efficiency greatly undermines the effectiveness and impact of many of these efforts. There are some proposed solutions that deal with part of the problem, like the development of wider metrics that encompass areas that the current normative leaves out (Blanco-Davis and Zhou, 2016) or the implementation of a more modern and interconnected lifecycle framework on the ships.(Ang, 2017) But they require a considerable investment to be implemented in such a way that they transform the sector's landscape.

1.1. Objectives

Because of the complexity of this discussion, this paper will aim to develop a map of the current state of the Energy Efficiency in ships from a practical point of view. This overall objective can be divided in three fronts:

-

-

Present a broad look of the legislature and normative that have an impact on energy efficiency.

-

-

Carry out a comprehensive study of the efforts made in the last decade to increase to increase the energy efficiency of the ships.

-

-

Display some options that have been proposed to expand the energy efficiency of the entire maritime transport sector, along with discussing potential obstacles these energy efficiency measures might have for their implementation.

The main contribution of this review is to serve as an introduction to help other studies have a solid understanding of the current state of the maritime sector and its stance on energy efficiency, as the continuous effort made in this field helps bring the industry closer to a greener tomorrow.

2. Regulatory framework

Something that must be stressed is that there is no normative directly addressing energy efficiency on ships as their main point of regulation. The existing rules about ship efficiency are not autonomous, but are dependent of those concerned about ambient pollution, specifically about greenhouse emissions to the atmosphere. For example, the main measurement of energy efficiency, the EEDI, is not appropriate for some types of ships or those which use certain power systems, and its method of measuring efficiency is directly connected with CO2 emissions (Ančić et al., 2018)

It is thus vital to comprehend the origin and the main concern of the current normative to understand the investigation and research done in the field of energy efficiency in ships. Therefore, a series of regulations will be shown, along with their reach and a description of the main enforcements. Even those regulations not directly concerned with the energy efficiency can impose limitations in the development of more energy efficient ship systems.(Table 1)

Table 1. Main regulations of ship.

| Name | Reach | Description |

|---|---|---|

| International Maritime Organization | International | United Nations specialized agency with responsibility for the safety and security of shipping and the prevention of marine and atmospheric pollution by ships. |

| EU Monitoring, reporting and verification | European | European strategy for progressively integrating maritime emissions into the Green House Gases policy by the organized monitorization of fuel consumption of ships. |

| European Ship Recycling Regulation | European | Normative seeking to reduce the negative impacts linked to the recycling of ships, along with imposing a number of safety and environmental requirements. |

| Clean Shipping Index | European | Practical tool for evaluating and classifying the environmental performance of ships, with discounts on port and faraway dues for those that best comply. |

| Hong Kong Convention or the Safe and Environmentally Sound Recycling of Ships | International | Normative intended to address all the issues around ship recycling, including regulations for the design and operation or an inventory of hazardous materials. |

| Poseidon Principles | International | World's first sector-specific, self-governing climate alignment agreement amongst financial institutions, establishing a global framework for assessing and disclosing the climate alignment of ship finance portfolios. |

| Sea Cargo Charter | International | Framework for disclosing the climate alignment of ship chartering activities around the globe, setting a benchmark and actionable guidance for that end. |

Below is the evolution of the previously shown regulations from their creation to the present day, with an added description of each date and highlighting those who are more relevant to the sphere of energy efficiency in ships. The IMO in particular is so important in the global context of this subject that it will be described in its own section.

2.1. International maritime organization (IMO)

The next table will show the general timeline of the creation of the most important IMO measures and normative to the field of energy efficiency, while also highlighting the most relevant: (IMO, Anon,) Table 2.

Table 2. Timeline of the IMO regulations.

| Date | Description of the relevant changes in that date |

|---|---|

| 1948 |

|

| 1958 |

|

| 1967 |

|

| 1973 |

|

| 1997 |

|

| May 2005 |

|

| April 2009 |

|

| August 17, 2009 |

|

| July 2011 |

|

| October 2016 |

|

| March 2018 |

|

| January 2019 |

|

| November 2020 |

|

Other important dates of conventions being adopted are the following:

-

-

2001: Implementation of the convention about anti fouling systems (AFS 2001)

-

-

2004: Adoption of the convention about ballast water management to prevent the invasion of alien species is adopted (BMW 2004)

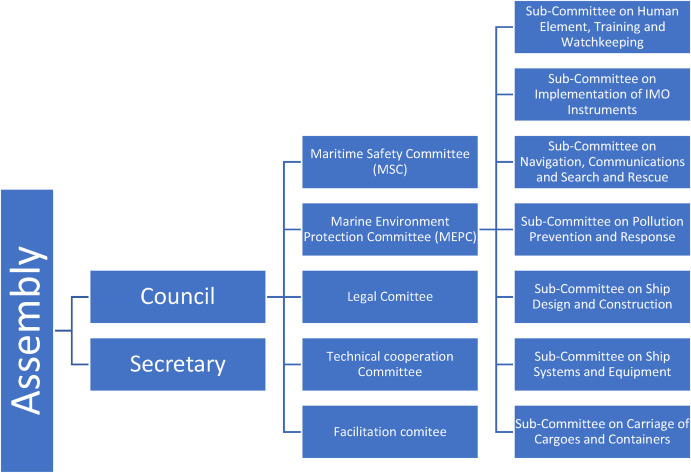

With all these conventions and more, The International Maritime Organization (IMO) is the most prominent of the entities in charge of managing the efficiency of the maritime transport sector(IMO,). IMO's role is to create a level playing field so that shipowners have a variety of ways to solve their financial problems in such a manner that they do not require budget cuts that jeopardize the safety of the personnel, the structure, or the environment, as well as generally promoting innovation and efficiency. Most other systems dealing with energy efficiency or especially environmental impact of ships usually rely on IMO criteria to establish their own measures. The structure of the International Maritime Organization is as it follows: (See Fig. 1)

Fig. 1. Structural management of the International Maritime Organization.

Fig. 1. Structural management of the International Maritime Organization.The sub committees also influence and assist the Maritime Safety Committee, besides being open to all Member States. The most relevant facet of the IMO in the sphere of energy efficiency is its technical committees, most critically; the Marine Environment Protection Committee or MEPC, which regulates the affairs concerning the protection of the marine environment and the questions of energy efficiency through CO2 emissions.

The IMO has also created several conventions that are very significant and important for navigation, with the key examples being:

-

-

International Convention for the Safety of Life at Sea(SOLAS)

-

-

International Convention for the Prevention of Pollution from Ships (MARPOL)

-

-

International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW)

The most important convention in the objective of energy efficiency is by far the MARPOL.

2.1.1. The MARPOL convention

The MARPOL, or International Convention for the Prevention of Pollution from Ships, is the main international convention covering prevention of pollution of the marine environment by ships from either operational or accidental causes. While originally created in 1973, an updated version was adopted in 1978 and the combined instrument entered into force first in 1983, but the entirety of the regulations proposed wouldn't be completely enforced until 2005. The structural organization of the MARPOL convention consists of a series of regulations aimed at minimizing pollution from ships, divided in six technical annexes with specific instructions to prevent concrete methods of pollution: Fig. 2.

Fig. 2. Structure of the MARPOL convention.

Fig. 2. Structure of the MARPOL convention.The most important part of the MARPOL for the subject of energy efficiency is Annex VI: Prevention of Air Pollution from Ships, the last one to enter into force and which from 2011 also covers mandatory technical and operational energy efficiency measures aimed at reducing greenhouse gas emissions from ships.(IMO,)

Among these measures are the most important ones related to the area of energy efficiency nowadays as defined by the IMO itself. These are the following:

-

-

Energy Efficiency Design Index (EEDI): This is the most important technical measure for new vessels, and its main function is to promote the usage of more energy-efficient equipment and machinery in new ships. This measurement aims to be gradually adjusted every five years to stimulate continuous innovation and technical development of the design phase, starting with the baseline reference value in 2013 (Phase 0) and ending with a value around 30% lower depending on the type of ship in 2025 and beyond (Phase 3). While it's mostly dedicated to cargo ships, but there's an amendment in 2014 to account for the evaluation of Ro-Ro and passenger ships, with their corresponding reference values.

-

-

Energy Efficiency Operational Index (EEOI): This technical measure allows shipowners and operators to measure the fuel efficiency of a ship in service and to gauge the effect of any changes in the operation like improved voyage planning or more frequent propeller cleaning.

-

-

Ship Energy Efficiency Management Plan (SEEMP): It is an operational measure that provides an approach for shipping companies to manage the efficiency performance of ships and fleet over time using, for example, the EEOI as a monitoring tool. The development of the SEEMP incorporates best practices for fuel efficient ship operation and guidelines for voluntary use of EEOI on ships.

In conjunction, these measures help promote new technologies and practices when seeking to optimize the performance of a ship (IMO,) However, in June 2021 the MEPC adopted some new amendments to the Annex VI of Marpol to improve further the energy efficiency of ships and are expected to enter into force on 1 January 2023. The measures in question are:

-

-

Energy Efficiency Existing Ship Index (EEXI): Appears in the amendment MEPC 333(76). The main function of this measurement is to evaluate the performance of ships in a similar way to the EEDI, covering the same ship types and sized but applicable to all existing vessels regardless of their build date. Owners of ship managers need to calculate the EEXI of ships in their fleet and make sure that their EEXI values are lower than the required EEXI.

-

-

Carbon Intensity Indicator (CII): Introduced in four amendments explaining the indexes and how to work with them, from the MEPC 336(76) to the MEPC 339(76). This measurement determines the annual reduction factor needed to ensure the continuous improvement of the ship's operational carbon intensity within a specific rating, on a diminishing scale from A to E. This is an ongoing task that requires to be calculated every year starting from 2023 and must be reduced annually. Any ship classified as E or with three consecutive years as D must submit a corrective action plan to achieve rating C or better.

The adoption of the new measures would build on IMO's previously adopted mandatory energy efficiency measures, to lead shipping on the right path towards decarbonisation (International Maritime Organization, 2021).

2.1.2. Ship classification according to the IMO

Before dwelling into other regulatory systems besides the IMO, it must be noted that there are several kinds of vessels depending on their function and said function can impose some constraints in the types of efficiency measures the ship can implement before its performance is diminished.

Because of this, some types of ships have more specific regulations provided to them, like in the case of the EEDI where each type of ship uses different parameters when calculating the value of reference. This is also the main reason several studies center their efforts on specific kinds of vessels for a more focused approach, even if in most cases their measures can also be implemented on other ship types.

And so, according to the IMO, there can be distinguished several important cargo ship types: (Imo, 2011)

-

-

Tanker: A ship constructed or adapted primarily to carry either an oil or other chemicals in bulk in its cargo spaces.

-

-

Bulk carrier: A ship which is intended primarily to carry dry cargo in bulk, like ore.

-

-

Gas carrier: A cargo ship constructed or adapted for the carriage in bulk of any liquified gas.

-

-

Container ships: A ship designed exclusively for the carriage of containers in hold and on deck.

-

-

General container ships: It refers to a hip with a multi-deck or a single deck hull designed primarily for the carriage of general cargo. (This excludes specialized dry cargo chips like livestock carrier, barge carrier, heavy load carrier, yatch carrier and nuclear fuel carrier)

-

-

Refrigerated cargo carrier: A ship designed exclusively for the carriage of refrigerated cargoes in holds.

-

-

Combination carrier: A ship designed to load 100% deadweight with both liquid and dry cargo in bulk.

There are other types of ships that the IMO touches upon but are not dedicated to the transport of cargo, with the Ro-ro and Passenger ships being the most important among those. The main measure of those ships is not the deadweight but either the cargo space or the number of passengers respectively, so the normative for them is registered accordingly.

Of all these kinds of ships, those who compromise most of the total ships emissions according to the International Council of Clean Transportation Report of 2013 are the Container ships (23%) the Bulk Carriers (19%) and the Oil Tankers(13%) (Amoraritei, 2019) (Constantin and Amoraritei, 2018) Because of this a lot of the studies regarding energy efficiency measures come from them, but there are still some noteworthy works done on the behalf of other types of ships, most notably cruisers.

Before moving on to the rest of the regulations, it's sensible to point out some of the most recent trends in compliance with energy efficiency requirements among different types of ships.

As of 2017, an analysis realized using official IMO data and conducted by the organization Transport and environment showed the following results regarding EEDI and energy efficiency of several types of cargo ships: Table 3

Table 3. Energy efficiency trends on differen types of cargo ships.

| Type of cargo ship | Efficiency improvements of new ships relative to the baseline EEDI value of 2013. | Share of ships built in 2013–2017 already complying with the post-2025 EEDI target. |

|---|---|---|

| Containerships | 58% more efficient | 71% of built containerships |

| General cargo ships | 57% more efficient | 69% of built general cargo ships |

| Gas carriers | 42% more efficient | 13% of built gas carriers |

| Oil Tankers | 35% more efficient | 26% of built oil tankers |

| Bulk Carriers | 27% more efficient | 1% of built Bulk Carriers |

It's possible to see that many of the ships that have been evaluated are already complying with the EEDI requirements of beyond 2025, which is the last phase established in the normative and the strictest. Of special note are the containerships, of which more than 70% comply with the regulations and can reach up to 58% more efficiency than the baseline, compared with the post-2025 requirements of 30%. This stands in stark contrast with the bulk carriers, of which the best ships barely manage to reach 27% of energy efficiency and only 1% get even close to the level of the post-2025 EEDI requirements.

While this is a very positive situation for the containerships type of ships, especially since they emit around a quartet of the global ship CO2 emissions, this also means that the regulation is not fulfilling its objective of promoting better designs or technological innovation. The study even suggests that the performance of the best ships in the fleet would be a good place to start when revising existing or setting new EEDI requirements. (Transport & Environment, 2017):

2.1.3. Specific european regulations

The next set of regulations that will be examined are those that are implemented specifically at a European level, or those who are originated in a European country. The main organizations examined will be the EU Monitoring, Reporting and Verification (MRV), the European Ship Recycling Regulation (SRR) and the Clean Shipping Index (CSI). The dates that are especially relevant will be highlighted(Table 4).

Table 4. Timeline of the European regulations.

| Organization | Date | Description |

|---|---|---|

| MRV | June 2013 |

|

| MRV | April 2015 |

|

| MRV | July 2015 |

|

| MRV | January 2018 |

|

| SRR | November 2013 |

|

| SRR | December 2013 |

|

| CSI | 14 November 2017 |

|

| CSI | January 2018 |

|

2.2. Other international regulations

The following table will show the general timeline of the creation of other international regulations outside the IMO that possess some relevancy to the subject of energy efficiency in ships. The main organizations examined will be the Hong Kong Convention (HKC), the Poseidon Principles (PP), and the Sea Cargo Charter (SCC). Those which have the most impact will be highlighted (Table 5).

Table 5. Timeline of other international regulations.

| Organization | Date | Description |

|---|---|---|

| HKC | May 2009 |

|

| PP | November 2017 |

|

| PP | April 2018 |

|

| PP | June 2018 |

|

| PP | August–September 2018 |

|

| PP | October 2018 |

|

| PP | November 2018–February 2019 |

|

| PP | 18 June 2019 |

|

| SCC | June 2018 |

|

| SCC | September 2018–April 2019 |

|

| SCC | October 2019 |

|

| SCC | November 2019–March 2020 |

|

| SCC | March 2020 |

|

| SCC | March 2020–July 2020 |

|

| SCC | 7 October 2020 |

|

2.3. Generalized framework of energy efficiency

In this section only the specific regulations that have a direct impact on the energy efficiency of the ships are shown, consisting of those that were already highlighted in the previous sections in chronological order (Table 6).

Table 6. Generalized framework timeline.

| Scope | Date | Description |

|---|---|---|

| IMO | April 2009 |

|

| IMO | July 2011 |

|

| European | December 2013 |

|

| European | January 2018 |

|

| European | January 2018 |

|

| IMO | January 2019 |

|

| International | 18 June 2019 |

|

| International | 7 October 2020 |

|

Whether because of the desire to apply to the regulations or because of initiative, currently there is a continuous effort in the research of this field, both in a general sense or applied to specific types of ships.

The next sections will be dedicated to examining several advancements and proposals for power optimization on the ships. The process of optimization consists of the selection of the best solution out of many feasible ones based on a set of criteria, which in this case includes the maximum possible energy efficiency. (Papanikolaou, 2010) This will help to portray a clearer picture of the current situation and of the of the research being done in this field.

To put this into perspective, the initial IMO GHG strategy aims to reduce carbon intensity of international shipping by 2030 by 40% compared to 2008. The draft amendments on 2020 to the MARPOL convention would require ships to combine a technical and an operational approach, and so, most of the measures can be divided between those that need to be enforced while designing a ship, and those that can be applied to the ship in the operational phase.

3. Energy efficiency at the design stage

Ship design is a complex endeavour that requires successful coordination of many disciplines, as the ship itself consists of an intricate system integrating a variety of subsystems and their components. (Papanikolaou, 2010) But from the last decade alone there has been a conscious effort not only to reduce emissions, but also the cost per voyage of the vessels, of which the price of fuel is a significant contributor (Ang, 2017).

The biggest advantage of modifications on the design of the ship is that once implemented they don't require constant monitoring and adjustments to have an optimal performance, only requiring the regular ship maintenance. This leaves the ship with an optimized efficiency and ecological footprint since its foundation and for the duration of its useful life. The methods proposed to improve their efficiency range from alternative fuels and engines to hull modification and exhaust gas waste heat recovery. (Tokuşlu, 2020)

To evaluate the impact of these measures, there exist numerous methods depending on the type of the ship, but most use the EEDI implementations as a baseline. This is not a requirement, however, and it makes it more difficult the task of evaluating the effectiveness of some of these measures. Therefore, there will be separate sections for those studies that use the EEDI and another one for those that don't, with each section being divided depending on the type of modification done.

3.1. Studies that employ the EEDI as an evaluation tool

The EEDI is a very useful as a point of comparison between different measures despite its shortcomings, because having a standardized set of values makes it easier to evaluate the impact of a system. The following table shows several studies about measures regarding energy efficiency, alongside the type of ships evaluated and their impact on them in terms of EEDI reduction (Table 7).

Table 7. Design measures that assesed their impact using the EEDI.

| Type of modification employed | Description of the method | Type of ship examined | Impact | Source |

|---|---|---|---|---|

| Modification of hull parameters | Restoring historical adimensional design parameters like block coefficient. | Tankers and bulk carriers of all sizes. | The EEDI values are reduced between 10 and 15% in the fleets examined. | (Kristensen and Lützen, 2012) |

| Reduction of main ship dimensions like length and beam | Panamax tankers with influence of bulk carriers. | The EEDI values diminish between 2.5% and 0.7% per meter subtracted. | (Lützen and Kristensen, 2012) | |

| Propulsion system optimization | Innovative propulsion methods like the Organic Rankine Cycle | LNG carriers. | The EEDI diminishes up to 0.3 below the reference case in the best systems. | (El Geneidy, 2018) |

| Electric propulsion systems. | Passenger vessels. | Both structures examined comply with phase 3, but the COGES system has greater margin of error. | (Ammar and Seddiek, 2021) | |

| Specific LNG carrier propulsion | LNG carriers exclusively. | Of the systems examined, only the diesel electric complies with phase 3, but with a heavy methane slip. | (Attah and Bucknall, 2015) | |

| Hybrid propulsion systems | Hybrid systems on general cargo carriers | Small and fast general cargo carriers. | Two of the investigated cases comply even with the strictest phase of the EEDI. | (Øverleir and AuthorAnonymous, 2015) |

| Fleets of hybrid systems | Ro-Ro and Passenger ships. | Both types of systems examined have EEDI values below the reference of the ship. | (Ančić et al., 2018) | |

| Alternative fuel sources | Varied array of alternative technologies like shaft generators. | Very large crude carrier. | The combined effects of innovative technologies produces a drop in the EEDI of up to 0.34, around 16%. | (Faitar and Novac, 2016) |

| Propulsion for Liquid hydrogen tankers. | Liquid hydrogen tankers exclusively. | The optimal system analysed was a steam turbine with a hydrogen boiler and complies even with phase 3 of the EEDI. | (Ahn, 2017) |

The next sections will expand the information on the studies depicted on the table, divided by the type of modifications performed on them.

3.1.1. Modification of hull parameters

The optimization of the hull form is a longstanding method of improving the performance of the ships for various objectives, ranging from increasing the hydrodynamic performance to enhanced survivability and transport efficiency. (Papanikolaou, 2010) Therefore it should not come off as a surprise that there have been attempts to reduce the EEDI by enhancing the shape of the ship.

The overall the effects of the form of the ship hull is considerable, as one study proven by using historical data of tankers of the last 30–40 years. Analysing the adimensional design parameters of the ships and their corresponding EEDI values, the conclusion reached was that the EEDI of the analysed ships has been increasing for the last decades due to several factors like a higher block coefficient and lower length displacement ratio. Returning those values to their historical minimum can reduce the EEDI significantly (10–15%) without sacrificing cargo capacity. (Kristensen and Lützen, 2012)

The direct influence of the design parameters on the consumption of the ship has also been observed, mostly concerning the length, beam, and draught of the vessels. An increase of 1% in any of them for a given deadweight reduces the block coefficient of the ship and results in a decrease in power demand. Said decrease ranges from around 4,6% in the case of length, 2% in the case of beam, and 2,8% in the case of draught. The positive impact of increasing the beam is reduced because of the increased beam-draught ratio (B/T) which increases the residual resistance on the ship. All these variations also influence the EEDI, although in a smaller proportion than the fuel demand, between 2.5% and 0.7% per meter subtracted depending on the parameter. Conversely, an increase of 1% in the design speed of the ship generally results in a rise of power demanded, roughly 2,9%. While all these analyses were performed on Panamax tankers, the study also concerned itself with the efficiency of bulk carriers. (Lützen and Kristensen, 2012)

3.1.2. Propulsion system optimization

As the CO2 emissions are influenced by the installed power of the main and auxiliary engines as well as the quality and quantity of fuel burned in them, one of the main ways to reduce greenhouse emissions is by the optimization of the main engines and therefore the propulsion system of the ship. (Amoraritei, 2019)

New technologies have been very helpful in this regard, and some studies have simulated the energy efficiency of some innovative propulsion systems for cruise ships. Cruise ships were chosen because the range of accommodations required for passengers make it more imperative to optimize the energy of the ship. Of all the systems analysed, the dual pressure steam systems and specially the Organic Rankine Cycles offered the greatest potential benefits for the cruise ship industry, reaching a better EEDI, operational efficiency and lower fuel consumption than the rest, even if only by a low margin. (El Geneidy, 2018)

Another example of attempts at engine optimization are the electric propulsionsystems, whose economic and environmental impact is being investigated to achieve more efficient ship operations in commercial, cruise and naval vessels. One of these research projects studied two electric propulsion options on a Passenger ship, a diesel electric and a combined gas turbine electric and steam (COGES). The latter was found out to have lower EEDI (Encompassing less than 90% of the reference EEDI in contrast to the almost 95% of the Diesel electric) and can be proposed as an upgraded and cost-effective option for ships that use gas turbines as their main propulsion. (Ammar and Seddiek, 2021)

It's also worth mentioning that some types of vessels have more specialized requirements within their systems, which in turn demands peculiar responses. Of these types of ships, a common example are the gas carriers, due to the very precise requirements of their cargo. For example, the LNG is transported at −160 °C and at near atmospheric pressure, which inevitably causes the LNG to boil off due to imperfect insulation and sloshing in the tanks, and it is the need to handle this boil off gas that has created very distinct demands in the propulsion of these ships, in which steam power predominates. Besides a steam turbine, some other options have also been considered, like a slow speed diesel with re-liquefaction plant, and a dual fuel diesel electric propulsion. Of those three the last one seems to be the most efficient and the only one that complies with Phase 3 of the EEDI, but only regarding CO2, if methane is included, it has the highest emission rate. (Attah and Bucknall, 2015) In other areas, however, the LNG carriers are remarkably like the rest of the cargo ships. Unlike the engines, the propulsion systems for LNG carriers do not have specific propulsive requirements, and several factors like speed, trade distance and maintenance cost can be used to select the system most adequate for each case. (Huan, 2019)

3.1.3. Hybrid propulsion systems

Hybrid energy system or Hybrid Power System (HPS) is a broad term used to describe a structure consisting of a combination of a prime mover and an electrical energy storage system, usually some form of battery. This device stores the energy produced by the prime mover during lighter loads and releases it under heavy loads. This reduces the fuel requirement of the prime mover and allows it to operate constantly at maximum efficiency. Although this measure has yet to be implemented on a large scale for several types of ships, there are others that have been more widely considered, for example ferries, tugboats, fisher vessels and other small craft (Nal et al., 2022)

This should not be a detriment to the implementation of hybrid systems in other vessels. One example of the considerable potential of these systems is in the general cargo carriers. Despite the market being increasingly dominated by specialized vessels, the general cargo ship segment is a shipping sector that is crucial for the global trade to function. These vessels are often specialized for niche markets, but also optimized for carrying many types of cargo, which leads to a poor EEDI performance. This has been the motivation of analysing the possibility of using a hybrid energy system, and it was found that said system has many advantages like enabling cold ironing, eliminating frequent load variations and easier power redundancy. The overall efficiency is also higher, with two of the studied cases complying with even the strictest phase of the reference EEDI. (Øverleir and AuthorAnonymous, 2015)