1. Introduction

In December 2019, the Chinese Center for Disease Control and Prevention (CCDC) identified a novel beta-coronavirus called 2019-nCoV, COVID-19 or officially known as Severe Acute Respiratory Syndrome Coronavirus 2 (SARS-CoV-2) (Xie and Chen, 2020). At the beginning of 2020, the coronavirus was still thought to spread only in a specific part of the globe; however, unfortunately it can seen that the COVID-19 has been spreading worldwide over time. World Health Organization (WHO) had announced that 2019-nCoV could be characterized as a pandemic (Covid and Team, 2020). Fever, cough, and shortness of breath are the common symptoms of the disease. Sputum production, muscle pain, and sore throat are the other less common symptoms (Organization, 2020). In some studies, it has been shown that the virus also involved the central nervous system and the symptoms of loss of smell and difficulty in breathing (Li et al., 2020). “Face masks are physical barriers to respiratory droplets that may enter the mouth and nose and to the expulsion of mucosalivary droplets from infections individuals” (Chua et al., 2020). As the number of diagnoses increases, it continues to show different symptoms in new cases. The virus is usually transmitted from person to person through droplets formed due to coughing, talking, sneezing, etc., and contact transmission such as contacting with oral, nasal, and eye mucous membranes (Lepelletier et al., 2020). Several authors have also reported about the viability of SARS-CoV-1 and SARS-CoV-2 on surgical masks, printed paper, tissue, wood, glass, banknotes, plastic, stainless steel, layers under a variety of temperature and relative humidity (RH) conditions (Rowan et al., 2021).

This is the worst pandemic ever, and it can be slowed or stopped by the effort of individuals. Wearing a mask has now become essential self-defense for everyone. There is a common saying, “wearing masks is not only for protecting ourselves but also for the protection of others.” Face masks are essential medical textile products used in different areas such as industrial, surgical, decoration, extreme sports, etc. They can be developed by making use of other materials and a variety of structures. Self-isolation can be managed for a while, but it cannot be continuous, and at this point, face masks gain importance to provide partial freedom to people. The average diameter of a coronavirus (an entire virus particle) is around 100 nm (Neuman et al., 2006). It is a very tiny particle that cannot be filtered by most of the available face masks, yet the aim of using the mask is to stop microscopic droplets that act as a virus carrier, not the virus itself. When a person coughs, talks, or even breathes, 900 to 300,000 liquid particles can be thrown from the mouth. Another essential function of the mask is to slow down the traveling speeds of these particles as a cough can be send up to 60 mph.

Therefore, Covid-19 is becoming a global threat to public health. The disease is spreading rapidly across the world in the mode of human-to-human transmission in society and family settings (Phan et al., 2020). So, the need for effective and widely available medical services and facilities is rising day by day (Chan et al., 2020). Nowadays, many nations have published an advisory circular for compulsory use of facemask during any outhouse activities such as marketing, traveling, office works, etc. The use of facemask can protect healthcare personnel, patients, healthy individuals, co-workers, colleagues, family members, etc., from spreading COVID-19 during this pandemic and for any other viral outbreaks. The facemask is like a filter to protect the wearer from inhalation exposure to airborne viruses, particles, etc., to prevent the rapid transmission of infectious diseases. Such filtering facemasks are either pharmacologically or non-pharmacologically used (Silva et al., 2020). The main function of a face mask is to protect the wearer from the inhalation of the aerosol present in the air and prevent infection of viral disease as well as infecting others (Yao et al., 2019). However, the first COVID-19 vaccine, manufactured by Pfizer-BioNTech, are being administered in the UK today (Rowan et al., 2021).

Tons of petrochemical-based materials are used to produce facemasks well-known for their non-degradable nature, and they will undoubtedly cause environmental issues over time. Since both during and post-use problems, there is a need to develop bio-based facemasks. Natural textile-based face masks are designed and produced by integrating smart biostructures, chemicals, or technologies into the textile materials to provide more functionality such as comfort and protection to the wearer or patient. The production purposes depend on the usage area and react with environmental factors and warnings. Modern medical textiles have superior properties such as antibacterial, antifungal, prevent allergies, cross-contamination and odor, durable, and many more benefits. It is suggested that nanofiber membranes for filtration can also be used as filter layer face masks (Das et al., 2020). The usage of bio-based nanostructures is gaining importance for developing advanced masks. This article reviews the various approaches for preparation, raw materials, characterization, features, and applications of biodegradable face masks.

2. Facemask

A facemask is one of the Personal Protective Equipments (PPEs) that should be used for shielding healthy people (who shield themselves in touch with the infected person) or for monitoring origins (wear by the infected person to avoid transmission). The mask is worn to minimize exposure to various hazards such as physical, chemical, heat, biological, electrical, and airborne particulate matters. Other products that come under PPEs are earplugs, gloves, goggles helmets, full-body suits, etc. The most preferable PPE in COVID-19 epidemic is N95 (Disposable air-purifying Masks-N95 3 M & N95 S). These are generally three-layered structures made of polypropylene fibers: external layer 40 μm, middle layer 8 μm, and inner layer 40 μm. N95 stands for a filtration capacity of the mask more than 95%, which can block tiny particles, about 0.1 (μm) in size. The approximate size of the coronavirus (Covid-19) is around 100 (80–120) nanometres.

In most cases, the Covid-19 spreads in droplet form (droplet Size is about 5–10 μm) (WHO 2020). Various public protection organizations and governments organisations have provided numerous recommendations for wearing face masks to fight against the COVID-19 pandemic. Furthermore, the World Health Organization and other global health organizations circulated advisory to use facemask time to time to prevent transmission of air infectious disease such as flu.

3. Classification of face masks

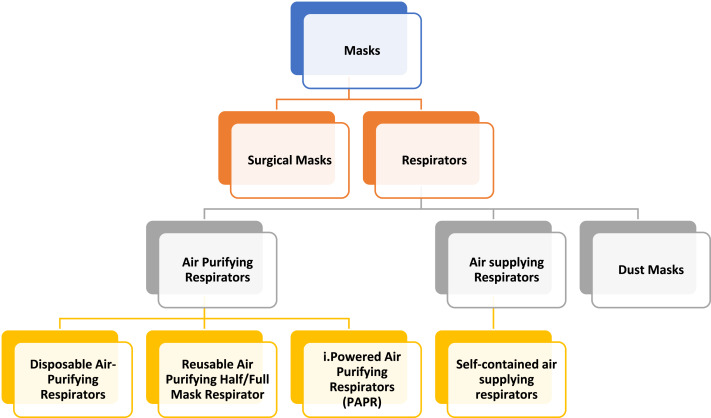

Generally, masks can protect the wearer from inhalation of hazardous gases, small particles (i.e., pollens, allergens), and airborne microbes (i.e., bacteria, virus). The type of masks which would be useful is decided through the working environment conditions, type of illness, or other medical requirements. For instance, firefighters or mineworkers need to use selective masks equipped with breathing apparatus. Masks protect the wearers or excel the breathing in harsh environments and diminish the spreading of viral diseases. Maclntyre and Chughtai have reported that wearing masks during the epidemic decreased the chances of being infected and spreading infections (MacIntyre and Chughtai, 2020). Mainly, masks are divided into two major categories; (i). Surgical masks, and (ii). Respiratory masks. Surgical masks are profound for healthcare persons, which protect the patients by preventing the bacterial liquid shed or aerosols from the wearer's mouth or nose. Respirators are those masks specially designed to protect the wearer from airborne viruses, bacteria, hazardous gases/fumes, and small particulates. Different types of respirators available in the market are defined based on filtration/penetration capacity and type of filter cartridge. A classification of masks is shown in Fig. 1.

Fig. 1

Fig. 13.1. Surgical masks

A surgical mask was used mainly after 1960 in different countries. These masks are prepared from nonwoven fabrics through the melt-blowing process. Surgical masks have three layers; the outer layer was made from nonwoven fabric. It acts as a water barrier, while the middle layer was medical-grade filter paper, and the inner layer is a soft nonwoven fabric. The structure of the surgical masks was varied according to the country's regulations (Table 1). The function of the surgical masks is to prevent the patients from catching the bacterial liquid droplets or aerosol from the health care person's mouth or nose. Usually, surgical masks do not allow to penetrate large diameter particles (i.e., droplets, splashes, sprays, respiratory salves), droplets, or aerosols having a diameter of 3.0 μm. The penetration efficiency was >95% against bacteria, droplets, or other aerosols. However, surgical masks not filtered the smaller size microorganisms, small particles (which are transmitted during coughing, sneezing) present in the air. This type of mask was not fitted well on the face, and thus, the chances of infection were too large an extent.

Table 1. Surgical masks standards according to the different countries.

| Country/standards | Particle Filtration Efficiency | ||

|---|---|---|---|

| China: YY0469 | BFE: 3.0 μm (>95%) & PFE: 0.1 μm (>30%) | ||

| USA: ASTM F2100 | Level-1 | Level-2 | Level-3 |

| 3.0 μm (>95%) 0.1 μm (>95%) | 3.0 μm (>98%) 0.1 μm (>96%) | 3.0 μm (>98%) 0.1 μm (>98%) | |

| Europe: EN 14683 | Type-1 | Type-2 | Type-3 |

| 3.0 μm (>95%) | 3.0 μm (>98%) | 3.0 μm (>98%) | |

3.2. Respiratory masks

Respirators are usually used to inhale in hazardous/toxic atmospheres (i.e., biological contaminants/microorganisms, dust, mists, gases, fumes, or oxygen-deficient atmosphere). These kinds of masks have different types of ratings and names according to usage in different environments and types of filters or cartridges. Air-purifying respirators and air-supplying respirators are the two main types of respirators. The main advantages of the respirators are entirely fitted on the face, which stops the passage of the hazardous particulates from the sides. Generally, respirators can filter the 0.01 μm to 0.3 μm particulates with 95–99% efficiency. Thus, respirators are most useful in different industries, including defense, healthcare, pharmaceutical, oil & gas, mining, construction, agriculture, textile, cement, public safety services, etc.

3.2.1. Air-purifying respirators (APRs)

Two different types of APRs are available, i.e., disposable and reusable APRs. Disposable APRs are half-face masks, while reusable APRs have two different categories: half-face masks and full-face masks. Both masks have their advantages and disadvantages, which include usability, filtration capacity, and filtration efficiency. Both types of masks and their categories are described below.

3.2.1.1. Disposable air-purifying respirators (DAPRs)

Disposable APRs prevent the passage of the particulates (<0.3 μm) and provide filtered air to the wearer. These masks have different categories as per the National Institute of Occupational Safety and Health (NIOSH). Each category has definite Letters (i.e., N, R, P) and Number (i.e., 95, 99, 100), representing the masks' usage in different environments, including types and filtration efficiency. Three kinds of disposable APRs are widely used, i.e., N-series, R-series, and P-series. These kinds of masks are lightweight, relatively comfortable, and inexpensive. Further details of each DAPRS were described in Table 2.

Table 2. Different types of the Disposable air purifying respirators.

| Disposable APRs | Disposable APRs Rating Letter class | Disposable APRs Rating Number class | Properties & Usage |

|---|---|---|---|

| N-series i.e., N95, N99, N100 | N for Not resistant to Oil |

95 means filter the 95% of the 0.3 μm particulates. 99 means filter the 99% of the 0.3 μm particulates. 100 means filter the 99.97% of 0.3 μm particulates. |

|

| R-Series i.e., R95 | R for Resistant to Oil |

|

|

| P- series i.e., P95 and P100 | P for Oil Proof |

|

3.2.1.2. Reusable air-purifying respirators (RAPRs)

Reusable APRs are equipped with cartridge or filters which are replaceable. Two different kinds of reusable APRs are available, half-face reusable air-purifying respirators (HFRAPRs) and full-face reusable air-purifying respirators (FFRAPRs). The type of cartridge or filters governs the usability of both APRs in specific working environments, types of cartridge, or filters. Both RAPRs possessed the same structures-two sets of rubber straps, mouthpiece and two cartridges/filter with NIOSH approval. Both of the RAPRs fitted in such a way on wearer's face that creates the facial seal and filters the incoming/ongoing airs. Further properties, advantages, and disadvantages of RAPRs are explained in Table 3.

Table 3. Features of RAPRs.

| HFRAPRs | FFRAPRS | |

|---|---|---|

| Face Fitting |

|

|

| Advantages |

|

|

| Disadvantages |

|

|

| Types of Cartridges |

|

|

| Applications |

|

|

3.2.1.3. Powered air purifying respirators (PAPR)

This type of respirator also contains filters, including a portable fan that is powered by a battery. The fan can be drawing the air through the chemical filters and blow it into the helmet facepiece. Two different types of PAPRs are available (i.e., half and full-face pieces). These kinds of masks are beneficial for concentrated hazardous gases, mists, or fumes in atmospheres. Due to the fan, the air pressure inside the helmet is adequate, and the wearer can easily breathe in a harsh environment. However, such a mask is expensive; usability is limited to battery and fan life and very heavy due to the battery. Every time wearers needed to take the battery with them, which limits the applicability of the respirators. It couldn't be useful in oxygen-deficient environments.

3.2.2. Air supplying respirators (ASRs)

Unlike APRs, ASRs have individual tanks or gadgets which supply oxygen to the wearer. These self-containing breathing respirators are equipped with high-pressure oxygen cylinders which provide clean and fresh air to the wearer. Usually, pressure cylinders are on the back of wearers, and due to this, it is heavier, almost 20 to 30 pounds. This pressure cylinder provides 40 min of fresh oxygen. These respirators provide the maximum degree of protection in any kind of air-contaminated environment. Firefighters and mining workers usually use this type of respirator.

3.3. Dust masks

Dust masks protect the wearer by preventing the passage of dust particles, aerosols, pollens, tiny solid particles, and droplets. It is also known as a filtration face mask (FFP) or respiratory protection mask. It is one type of mechanical respirator. These masks are certified by the European Union (according to EN 149 standards). According to filtration efficiency, dust masks are classified into three categories, i.e., FFP1, FFP2, and FFP3. Other properties of the FFP1, FFP2, and FFP3 are described in Table 4.

Table 4. Properties of Dust masks.

| FFP1 | FFP2 | FFp3 | |

|---|---|---|---|

| Filtering Capacity | Minimum 80% | Minimum 94% | Minimum 99% |

| Leakage | <22% | <8% | <2% |

| Colour of Mask | No specific colour codes. Depends on companies. | ||

| Elastic colour | Yellow | Blue or white | Red |

| Particle Filtration | Small solid particles (>5 μm) | Powdered Particles (2–5 μm) | Very fine particles (<2 μm) |

| Exhalation Valve | No | Yes | Yes |

| Medical Use | Lung dieses (i.e., Silicosis, anthracosis, asbestosis, sideroses. | Influenza viruses, Severe acute respiratory syndrome (SARs), Bacteria of pneumonic plague and tuberculosis | Bacteria, viruses |

| Applications | Mining Industries, Cement industries | Glass industries, Foundry, construction, pharmaceutical and agriculture | Ceramic industries |

3.4. Other types of masks

Besides respirators and surgical masks, another type of protective mask is also available, that can protect against particulates, aerosols, and microorganisms effectively. Such types of masks are KN95 and cloth masks. KN95 has four layers in which the middle layer acts as a filter layer fabricated from a combination of needle-punched cotton and fabric. After that melt-blown fabric layer is protected by the outer layer. Both sides of the outer layers are made up of nonwoven fabric. This type of mask has 95% filtering efficiency. FDA, ISO and CE approve this mask. Cloth masks are not medically approved masks, but they offer limited protection against germs, particulates, or droplets. Due to the lack of masks in markets, peoples made cloth masks to protect themselves from viruses, bacteria, or particulates. This fancy mask is generally prepared from the fabrics of cloths (i.e., cotton) or sponges. However, such fancy masks are partially protecting the wearers from large droplets or big particles.

Furthermore, CDC (Centers for Disease Control and Prevention) recommended wearing the Surgical masks over the cloth masks also worked well against the COVID-19. These kinds of double masks prevent the spreading as well as exposing or protecting the wearers from viruses. Additionally, it was also recommended to wear multiple layer masks (i.e., KN95/surgical mask or cloth mask or Cloth mask/surgical mask), which dramatically prevent the virus exposure and spreading.

4. Necessity and effectiveness of wearing of a mask to prevent COVID-19 transmission

The use of face masks is preliminary essential to stop spreading coronavirus through the air, potentially carrying microscopic droplets full of coronavirus. It can spread while talking, breathing, or coughing and contacting the body's parts to where the viruses are already positioned. These are basic human behavior, and all of them work with the invisible airflow system. In an epidemic situation, the primary use of the mask is to slow down or stop the airflow as it is the primary carrier of viruses. It is vital to understand that viruses do not float around by themselves. They fly out in droplets of moisture. The principal neccessity of using the mask is to stop these moisture droplets. Some of those droplets can evaporate into nanoparticles of infection that can float with air-exposed to person through mouth or nose without the mask (If some persons haven't worn mask). Viruses are extremely hard for any type of mask to filter out. It is crucial to stop moisture droplets into the breathing zone of the occupants. The droplets cannot evaporate in the humid space between the mouth and the mask since the virus can be captured by most of the face masks.

At this point, the effectiveness of both the face mask and respirator is not so different from each other. An overview of currently available masks is given in Fig. 2. It was seen that single-layered (surgical masks) could filter out 60–63% of the air droplets while N- series and dust masks could be more convenient to protect ourselves from the viruses. Noticeably, each mask has its own fitting on the mouths. In such cases, N-series, Dust masks, or double layer masks (surgical masks covered with cloth masks could be efficient to prevent virus exposer. Additionally, it is seen that these masks are produced mainly by synthetic materials, which will create new environmental problems as well as health issues for the wearer. Due to such foreseen, it is crucial to develop biodegradable, effective and eco/skin-friendly face masks by making use of nanotechnology.

Fig. 2

Fig. 2Another major benefit of using a mask is to slow down the droplet's momentum. For this, the mask needs to be appropriately fitted to the face. Fitting the mask to nose and mouth is crucial to stop spreading the virus. It is generally suggested to use a multi-layered face mask as each layer performs different behavior to provide functional protection during breathing. Especially, the skin-touching layer should be made by a soft-skin friendly biodegradable material for personal comfort as well as adequate protection. It should also be absorbent material as the droplet and moisture need to be blocked.

The use of facemasks can be uncomfortable; however, face masks do not lead to lowering the body's oxygen levels nor CO2 intoxication as healthcare workers use different masks and work all day in masks, and there is no detected harm for health (Yang et al., 2017). There are different qualitative methods to measure the breathing zone. Schlieren imaging is one of the well-established optical methods to visualize airflow by capitalizing the refraction of light when entering a medium of different densities (Settles, 2012). The preliminary results show that wearing a cloth mask over the nose and mouth can significantly reduce the risk of spreading the virus or getting infected. It simply indicates how face masks work to slow airborne infection or stop viruses (Matthew E. Staymates, 2020). Health care providers should wear medical masks in all areas of a hospital. High-speed visualization of airflow has been shown in Fig. 3.

Fig. 3

Fig. 3A straightforward and practical demonstration has been performed by Dr. Davis to show how important and useful to wear a facemask to stop spreading viruses (PROVIDENCE NEWS TEAM, 2020). He placed agar plates to his face to determine how droplets and respiratory particles transferred with basic human acts such as talking, singing, sneezing, and coughing with and without a facemask. The results clearly show that the droplets were directly transferred into the culture dishes without a mask (Fig. 4). The tested facemask blocked nearly all droplets since it is expected to stop spreading coronavirus as well as respiratory droplets are the principal carrier of any bacteria and viruses.

Fig. 4

Fig. 4Multi-use masks are developed by considering the environmental problems and the worldwide insufficient mask supply. Different masks were tested after the cleaning process for their filtration efficiency for reuse. It is found that the mask can be decontaminated by autoclaved and 70% ethyl alcohol treatment. Both approaches have shown an excellent decontaminating ratio. The filtration efficiency of the autoclaved masks is better than 70% ethyl alcohol treatment, and the filtration efficiency is maintained up to 2 autoclaving processes (Kim et al., 2020). There is also a simple method used to decontaminate the masks for multiple reuses. The used masks were soaked in hot water at above 56 °C for 30 min, which is the recommended atmosphere to kill coronavirus. After the washing, the masks were got dried by a hair drier. The finding of this study has an important application for the reuse of polypropylene (PP) masks as most of the mask produced by PP. It is claimed that the hot water decontamination positive (+) charge regeneration method can be applied to PP masks up to 10 times and the results showed that the filtration efficiency is not changed significantly (Wang et al., 2020).

5. The role of facemask as a filter for bacteria and virus

Filter media is one of the essential parts of the face mask. Generally, fibrous materials such as nonwoven fabrics are used to create the filter media, a particulate matter filter designed according to the size of the particle matter to be filtered. The particulate matter (PM) can be classified as per their size such as ultrafine (<0.1 μm), fine (0.1–2.5 μm) and coarse (2.5–10 μm), which are expressed as PM 0.1, PM 2.5 and PM 10, respectively (Nam et al., 2019). The filtration mechanism for the nonwoven type depth filter is described by various theories such as interception, diffusion, inertial impaction, intermolecular interactions of the filtrate particles on the surface of the filter media. These mechanisms are suitable as per the size of the particles and the size of the pores/fiber of the filter media as shown in Fig. 5 (Tebyetekerwa et al., 2020). The size of the virus particles is tiny (ca. 20–400 nm), and the size of a coronavirus is in the range of 100–160 nm. Therefore, Brownian diffusion is the sole filtration mechanism for the facemask suitable for COVID-19 (Mao, 2017). An infected person releases pathogenic aerosols during speech, exhalation, sneezing, and coughing. The facemask can achieve the necessary respiratory protection against aerosol particles. Nonwoven filter media is more effective than woven ones (Chellamani et al., 2013).

Fig. 5

Fig. 56. Natural textile cloth face mask

Natural cellulosic fibers like cotton, flax, hemp etc. have good mechanical strength, hydrophilicity, and biocompatibility, and can resist protein adsorption and biofouling. Therefore, they are still widely used in viral filters (Junter and Lebrun, 2017). It has been observed that the self-designed three-layered cellulosic cotton mask could be a potential substitute for a medical mask that is mainly made of synthetic polymer. A mask made of synthetic polymers may cause a respiratory infection during use. A healthy person in a micro-environment inside a bedroom or inside a car with air conditioning can use the cotton mask regularly since the cotton mask is natural, non-toxic, washable, and reusable (Ho et al., 2020). With this concept, a 2-layer 100% organic cotton face mask mouth mask with filter pocket (elastic-free) was developed, which is made of super soft and pure organic cotton fibres in a tightly knitted fabric structure. Hemp is another natural fibre that has a large surface area for trapping micro-particulates and microbes. A bilayer 100% hemp and organic cotton cloth face mask can better protect our skin, nose, and mouth. The masks can be cleaned and disinfected by treating inside boiling water for 30 s (Schoenberg, 2020).

Various antiviral coatings are applied on natural textile fabrics to enhance the performance of the mask against viral barriers and disinfection. Cellulose acetate fabric was coated with a polycation named polyethyleneimine (PEI) by the process of adsorption. The coated fabric is antiviral and used to prepare an antiviral mask (Tiliket et al., 2011). The strong virus capturing ability of the mask is attributed to the strong electrostatic attraction between polycationic PEI and negatively charged viruses (Tiliket et al., 2016). In another study, the surface of cotton nonwoven fabrics is modified with catechin polyphenol molecules by laccase enzymes to prepare the antiviral mask and wipes (Catel-Ferreira et al., 2015). Two-layered nonwoven support of such material is found to be an appropriate virus barrier.

Apart from the coloration and skin safety, herbal resources present in our nature retain various functional properties like anti-microbial, antifungal, UV protection, insect repellent, and aroma finishing to the natural textile fabrics. Therefore, various herbal extracts are used for the preparation of biodegradable masks that are claimed to be virus neutralizer and resist pathogens effectively (Kim et al., 2020). The herbal extract obtained from tulsi, neem oil, ajwain, black pepper, turmeric, gum arabic, sandalwood, clove, and saffron were applied on the nonwoven nanofiber filter media to prepare biodegradable bio-based facemasks, named ‘pavitrapati, which is a patented invention of metallurgical and materials engineering department of The Defence Institute of Advanced Technology, Pune, India (DIAT). The mask showed properties such as antifungal, antiviral, antibacterial, biodegradable, super-hydrophobic (outer layer) and hydrophilic (inner layer) useful against COVID-19. The top and bottom layer of the masks are made of cotton fabrics (superhydrophobic and hydrophilic, respectively) and the middle layer is a nanoweb made of biodegradable polymer enriched with herbal extracts as mentioned above. The pore size of the mask is about 10–20 nm and therefore capable of filtering the coronavirus.

100% cotton cloth (double layer) is about 70% effective as a surgical mask for capturing small particles, which is breathable too (Office of the Principal Scientific Advisor (PSA) of the Government of India). Since the cotton fabric is the most available in our home, plenty of mask attempts have been made using natural resources such as turmeric, neem, tulsi, etc, either alone or in their blend to enhance the antiviral effect (Pandit et al., 2018). In addition to cultivated plants, agro-processing wastes like peanut skin, pomegranate rind, walnut bark, etc are loaded with an abundant amount of phytochemicals like saponins, flavonoids, and glycosides, which provide characteristics to the textiles such as anti-microbial (Jose et al., 2019), antioxidant (Pandey et al., 2017), ultraviolet and deodorizing properties in addition to good colour (Teli and Pandit, 2017). The principle phytochemicals responsible for colour, anti-microbial and antifungal activity, their mode of action, method of application, and evaluation of bacterial resistance are attempted to fight against COVID -19 at the maximum possible extent as a protective initiative. The anti-microbial property of textiles to prevent degradation of textile by microorganisms can be achieved through four possibilities which are given as follows (Purwar, 2019):

-

•

Kill organism: This applies to hygiene and aesthetic finishes. The process of destroying microorganisms can be achieved with biocide either in two ways. There can be a chemical reaction with the cell membrane, which stops the metabolic process, e.g., silver and mercury-based biocide work, displacing hydrogen ions from bacteria with relevant metallic ions. Alternatively, the biocide can penetrate the cell wall and poison the cell from within.

-

•

Block enzyme: The enzymes are produced by break down a material even when treated with a biocide. Many of the enzymes associated with the breakdown of cellulose are identified but blockage, yet not practical.

-

•

Insert a barrier: This can be achieved by coating the textile substrate and this coating prevents microbial activities. The use of organic silicone polymer that contains quaternary ammonium groups, forms a bio-barrier on the fabric.

-

•

Modification of fiber: In this process, fiber can be treated with a chemical that can react with the appropriate site on the molecule. The biochemical reaction carried out by the microorganism via its enzyme can no longer occurs.

Dyes are coloured organic compounds which are having an inherent affinity to fiber. They are fixed on fiber through chemical bonding. To value addition of the ordinary mask, herbal resources have been applied on the cotton fabric to get antibacterial protection. However, the primary focus has been depicted in the antibacterial property of the ordinary mask so that it can be widely used for protection (Fig. 6).

Fig. 6

Fig. 67. Use of biopolymers for preparation of facemasks

The use of the biomaterials such as alginate, chitin, chitosan, gluten, poly (vinyl alcohol), poly (lactic acid), poly (lactic-co-glycolic acid), polycaprolactone, poly (ethylene oxide), cellulose acetate, and their blends for the preparation of facemasks is worthy and sustainable. However, a new approach, methodology, and production setup may be required to manufacture the same. Even the bio-polymers are costlier than that of petroleum-based polymers, yet there are many researchers and entrepreneurs favoring the use of biomaterials in place of petroleum-based non-biodegradable materials. Many enterprises also have launched bio-masks that are efficient and sustainable.

Gluten, is a by-product of cereal industries, having good cohesive and barrier properties can be used to prepare filaments with reasonably good mechanical strength. Gluten can be successfully electrospun in its pure form or blended with poly (vinyl alcohol) (PVA). The 5% gluten blended PVA electrospun membrane exhibits 99% filtration efficiency against gold and silver nanoparticles (Das et al., 2020). It is also possible to make a carbon blended gluten nanofiber filter membrane for the fabrication of facemasks (Aziz et al., 2019). The developed masks are fire resistant and biodegradable (Dhandayuthapani et al., 2014). Gluten can be chemically modified for enhancing the surface charging during electrospinning for manufacturing ultrafine nanoweb filter media (Capezza et al., 2020). Carbonization of the gluten nanoweb generated an active surface with a higher specific surface area in favour of viral filtration. Carbonized gluten nanofiber web can be laminated between plasticized gluten nanofilms and vacuum-formed to shape the mask as per facial contours.

Biopolymer-based masks were effectively used for the release of the active ingredients through skins. Coltelli et al. have prepared the poly (hydroxyalkonate) and starch-based beauty mask to release active molecules, keratocytes (Coltelli et al., 2018). Similarly, bacterial cellulose is used to prepare the delivery of the active molecule (Perugini et al., 2018).

8. Electrospun nanofibers: solving global issues

The nonwoven filter media can be manufactured by electrospinning technology. In this technique, high voltage is applied to the polymer solution to form a fine filamentous structure ((Ramakrishna et al., 2006). The technology is well established, cost-effective, easy to scale up, and accepted by industries for the preparation of fibrous membrane media (Purwar et al., 2016). The process can be easily optimized to design filter media as per the required pore size distribution, thickness, and permeability (Tebyetekerwa et al., 2020). Scanning electron microscope images of few electrospun nanofiber mats collected on different geometries and styles for suitable fabrication of facemask are shown in Fig. 7. Owing to the high porosity (~80%), tortuosity and large specific surface area, the electrospun filter media can offer high filtration efficiency (Zhu et al., 2019). Moreover, various polymeric materials can be processed through the machine, which is an essential requirement for biodegradable polymers to prepare the membrane media (Zhu et al., 2017). Various biopolymers, such as alginate, chitin, chitosan, gluten, polyvinyl alcohol (PVA), polylactic acid (PLA), polyethylene oxide, cellulose acetate, polycaprolactone, etc. and their blends have been utilized to prepare nanomembranes for nano-filtration (Thavasi et al., 2008). Though all these biopolymers are not biodegradable, they are still renewable (Kadam et al., 2018).

Fig. 7

Fig. 7Electrospun fibers are studied with great flexibility for usage in several specific applications (Das et al., 2020). Many experiments usually use nonwoven arrays of fiber constructed from smooth fibers (Haider et al., 2020). In addition to nonwoven arrays, research for future implementations was constrained for certain fibrous assemblies (Naghieh et al., 2018). However, the usefulness of electrospun nanofibers has been recognized and explored for various fields such as health care, biotechnology and environmental technologies, protection and safety, and energy storage and development. (Molnár and Mészáros, 2020).

8.1. Skin healing and skin care treatment via facemask

A disposable face mask that includes an internal face layer that provides skin care, worn next to the wearer's face. The innermost layer is coated with a solution that provides for moisturizing and care of the scalp, namely aloe vera, vitamin E, vitamin C, grape seed extract, and peppermint. While using the face mask, the product moisturizes, soothes, and cures the hair, growing skin irritations. The face mask of the new technology that contains certain layers including one intermediate filter media layer that is typically coextensive and at least one additional layer that is generally coextensive (Mehta et al., 2019). In immunocompromised patients with lung intrusion and hypoxemic acute respiratory failure, a legitimate alternative to a face mask could be the case, increasing patient tolerance (i.e., the number of hours of sustained non-invasive positive pressure ventilation (NPPV) usage uninterrupted) and levels of problems directly linked to the use of NPPV (Potnis et al., 2019).

8.2. Fragrant film in the facemask

Stratum corneum is the greatest barrier to skin moisturization of cosmetics. There have been various solutions to the obstacle, including introducing natural cosmeceuticals into beauty items to improve moisturization effects. Here an electrospun formulation was used to create dry facemasks that can host cosmeceuticals in the pores of mesoporous silica. The applied voltage of 12 ± 2 kV Ethanolic solutions comprising 40% w/w of the marketable facemask and mesoporous silica (7th Heaven Dead Sea peel-off façemask) is prepared and electrically extracted at 30 μL min−1. In vitro characterization and release, experiments are performed using fluorescein dye as a model sample. The fibrous existence of the resulting matrix was verified by Scanning Electron Microscopy (SEM) images displaying an average diameter of 298.32 nm of fiber. Because of this fibrous nature, the electrospun mask has a strong, active load power, with 100% release within 60 min. The touch angle, thermal analytics, and Fourier Transform Infrared Spectroscopy (FTIR) revealed that the formulations are consistent and stable (Galantucci et al., 2006).

8.3. Optimized cooling via facemask

Throughout the facial mask design, a multi-layered face mask covered with discontinuous patterns of material for the phase shift which is applied to guarantee that the microclimate cools in the dead room of the face mask (Riggons and Henry 2014). Optimized cooling is tailored by the careful placement of layers covered with phase change material inside the mask framework and additionally tailored by the quality and amount of the phase change material in connection with the temperature-responsive areas of the face and regions with the maximum exhaled breath flux (Yang et al., 2017). The type of mask may also be modified to maximize skin interaction with the substance in the phase change and decrease dead room, decreasing the amount of hot exhaled air and cooling with less phase change content (Rogers and Bosker, 2004). The discontinuous patterns of the substrate for the phase shift can include the inter-layer distance between the mask layers, which may increase resistance to splash (Roberge et al., 2012).

8.4. Usage of perfect build contoured facemask through modern CAD techniques

Embodiments of facemasks may use computer-aided design and computer-aided development to create personalized facial masks (Wei et al., 2017). Device software may be programmed to collect face topography details, develop a mask based on topography knowledge, and submit mask knowledge to a computerized production system. The app may interact with a scanning system to gain facial topography and a template production computer. The scanning tool will include a linear scan non-contact laser imager in an embodiment. In an implementation, the scanning system may be shifted manually to scan a person, removing the need for the motive appliance (Sun et al., 2005). In these modes, location data from a location sensor attached to the scanning system may be calculated using the hardware (Wei et al., 2018).

9. Challenges and future prospects

The first challenge of the preparation of a biodegradable mask is to create a pore size in the range of 100–160 nm, which is the size of the coronavirus (Pellett et al., 2014). The second challenge is to enhance the performance properties such as moisture and fire resistance and enhancing mechanical properties. The performance of masks should be better characterized in four dimensions such as filter efficiency, differential pressure, fluid resistance, and flammability. Capturing nanoparticles, including viruses, bacteria, aerosols, etc., is a key process in nano-filtration, separation, and biomedical applications of a mask. Mechanisms of soft particles such as aerosol capture using nanofiber networks are proposed focusing on the protection against or removal of viruses which helps design facemask for protection against the coronavirus (Wan et al., 2013). Further challenges are generating a mask that can reduce the exposure limit to the wearer by inhibiting or killing the bacteria, viruses, or other hazardous biological microorganisms.

10. Conclusions

A face mask is one of the Personal Protective Equipments (PPEs) worn to minimize exposure to various hazards, including COVID-19. As of early July 2020, at least 88% of the world's population are recommended to use facemasks in public, and more than 75 countries have declared it mandatory to use masks. Therefore, wearing a face mask has rightly become the new regular habit, as we try to protect ourselves and others from COVID-19. The masks can be classified as mainly two types such as surgical masks and respirators. A surgical mask was used mainly after 1960 in different countries with a multilayer nonwoven structure made of synthetic polymers like polypropylene. The respirators are usually utilized to inhale in hazardous/contaminated atmospheres such as biological contaminants/microorganisms, dust, mists, gases, fumes, etc. The Particle Filtration Efficiency (PFE) of the surgical mask is achieved about 98% against 3-μm particle size at level 3 protection. Respirators can filter the 0.01 μm to 0.3 μm particulates with 95–99% of efficiency. Thus, respirators are most useful in different industries, including defense, healthcare, pharmaceutical, oil & gas industries, mining, constructions, agricultural, textile, cement, public safety services, etc. These non-biodegradable masks cause severe environmental pollution and subsequent secondary health hazards. These conventional masks are gradually replaced by biodegradable masks made of biodegradable and bio-based materials, which are environment-friendly, zero-hazardous, long-lasting, lightweight, comfortable, and affordable. Various biopolymers, such as alginate, chitin, chitosan, gluten, poly (vinyl alcohol), poly (lactic acid), poly (ethylene oxide), poly (lactic-co-glycolic acid), cellulose acetate, polycaprolactone and blends of these biopolymers, have been used as raw material of electrospinning to nanofiber membranes as a material of masks. These biodegradable nanofiber membranes are used as one constituent layer in the facemask to prevent viral penetration as well as other functions, including skin healing, skincare, moisturizing, etc. Also, conventional natural fiber textile fabrics are used to prepare multilayer mask for general use as a cheap and biodegradable alternative. The anti-microbial performance of such masks is enhanced by applying various herbal extracts such as turmeric, neem, basil, aloe vera, etc. These masks are skin-friendly, anti-microbial, antifungal, UV protective, insect repellent, and aroma enriched. Also, some herbal extracts give natural colour to the masks, which will enhance aesthetic appeal too. There are sufficient pieces of evidence in the literature about the manufacturing, use, and performance of such biodegradable masks and proved their efficacy in preventing and killing microorganisms, including the coronavirus. Therefore, it is time to adopt biodegradable alternatives for the sake of the environment and ecosystem to prevent the invitation of another unknown pandemic in the near future inorder to protect hazards caused by the non-biodegradable disposal of synthetic masks.