1. Introduction

Nuclear power is the fifth most significant source of electricity in India after coal, gas, hydroelectricity, and wind power. Nuclear technology uses energy released by splitting the atoms of fissile elements to generate electricity. Even though current nuclear power plants use improved technologies and higher safety standards to reduce radiation exposure risk there has been an incident of radiation exposure. Hence shielding in nuclear containers is essential to protect the people and the environment from the effect of harmful radiation [1].

Radiation is a process that occurs naturally in the form of light waves, heat etc., but can also be generated artificially from man-made sources such as radio waves, X-rays, microwaves, from nuclear power plants, medical applications etc. [2]. Radiation can be double-edged depending on its source and applications. In particular, the hazardous radiations of great concern are the highly penetrative gamma radiation and neutron radiation are difficult to attenuate. Therefore, it is essential to protect people from vulnerable problems associated with excessive radiation exposure. Based on the energy of particles emitted, they are classified into ionisation radiation and non-ionisation radiation. Radiation in which energy is not sufficient enough to produce ions is known as non-ionisation radiation. Visible light, ultraviolet light, infrared waves, thermal radiation, radio waves, transmission waves are some examples of non-ionisation radiation. This radiation does not cause much effect on the external environment compared with ionisation radiation. Radiation where the energy of the wave is very high which results in the ionisation of atoms on collision is called ionisation radiation. It removes an electron from an atom and creates an ion. When a radioactive element decays it gives out energy particles or rays; this phenomenon is known as nuclear radiation. Radiation is a phenomenon in which energy is transmitted in the form of particles or waves in space or through any medium. This includes gravitational radiation, electromagnetic radiation, particle radiation etc. [3].

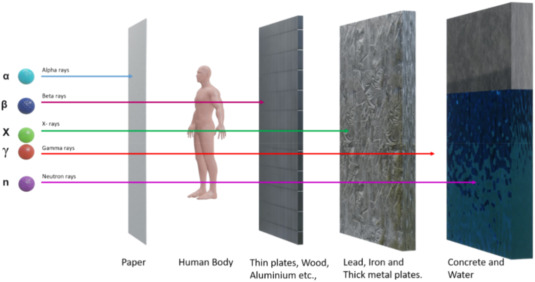

There are many kinds of ionisation radiation like alpha (α) radiation, beta (β) radiation, gamma radiation (γ) and neutron radiation [4,5] as shown in Fig. 1. Alpha particles do not cause much damage to human cells as they do not penetrate much but when these radiations are inhaled, it causes great damage to cells. They can be shielded with thin metal plates or even with a paper. Beta radiation can penetrate human skin up to 1 or 2 cm and are less dangerous when compared to gamma radiation. This can be shielded by using stack of papers, wood plates or even plastic material. Gamma radiations are more powerful and penetrate more than alpha and beta radiation. Gamma rays can easily penetrate through human body and can cause severe damage to body [6]. These radiations require a dense or thick material such as lead block [7] which is very costlier, iron block or depleted uranium to prevent their penetration. Neutron radiation consists of free neutrons. They are categorized based on their speed and energy. The common source for neutrons occurs in nuclear reactors where either there may be a nuclear fission reaction or nuclear fusion reaction. Neutrons do not ionize atoms in the same way that charged particles do, they ionize the particle by absorption. Neutron when collided with any non-radioactive material can make them into radioactive substance. This process is known as neutron activation. Not all particles get activated, for example, water absorbs neutrons but they become heavy and are in a stable form. So, water is an example that is used for shielding of neutrons. This radiation can cause more effect to the human body than gamma radiation.

Fig. 1. Types of radiation and penetration.

Fig. 1. Types of radiation and penetration.To a large scale, radiation exposure causes radiation sickness, genetic mutations, sterility, paralysis, cancer, and death in humans, depending on the dose and period of exposure. Non-penetrating and penetrating radiation can ionize or damage the human body cells. The penetrating radiations such as gamma rays and neutrons can enter the body and damage the cells of various organs. Neutron radiations when exposed to humans can lead to neurological disorders, vomiting, drop in blood count, nausea, hematopoietic syndrome, etc. [2,[8], [9], [10]]. Shielding is an essential component in various fields to ensure the safety and well-being of individuals and the environment by mitigating the harmful effects of radiation. Neutron radiation is a kind of ionisation radiation that emits free neutrons which creates a severe impact when exposed to the external environment. So, it is very important to shield neutron radiation leakage from nuclear power plants to create a hassle-free environment.

Based on the above facts, it is reported that the shielding of neutrons is very much required for the safety of the people working in such environments. Concrete is well recognized for neutron shielding and, the addition of various additives can enhance its shielding capacity. A report which comprises all such possible additives are not reported so far, as far as the authors knowledge. The current paper addresses this aspect by presenting a critical review of the various additives that can be incorporated into the concrete to enhance its neutron attenuation capacity along with the corresponding test procedures.

1.1. Neutron ray interaction with matter, mechanisms and measurement parameters

The main interaction mechanism of neutrons is by scattering and capture/absorption. Neutrons are arbitrarily divided into slow (thermal) and fast (energies of 1 MeV and above). Fast neutrons are effectively attenuated by the high neutron scattering cross-section of the low mass number elements (hydrogen, carbon, oxygen). They include polyethylene terephthalate (PET) [11], paraffin and polyethylene. Hydrogen is exceptionally effective at thermalizing fast neutrons because its nucleus includes only one proton with a mass nearly identical to that of a neutron; hence, elastic scattering results in the neutron, losing the highest energy. Hence shielding against minor sources is done with plastics and against fast sources with concrete or water. After slowing down, a substance with a large capture cross section such as boron or cadmium is used to capture neutrons [[12], [13], [14]]. The probability of a neutron interaction is (where σ - is the cross-section, N – No. of nuclei area A). The unit of cross-section is barn (10−24 cm2). The capture cross-sections vary significantly from one nucleus to another. Boron-10, cadmium, gadolinium, and lithium-6 all have very large capture cross-sections, which allows them to be employed in neutron detectors or reactor control systems [10].

Neutrons interact with matter in three ways: inelastic scattering, elastic scattering and neutron absorption. A neutron with an energy exceeding 10 MeV undergoes inelastic scattering and a neutron with an energy ranging from 1 to 10 MeV undergoes elastic scattering, hence the slow neutrons are brought to the nucleus by this absorption process, which further causes the nucleus to undergo excitation and releases α and γ –rays [[8], [9], [10],15,16]. Table 1describes the four main mechanisms of neutron ray interaction with the matter and is illustrated in Fig. 2.

Table 1. Types of neutron ray matter interaction.

| S. No | Type of Interaction | Description | Reference |

|---|---|---|---|

| 1 | Elastic Scattering | Neutron collide with the target nucleus with changes in velocity. The incident neutron will transfer some kinetic energy to the target nucleus. The neutron-target system acquires the same amount of kinetic energy before and after interaction. | Gaurav et al. [13] |

| Schmidt et al. [15] | |||

| Florez et al. [17] | |||

| Abdullah et al. [18] | |||

| Sivathanu et al. [19] | |||

| El-Sayed [20] | |||

| 2 | Inelastic Scattering | In an inelastic scattering interaction between a neutron and a target nucleus, a part of the incident neutron's energy is absorbed by the recoiling nucleus, and the nucleus stays in excited state. To achieve its ground state, the nucleus releases the excitation energy by producing one or more gamma rays. The neutron and target nucleus are not altered. | Gaurav et al. [13] |

| Schmidt et al. [15] | |||

| Florez et al. [17] | |||

| Abdullah et al. [18] | |||

| Sivathanu et al. [19] | |||

| El-Sayed [20] | |||

| 3 | Neutron Capture | In neutron capture or radiative capture, a compound nucleus is formed by absorbing incident neutron. The compound nucleus then decays to reach its ground state with release of gamma rays. This process can occur at all incident neutron energies, but the probability of the interaction strongly depends on the incident neutron energy and the target energy (temperature). | Gaurav et al. [13] |

| Schmidt et al. [15] | |||

| El-Sayed [20] | |||

| 4 | Nuclear Fission | Nuclear fission is a nuclear reaction in which the heavy nucleus splits spontaneously into lighter nuclei with release of large amount of energy. | Gaurav et al. [13] |

Fig. 2. Neutron ray interaction with matter [a. Elastic scattering, b. Inelastic scattering, c. Neutron capture, d. Nuclear Fission.

Fig. 2. Neutron ray interaction with matter [a. Elastic scattering, b. Inelastic scattering, c. Neutron capture, d. Nuclear Fission.1.2. Importance of neutron ray shielding

If the neutron ray radiation is exposed for longer period, damage will be higher, so reducing the exposure time near the source of radiation is the preeminent option to lessen the damages. As the distance between source and the body increases, the effect of radiation proportionally decreases. Proper shielding is the foremost method to prevent the high intensity of radiation.

Neutrons can be slowed down using materials that have light atoms. Hydrogen nucleus contains only one proton. Both neutron and proton have almost equal masses. So, when a neutron collides with hydrogen nucleus, the entire energy is transferred to proton and as a result the neutrons are slowed down. On the other hand, when neutron collides with some other heavy nucleus it will bounce and changes its direction. There won't be any change in the speed of neutron. Hence the selection of a material for neutron shielding should be in such a way that it has higher percentage of lighter atoms. Water which is rich in hydrogen can only slow down the neutrons but does not absorb them effectively. Materials having high neutron cross section is used to absorb neutrons. Boron, lithium, and cadmium have high cross section values and hence can be used to absorb slow moving electrons [21].

Additives have been widely used in concrete during the last two decades as they provide a promising option to improve the neutron attenuation characteristics of concrete, which otherwise also possess good neutron shielding capacity. This paper presents a state-of-the-art review of the various additives being used in concrete to improve the neutron attenuation coefficient, the importance of neutron shielding and various test procedures. In general, the current paper offers a critical review of nearly 100 past studies and enables the reader to identify the gaps in the existing literature, which could be investigated in future work.

2. Materials for neutron ray shielding

Due to biological harm caused directly by the neutrons, researchers have concentrated on the development of effective radiation shielding materials which can be used in nuclear power reactors. The various additives used in concrete for the neutron ray shielding are explained in this section. These additives can enhance or diminish the strength of concrete. Some additives, such as supplementary cementitious materials (SCMs) like fly ash or silica fume, can increase the compressive strength of concrete when used in appropriate proportions. On the other hand, an excessive amount of these additives or an improper mix design can lead to a decrease in strength. Apart from the strength characteristics, they can affect the durability of the concrete also. Concrete durability refers to its ability to resist various deteriorating factors over time, such as freeze-thaw cycles, chemical attack, abrasion etc. Additives can positively impact durability by enhancing resistance to specific factors. For example, the incorporation of pozzolanic materials like metakaolin or slag can improve the concrete's resistance to chemical attack. However, it is crucial to ensure that the additives do not compromise other durability aspects, such as the concrete's resistance to sulphate attack, alkali-aggregate reactions etc. Along with these, additives like high-density aggregates, magnetite, boron enriched substances, can be used to increase the concrete's ability to attenuate neutrons. However, it is essential to evaluate the impact of these additives on the strength and durability properties. Achieving a balance between improving neutron attenuation capacity and maintaining the desired mechanical properties requires careful consideration. Engineering specifications and testing protocols are existing to evaluate the overall performance of concrete with additives. These tests assess not only the strength and durability but also other factors like workability, setting time, and shrinkage.

2.1. Water

Water is an excellent and common neutron shielding material owing to its high hydrogen concentration and availability. Since, hydrogen (H) and oxygen (O2) have low atomic numbers, the amalgamation could not be a suitable barrier against gamma radiations. This disadvantage can be overcome by the large shielding thickness. Water fully moderates neutrons. When the thickness of water layer is increased some neutrons are also absorbed but results in emission of secondary gamma rays with high energy that requires further shielding (Fig. 3). So water alone cannot be used as material to shield neutrons.

Fig. 3. Fast neutron interaction with water.

Fig. 3. Fast neutron interaction with water.Blizard et al. [22] found that a minimum of 7% water content in concrete is sufficient for slowing down the neutrons having intermediate energies. At this energy they can be easily captured. With reference to removal cross sectional theory an increase in water content will improve overall neutron attenuation. Contrary to this observation, Prochon et al. [23] commented that there is no impact of water cement ratio and there is no evident relationship between neutron shielding efficiency and bound water concentration.

2.2. Concrete

From the inception of nuclear industry, concrete is gaining widespread use as a shielding material to provide protection against radiation hazards. This is due to the ease of fabrication, low cost of construction, maintenance and its excellent radiation attenuation property (Fig. 4). Concrete is a material that has large amount of hydrogen and is having a density higher than that of water. Hence it can even shield secondary gamma rays produced. Concrete is a heterogeneous mixture of many component materials. In order to shield neutrons, concrete should have greater density in comparison with conventional concrete. The density of the concrete can be increased by adding various additives like iron, steel balls etc. Salim et al. [24] reported that concrete is a very significant material for shielding neutron. Concrete contains elements like hydrogen, iron that can effectively shield fast neutrons which are generally very penetrative. Brandt et al. [25] explained that gamma and neutron radiation leads to loss of water in shielding concrete which makes the concrete less effective.

Fig. 4. Fast neutrons interaction with concrete.

Fig. 4. Fast neutrons interaction with concrete.Concrete structures and radiation shielding effectiveness are affected by changes in cement and aggregate proportions. As an alternative to modifying the cement or aggregate concentration, concrete with additives may be able to shield against neutron rays more effectively than ordinary concrete. Fig. 5shows the classifications of radiation shielding concrete (RSC) based on types of aggregates used.

Fig. 5. Classifications of RSC based on types of aggregates.

Fig. 5. Classifications of RSC based on types of aggregates.Some of the materials or additives used in RSC to improve the neutron attenuation characteristics of concrete are explained below as shown in Fig. 6.

Fig. 6. Additives used in Radiation Shielding Concrete.

Fig. 6. Additives used in Radiation Shielding Concrete.2.2.1. Boron carbide

Boron carbide is a rhombohedral crystalline material which is represented as B4C. It is called as ‘Black Diamond’ because of its extreme hardness. It has a Mohr's hardness between 9 and 10 and is used in making bullet proof vests, armour plating, padlocks, wear resistant products etc. It is also used as neutron absorbers in nuclear reactors, neutron shielding material, control rods, abrasives etc. [7]. Boron is found in significant proportions on earth in compounds known as borate minerals. There are about 100 distinct types of borate minerals, but the most prevalent are borax, kernite, ulexite, and so on. The composition of natural boron primarily consists of two stable isotopes, namely 11B (80.1%) and 10B (19.9%). B4C powder can be manufactured through a chemical reaction of carbon with B2O3 by a carbothermal reduction (gas phase reactions) in an electric arc furnace. Boron carbide is a neutron absorber because of its high B content with a density of 2.52 g/mL at 25 °C. Other properties of boron carbide are insolubility in water, odourless, elastic modulusof 460 GPa, high boiling point and specific gravity 2.52 g/cm3.

Salim et al. [24] reported that boron 10B isotope can easily capture thermal neutrons due to its high capture cross-section property. So when boron is added to concrete, it increases the neutron shielding capacity effectively. Addition of boron to concrete can be carried out in different ways such as boron being added to water directly or adding boron containing materials to concrete.

Abdullah et al. experimented with boron carbide powder (B4C) added in concrete in the ratio of 5%–20% by weight of cement. The neutron radiation exposing results showed that the neutron attenuation effect increases with increase in B4C content [26,27]. They also reported that the concrete density got reduced by the addition of B4C content and hence the compressive strength of the concrete also decreased [18,27,28]. Boron has an adverse impact on the mechanical and hydration properties in radiation shielding concrete (RSC) [29,30], notably in the interfacial transition zone (ITZ) between cement pasteand aggregate. Such adverse effects have been associated with the Portland cement retardation process [[31], [32], [33], [34], [35], [36]] due to the formation of calcium borate hydrate(C–B–H) layer.

Yusof et al. [37] developed boron carbide concrete and the radiation test was carried out by exposing neutron energy source of 241 Am–Be for 15 h at a dosage rate of 29.08 mR/h. The attenuation coefficient of concrete with 20% B4C content is 0.3 cm−1 and concrete without B4C content is 0.24 cm−1. Also, 20% B4C added concrete absorbs more neutrons than 5% B4C added concrete [38,39]. Kharita et al. [33] also reported the effectiveness of B4C as a neutron radiation shielding material.

High density concrete is mostly used for high radiation shielding purposes. Sariyer et al. [40] studied the effect of ferro boron (Fe–B) and boron carbide (B4C) in concrete as aggregate for neutron shielding purposes. The boron carbide and ferro boron added in concrete are ranged from 0% to 20%. However, the concrete prepared with Fe–B resulted in better shielding performance than B4C added one as the Fe–B contains iron particles that have the tendency to slow down fast neutrons by means of the inelastic scattering mechanism [41].

Satish et al. [42] studied the removal cross-section in cement mortar cube with boron carbide as a replacement to cement. From the study they observed that the addition of boron carbide improves the neutron attenuation with a reduction in compressive strength. B4C was increased in the range of 5%, 10%, 15%, 20% and 25% by weight of cement. They found 15% replacement of cement with boron carbide revealed better performance in terms of both strength and neutron absorption. To compensate for the decrease in strength, the addition of pozzolans like metakaolin, micro silica, was added. Studies reported that, addition of silica fume up to 15% causes a significant increase in the mechanical properties and minimal improvement in the radiation shielding properties [43]. The author [42] also performed durability properties, EDS, and SEM analysis to study its microstructural characteristics. The macroscopic removal cross section of the concrete specimen was calculated using suitable analytical methods [44].

B4C nanostructure, manufactured using ball milling method were added up to 5% of total weight of cement for radiation shielding in concrete. SEM analysis and XRD were performed for B4C nanostructures and observed that the compressive strength of B4C nanostructure added concrete shows good results [45].

Shen et al. [46] observed that the neutron radiation of boron carbide containing cement materials decreases with increase in the B4C and thickness of the specimen. Both compressive strength and flexural strength initially increased up to addition of 10% B4C in specimen, beyond which it sharply decreased. They conducted the neutron attenuation measurements by using 14.8 MeV neutrons from the 5SDH-2 accelerator. Abdullah Y et al. [18] experimented with concrete samples of size 100 mm × 100 mm × 100 mm made of boron carbide concrete and irradiated with neutron radiation of 252-californium. It is noted that the radiation attenuation properties of sample containing 20% B4C has highest attenuation characteristics than 5%. Thus, higher content of B4C absorbs more neutrons [38,39].

Experimental and analytical studies were carried out by Chidiac et al. [47] to observe the effect of powdered form of B4C in concrete as neutron shielding material. The presence of sassolite in boron-containing compounds retarded the initial setting time of cement which affects hydration. However, because of the filler effect of fine boron carbide particles, the cement hydration process was greatly increased. The addition of boron carbide powder to concrete as replaced with fine aggregate has no impact on gamma ray shielding and moderately increases its fast neutron attenuation properties when a large percentage of B4C powder is used. Analytical studies were carried out for B4C added RSC concrete mixes for energies ranging between 10 keV and 10 MeV. The authors concluded that a concrete mix with 50% B4C per cement is favourable to the development of concrete early age characteristics to obtain the effective neutron attenuation. According to the literature on the use of boron carbide, sassolite (boric acid) and borax even in small amounts delay the setting time of cement [40,[48], [49], [50], [51], [52]].

The addition of high-density materials such as ferro-boron and iron can improve the neutron shielding capacity of concrete [40,53], the shielding capability improved while the thickness of concrete decreased. FLUKA code is used to check the neutron attenuation capacity of concrete by adding B4C, FeB, and Fe [54]. These additive materials in concrete varies between 0% and 20%. The interaction of a 1000 MeV proton beam with a 50 mm × 50 mm × 50 mm copper target was used for the production of energetic neutrons. The results suggest that composite concrete can outperform conventional concrete as a neutron shielding material, especially if its density is raised. From the experiment it is clear that B4C is ineffective against high energy neutrons since it has low density. As a result, increasing B4C concentration should not result in a major change in attenuation rates. Hence the concrete with B4C can be used for slow neutron attenuation. As a result, concrete with varied ratios of FeB and Fe could be used with less concrete thickness and neutron resistance properties.

Dijulio et al. [55] developed a neutron shielding concrete by adding B4C for neutron capture and hydrogen atom in polyethylene form. It is found that the concrete was not strong as it exhibits 15% lower mass density when compared to reference concrete. But the shielding efficiency of neutrons is higher up to 40% compared to reference concrete. PVA fibers and B4C were used in concrete by Rico et al. [56]. PVA fibers are incorporated to minimize the spalling effects of concrete and also to improve the mechanical properties. 5% B4C is used in their study to increase the neutron shielding, and the related performance was tested at elevated temperature ranging from 100 °C to 1000 °C. Physical and mechanical properties were studied, and the result showed that the elevated temperature decreases the mechanical properties with increased porosity due to the melting of PVA fibers, and resulting into reduced shielding effect.

2.2.2. Iron oxide aggregate - boron carbide

Majid et al. [57] conducted an experiment on radiation shielding concrete by incorporating iron oxide aggregates and boron carbide powder. Two variants of iron oxide aggregates, namely hematite and magnetite aggregates, were investigated. Cement was partially replaced with boron carbide at 2.5%, 5%, and 10% respectively. The study focused on evaluating the compressive strength, ultrasonic pulse velocity, and density of the concrete specimens. To determine the linear attenuation coefficient, the specimens were subjected to gamma radiation using 60Co isotopes. The addition of nano silica helped to compensate for the decrease in compressive strength caused by boron carbide, eventhough it slightly reduced the linear attenuation coefficient by 4%. Nonetheless, the concrete mixes containing both boron carbide and nano silica consistently exhibited superior properties compared to conventional concretes. Monte Carlo simulations were employed by the authors to quantify the linear attenuation coefficient, and the results closely aligned with the actual observations, with a maximum discrepancy of 2% for gamma-rays.

The presence of boron carbide decreases the concrete compressive strength and increases the porosity [24,27,48]. Hence in order to compensate this strength parameter 5% of nano silica is added to the concrete mix [[58], [59], [60]]. Other admixtures like silica fume [61,62], micro silica, and flyash [63] can also be added to concrete to compensate for the strength reduction. By adding flyash and micro silica to cement, concrete is strengthened. Also, CSH (Calcium Silicate Hydrate) gel is formed around the cement particles, resulting in a highly dense, nonporous.

Gencel et al. [64] tested the gamma-ray and neutron shielding properties of concretes with varying hematite concentrations. Their findings indicated that the inclusion of hematite in concrete does not impact neutron absorption but enhances both gamma ray attenuation and mechanical strength.

Apart from this, the authors [[65], [66], [67], [68], [69]] also used hematite and magnetite aggregate [70] for their study and concluded that it is having a good neutron attenuation characteristic.

2.2.3. Boron mixtures

Kharita et al. [33] used boric acid (H3BO3), boron frit, and borax (Na₂[B₄O₅(OH)₄]·8H₂O) in concrete to check the radiation attenuation. Due to the adverse effects on the cement setting process, the inclusion of boric acid [71,72] and boron frit is not suited for improving the shielding characteristics of concrete. Boric acid is added up to 3% by weight of cement or 0.5% of the total concrete volume is acceptable. Similarly, 0.5% borax addition in total volume of concrete did not show any significant effects on strength of concrete. The test results concluded that borax has poor shielding efficiency for gamma rays but was efficient in thick concrete (1000 mm) shields, because it reduces the capture of gamma rays up to 80% better than unborated concrete. Further studies are carried out using boric frit [73] and boric acid [71] for radiation attenuations.

2.2.4. Siderurgical aggregate

Siderurgical aggregates a by-product from electric arc furnaces having high density were mixed with concrete to study the radiation shielding property. High density materials are widely used for radiation shielding. Aggregates having density [74] more than 3000 kg/m3 rich in iron oxides [57] such as limonite, ilmenite, hematite, magnetite, goethite [75,76], are used in high density concretes for gamma radiation shielding. Hydrogen (H) and Carbon (C) are the chemical elements having large neutron scattering cross sections. High cement volume will provide a huge amount of C based and hydrated products. The author [77] studied the shielding efficiency of siderurgical aggregate concrete (SA) such as SLC (concrete mix with fine and coarse siderurgical aggregate with limestone incorporation), SSC (concrete mix with fine and coarse siderurgical aggregate with crushed siderurgical aggregate sand 0–2 mm incorporation) with the ordinary magnetite concrete (MMC) and lime stone concrete mix (LLC). Physical and mechanical properties were carried out for different mixes, gamma radiation and neutron shielding studies were performed analytically using MAVRIC and MCNP codes. Furthermore, an investigation was carried out to determine the effect of the w/c ratio and cement content on shielding efficiencies. SA added concrete performs similar to limestone aggregate and magnetite concrete in terms of linear attenuation coefficient and neutron transmission rate. The increase in cement and the water cement (w/c) ratio resulted in a drop in the linear attenuation coefficient and a decrease in the neutron transmission rate, but the change in the w/c ratio had no effect on the neutron transmission rate.

2.2.5. Polymer incorporated concrete

Piotrowski et al. [78] reported that polymer addition resulted in a considerable improvement in neutron shielding characteristics. Polymer Cement Composite(PCC) repair mortar shows good results in fast neutron attenuation and also thermal neutron absorption. This is most likely owing to the higher amount of hydrogen atoms from the polymer hydrocarbon chains.

Epoxy resin increases the shielding characteristics of mortars and concrete for neutron radiation, and the insertion of such polymer into heavyweight concrete can improve its neutron shielding effectiveness. Piotrowski et al. [79] used gadolinium and epoxy resin to improve the thermal neutron attenuation. Gadolinium is an effective material for attenuating lower energy neutrons but is ineffective for rapid neutron shielding; no drop in flux were observed for thicknesses.

A number of plastics such as polyurethane, polyvinyl chloride and polystyrene are considered as hazardous. Malkapur et al. [80] examined the neutron and gamma radiation shielding by impregnating waste plastics in concrete called waste polymer incorporated concrete (WPIC). Six different concrete mixes, control concrete (CC), polymer incorporated mix (P), polymer incorporated mix with steel slag as fine aggregates (PS), PS with full replacement of coarse aggregate by iron ore pellets and steel slag as fine aggregate (PSI), PSI with additive borax admixture (PSIB) were cast and tested to study the radiation shielding efficiencies. 241Am–Be radiation source was used to irradiate all the slab specimens. WPIC mix (PS, PSI and PSIB) attained acceptable compressive strength and neutron shielding properties. PSIB mix shows reduction in neutron dose transmission in the range of 30–40.7% than control concrete (CC). FLUKA code [44] is also used to study the attenuation properties for different types of radiation sources.

Belyakov et al. [81] used furfurylidene-C3H6O polymer concrete and polymer cement (PCC) concrete with pulverised polyethylene as a filler material. The relaxation length of neutron with energy greater than 0.5 MeV were measured. Polyethylene added to concrete reduces 25–30% of the shielding thickness of concrete and achieves good neutron attenuation.