1. Introduction

Nowadays, due to depleting high-quality ores and rich resources, the importance of processing low-grade and complicated iron ores, specifically those with high silicate gangue minerals, in a cost-effective and environmentally friendly manner is becoming increasingly evident (Birinci and Gök, 2021, Fang et al., 2019, Kumar and Luukkanen, 2019, Mehrabani et al., 2010). Processing iron oxides could be varied based on their deposit types and associated gangue phases (Yellishetty et al., 2010). Magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO[OH]), limonite (FeO[OH].nH2O), and siderite (FeCO3) are the main iron oxide minerals (Filippova et al., 2014, Gao et al., 2020, Liu et al., 2022a, Liu et al., 2014, Liu et al., 2019, Montes and Montes Atenas, 2005, Wang et al., 2022b). Magnetite is particularly important due to its occurrence in large quantities and its ability to be economically mined, while it has straightforward processing via mainly low-intensity magnetic separation. However, a significant proportion of the iron reserves in Earth's crust is completely oxidized iron, mainly hematite. Nowadays, with the decrease in the grade of magnetite reserves in shallow deposits, it is necessary to extract it from greater depths (Nakhaei and Irannajad, 2018). Thus, extracting and beneficiating other complicated iron ores, more specifically hematite, goethite, and ultrafine magnetite, is essential to completely meet the needs of industries (Arvidson et al., 2013, De Moraes and Kawatra, 2010, Eisele and Kawatra, 2010, Haselhuhn and Kawatra, 2015, Kawatra et al., 2004, Shen and Huang, 2005, Zhang et al., 2022, Zhang et al., 2017, Zhu et al., 2022).

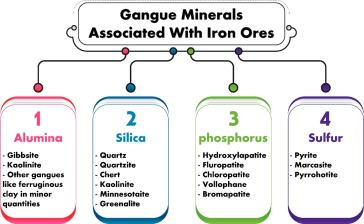

Several separation methods can process these complex iron oxides and reject their associated gangue content, including washing, magnetic-based techniques, gravity-based methods, and flotation separation (most practically a combination of these separation techniques) (David et al., 2011, Svoboda, 1989, Zeng and Dahe, 2003). However, the fine association of gangue minerals with valuable iron oxides makes physical separation methods somehow inefficient (Filippov et al., 2014), especially for ultrafine silicates, which can be mentioned as the prevalent gangue phase in iron oxide deposits. Others can be added to this list as phosphorous, alumina, and sulfur (Fig. 1) (Pattanaik and Venugopal, 2018).

Fig. 1. Gangue minerals associated with iron ores (Pattanaik and Venugopal, 2018).

Fig. 1. Gangue minerals associated with iron ores (Pattanaik and Venugopal, 2018).Flotation is the most widely used and effective processing method for fine and ultrafine liberated iron oxide mineral separation, which can be carried out directly or indirectly (reverse flotation). Currently, there has been a growing trend toward reverse flotation, in which the surface of iron oxide minerals is deactivated by adding depressants (Li et al., 2019, Yang and Wang, 2019). Various reasons can be considered for such a trend, such as the high iron oxide minerals/silicate ratio in the ores, being more cost-effective than direct process, less sensitive to slimes, and enhancing the selectivity (Lu et al., 2017, Shrimali et al., 2017). Moreover, silicates can be strongly activated by the abundant Fe3+present in the silicate-iron oxide mineral flotation system due to the highly reactive Fe3+ resulting from mineral dissolution. Thus, their separation could be quite challenging in practice through direct iron oxide flotation (Yuan et al., 2018, Ng et al., 2015, Peng et al., 2017, Vidyadhar et al., 2012).

Several different depressants have been used for iron oxide depression during its reverse flotation (mostly polysaccharide-based and polyphenolic-based), which some review articles have named them through the general iron oxide flotation conditions (Araujo et al., 2005, Filippov et al., 2014, Houot, 1983, Ma, 2012, Rath and Sahoo, 2020, Uwadiale, 2010). However, no review has comprehensively investigated the mechanisms and conditions of biodegradable depressants during the reverse flotation of iron oxide minerals. Since it is essential to understand the behavior of iron oxide minerals in the presence of these depressants, the present review aims to robustly explore the performance of various environmentally friendly depressants used in the effective separation of iron oxides from their accompanying troublesome gangue phases. Numerous factors that have to be considered for their applications have been reviewed. Adsorption mechanisms were analyzed, and gaps within each area were highlighted.

2. Iron oxides flotation routes

Iron oxide minerals and their associated gangues are varied in their physicochemical properties, which results in different flotation behavior (Montes and Montes Atenas, 2005). As mentioned, the direct flotation (DF) route could be a way to separate iron oxide minerals from their gangues. However, the presence of hydrolyzable cations such as Ca2+, Mg2+, and Fe3+ ions in the flotation environment significantly decreases the selectivity of the direct flotation route by activating gangue surfaces that also float along with iron oxide minerals (Ma, 2012). Thus, the DF process seems to be a potential technique for concentrating iron oxides from tailings. In this route, although fatty acids have been reported as appropriate collectors, the depression of gangue minerals is challenging (Marins et al., 2020, Matiolo et al., 2020, Pan et al., 2019, Tang and Tong, 2020, Wang et al., 2022a).

To tackle problems involved in DF, reverse flotation has been considered for processing iron oxide ores, which can be divided into two categories: reverse anionic flotation (RAF) and reverse cationic flotation (RCF) (Han et al., 2022b). Through reverse flotation, iron oxide minerals would be deactivated by different depressants (Fig. 2) to minimize their collector adsorption, and gangue phases will be floated with various collectors (Table 1). RCF has been the most extensively used route for upgrading iron oxide minerals (Marins et al., 2020). As the most common impurity, quartz is usually floated with ether amines in RCF. When mineral processors had no access to amines, early quartz flotation was conducted using the RAF method, which can be employed for activated quartz (Araujo et al., 2020, Lima et al., 2013, Safari et al., 2020, Silva et al., 2021, Yehia et al., 2021).

Fig. 2. Schematic representation of main flotation routes for iron oxide ores.

Fig. 2. Schematic representation of main flotation routes for iron oxide ores.Table 1. Common anionic and cationic collectors in iron ore reverse flotation.

| Type | Collector | Floated Mineral | Depressed Iron Ore | pH | Ref. |

|---|---|---|---|---|---|

| Anionic | Sodium Oleate | Quartz | Hematite | 9 | (Yang and Wang, 2019) |

| Sodium Oleate | Quartz | Hematite | 11.5 | (Ma et al., 2011) | |

| Sodium Oleate | Quartz | Hematite | 11.5 | (Han et al., 2022a) | |

| Sodium Oleate | Quartz | Siderite | 11.4 | (Luo et al., 2016) | |

| Oleic Acid | Apatite | Hematite | 7 | (Yehia et al., 2021) | |

| Sodium Alginate | Chlorite | Hematite | 11.5 | (Fu et al., 2021) | |

| A 1:1 mixture of Alke 742 FL and Dirole | Quartz Apatite | Magnetite Hematite Goethite | 9.5 | (Tohry and Dehghani, 2016) | |

| TD-II | Quartz | Hematite | 11.5 | (Sobhy et al., 2021) | |

| TD-II | Quartz | Hematite | 11.5 | (Tao et al., 2021) | |

| Cationic | Ether Amine | Quartz | Hematite | 9.5 | (Lima et al., 2013) |

| Ether Amine | Quartz | Hematite | 10.5 | (Ma et al., 2011) | |

| Ether Amine | Quartz | Hematite | 11 | (Han et al., 2022b) | |

| Dodecyl Amine | Quartz | Hematite | 8 | (H. Wang et al., 2021) | |

| Dodecyl Amine | Quartz | Hematite | 10 | (Dong et al., 2022) | |

| Dodecyl Amine | Quartz | Magnetite Hematite Pargasite | 10 | (Filippov et al., 2010) | |

| EBAB | Quartz | Magnetite | 7 | (Huang et al., 2014) | |

| Amide Amine | Quartz | Hematite | 11 | (Macedo et al., 2022) |

EBAB: ethane-1,2-bis(dimethyl-dodecul-ammonium bromide.

In the reverse flotation of iron oxides, sodium silicate, and sodium co-silicate have been reported as promising depressants by which an iron concentrate with high recovery could be resulted (Arantes and Lima, 2013, Tohry and Dehghani, 2016). However, efficient and selective inorganic depressants can cause serious environmental issues and increase the costs associated with their handling (Mu et al., 2016). Thus, depressants derived from natural resourceshave recently gained considerable attention in various flotation systems. Their comparatively low price and biodegradable, environmentally friendly, and green nature make them ideal alternative reagents (Bicak et al., 2007, Dong et al., 2021, Liu et al., 2022b, Liu et al., 2021, Mu et al., 2016, Sanwani et al., 2021, Valdivieso et al., 2004).

3. Natural depressants

Biodegradable chemicals refer to naturally-occurring substances that can be decomposed into simpler harmless components to humans and the environment. Since microorganisms (bacteria and fungi) carry out the biodegradability process, using these organic chemicals can greatly help move towards green and environmentally friendly processes (Hyvönen et al., 2005). Different eco-friendly depressants have been investigated for iron ore oxides depression flotation, including polysaccharides polymers (starch and guar gum), wood extracts (lignosulfonate-based biopolymers), and tannin-based depressants (tannic acid and quebracho). These substances display a high degree of complexity in terms of chemistry and interaction characteristics. Additionally, raw material composition and flotation route can significantly affect the obtained results in the separation process (Bulatovic, 2010, Bulatovic, 1999). However, these reagents usually have similar structural characteristics as follows: (I) They have a hydrocarbon-based backbone that can easily adsorb on the mineral surfaces, driving them hydrophilic; (II) In most cases, a great number of hydroxyl (OH−) groups have been distributed throughout the structures, making them able to develop hydrogen bonding or ionization; (III) They contain various strongly hydrated polar groups, such as SO32−, COO−, etc. which are also frequently dispersed through the molecule (Pugh, 1989). It is generally believed that these reagents can adsorb onto the mineral surface through various interactions. Their hydrophilic functionalities improve the surface's hydrophilic properties, reduce bubble-particle attachment, and facilitate iron oxide mineral depression (Beaussart et al., 2009, Kar et al., 2013).

3.1. Polysaccharide-based depressants

3.1.1. Starch

Starch is a colorless semi-crystalline solid substance that can be found in various sources such as plants, cereals, and fruits. Starch has been extensively employed in various industrial applications since it is an inexpensive, available, and environmentally friendly polymer (Rath and Sahoo, 2022). This nonionic polymer has been categorized as a polysaccharide composed of glucose monomers bound to each other through glycosidic bonds. Starch's primary chemical representation is (C6H10O5)n, where “n” stands for the units of aldohexose, a monosaccharide (Laskowski et al., 2007, Liu et al., 2000, Yang and Wang, 2018).

Normal starch generally contains two types of glucose polymers, namely amylopectin (AP) and amylose (AM) (Fig. 3). However, phosphorus, fatty acids, proteins, and some other inorganic substances are starch’s impurities. Frequently, industrial-grade starches comprise 70–80% AP, 20–30% AM, and <1% lipids, proteins, and other components (Kar et al., 2013, Rath and Sahoo, 2020). Both AM and AP are polysaccharides composed of 1,4-linked α-glucose monomers. While AM is basically a long linear molecule, AP is a highly-branched molecule composed of numerous chains linked together by 1,6 linkage (Correa de Araujo, 1988, Pawar et al., 2008, Zhao et al., 2021).

Fig. 3. Amylose (AM) and amylopectin (AP) structures (Pawar et al., 2008).

Fig. 3. Amylose (AM) and amylopectin (AP) structures (Pawar et al., 2008).Each starch polymer contains three hydroxyl groups free on the cyclic glucose units, and they may rotate to one side of the glucose ring, increasing the hydrophilicity of that side. The other side is somewhat hydrophobic because of –CH groups. It is known that, in aqueous solutions, AM creates a helix through six glucose monomers per turn. The internal helix is hydrophobic, while the outer shell is mostly hydrophilic (Pavlovic and Brandao, 2003). AP can be a flotation or flocculation reagent, while AM has a low affinity for reacting with minerals (Kar et al., 2013).

Since fine particles in the flotation process have high specific surface areas, the consumption of natural starch as the depressant is too high. Starch is usually modified through different methods, including chemical, physical, and compound modifications, to improve its adsorption on the surface of iron oxides. In this way, starch consumption in the froth flotation process is reduced (Tharanathan, 2005). Among them, chemical techniques are the most common modification (synthesizing) method, which produces modified products, namely carboxyl methyl starch, dextrin, phosphate ester starch, and oxidized starch (Cao et al., 2015, Fletcher et al., 2020, Yue and Wu, 2018, Zhou et al., 2019). There have been reports of effectively using modified starches in froth flotation, but only for laboratory studies. In mineral processing plants, caustic starch has been extensively employed in RAF and RCF for beneficiating iron oxide minerals. New forms of starches have been produced in recent years to improve their depression efficiency. It can also depress other minerals, such as separating copper sulfides from carbonaceous materials (Chimonyo et al., 2020a, Chimonyo et al., 2020b) and fluorite from calcite (Sun et al., 2022).

3.1.1.1. Starch types

Starch can be produced from various sources, such as rice, corn, potato, etc. (Table 2). Corn starch is commonly used as a depression reagent for iron-containing minerals because of its effectiveness, affordability, and availability (Kar et al., 2013). Soluble starches (soluble only in hot water) are frequently used in flotation (Quast, 2017). When parameters such as solution pH, temperature, or mass ratio of AP/AM are increased, the solubility of starch increases (Yang et al. (2017) exhibited that the more the percentage of AP in starch structure, the easier its dissolution). However, using alkali or thermal techniques, the gelatinization process can also improve starch’s solubility. Starch dissolution consists of three phases: swelling, rupturing, and releasing starch molecules/ghosts (Yang et al., 2017). Corn starches are inexpensive and green depressants for depressing iron oxide minerals, but their solubilities in water with natural pH and at ambient temperature are low (Yang et al., 2017). After the dissolution of starch in an aqueous environment, a complex system is created, which consists of two parts. A portion of the reagent is dispersed, while the rest is associated with molecules. The main characteristics of an aqueous starch system are pH and the electrolytes present in the aqueous environment. Although starches generally react with alkali solutions, the reactions could be complex (Quast, 2017).

Table 2. The characteristics of different types of starch (Kar et al., 2013).

| Species |

Granule Size (μm) |

Avg. Size (μm) |

AM (%) |

AP (%) |

M.W. (Da) |

Moisture (%) |

Fat (%) |

Protein (%) |

Phosphorus (%) |

|---|---|---|---|---|---|---|---|---|---|

| Rice | 2–13 | 5.5 | 0 | – | 8.9 × 10 7 | 12 | 0.4 | 6.7 | 0.06 |

| Corn | 5–25 | 14.3 | 28 | 70 | 2.27 × 108 | 13 | 0.8 | 0.35 | 0.02 |

| Potato | 10–70 | 36 | 20 | 73 | 1.9 × 105 | 19 | 0.1 | 0.10 | 0.08 |

| Soluble | – | – | 25 | 75 | Low | 20 | – | – | – |

One of the new forms of chemically modified starches is metallic-starch complex (MSC) solutions. To synthesize MSCs, an ionic solution of relevant metal is mixed with a caustic starch solution. The MSCs are nano-sized colloidal complexes arranged by hydrophilic metal hydroxide as the colloidal nucleus on which hydroxyl and starch complex is adsorbed. This process leads to the creation of a bigger molecule than caustic starch. Yue and Wu (2018) exhibited that the depression effect of some MSCs (Fe3+, Zn2+, Pb2+, and Mg2+) on the surface of iron oxides such as hematite was more than the caustic starch, and the order of their depression effect is as follows: Zn2+-starch > Pb2+-starch > Fe3+-starch > Mg2+-starch > Caustic starch. However, it was noted that the Fe3+-MSC showed the highest selectivity among MSC depressants in flotation experiments (Yue and Wu, 2018).

As mentioned, based on their chemical structures, starch types may lead to different metallurgical responses (Table 3). It was reported that maize starch does not modify hematite wettability during RCF; however, it can effectively limit the adsorption of a cationic collector (mono ether amine) on the hematite surface. Higher concentrations of amine may have an adverse effect on the separation process; thus, it should be avoided (Shrimali et al., 2018). A comparison impact study of four distinct starches (including soluble starch (SS), corn starch (CS), potato starch (PS), and rice starch (RS)) for hematite depression in RCF utilizing dodecyl amine as the collector showed that SS could lead to the maximum hematite recovery. The performance of SS was shown to be superior to that of other starches in all circumstances (Kar et al., 2013). Hematite can be clearly depressed by soluble starch during apatite flotation by sodium oleate, and apatite can be floated satisfactorily at a pulp pH of 10. However, using a high amount of soluble starch would be reduced the process efficiency (Bai et al., 2019).

Table 3. Application of various starches in iron oxide flotation.

| Depressed mineral | Associated minerals | Starch type | Dosage | pH | Collector | Metallurgical responses | Ref. |

|---|---|---|---|---|---|---|---|

| Hematite | Quartz | Corn | 5 mg/L | 8.5 |

DAC 22 mg/L |

Fe Grade: 65% Hematite Recovery: 97% |

(Yang et al., 2017) |

| Magnetite, Paragasite | Quartz | Corn | 100 mg/L | 10 |

DDA 24 mg/L |

In the presence of Fe–Mg–Al-bearing silicates, corn starch cannot selectively depress magnetite at pH 10. |

(Filippov et al., 2013) |

| Hematite | Quartz | Corn | 600 g/t | 10.5 |

AEA 45 g/t |

Fe recovery: 65% SiO2content < 1% |

(Turrer and Peres, 2010) |

| Hematite | Quartz | Corn | 500 g/t | 9 |

NaOl 5000 g/t |

Hematite Recovery: 70% | (Yang and Wang, 2019) |

| Hematite | Quartz | Gelatinized Corn | 1000 g/t | 9.5 |

Ether Amine (150 g/t SiO2) |

Recovery: 79% | (Lima et al., 2013) |

| Hematite | Quartz |

Causticized Corn |

100 mg/L | 10.5 |

MEA 50 mg/L |

Hematite recovery: 97.7% | (Shrimali et al., 2018) |

| Hematite | Quartz | Caustic | 1200 g/t | 7.5 |

DDA 625 g/t |

Fe Recovery: 81.79% | (Yue and Wu, 2018) |

| Fe3+-Starch | Fe Recovery: 86.50% | ||||||

| Zn2+-Starch | Fe Recovery: 89.40% | ||||||

| Pb2+-Starch | Fe Recovery: 88.15% | ||||||

| Mg2+-Starch | Fe Recovery: 85.47% | ||||||

| Hematite | Quartz |

Soluble Starch Corn Starch, Potato Starch Rice Starch |

400 g/t | 10.5 |

DDA 32 g/t |

Fe Grade: 64% Hematite Recovery: 89% |

(Kar et al., 2013) |

| Hematite | Quartz | Sorghum | 10 mg/L | 10 |

Ether Amine 20 mg/L |

Quartz floated: 98% Hematite floated: 5% |

(Silva et al., 2019a) |

|

Goethite Magnetite Siderite Hematite |

P2O5 |

Starch Guar gum |

1200 g/t | 10.5–11 |

Tall oil 800 g/t |

P2O5 Grade: 37% P2O5 Recovery: 83% |

(Nanthakumar et al., 2009) |

DAC: dodecyl ammonium chloride, DDA: dodecyl amine acetate salt, MEA: mono ether amine, AEA: alkyl ether amine, NaOl: sodium oleate.

The effects of various starches (corn, wheat, potato, rice, and dextrin) were examined for hematite depression in a mixture containing 80% hematite and 20% quartz using cetyl trimethyl ammonium bromide (CTAB) as a cationic collector for quartz. It has been reported that corn and wheat starch performed better than the other types (Abdel-Khalek et al., 2012). Yang and Wang examined different corn starches varying in ratios of AM to AP (including waxy starch (WS, 0:100), normal starch (NS, 27:73), and Gelose 50 (G50, 50:50)) for column RAF separation of hematite from quartz. They indicated that corn starch with a higher AP content decreased froth and collection zone of Fe more than corn starch with a lower AP content. According to their findings, the overall performance of RAF followed the order of WS > NS > G50 (Fig. 4) (Yang and Wang, 2019).

Fig. 4. The effect of various starches on the iron recovery and grade in the hematite-quartz flotation system (Yang and Wang, 2019).

Fig. 4. The effect of various starches on the iron recovery and grade in the hematite-quartz flotation system (Yang and Wang, 2019).Corn, sorghum flour, and sorghum starch were examined for hematite depression in the CRF. Sorghum starch showed great potential as an alternative to corn starch. In alkaline pH (9–10), both sorghum and corn starches can be effective depressants for hematite depression. However, sorghum flour requires greater dosages to perform similarly (Silva et al., 2019a). In all pH levels examined (3–12), sorghum starch doses less than 40 mg.L−1 recovered more quartz than corn starch. Quartz floatability is intensely reduced by adding sorghum or corn starches; however, it is hardly affected by the presence of sorghum flour. It also should be noted that high dosages of starches as a depressant can result in poor separation efficiency. The best quartz floatability was obtained using sorghum starch as a hematite depressant, especially at low dosages and pH 9 and 10 (Silva et al., 2019a, Silva et al., 2019b).

3.1.1.2. Surface interactions

Starch strongly adsorbs onto some minerals, such as hematite. Different mechanisms have been detected for starch adsorption onto various mineral surfaces. It has recently been demonstrated that hydroxyl ions on starch molecules and hydroxylated metal locations on the surface of minerals interact together strongly, which is responsible for the chemical adsorption of starch. (Filippov et al., 2013, Laskowski et al., 2007, Moreira et al., 2017, Partridge and Smith, 1971). In general, the main adsorption parameters are the adsorbent mineral, starch type, starch concentration, and other soluble substances, pH (Schulz and Cooke, 1953).

The hydrogen bonding between numerous (–OH) groups present in the starch structure, and the hematite surface was thought to be responsible for the hematite depression by starch. However, starch selectively adsorbs on the hematite surface mainly because of numerous hydroxylated Fe-sites on the hematite particles (Rohem Peçanha et al., 2019). It has also been reported that polysaccharides such as starch have a low affinity for some other minerals (quartz, for instance). However, starch as a macromolecular polymer can bind particles together during flocculation, leading to slight depression of quartz (Chen et al., 2007, Yang et al., 2017). Starch adsorbs onto only silicon surface sites on the quartz, predominantly at pH values between 1.8 and 5.0 (Rohem Peçanha et al., 2019). In RCF of iron ore, using an amine-based cationic collector (alkyl ether amine) can increase starch adsorption on the quartz particles, leading to hydrophobic surfaces (Lima et al., 2013). Sodium oleate (C18H33NaO2), another well-known collector of activated quartz (usually by metal ions such as Ca2+), would adsorb on the hematite surface without starch. While investigations revealed that when using starch, the distance between the hematite surface and oleate ion is too wide to allow oleate adsorb (Li et al., 2019).

It was reported that the iso-electric point (iep) of pure hematite (in the absence of flotation reagents) varied from 4.5 to 7.1 (Table 4). The factors influencing this variation are sample preparation methods, conditioning time, zeta-potential measurement techniques, and mineralogy. The general assessment indicated that various starches affect the hematite iep. No noticeable shift was documented with the addition of soluble starch (from 6.2 to 6) and rice starch (from 6.2 to 6.1) on hematite. However, its iep was changed to 6.8 and 7.1 when potato and corn starch was adsorbed on its surface, respectively. The caustic starch and Fe3+-starch also could decrease hematite’s iep from 6.5 to 4.5 and 6.2, respectively (Yue and Wu, 2018). Starch generally drives the hematite surface charge more negatively (Table 4) (except in some reports (Abdel-Khalek et al., 2012, Kar et al., 2013)).

Table 4. Iso-electric point of hematite with and without the addition of various starches.

| Absence of Depressant | Presence of Depressant | Depressant | Dosage (mg/L) | Ref. |

|---|---|---|---|---|

| 4.8 | Zero at pH > 4 | Starch | 500 | (Rohem Peçanha et al., 2019) |

| 5.82 | Zero at pH > 4.5 | Starch | 40 | (Bai et al., 2019) |

| 4.5 | 3.1 | Starch | 12 | (Moreira et al., 2017) |

| 4.5 | 3.5 | Starch | 25 | |

| 4.5 | 3.2 | Starch | 550 | |

| 6.5 | 4.5 | Caustic Starch | 10 | (Yue and Wu, 2018) |

| 6.5 | 6.2 | Fe3+-Starch | 10 | |

| 6.2 | 6 | Soluble Starch | 1000 | (Kar et al., 2013) |

| 6.2 | 7.1 | Corn Starch | 1000 | |

| 6.2 | 6.1 | Rice Starch | 1000 | |

| 6.2 | 6.8 | Potato Starch | 1000 | |

| 7.1 | 9.2 | Wheat Starch | 1500 | (Abdel-Khalek et al., 2012) |

Lima et al. (2013) examined the impact of ether amine (as a quartz collector) and gelatinized corn starch (as depressant) dosages during RCF for three size fractions of hematite, including fine (−45 μm), coarse (−150 +45 μm), and global (−150 μm). Since the coarse particles possess a lower specific surface area (Table 5), they need a lower starch concentration to be depressed. The proper starch dosage for the coarse fraction was between 250 and 500 g.ton−1. In higher dosages, there was the possibility of unbound starch molecules onto the mineral surface in the solution. The increase in starch dosage from 500 to 1000 g.ton−1 could result in a modest rise in SiO2 content in the concentrate. It was also concluded that increased amine dosages might cause clathrateformation between amine and starch molecules, explaining the rise in SiO2concentration in coarse-size concentrates. For effective flotation, the total amine consumption for the coarse fraction was five times higher than for the entire fraction and seven times higher for the fine fraction (Lima et al., 2013).

Table 5. Specific surface area and amine dosages for the three hematite size fractions (Lima et al., 2013).

| Fraction | Size (μm) | Specific surface area (cm2/g) |

|---|---|---|

| Global | −150 | 550 |

| Coarse | −150 + 45 | 450 |

| Fine | −45 | 750 |

Unlike usual depressants that are mainly used at froth flotation, starch may not prevent surfactant adsorption. During calcite flotation, for instance, starch adsorption increased by oleate (collector) presence, indicating a significant cooperative interaction between the adsorbed starch and oleate ions (Somasundaran, 1969). In the hematite RCF using dodecyl amine as a collector, the presence of starch increases amine adsorption in acidic solutions but decreases its adsorption density in alkaline pH. Additionally, starch adsorption can be improved by increasing amine concentration up to 10−4 mol.L−1 and then decreasing it (Partridge and Smith, 1971). It has also been proven that branching can enhance starch adsorption's surface activity and selectivity. Branching may happen by altering the alkali or acid properties of the solution, temperature, or through oxidation (Quast, 2017).

Along with the depressing effect of starch on hematite, it has been demonstrated that corn starch can also flocculate fine particles in the flotation separation of hematite. The flocculation effect is based on particle size, with more flocculation for smaller particles. Thus, starch serves as both a depressant and a flocculant in the reverse flotation of iron oxide ores. It can act as a depression reagent by not allowing the adsorption of a collector (amine) on the surface of hematite, maintaining it hydrophilic, and as a flocculation agent, aggregating fine particles of hematite. The flocculation effect, in turn, is significant. If the fine hematite particles are not flocculated, the flotation efficiency may be considerably reduced due to their presence in the froth zone during the reverse flotation. The results have also indicated that the flocculation effect is because the corn starch depends on the hematite particle size, and a higher flocculation effect occurs for a −5 µm size fraction (Shrimali et al., 2018). The flocculation of fine particles using starch was also confirmed by Liu et al. (2006). It was shown that moderately high molecular weight polymer depressants such as corn starch and carboxymethyl cellulose (CMC) with a molecular weight of about 700,000 render the hematite and hydroxyapatiteparticles hydrophilic. Therefore, these particles flocculated. This phenomenon depresses the genuine flotation of the hematite particles and reduces their mechanical entrainment (Liu et al., 2006).

3.1.1.3. Mineral’s impact

Generally, the recovery of quartz flotation can be adversely affected when carbonate-bearing gangues, siderite (FeCO3), and dolomite (CaMg[CO3]2) are present in the flotation system. Under these conditions, iron oxides cannot be selectively separated from quartz (Faramarzpour et al., 2022, Wonyen et al., 2018). This phenomenon occurs because of the CaCO3 formation, which can precipitate on the quartz particles and interact with starch molecules (Luo et al., 2016). A molecular simulation study assessed the performance of various reagents in a flotation system containing hematite, quartz, and siderite. Results demonstrated that both hematite and siderite could react with starch. While calcium ions (in CaCl2 solution) did not interact with the siderite particles, and hydroxyl radicals could locate there. The formation of Ca(OH)+ and its connection to –COO− led to quartz separation. However, the activation of quartz surfaces by Ca2+ could not occur when fine particles of siderite covered the quartz surface. Therefore, quartz particles were unfavorably inhibited in iron reverse flotation. It should be noted that oleate ions (collector) could penetrate the layer of starch adsorbed on the surface of siderite particles and enhance its floatability. In other words, the high content of fine siderite negatively affects the flotation separation efficiency (Hao et al., 2018). It was also reported that siderite could affect RAF of hematite from quartz considerably more than dolomite (Luo et al., 2016).

In addition to hematite, other iron-bearing oxide minerals, such as magnetite and pargasite, can be depressed using starch in the reverse flotation process. Pargasite, a complex inosilicate mineral of the amphibole group with formula NaCa2(Mg, Fe2+)4(Fe3+, Al)Si6Al2O22(OH)2, is present in some iron deposits. Some research has investigated the possibility of using starch in systems containing this Fe–Mg–Al-bearing amphibole (Filippov et al., 2010). After using starch, significant changes in pargasite surface characteristics imply that starch can bind to the amphibole particles. The reason for this reaction is both H-bonding with hydroxyl groups present on the surface (as in the case of quartz) and the development of a surface chemical complex with metal atoms (as in the case of magnetite) (Filippov et al., 2013). The substantial depression impact of starch during magnetite and pargasite flotation with an amine relative to quartz could be explained by a starch adsorption process based on chemical complex formation. A significant starch adsorption affinity was reported for the surfaces of Fe–Mg–Al-bearing silicates. Various flotation experiments revealed that pargasite did not float with the DDA after adding starch to the flotation system, and its recovery was negligible.