1. Introduction

Renewable energy production has become of great importance to measure environmental conservation and energy efficiency because of the rising in environmental pollution and energy security issues (Ramírez-Islas et al., 2020). Among the variously known biofuels, biogas contributes significantly to: (i) prevent environmental pollution, once bio-digestion neutralizes the effluent polluting potential (Yücenur et al., 2020); (ii) assure ecological balance by recovering significant resources during biomethane production (Sánchez et al., 2017), and reducing the greenhouse gas emissions (Mirmohamadsadeghi et al., 2019). Therefore, biomethane is also expected to play a crucial role in the circular economy (Tabatabaei et al., 2020).

Recycling and reuse are the main concepts in a circular economy (CE), as it aims to reduce waste production, recover sources at the end of their product's life and bring them back into the economy/market, thereby minimizing environmental pressure (Sharma et al., 2020). The concept above also allows more job creation opportunities and enables the conversion of waste into treasure: new clean energy (Wainaina et al., 2020). However, a successful transition from a linear to a circular economy requires new policies and financial structure, awareness among the general public, and the support of policymakers and financial stakeholders (Achinas and Euverink, 2020).

Within the scenario of increased interest on CE in the last half-decade, biorefinery serves as a strategic mechanism for implementing a circular (bio)economy (Ubando et al., 2020). Following this idea, any bioeconomy-oriented technology that fulfils the zero waste requirement, preventing valuable resources from leaking out of economies and generating higher-value byproducts, is crucial for reaching CE objectives (Kaszycki et al., 2021). Therefore, the anerobic digestion (AD) process is a technology that enables a waste management solution with simultaneous energy production. Indeed, this approach allows the production of renewable biofuel, mainly composed of biomethane and carbon dioxide, and a nutrient-rich liquid residue known as digestate that can be used as organic fertilizer (Kumar and Samadder, 2020).

Like any other process, AD has its own benefits and disadvantages. The key drawbacks associated with this method are the long retention time, low heating value of the produced biogas (Neshat et al., 2017) and the high cost associated with process automation and control (Maraba and Bulur, 2017). Nonetheless, many studies have focused on mitigating these drawbacks by applying different approaches such as (i) pre-treatment to deal with high-resistant materials, (ii) reactor design enhancements, and (iii) use of various additives to facilitate the process (Rasapoor et al., 2020). Among the biomass sources that have been traditionally used by AD technology as a waste management practice are sewage sludge (Liu et al., 2020), animal waste (Yao et al., 2020), food waste (Zhang et al., 2020), agricultural and forest residues (Abraham et al., 2020), industrial effluents (Charalambous et al., 2020) and others. That said, it is noteworthy that Brazil has become an agricultural powerhouse (Stabile et al., 2020) and has a high agro-residue biomass potential.

Cassava is one of the most important socioeconomic staple crops, primarily exploited by farmers in the north and northeast of Brazil. Its processing generates three major types of waste: solid (peels, leaves, stems), liquid (cassava wastewater), and air emission (from burning wood) (Olaoye et al., 2020). Cassava wastewater, for example, contains high levels of nutrients (Meier et al., 2020), but it is usually discarded directly on the soil, causing serious environmental problems, such as soil poisoning and contamination/eutrophication of water bodies (Araujo et al., 2020). Indeed, as waste management practices are poorly developed in the country, the residues are typically disposed of through landfills (Welfle, 2017), or in the case of agro-residues, released without any treatment instead of exploring it for resource recovery (Chavadej et al., 2019).

Several technologies have been studied to treat cassava residues before disposal. The high production rates of these residues motivate biorefinery exploits, resulting in the production of valuable bioproducts and bioenergy (Padi and Chimphango, 2020), like biohydrogen (Meier et al., 2020), bioethanol (Rewlay-ngoen et al., 2021), coagulant aid (Kumar et al., 2020), pesticide (Zevallos et al., 2018), etc. Nonetheless, these technologies' efficiency varies, and most are capital intensive (Olaoye et al., 2020). AD is a more appropriate solution for addressing this environmental issue as it also produces a biomethane, which is particularly valuable for being used locally to produce heat and electricity (Sánchez et al., 2017), and an effluent containing nutrients (nitrogen, phosphate, and potassium) which can be applied as biofertilizer in agriculture (Araujo et al., 2020).

Biorefineries based on cassava waste could be a key to achieving much-needed cassava agro-industrial expansion and also a reliable energy source for starch production. Therefore, the present study intends to reestablish the interest in cassava wastewater and sustain its energy production adoption in Brazil. It reviews certain aspects of cassava production/processing, introduces the concept of biorefinery and highlights the anaerobic digestion – process factors, co-digestion, and pretreatment – of cassava residues as an effort to maximize the biogas production. Finally, the challenges for its adoption and an outlook for the future are also presented systematically.

2. Brazilian energetic scenario

Brazilian Energy Balance (2020) indicates that the country's energy matrix is still heavily reliant on non-renewable sources (fossil). About 34.4% of the country's energy supply comes from oil and its derivatives. The country's second most available source is biomass (18.0%), mainly from sugarcane ethanol, followed by hydropower (12.4%). Therefore, the current Brazilian energy matrix has a high reliance on non-renewable energy sources, with some progress in the use of biomass as a source of energy.

Despite the relevance of bioethanol to the country's energy matrix and energy security, there are some disadvantages to produce this liquid biofuel. Among these disadvantages can be listed: (i) the need for large cultivation areas; (ii) deforestation to acquire arable lands; (iii) the environmental and social impacts of large-scale agribusiness; and (iv) the use of nitrogen fertilizers, which can cause eutrophication (Santos et al., 2021). Moreover, since the Brazilian power generation grid is primarily hydric, it is highly vulnerable to climate changes and drought conditions.

Hence, Brazil needs to diversify/increase the supply of renewable energy sources (RES) and the country has committed to raise the participation of non-hydro RES up to 23% until 2030, in its Intended Nationally Determined Contribution – iNCD, by concentrating on wind, solar and biomass sources (Rosa et al., 2020). And given it geographical position, Brazil has a huge bioelectrical potential, mainly if government policies were suitable to each exact sector's demand (Lima et al., 2020).

Another goal of Brazilian iNCD is to reduce GHG emissions by 37% in 2025 and 43% by 2030, when compared to 2005 rates (MMA, 2020). However, most of Brazil's CO2 emissions are from the Agriculture, Forestry and Other Land Use sector, then, with deforestation in the Amazonia region and the legal progress of harvesting lands, particularly from 2018, these reduction goals may be compromised (Goes et al., 2020). All of this reinforces the importance of raising renewable energy production and reducing GHG emissions.

Within this scenario, biogas and biomethane production can contribute to achieve both goals. According to the European Biogas Association (2020), the sector decreases emissions through several different pathways, like avoiding pollution by substituting fossil fuels, preventing methane escapes from manure, producing green fertilizer that substitutes carbon-intensive chemical fertilizers and storing carbon in soils. Therefore, waste biomass, such as cassava residues, would be a valuable feedstock for the development of clean and renewable energy for agro-industrial regions and, simultaneously, a tool for mitigating the environmental effects of agro-industrial production (Ribeiro et al., 2020).

3. Cassava processing residues

Cassava (Manihot esculenta Crantz) is a South American native plant of significant nutritional value, used as food or raw material for some processed products as cassava flour, tapioca and cassava starch (Sánchez et al., 2017). According to the Food and Agricultural Organization (FAO), the world produced approximately 303,6 million tons of cassava root in 2019, being Africa the most significant producer (~192 million tons), followed by Asia (~ 85 million tons) and Latin America (~26 million tons), of which Brazil produced approximately 17 million tons. This crop is also ranked fifth globally, as the most broadly used source of starch, and third among food crops consumed in tropical regions (García et al., 2020).

Cassava can be categorized into sweet (directly consumed) and bitter cassava, and it is organically rich in starch (dry weight up to 80%) (Okudoh et al., 2014). This root crop requires about 760-1015 mm of rainfall per year, but this plant can use nutrients from its stalks and its storage roots, making it a hardy plant that can withstand prolonged droughts (Marx, 2019). Cassava also grows well on infertile soils with limited inputs of fertilizers, herbicides, and insecticides. Thus, cassava is considered a cheap and sustainable agricultural feedstock (Zhang et al., 2016). Furthermore, it can also be harvested at any time from 8 to 24 months after its planting.

The crop can be marketed in natura for its use in several dishes, but its major portion is processed into flour/starch and in smaller amounts into traditional foods such as cassava chips (Carvalho et al., 2017). Cassava processing is energy consuming as well as water-intensive (García et al., 2020) and requires the root (i) peeling, (ii) grating and (iii) pressing or washing, which generates a large amount of waste (solid residuals and liquid effluent). Among the primary solid residuals are peels, stems, and leaves, that can be used further for the crop propagation, in the case of stems, for animal feed, in the case of peels, and the leaves usually remain in the soil, where they decompose (Sánchez et al., 2017). The carbohydrate-rich liquid effluent or cassava wastewater (CW), also called ‘manipueira’ in Brazil, is produced in large quantities, once at least 600 L of CW is generated per ton of processed root (Carvalho et al., 2017), and it is harmful to the environment once it contains a significant concentration of organic matter (Peres et al., 2019). The CW analysis in literature ratifies the high values of chemical and biochemical oxygen demand, as shown in Table 1.

Table 1. Analytical values of cassava wastewater.

| Wadjeam et al. (2019) | Peres et al. (2019) | Andrade (2020) | Sun et al. (2012) | |

|---|---|---|---|---|

| pH | 5.18 | 3.9 | 4.5 | 4.71 |

| BOD (g/L) | – | 29.2 | – | 6.3 |

| COD (g/L) | 21.69 | 101.38 | 69.83 | 10.50 |

| Total solids (g/L) | 16.89 | 92.9 | 57.92 | – |

| Volatile solids (g/L) | 16.48 | 73.4 | 42.27 | – |

| Nitrogen | 0.03 (%) | 2.14 (%) | – | 524.5 (mg/L) |

| Cyanide (mg/L) | – | – | 13.2 | 2.3 |

In addition to organic pollutants, CW also has toxicity resulting from a glycoside named linamarin that exists in all parts of the plant (Sánchez et al., 2017). Linamarin reacts when cassava cells are mechanically disintegrated during the harvesting/processing and releases cyanide which may cause many health problems in those exposed (Fukushima et al., 2016). Nevertheless the literature showed that the toxicity content of cassava residues varies depending on altitude, geographic location, harvesting time, crop variety, and seasonal conditions (Ndam et al., 2019).

In northeast Brazil, cassava processing is usually carried out in small facilities, which commonly release its effluents nearby without any treatment. However, when large amounts of these contaminants are dumped, it causes serious environmental problems such as soil contamination, unpleasant odors, disease vectors and water pollution when washed out to waterways, with consequent poisoning and deaths of fish and other aquatic animals (Peres et al., 2019). Nonetheless, it is essential to emphasize that these cassava-based residues can be biologically converted into various higher-value products, intending to maximize the bioresource utilization (Zhang et al., 2016).

Versino et al. (2019), for example, developed a controlled-release fertilizer using cassava starch and bagasse composite materials for agricultural applications. Mena-Durán et al. (2018) synthesized metal-free electrocatalysts for oxygen reduction using cassava residues through a thermal functionalization with sulfuric acid. Escaramboni et al. (2018) studied the ethanol biosynthesis by cassava bagasse fast hydrolysis using amylases, while Tanaka et al. (2019) reported the production of high-concentration bioethanol from cassava stem. Finally, Jiraprasertwong et al. (2019) examined the biogas production from CW utilizing an up-flow anaerobic sludge blanket (UASB) reactor of three stages, and Corbari et al. (2019) evaluated the loading rate and inoculum effect on the output of hydrogen from CW digestion.

Moreover, despite the remarkable improvements in anaerobic systems, the anaerobic conversion of easily degradable wastewaters, such as CW, depends on controlling the reactor alkalization to prevent the negatives effects from organic acids accumulation. Among the viable alternatives to manage this, it is possible providing alkalinity to the process using alternative agents like the calcium oxide from oyster shells, as proposed by Andrade (2020), who examined the biogas production from cassava wastewater after its pH stabilization with natural oyster shells.

3.1. AD for cassava residues as a biorefinery approach

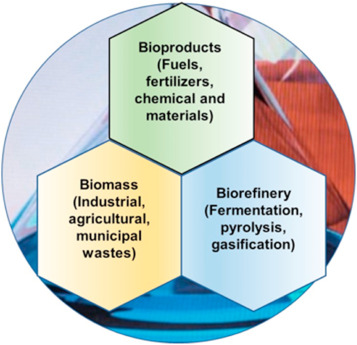

The biorefinery concept (Fig. 1) is related to converting biomass into energy and a broad range of bio-based products, which could maximize the system profitability (Khoshnevisan et al., 2019). When based on bio-digestion, this process reduces the amount of organic matter present in the waste, making it less polluting when dumped into the environment and also allowing it to be used as biofertilizer (Sánchez et al., 2017); besides producing biomethane, which can be used for heat and electricity production (Náthia-Neves et al., 2018). Moreover, unlike natural gas and oil, burning biogas and biomethane does not raise CO2 levels in the atmosphere, instead allows it to circulate in short carbon cycles, potentially assisting the planet in achieving climate neutrality by 2050 (EBA, 2020).

Fig. 1

Fig. 1Anaerobic digestion is a proven waste-to-energy (WtE) process that is widely used for treating biowastes such as food waste (Panigrahi et al., 2020), municipal solid waste (Ghosh et al., 2020), livestock manure (Ramírez-Islas et al., 2020), wastewater streams (Charalambous et al., 2020), among which can be the cassava wastewater (Jiraprasertwong et al., 2019). This process can convert a considerable amount of COD (>50%) into biogas which may be used as fuel for self-energy efficiency, depending on the subsequent purification, once the biogas produced has impurities such as hydrogen sulfide, nitrogen and carbon dioxide (Gunes et al., 2019). Another co-product of AD is named digestate, a mixture of partially digested or undigested substances, living/mineralized microbial cells and inorganic mineralized molecules (Slepetiene et al., 2020). It typically contains nitrogen, phosphorus, and potassium, which gives it a potential for being used as organic fertilizer (Czeka et al., 2020); however, recent studies show the necessity of performing ecotoxicity tests before its use in agriculture (Cruz et al., 2019). Table 2 compares the benefits and drawbacks of AD.

Table 2. The pros and cons of the anaerobic digestion process.

| ✓ Advantages | ✗ Disadvantages | References |

|---|---|---|

| Biomass sludge production is lower than in aerobic processes, with 10% converted into mud and 90% into biogas | The microbial culture inside the reactor takes a long time to stabilize | Chernicharo, 2007 |

| The waste-derived biogas mitigates GHG emissions, so it should be considered climate-neutral | Complex materials require pre-treatment or co-digestion | Wang et al., 2021 Rasapoor et al. (2020) |

| The final residue (digestate) is nutrient-rich and can be used as fertilizer in agriculture | Post-treatment of the digestate may be necessary before its application in agriculture | Slepetiene et al. (2020) Tigini et al. (2016) |

| More cost-effective for energy recovery with low environmental effect than other biological methods | Key parameters (temperature, pH, feed rate, inhibitor presence) must be constantly monitored |

Kothari et al. (2014) Wu et al., 2019 |

AD is considered an intricate biochemical process, separated into four key stages (hydrolysis, acidogenesis, acetogenesis, methanogenesis), in which a consortium of microorganisms degrades the organic matter, in oxygen absence, obtaining a methane-rich biogas production (Kapoor et al., 2020) as shown in Fig. 3. Hydrolysis is commonly the rate-limiting stage in AD, and it is initiated when exo-enzymes (amylase, cellulase, lipase, xylanase, and protease) are excreted by hydrolytic bacteria and adsorbed onto the surface of the substratum. It leads to polymers conversion into (i) monomers and (ii) water-soluble oligomers. In the acidogenesis stage, the released products are converted into short-chain fatty acids (propionate, acetate, butyrate, and lactate), alcohols (methanol, ethanol), and gaseous by-products (H2, NH3, CO2, and H2S) (Mirmohamadsadeghi et al., 2019). In these two first stages, undesirable oxygen can be consumed by facultative anaerobic microbes. The compounds formed in the preceding phases are transformed into acetic acid, hydrogen, and carbon dioxide (CO2) in the third stage (Leung and Wang, 2016). Finally, methanogens can produce methane from the acidification products (such as acetic acid, formic acid, CO2/H2, etc.) under strictly anaerobic conditions (Eqs. (1), (2), (3), (4), (5))) (Li et al., 2019).(1)CH3COO- + H2O→CH4 + HCO3-HCO3- + H+ →CH4 + 3H2O4CH3OH →CO2 + 2H2O(4)4HCOO- + 2 H+ →CH4 + CO2 + 2HCO3-4H2 + CO2 →CH4 + 2H2O

Due to the syntrophic relationships of the microbial communities involved, the process may suffer from instabilities (Nguyen et al., 2015), such as the volatile fatty acids (VFAs) accumulation, which leads to the digester failure by inhibiting the methanogens due to the pH decrease (Ryue et al., 2020). To mitigate this problem, several reports suggested: (1) to employ the two-stage fermentation once two different environmental conditions, for the leading bacterial groups, results in increased overall efficiency (Mari et al., 2019); (2) to use online monitoring/control methods as a way to enhance AD stability (Sun et al., 2019). Despite these two options, some other factors in the process design must be considered to reach the process stability and the highest output of methane.

3.2. Parameters affecting the biogas production from AD

During AD, several successive chemical and biochemical processes involving a consortium of microorganisms and enzymes occurs. However, the environmental conditions can alter the behaviors of these microorganisms and, as a result, several studies have indicated that the monitoring and control of operating conditions during the AD can boost its efficiency and ensure stable methane generation (Cruz et al., 2021). Therefore, some critical operational conditions, which are expected to improve the AD efficiency, may be continuously maintained within optimum ranges. These topics have been elaborated on below.

3.2.1. Alkalinity and pH

Changes in alkalinity and pH may directly affect the microorganisms; however, it is necessary to point out that each AD stage has an optimal pH: hydrolysis and acidogenesis, for example, prevail at a range of 5.5–6.0, while acetogenesis and methanogenesis rely on a 6.5–7.5 pHs (Pramanik et al., 2019). Furthermore, pH stability is also an important factor that controls inhibitory effects of VFAs and NH3, and it may be balanced with the use of additives that could provide a buffering effect in the system (Issah et al., 2020). Sometimes when the substrate is acidic, just as the cassava wastewater, it is necessary to adjust the initial pH before AD; Wadjeam et al. (2019), for instance, based on a regression analysis, achieved that the maximum hydrogen production would be got at an initial pH of 6.7; so, the initial pH was increased from 5.0 to 6.7; Gomes et al. (2016), in turn, adjust the pH from 5.0 to 6.5, by adding sodium bicarbonate, before feeding the reactor. Another common practice for easily-degradable wastewaters with rapid acidification (e.g., cassava wastewater, cheese whey, sugarcane vinasse) is the alkalinity adjustment during the process as an attempt to prevent adverse effects from the VFAs accumulation over the methanogens' metabolism (Palma et al., 2018). Some alkalinization strategies have been proposed by authors like Chavadej et al. (2019), who investigated the production of H2 and CH4 in a UASB of two-stage and maintained the first reactor pH at 5.5 by using a 1 M NaOH solution. Palma et al. (2018), however, proved that the use of dolomitic limestone, as an alternative to chemical compounds, is an adequate alkalizing agent even during organic overloading periods.

3.2.2. Temperature

The temperature profoundly influences methane production once it affects bacterial performance. AD process may be operated at psychrophilic (10–20 °C), mesophilic (30–40 °C), or thermophilic (50–60 °C) (Ryue et al., 2020). In the psychrophilic range, because of the low temperatures, the microbial growth is limited, and the reaction rates are slow, the reason why it is probably the least studied temperature range (Tassew et al., 2020). The thermophilic range provides some advantages like accelerated reaction rates, high gas production, and higher pathogen removal (Buffière et al., 2018). Chavadej et al. (2019) investigated the production of H2 and CH4, separately, from CW under thermophilic temperature (55 °C). However, thermophilic digestors are generally considered more energy-intensive and less stable than mesophilic ones (Mao et al., 2015). Then, the mesophilic range is the most commonly preferred (Leung and Wang, 2016). For tropical climates where cassava is grown, the mesophilic condition may be achieved without the need for external heat sources. Many studies have used the mesophilic range during the cassava wastewater AD; Jiraprasertwong et al. (2019), for example, experimented 37 °C, while Cheng et al. (2015) maintained the temperature at 35 °C. Finally, Amorim et al., 2019 investigated the methane production and organic matter removal via the anaerobic digestion of CW at 32 °C and 39 °C with different inoculums (cattle and goat rumen). In this specific study, the bovine rumen showed better results, but the temperature did not influence the biomass activity, which allowed the authors to state that the CW anaerobic digestion could occur at ambient temperature in semiarid regions of Brazil. After the range choice, it is also essential to give attention to temperature control; once if digestion temperature variations exceed 5 °C within a short time, this may lead to a significant decline in the biogas yield (Gaballah et al., 2020).

3.2.3. Carbon to nitrogen ratio (C/N)

The C/N ratio reflects the relationship between the amount of carbon and nitrogen in the substrate, and an optimal ratio is needed for an effective operation (Pramanik et al., 2019). In AD processes, the carbon digestion rate is 30–35 times faster than the nitrogen conversion rate; thus, the optimum C/N ratio usually is between 30:1–35:1 (Leung and Wang, 2016). High C/N ratios could lead to a lack of nitrogen for the methanogens, while low C/N ratios could lead to nitrogen accumulation as free ammonia, which is toxic for methanogen growth (Moukazis et al., 2017). A way to overcome this drawback is to balance the C/N ratio by mixing co-substrates (Cardona et al., 2019). Glanpracha, and Annachhatre (2016) assessed the AD of cassava pulp (CP) with pig manure at a mesophilic temperature to exemplify this. In this case, the introduction of a nitrogen-rich co-substrate (manure) overcame the inhibitory effects on methogens caused by the CP high C/N ratio; therefore, the digestion was successful.

3.2.4. Organic loading rate and hydraulic residence time

Another critical operational parameter is the organic loading rate (OLR) and the hydraulic residence time (HRT), once they affect both biogas yield and plant efficiency. OLR is set as the quantity of dry organic solids fed into the digester every day per unit capacity of the digester (Kothari et al., 2014). With a low OLR, the digester runs inefficiently, but if the reactor is overfed, imbalances among the four AD stages would be expected (Moukazis et al., 2017), and inhibitory compounds such as fatty acids could be accumulated, resulting in a CH4 reduction or even at the system failure (Mirmohamadsadeghi et al., 2019). In this regard, Jiraprasertwong et al. (2019) evaluated the AD of cassava wastewater at different loading rates from 5 to 18 kg/m3d (based on the total volume of liquid), and 15 kg/m3d was considered the optimal rate, which resulted in higher H2 and CH4 yields, as well as the highest COD removal. Retention time is the required time for organic matter to remain in a digester, while HRT is the average time spent in the digester by liquid sludge (Pramanik et al., 2019). According to Mao et al. (2015), an average retention duration of 15–30 days is required to treat waste under mesophilic temperature. A successful HRT also depends on the composition of the substrate and OLR. Thanwised et al. (2012), for example, evaluated some HRTs (3, 6, 12, 24 and 28 h) on COD removal and hydrogen production through AD in an anaerobic baffled reactor (ABR) and obtained an optimum HRT condition for their batch experiment of 6 h. Thanwised et al. (2012) explained that, in the case, the quantity of substrate fed into the system would increase when HRT was reduced.

3.3. Co-digestion and pretreatments for AD of cassava residues

Anaerobic co-digestion (AcoD) is the concurrent digestion of more than one organic matter to overtake certain mono digestion disadvantages (Kainthola et al., 2019). The AcoD process presents some main benefits: balancing the nutrients content and optimizing the C/N ratio, reducing inhibitory effects by dilution, increasing the feedstock digestibility, and enhancing methane production (Ghosh et al., 2020). Nonetheless, selecting substrates for co-digestion depends on the synergy between mixing two or more substrates. These synergies include improving the biodegradability that may be absent for a specific substrate type and balancing out nutrients for achieving the optimal condition (Ryue et al., 2020).

The agro-industrial cassava residues, including cassava pulp (Glanpracha and Annachhatre, 2016), cassava wastewater (Wadjeam et al., 2019), cassava stems (Martín et al., 2017), cassava stillage (Lu et al., 2019) have gained attention along with the development of starch processing manufacture. However, these residues are extremely rich in carbohydrate content and low in nitrogen concentration (Jiang et al., 2018) and present residual cyanide, which has been reported to be toxic to methanogens. In this scenario, both problems can be solved by introducing a nitrogen-rich co-substrate, which allows the C/N ratio to be adjusted to the optimum range and the cyanide content to be diluted (Glanpracha and Annachhatre, 2016). Additionally, this AcoD also decreases the amount of alkali needed for pH control and provides a methanogen inoculum (Wadjeam et al., 2019).

Among the co-substrates rich in nitrogen, some authors have considered the cassava residues co-digestion with cattle manure (Madeira et al., 2020), cattle rumen (Amorim et al., 2019), swine manure (Villa et al., 2020), and buffalo dung (Wadjeam et al., 2019). Glanpracha et al. (2018), for example, evaluated the cyanide degradation during the AcoD of cassava pulp with pig manure. The research concluded that the AcoD was successfully conducted; once after a short acclimatization period, the anaerobic sludge degraded the cyanide, indicating that its inhibition was reversible. Furthermore, applying some pretreatment is another possible approach for removing cyanide.

Within the AcoD scenario, Chavadej et al. (2019) also suggested the co-digestion of CW with cassava residue to improve the H2 and CH4 production separately by using a UASB reactor of two-stage, under thermophilic temperature and anaerobic sludge as inoculum. The system was operated under an optimum COD loading rate of 10.29 kg/m3d, and the first bioreactor pH was controlled at 5.5. As a result, the operation was suitable for converting lignocellulosic materials, and under the optimum concentration of 1200 mg/L of cassava residue, the production of H2 and CH4 had an improvement of 45.2 and 150%, respectively, when compared to the system without any cassava residue. Another strategy to improve the process performance is the addition of trace elements. Jiang et al. (2018) investigated the AD supplementation with nitrogen, nickel, cobalt, and sulfur, which guaranteed the microorganism proliferation due to covering the gap existing in the cassava residues nutrients.

As aforementioned, the cassava residues pretreatment is also a viable alternative, and as shown in Fig. 2, it is used before the fermentation process. Once the cassava wastes have a high proportion of carbohydrate and lignin, this first step enhances hydrolysis, which is the rate-limiting step and reduces the required retention time for AD (Mirmohamadsadeghi et al., 2019). Some pretreatments, classified into mechanical, ultrasonic, thermal, chemical, and biological, have been studied to enhance food wastes AD (Okudoh et al., 2014), but the pretreatment must be carefully chosen depending on each substrate characteristics. Table 3 enlists some pretreatment methods and their effects on methane and biogas yield from the available data in the literature.

Fig. 2

Fig. 2 Fig. 3

Fig. 3Table 3.

| Effluent type | Treatment | Process efficiency | Reference |

|---|---|---|---|

| Cassava residues | Biological pretreatment by a constructed microbial consortium | The maximum methane yield (259.46 mL/g-VS) was obtained after 12 h of pretreatment, and was 96.63% higher than the control | Zhang et al. (2011) |

| Cassava peels | Sequential combination of alkali and enzyme pretreatment | The methane yield improved in 56% | Moshi et al., 2015 |

| Dry cassava residue and swine manure | Microwave-heated acid hydrothermal pretreatment | Low biohydrogen yield | Lin et al., 2017 |

| Cassava residues | Ionic-liquid of N-methylmorpholine-N-oxide (NMMO) | The general conversion to hydrogen and methane improved to 21.4/27.9%, respectively | Cheng et al. (2015) |

| Cassava wastewater | Chemical and heat pretreatment | The highest biogas productivity (91 ± 14 mL) was achieved with the chemical pretreatment | Mañunga et al. (2019) |

| Cassava starch wastewater | Sequential combination of oyster shell-based alkalinization and photocatalytic removal of cyanide | The pretreatments improved the biogas production by 27.6% and reduced the digestate toxicity | Andrade (2020) |

| Cassava pulp | Liquid hot water (LHW) | The methane production rate and the methane yield of the pretreated cassava pulp were 1.6 times and 35% higher than the control | Varongchayakul et al., 2021 |

Among the scarce studies with cassava residues pretreatment are Zhang et al. (2011), who constructed and applied a thermophilic microbial consortium with high cellulose degradation capability for cassava residues combined with distillery wastewater before the AD. In this case, the pre-treated effluent AD resulted in a maximum methane yield of 259.46 mL/g VS, which was 96.63% higher than the control (131.95 mL/g VS) without pretreatment. Paulo et al., 2013 included a prior one-step fungi treatment, aiming to raise the pH and buffering capacity of the CW before an anaerobic biodegradability assay. As a result, the pre-treated CW reached a 6.4 pH, which provided stability during the assay and showed the possibility of a system operation without the addition of buffer.

Investigating the effects of some pretreatments (microwave heating - MHAP and steam heating - SHAP) to improve the cogeneration of hydrogen and methane, Cheng et al. (2015) obtained: (1) a higher hydrogen yield (106.2 mL/g TVS) after SHAP; and (2) a higher methane yield (93.2 mL/g TVS) after MHAP. The explanation for these results is based on the significant degradation of the lignocellulosic structure and the breakdown of high molecular weight carbohydrates into low molecular weight, reducing sugars which were quickly consumed by productive hydrogen bacteria. Additionally, Andrade (2020) proposed two sequential treatments before cassava wastewater anaerobic digestion. The first used natural oyster shells (as a source of CaCO3) to stabilize the CW pH, while the second focused on cyanide detoxification using photocatalytic degradation with Degussa P25 TiO2. The pretreatments were found to be effective in favoring the biogas output, which increased 11% and reduced the digestate toxicity.

Cassava wastewater has also been reported in the literature as a good substrate for hydrogen production through anaerobic digestion (Corbari et al., 2019). The necessity of pretreatments to enhance this production also exist: Leaño and Babel (2012), for example, studied three different pretreatment methods (i. sonication, ii. OPTIMASH BG® (enzyme), and iii. α-amylase) on CW to enhance biohydrogen production rate and the inoculum (anaerobic seed sludge) was also subjected to pretreatment, in this case, of heat, to inhibit the methanogens. All the pretreatments’ methods used showed a considerable influence on the H2 production rate compared to control. However, the α-amylase pretreatment procedure demonstrated higher H2 yield. Mañunga et al. (2019), in turn, investigated the influence of two pretreatments (chemical and heat) for the inoculum on the fermentative hydrogen production from CW at room temperature; and achieved the highest H2 production after the inoculum heat pretreatment.

3.4. The potential application of AD products

In the search for maximizing the economic and environmental feasibilities of AD plants, this section brings information about the main products of AD processes: biogas and digestate, aiming to establish a circular economy by utilizing them.

3.4.1. Biogas

Among all sustainable and renewable energy sources, biogas has significantly received attention as a relevant biofuel (Qyyum et al., 2020). Its utilization in energy generation brings several economic, environmental, and climate advantages (Gaballah et al., 2020). Depending on the source of organic matter is used, biogas mainly consists of methane (50–75%), carbon dioxide (25–50%), and traces of other gases, such as ammonia, hydrogen, and hydrogen sulfide (Merico et al., 2020). It can be applied for heating/electricity production or upgraded to biomethane and employed as vehicle fuel or pumped into natural gas grids (Fig. 3) (Westerholm et al., 2020). In the latter cases, the upgrade process must clean the biogas from CO2 and other impurities and thus increase the methane content and its heating value (Gustafsson et al., 2020).

Biogas and Bio-Natural Gas (BNG) have played relevant roles in renewable energy strategies, mainly in European and Asian countries, which understood the necessity to formulate relevant policies and regulations to support this industry growth (Xue et al., 2020). In Europe, for example, 18,202 biogas installations were in operation in 2018, which represented a Europe-wide installed electric capacity (IEC) of 11,082 MW and 63,511 GWh produced from biogas (EBA, 2019).

Despite all the advantages of biogas production, this technology is still underdeveloped in Brazil and only started to be used in energy generation in 2010 (Freitas et al., 2019). According to CIBIOGAS (2020), there were 675 biogas plants in Brazil, of which 638 were in operation for energy purposes in 2020. However, only 42 of these biogas plants were considered of large-scale, and despite having the smallest number of plants, this category produced the largest volume of biogas (1.438.855.500 Nm3/year), which represented a total energy capacity of 222,247.8 kW in 2020 (ANEEL, 2021), as shown in Table 4. Moreover, biogas produced just 1.366% of electric energy in the year in question (ANEEL, 2021). Despite the data mentioned above, Brazil has significant potential and many possibilities for biogas production and use.

Table 4. Power plants for biogas production in Brazil.

| Source | No of biogas plants | Power (kW) | Participation on biomass matrix (%) |

|---|---|---|---|

| Agro-industrial waste | 4 | 31,867.00 | 0.20 |

| Forest waste | 1 | 5000.00 | 0.003 |

| Animal waste | 15 | 4741.20 | 0.003 |

| Urban waste | 22 | 180,639.60 | 1.16 |

| Total | 222,247.8 kW | 1.366 | |

Source: ANEEL, 2021.

In Brazil, high agricultural activity and urban densities generate large waste quantities, which could produce biogas (Ferreira et al., 2018). The potential for biogas production from several substrates in the Brazilian market has been reported in the literature. Bernal et al. (2017) analyzed the energy generation potential and the economic feasibility of the biogas production from vinasse; Santos et al. (2018) analyzed the AD of seven varieties of wastes – municipal solid waste, wastewater from UASB, sludge from anaerobic treatment, vinasse, cattle, pig and poultry manure – and evaluated its application in (i) electricity generation, (ii) bus fleet fuel and (iii) reducing CO2 emission; Nadaleti (2019), in turn, demonstrated in an energetic, economic and environmental way the possibility of using the rice parboiling waste to produce biogas or hydrogen-rich syngas; and Pin et al. (2020) performed an economic feasibility analysis for implementing a biogas system in a coffee roasting production.

Despite these studies, nothing was found to determine the economic and technological feasibility of biogas output from cassava wastewater. These assessments are of great importance once cassava is grown mainly in Brazilian regions marked by substantial social inequalities, so the implementation of energy generation plants in these areas would bring environmental, social and economic gains.

3.4.2. Digestate

Organic matter digestion also produces a liquid digestate, besides the high energy gas (biogas) but, although biogas is intensively debated as a source of renewable energy, digestate has a minor position in academic and political debates (Stürmer et al., 2019).

Digestate is composed of mineral and not entirely degraded organic molecules. It is a valuable AD by-product once it contains vital nutrients (N, P, K, etc.), which allows its use as organic fertilizer (Slepetiene et al., 2020). When compared with undigested manure and chemical fertilizers, the digestate application leads to higher available nutrients, increased microbial activity, increased nitrogen mineralization capacity and soil respiration (Kataki et al., 2017). Therefore, the digestate application as fertilizer allows the circular economy approach and decreases the mineral fertilizer demands, which is usually associated with a negative impact on the environment (Czeka et al., 2020).

Despite digestate beneficial properties, it also has to meet quality standards in terms of pathogens, heavy metals, and polychlorinated biphenyls (PCBs) (DaRos et al., 2018); besides that, digestate management and consumer demand rely on the digestate legal status as waste or by-product (Beggio et al., 2019). Still, many countries do not have a specific legal framework for digestate use, obligating it to be classified as waste, which leads to more expensive legal procedures for allowing its recovery and marketing (Guilayn et al., 2019).

The variation in digestate composition has been indicated as a bottleneck for its marketing (Dahlin et al., 2015). Even minor variations in substrates used in an AD process can lead to changes in digestate properties (Czeka et al., 2020). Although some authors reported the digestate efficiency as fertilizers or soil amendment, other studies demonstrated potential biological adverse effects, e.g., due to the presence of heavy metals (Kupper et al., 2014), antibiotics (Jiang et al., 2018), pathogenic bacteria (Nag et al., 2020), and necessity of applying pretreatments to increase its quality to acceptable levels before its application (Alburquerque et al., 2012).

These significant variations in the digestate quality resulted in more scientific debates about the behavior of anaerobic digestates as fertilizer agents. Risberg et al. (2017), for example, investigated a wide variety of organic fertilizers (20 digestates, 10 cow manures, and 10 pig slurries) concerning their chemical composition and their impact on soil microbial activity. The results suggested that digestates may be more appropriate fertilizers for heavier soils with clay and carbon content due to their greater levels of ammonium and smaller levels of organic carbon than cattle manure and pig slurry. Kataki et al. (2017) evaluated three types of anaerobic digestate (cow dung, Ipomoea carnea/cow dung, rice straw/green gram stover/cow dung); each digestate feedstock was processed as separated solid, liquid and ash from solid digestate and characterized to understand their fertilizer prospects. From the FTIR spectra, it was inferred that the solid digestates could be used as organic amendments, while limited organic functionalities in liquid digestate implied its potential as a source of inorganic minerals. It was also observed that digestates from rice straw/green gram/cow dung were not phytotoxic in any application, whereas Ipomoea digestates in the liquid phase showed a relevant inhibitory effect on Vigna radiate.

Phytotoxicity or ecotoxicity analysis is an important parameter to evaluate the real digestate impact on crops, and it represents an index of its ecotoxicological impact (DaRos et al., 2018). The analyses consist of bioassays battery with organisms that represent different positions in the food chain to achieve more realistic results that describe the impact on the environment (Tigini et al., 2016). In this context, besides Kataki et al. (2017), few other researchers have utilized phytotoxicity tests to evaluate different digestates: Da Ros et al. (2018), for example, investigated digestate from winery wastes focusing on phytotoxicity with macrophytes (Lepidiumsativum, Sinapis alba, and Sorghumsaccharatum). Coelho et al. (2018) analyzed eleven samples of commercial liquid anaerobic digestates, using Lepidium sativum as bioindicators, and compared them to the concentrations recommended in the Irish digestate standards. Cruz et al. (2019) used Lactuca sativa as toxicity level bioindicators to evaluate the digestate from dairy wastewater inoculated with sewage sludge. Nonetheless, just a study evaluating the digestate from cassava residues was found in literature: Andrade (2020) who also used the Lactuca sativa for evaluating the CW and found that the anaerobic digestion favored the reduction in the effluent phytotoxicity. Nevertheless, it is still possible to use other bioindicators to evaluate this digestate and then, compare the results with some existent digestate standard, once Brazil does not have one.

4. Future challenges and directions

As a consequence of Brazil's vigorous agricultural activity, it has a high potential for biogas production. In this sense, the search for moving from a linear to a circular economy reinforces the necessity of recovering resources from organic wastes. Furthermore, cassava residues, just as cassava wastewater, become a relevant option, mainly for family farmers that survive from this crop.

The biogas production from this residue would not just produce energy, but it would also bring environmental, economic, and social gains for regions like the Brazilian north and northeast. Nevertheless, besides the importance of research initiatives to enhance biogas sovereignty, in cases of its production from CW, the number of studies evaluating this potential or its economic feasibility is still limited.

Expanding the use of agro-residue biogas technologies would help to diversify the energy matrix of Brazil and could play an important role in the conversion of waste into energy. It is necessary to bring together research institutes, governmental bodies, and financial institutions to demonstrate the benefits of this technology and create new policies and public incentives for its utilization.