1. Introduction

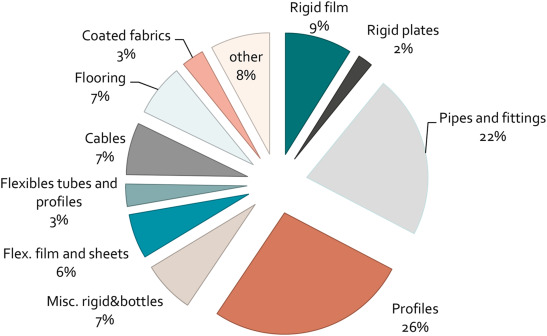

Polyvinyl chloride (PVC) is a popular plastic due its long lifespan and good mechanical, electrical, chemical, thermal resistance properties. In 2017–2018, 5.5 million tonnes are produced globally per year including 5.5 million tonnes in Europe (VinylPlus, 2018). PVC is used in building and construction, automotive, piping and cable industries including many household goods. The PVC material is strong, durable, lightweight and versatile; it makes a perfect material for many applications. More than 75% of the total PVC is used in industrial applications and especially the building and construction sector where PVC products have long life span of over 10-years (Fig. 1).

Fig. 1

Fig. 1Construction, automotive, packaging and electronics industries are the main sectors where PVC plastics are used in Europe (PlasticsEurope, 2017). For instance, more than 60% of PVC production in Western Europe is used in buildings and within the construction sector alone (ECVM, 2018). These four sectors were focused on in our study.

Achieving different PVC properties requires different additives, such as stabilizers, colorants, or plasticizers, which can pose different environmental and health risks along their lifecycle. However, prone to increasing restrictions and regulations, hazardous PVC additives used in the past now appear in waste streams and complicate waste management. For instance, material recycling of older PVC is often complicated due to the on-going phase-outs of phthalates such as bis- (2-ethylhexyl) phthalate (DEHP), dibutyl-phthalate (DBP), diisobutyl-phthalate (DIBP) and benzyl butyl phthalate (BBP), which are restricted by the EU's REACH regulation. Incineration of PVC waste has been historically problematic due to the formation of dioxins, hydrochloric (HCl-) compounds, and solid waste containing heavy metals. Meanwhile, landfilling is increasingly restricted in many countries and it is the least preferred option in the waste management hierarchy (Hopewell et al., 2009).

In 2000, the European Commission released a green paper for PVC waste (EC, 2000c) assessing various environmental and human health aspects and impact reduction options. A series of measures were listed to address different PVC waste management issues. For instance, a voluntary commitment of the PVC Industry called Vinyl2010 has been signed by the European PVC industry, which detailed measures to address organochlorine emissions through sustainable use of additives and various controlled-loop management strategies. Its successor, VinylPlus, has put an annual recycling target of 900,000 tonnes by 2025 and at least 1,000,000 tonnes by 2030. By 2017 the initiative has 640,000 tonnes (Fig. 2). About half was recycled of window and door profiles, where Germany and the UK stood for the bulk of the activities (VinylPlus, 2017b).

Fig. 2

Fig. 2Other than the data from VinylPlus, information on PVC waste management is relatively scarce including regional or country statistics from official EU's accounting systems. Older data of 1999 are available from Plinke et al. (2000), who detailed the status of PVC waste management for EU-15. Recently, Ciacci et al. (2017) made estimations for and modelled PVC stocks in use and waste generation for the entire EU. This was based on export, import and production data, but the study did not detail the information on national level nor focused on waste management.

When it comes to the Nordic region, it is usually praised for its high environmental standards and material recycling rates. However, the level of PVC recycling in the region is actually not clear. In this study our aimed to better understand the current trends and regional differences in PVC waste management focusing on Denmark, Sweden, Norway and Finland. Our guiding questions were following:

-

(1)

How is PVC waste managed in the selected Nordic countries?

-

(2)

What are the main reasons and policies behind the current status of PVC waste treatment?

2. Materials and methods

Information for this study was collected through concurrent literature reviews (databases and research reports) and expert interviews. In each country we selected groups of experts based on inputs from the Nordic Waste group and applied a questionnaire presented in Appendix 1. We employed a largely qualitative approach and, where feasible, asked for factual data to corroborate the qualitative answers. We allowed for more flexible question formulations to adapt to the qualitative nature of information and the interviewees’ reasoning.

Based on the collected information we made estimates on the quantities of PVC materials put on the market and the generated amounts of waste in different product groups. This required some assumptions, such as e.g. assessing the share of PVC material in end-of-live vehicles (ELVs) by the experts (Cullbrand, 2018) and then estimating the amounts of waste based on the national ELV data1 (Abraham, 2018). Similar approach has used for other product groups.

Our literature review covers background information of up to mid-2018, including (section 4.2) policies introduced before this time, if not indicated otherwise.

3. Limitations

The lack of recent secondary sources and the lack of experts with specialized knowledge about PVC waste in individual countries were the main limitations. Data on waste composition and presence of PVC were either poor, not available or outdated in many countries. This was complemented by experts’ interviews. The initially pre-selected pools of experts (6 experts per country) we not sufficient. In all countries, the initial response rate was small than expected (e.g. from the contacted 38 interviewees 9 responded in Finland), so we applied the snow-bowling approach to increase the interview pool. The increased interview pool was deemed sufficient to complement the existing literature.

4. Results: PVC use and waste management in the Nordic countries

4.1. PVC waste generation

Little recent reliable data exists on total PVC waste generation in the Nordic countries. Estimates have been made occasionally, mostly within the frames of different projects, and were not based on any formalized official reporting system or other systemic accounting. The available estimates for Norway, Finland and Sweden are extrapolates from old reports, average European data or experts’ evaluations (Table 1, Table 2, Table 3, Table 4). Based on the available data, the regional average of PVC generation is in the range of 5–5.5 kg/capita, which should be used with caution. For instance, the most recent PVC waste estimates for Denmark based on historical PVC supply and assumptions about expected product lifetimes (Lassen et al., 2018) are around 30,000 t of soft and 36,000 t for rigid PVC. This corresponds to 11 kg/capita or more than double than the regional average above. The study recognised, however, that rigid PVC waste available for waste treatment may only be half of the estimated amount. This is mainly due to assumptions about the lifetime in certain PVC products, such as e.g. sewer pipes, which may remain the ground for ever and never enter waste management systems (Lassen et al., 2018).

Table 1. Overview of PVC waste management in Denmark

| Waste stream | Generation | Collection | Treatment |

|---|---|---|---|

| PVC waste in total | 51-66 kt of PVC in products reaching end-of life in 2017: 30 kt of rigid and 36 kt of flexible PVC (Lassen et al., 2018) | 7 kt of PVC waste was separately collected in 2016 (Affalsdata, 2017) |

The separately collected PVC waste was treated as follows (Affalsdata, 2017): Recycling: 6.8 kt Energy recovery: 0.004 kt Landfill: 0.2 kt At least 50% of total estimated amount of flexible PVC contains of products that primary goes to energy recovery (Kiil, 2018) Recycling mainly happens abroad (Lassen et al., 2018) |

| PVC in C&D waste | 90 % of total rigid PVC supply and 25% of flexible PVC is used in C&D sector (Lassen et al., 2018) | Partly separate collection. Within the WUPPI system around 2.5 kt of rigid PVC waste from construction and demolition is collected annually, but the total amounts are likely to be higher. |

The separately collected rigid PVC waste is sent to recycling abroad Separately collected soft PVC waste is dedicated to landfill |

| ELVs | No reliable estimates |

Around 110,000 ELVs were collected and shredded in 2017 (DPA system, 2018) Around 100–150 kt of shredder waste annually Some dismantling of larger cable waste may exist, but the amount is unknown. Around 1.8-2.9 kt of PVC is present in SLF (estimate) |

SLF goes to energy recovery or landfill |

| WEEE and cables | No reliable estimates |

Four producer responsibility organisation takes care of collection of WEEE The amount of PVC in collected WEEE and cables is not known PVC from cables is to some extent collected as a 'secondary’ fraction from cables and wires primarily collected and recycled due to the copper or aluminium content () |

WEEE treatment is limited, mainly focused on pre-treatment and dismantling rather than end-of-life operations (Kjellsdotter et al., 2015). Recycling of WEEE and cables is focused on abstracting the value of metals, and not on plastics. No information that PVC from WEEE is recycled. Cables could be recycled throughout PlastSep process. PVC in cable waste either goes to recycling (PlastSep) or energy recovery |

| Packaging and other | 1,4 kt PVC supply for packaging | Roughly 30% of the plastic packaging waste was collected for recycling from households in Denmark in 2015 | PVC in packaging waste is generally sorted out as a reject fraction and sent to energy recovery. |

Table 2. Overview of PVC waste management in Finland (for data source, see the text above)

| Waste stream | Generation | Collection | Treatment |

|---|---|---|---|

| PVC waste in total |

20-30 kt post-consumers PVC waste based on old reports and estimation by interviewed experts 1-3 kt pre-consumers PVC waste (Pohjakaljio and Punkkinen, 2018) |

No nation-wide separate collection for PVC |

PVC mainly enters mixed waste flow and is sent to energy recovery MSW: 11% landfilled, 75% to energy recovery (Statistic Finland, 2018) Waste in total (except mineral): 41% recycling; 47% energy recovery in 2016 (Tilastokeskus 2016) |

| C&D waste | No reliable estimates. According to some preliminary results of an ongoing study investigating plastic streams, the main plastic streams in construction sector are PVC and PE plastics (Vaajasaari, 2018) | Some separate collection for pipes (mainly clean) and some bulky waste, but in general PVC waste from C&DW stream go to landfilling or incineration |

Separately collected pipes are exported for recycling (but minor amounts) Mixed waste incinerated/landfilled Bulky waste collected separately at the recycling centres is incinerated or landfilled (Norden, 2015) |

| WEEE and cables | No reliable estimates. |

WEEE covered by EPR and run by 5 producer organisations, that has a network with 550 collection points located at municipal recycling centres or private companies. Retail sector has an obligation to take back some consumers equipment's. Gathered from specific waste streams (e.g. from ELV dismantlers) In 2016, around 60 kt of WEEE collected, with 51 kt for recycling, 3 kt energy recovery and 3,6 disposal (Virtanen 2018) Around 0.12 PVC kt/year in collected WEEE (except cables) (rough estimate) |

PVC in WEEE goes either to incineration or exported. Plastics containing flame retardants go for special energy treatment in hazardous waste plants. Only a minor part goes to landfilling (Virtanen 2018) PVC in cables either locally incinerated or exported for recycling in Sweden (Walavaara, 2018). |

| ELVs | No reliable estimates. |

Some dismantlers separate large parts of plastics (e.g. bumpers), but in general it goes to shredder process and becomes SLF. In total 50–70 kt of shredder light fraction (SLF) is generated annually, which also includes PVC waste (no official data (Silvennoinen, 2018) Around 1.0-1.8 kt of PVC can be present in SLF (estimate) |

Main treatment method for SLF is energy recovery. Since 2017 due to changed legal requirement SLF is no longer treated as hazardous waste and non-hazardous waste-to-energy plants possible (Silvennoinen, 2018) |

| Packaging waste and other | PVC present in MSW <1% of MSW (around 20–30 kt/year)a (Tilastokeskus 2016). | Separate collection of plastic packaging waste through the bring collection system in connection with the producers' responsibility since 2016 (Dahlbo et al., 2018). PVC-containing commercial and consumer packaging (including other small PVC-containing waste items) are excluded from this system (Häkkinen, 2018; Uusiomuovi, 2018). |

PVC packaging is collected in mixed municipal waste stream and treated mainly by energy recovery (Häkkinen 2018). PVC collected within health care incinerated as hazardous waste |

- a

-

In 2016 total MSW generation was 2909 k-tonnes (URL: http://tilastokeskus.fi/til/jate/2016/jate_2016_2018-08-31_tie_001_en.html).

Table 3. Overview of PVC management in Norway (for data source, see the text above)

| Waste stream | Generation | Collection | Treatment |

|---|---|---|---|

| PVC waste in total | Around 25 kt of PVC annually (Sundt, 2018) | At municipal waste recycling stations, PVC-waste is either collected as 1) hazardous (mostly old flooring); 2) as part of the hard plastic waste (later treated as reject) or 3) as waste for incineration (Akselsen, 2018; Denvik, 2018; Skogly, 2018) | |

| Construction and demolition waste (C&DW) | 50% of all PVC waste generated in Norway (Sundt, 2018) |

4.5 kt of waste (mainly PVC) collected as hazardous (Larsen, 2018) Some collection for pre-consumer waste from: - flooring installation (0.046 kt in 2017) collected and sent for recycling in Sweden (Aar, 2018) - pipe waste (0.2 kt annually) by Pipelife Norge AS sent abroad (Kvendse, 2018; Tronvold, 2018). - PVC roof foil and membranes sent to RoofCollect (Germany) (Elstad, 2018) (Roofcollect, 2018) - Mixed with other C&DW (the major option) |

Hazardous PVC treated in the specialized incineration plants (Akselsen 2018) Minor recycling (mainly abroad (Sweden, Germany and the Baltics) Incineration – together with residual waste Some landfilling, no statistics (Eriksen, 2018). |

| WEEE and cables | No reliable estimates |

3 producer-responsibility organisations reports total 144 kt of WEEE collected (out of which 19 kt cables wires) collected in 2017 (EE-registret, 2017). 0.28 kt of PVC might be present in collected WEEE (except cables) (rough estimate) |

Deposited (after granulation) The biggest EPR organisation RENAS AS sells the cables to recycling companies such as Stena Recycling, KMT Gjennvining and Metallco (Dordipour, 2018) |

| ELVs | No reliable estimates |

143,664 EVLs collected annually Some bulky and hazardous components are dismantled from ELVs before these are sent to shredding plants (8 in Norway, 1 in Denmark or 1 Sweden) (Autoretur, 2017) In 2017, each ELV generated on average 189 kg of SLF 27.1 kt of SLF which also includes PVC waste (Autoretur, 2017) Ca. 3 kt of PVC can be present in SLF (estimate) |

- SLF treatment in 2017: - 35% to energy recovery - 49% to material recovery - 16% was landfilled (Autoretur, 2018) Some of the plastics in the SLF are separated at Stena Recycling in Halmstad, Sweden and sent for recycling to Galoo (Autoretur, 2018), a recycling company which owns two plants in the Netherlands and Belgium specialized on plastic recycling from SLF (Autoretur, 2017). |

| Health care | No reliable estimates. | No separate collection | Incineration for hazardous waste |

| Packaging waste | No reliable estimates |

Producer responsibility for packaging waste, Grønt Punkt Norge AS (responsible for 85% of the total packaging that enters the Norwegian market) collected 119n kt of plastic packaging waste in 2017: - 44,5% recycling - 52,7% energy recovery (Grontpunkt, 2018) |

In 2017, 1.683 kt of waste was incinerated in Norway. Some recycling of the mixed hard waste plastic, but no reliable estimates are available. |

Table 4. Overview of PVC waste management in Sweden (for data sources, see the text above).

| Waste stream | Generation | Collection | Treatment |

|---|---|---|---|

| PVC waste in total | No reliable recent estimates, 40 kt of post-consumers PVC, by an old report (Plinke et al., 2000) | Non-hazardous waste treatment In Sweden (excluding mining): 35% energy recovery, 25% recycling, 18% disposal, 21% other recovery, 18% disposal in 2016 (Swedish EPA, 2018) | |

| PVC in construction and demolition waste |

Around 60 kt of plastics in general in the sector, but share of PVC is unknown Approx. 1.8–2 kt PVC waste from flooring installation |

Pre-consumer plastic (installation) waste pipes: 5 kt/year, ca. 1.5 kt PVC (30% of the total). Up to 70% of plastic pipes in demolition waste consist of PVC, but the collected amounts are minor (Krantz, 2018) Installation waste from flooring collected by the Swedish Flooring Trade Association: 0.3 kt/year, mostly PVC. Collection of PVC pipes by The Nordic Pipe Association: roughly 0.07 kt Collection on a B2B-level may exist |

Around 60–80% of collected pipes are sent to recycling abroad; the rest - to domestic energy recovery (Krantz, 2018) Flooring installation waste from Tarkett collected within The Swedish Flooring Association is recycled in Ronneby. Roughly 12 % of total PVC waste from flooring installation is recycled, remaining goes to energy recovery Pipe waste collected within The Nordic Pipe Association is recycled abroad. Remaining part of PVC waste from C&DW is sent to energy recovery in mixed waste fractions (Elander and Sundqvist, 2015). |

| WEEE and cables | No reliable estimates | 163 kt of WEEE collected throughout the producers responsibility organisations in 2016 (Swedish EPA, 2018); 0.3 kt of PVC might be present in collected WEEE (except cables) (rough estimate); 28–32 kt cable waste (both postconsumer and pre-consumers waste) containing PVC are collected annually (Belleza and Youhanan, 2017) |

PVC in cable waste either goes to recycling or energy recovery/incineration 2-3 kt of cable granulates (mostly PVC) are recycled in Sweden, but it is declining trend (Youhanan et al., 2016) |

| ELVs | No reliable estimates |

Hazardous components and bulk materials from ELVs are dismantled before sending to shredding plants. Plastics generally ends up in SLF (Stenmarck et al., 2017); 193,013 ELVs were collected in 2017 (SBR, 2018) Around 3.1–5.2 kt/year of PVC in SLF (estimate). The amount of PVC in cables and it's treatment from ELVs is not known (Belleza and Youhanan, 2017) |

SLF goes to energy recovery or landfilling (Stenmarck et al., 2017) |

| Packaging | Generation of PVC plastic packaging waste is unknown |

Producers responsibility for packaging in place. In 2016, 212.5 kt of plastic packaging were put on the Swedish market and 99.7 kt of plastic packaging were sent to recycling (Naturvårdsverket, 2017). Compositional studies by major EPR origination showed, that “other plastics” including PVC consisted only 6% of weight (Stenmarck et al., 2018) |

PVC in packaging waste is generally sorted out as a reject fraction and sent to energy recovery. |

| Other | 7 kt plastic waste is collected at municipal recycling centres. Some compositional studies account PVC around 7 wt percent of the analysed amounts (Fråne et al., 2017) | Sorted PVC fraction is mainly sent to the Netherlands for recycling. PVC waste from health care go to energy recovery as hazardous or non-hazardous waste |

Our interviewees emphasised certain specifics of the Nordic market regarding PVC consumption. For instance, in Finland (Pohjakaljio and Punkkinen, 2018) and Norway (Sundt, 2018), the use of PVC for windows is rather small compared to other EU countries (e.g. in East and Central EU countries) due to consumers’ preferences for wood. Retailers have also recommended their suppliers to reduce PVC use in packaging making it less present in packaging (Vinylplus, 2018). In Denmark, the use of PVC in windows and door profiles is less than half of that in the rest of Europe (see Figs. 1 and 3).

Fig. 3

Fig. 3Very limited data are available regarding the division between pre-consumer and post-consumer PVC waste. In our interviews the latter was usually named as the major flow. In Finland, the annual generation of pre-consumer (production) PVC waste could be in the range of 1000–3000 t according to Pohjakaljio and Punkkinen (2018) or around 1000 t according to Vaajasaari (2018), which is only 3–10% of the total PVC waste generation (Vaajasaari, 2018). Much of production waste is relatively uniform and easy to reprocess in closed loop systems. For instance, more than half of the producers recycle over 90% of their PVC waste in Finland (Pohjakaljio and Punkkinen, 2018). Similar situation was found in other Nordic countries.

4.2. Policies on PVC material and waste

With the exception of Denmark, our surveyed countries do not have PVC-specific national waste management plans or other strategies. Pertaining to PVC waste is only general waste-related legislation, such as landfilling bans, taxes and restrictions for incineration.

4.2.1. Landfilling bans and taxes

Sweden and Finland have implemented bans on landfilling combustible and organic waste, with some exemptions for landfilling possibly granted. For instance, in Sweden two types of exceptions can be granted by county councils pending laboratory tests: (1) waste with a homogenous composition with less than 10% (weight) of TOC (Total Organic Carbon), and (2) heterogeneous waste with less than 10% (volume) of combustible waste may be landfilled (Swedish EPA, 2004). In Finland, exemptions from the landfilling ban on PVC are granted due to small local capacities for domestic recycling and restricted incineration requiring permits. Denmark has also ban on landfilling combustible waste since 1997, but a range of different policies and measures to avoid incineration of PVC were introduced here (see the next chapters). Norway has implemented a ban on landfilling of biodegradable waste2 with TOC over 10% since 2009. Legally it is still possible to landfill plastic waste such as PVC, but the ban on biodegradable waste has led to most of the combustible waste being treated through energy recovery. In 2010 the tax for waste treatment was lifted for energy recovery from waste, but remains applied for waste landfilling, which makes it more expensive than energy recovery (Norvegian EPA, 2013b).

4.2.2. Hazardous PVC substances and restrictions

All Nordic countries apply the EU directive requirements on the incineration of hazardous waste with organic halogens content (exceeding 1% expressed as chlorine) must be destructed at minimum 1100 °C (Wienchol et al., 2020). This implies, that separately collected PVC waste cannot be treated in simple energy recovery plants where lower incineration temperatures apply. Such requirements were implemented in e.g. the Swedish Ordinance on Incineration of Hazardous Waste (2013:253). In addition, some PVC waste, e.g. as soft PVC phthalate DEHP, are classified as hazardous if DEHP equals or exceeds 0.3% by weight.

In Norway some flexible PVC waste products, such as e.g. PVC flooring, roofing, folding walls or chairs, produced before the year 2000 should be collected as hazardous waste due to the high probability for phthalates, asbestos, lead or PCBs, which are regulated (Norvegian EPA, 2013a). PVC phthalate softeners, such as DEHP, BBP,DBP and DIBP, are listed in the Norwegian Priority List as hazardous (Miljodirektoratet, 2018) and PVC waste exceeding 5000 mg/kg-DEHP or DBP and 2500 mg/kg-BBP is hazardous (Norskgjenvinning, 2017).

Denmark is the only Nordic country, which historically has had different PVC-specific policy measures since 1990s concerning incineration of PVC materials containing hazardous substances. Multiple issues of the entire PVC value chain is addressed in "Strategy for the PVC Area” and “Status Report and Future Initiatives” issued by the Ministry of Environment and Energy in 1999 highlighted health and environmental impacts linked to disposal of waste PVC products (Lassen et al., 2018). In 2001 Denmark introduced new guidelines highlighting and explaining terms, such as “re-cyclable” (e.g. pipes and gutters, door and window profiles, panels) and “non-recyclable” PVC (e.g. floors and flexible panels, blinds, hoses, roof foils, carpets etc), which steered municipal approaches for treating PVC waste (Danish EPA, 2001). Rigid PVC products are considered recyclable and several flexible PVC products can be landfilled.

Danish waste legislation obliges municipalities to collect PVC waste separately, recycle recyclable waste and landfill non-recyclable PVC. Incineration of PVC waste ought to be avoided (Miljøministeriet, 2012). As a result, all Danish municipalities have set up schemes for separate collection of rigid and flexible PVC at manned recycling centres. Most of separately collected rigid PVC waste is being sent to recycling abroad. At the same time, certain ordinances prohibiting cadmium and lead in PVC products on the Danish market were also adapted (Miljø- og Fødevareministeriet, 2009). Today it is prohibited to import or sell PVC products containing more than 0.01 wt percent (100 ppm) of lead and 75 ppm of cadmium. Moreover, since 1999 two fees were implemented for PVC waste in Demark: a fee on PVC with phthalates and a weight-based fee on flexible PVC films (Onlaw, 1999). The fees aimed at decreasing the amount of PVC waste going to incineration and landfilling, decreasing the use of phthalates and incentivising more environmentally friendly packaging. The main motivations for such interventions were concerns over phthalates, hydrochloric acid produced during incineration and hazardous by-products after flue gas cleaning (Danish EPA, 2014). However, in 2004, rigid PVC was exempted from the fees once it was deemed suitable for mechanical recycling. In 2017, Denmark also lifted the fee on flexible PVC materials and film used in packaging. The Danish government makes it clear that energy recovery of PVC waste should be avoided (Grøndahl, 2018). At the same time the Danish ordinance on landfilling (Miljø- og Fødevareministeriet, 2013) does not instruct specifically about how to landfill PVC waste. Although combustible waste is banned from landfilling since 1997, landfilling of waste is subject to a landfill tax (Skatteministeriet, 2017).

4.3. PVC waste collection and management

Denmark is the only one collecting national statistics on separately collected PVC waste in the region. The official Danish statistics indicate that the separately collected (mainly rigid) PVC waste is around 7000 t/year, which is 10–13% of total PVC waste according to our estimates. Most of this PVC is recycled and some smaller part incinerated or landfilled (Table 1). Recycling takes place mostly abroad, because of high historical content of lead stabilisers in PVC, which are not allowed to be recycled in Denmark.

Although PVC waste shall be legally collected separately, a significant part of waste ends up in mixed fractions sent to energy recovery. The main reason is that flexible PVC are used in many consumer products which tend to end up as burnable waste fraction bypassing other possible treatments (Lassen et al., 2018).

Meanwhile, Finland, Norway and Sweden no state-governed separate PVC collection systems. Instead, smaller scale business-to-business systems for specific PVC waste fractions, mostly pre-consumer PVC waste, are in place. But PVC waste is not the major business for private waste companies. Meanwhile, post-consumer PVC waste are often collected and treated together with residual waste through energy recovery or are being landfilled, but data about the split was not available. Landfilling is likely to be applied less due to general decrease of landfilling of mixed waste, the ban on landfilling organic and biodegradable waste and landfilling taxes.

General statistics on total and mixed waste management indicates that energy recovery is a rather prevailing option compared to landfilling (Table 2-Table 4). Even in Finland, where landfilling has been the dominant option before 2000, it has been rapidly decreasing to about 11% by 2016 (Tilastokeskus 2016). There are 9 incineration plants for municipal waste in Finland and 1 for hazardous waste operated by Fortum Waste Solutions, which is the only plant that can accept separately collected PVC waste for energy recovery. The rest receive PVC in mixed waste streams, but normally do not accept PVC in larger quantities, as this leads to higher than permitted emissions of HCl and dioxins (Vaajasaari, 2018). Only three landfills have got temporary licences to accept limited amounts of PVC waste (Kärhä, 2018). The national ban on landfilling of organic waste, including PVC and the EU waste legislation in general are the main drivers for diverting PVC from landfills. The existing marginal local capacities for domestic PVC recycling and restricted incineration permits result in some exemptions from the landfilling ban. Generally, waste management costs and the increasing costs for virgin raw materials motivate local industries to consider PVC recycling as an economically feasible option (Kärhä, 2018). However, domestic recycling of PVC is severely limited by high costs and the inability to reach economies of scale. The available PVC waste is geographically dispersed, which inflates the costs of collection and transfer. At the same time the costs of sorting, management and recycling are high and the market for recycled PVC waste is weak (Pohjakaljio and Punkkinen, 2018).

In Sweden, where a significant incineration infrastructure (34 incineration plants) has been developed since 1970s, landfilling has become extremely low, especially after the introduction of landfilling taxes and the ban on landfilling organic and combustible waste. At the same time, the incinerators are reluctant to accept mono-streams of PVC waste fearing a corrosion in the flue gas cleaning systems induced by chlorine compounds. This can be prevented by mixing smaller amounts of PVC waste with other waste types (Stålenheim et al., 2015).

However, although PVC waste generally not subject to landfilling due to the landfill bans, it can still be landfilled under granted exemptions. Unfortunately, statistics on the total amount of landfilled PVC waste under the exemptions are not available.

In Norway, the generally low volumes of geographically dispersed separately collected PVC waster gives rather low profitability in recycling. The ban on biodegradable waste has led to most of the combustible waste being treated through energy recovery. This was also influenced by the tax for waste treatment being lifted for energy recovery from waste since 2010, but it still being applied for waste landfilling. It makes waste landfilling more expensive compared to energy recovery (Norvegian EPA, 2013b). Some separately collected flexible post-consumer PVC waste (e.g. flooring products) are collected as hazardous and treated in a few specialized incineration plants (Lindstad, 2018). Minor PVC quantities might also be collected as “plastic” with other municipal plastic streams (see section “Other waste stream”). A simplified generic regional PVC waste management scheme is presented in Fig. 4.

Fig. 4

Fig. 44.4. PVC waste in specific sectors

4.4.1. Construction and demolition

As significant amount of rigid PVC waste is generated in construction and demolition sector. In Denmark, more than 90% of rigid PVC is primarily used in the construction sector generating about half of the total PVC waste (Lassen et al., 2018). Similarly, 50% of all PVC waste flow in Norway and Finland originates in the C&D sector (Table 2-Table 3). PVC waste management in the C&D sector is similar to Fig. 4.

The main part of the separately collected rigid PVC waste in Denmark is collected through a nation-wide voluntary collection system WUPPI3 established by PVC producers and importers. The system unites around 1000 actors, such as private companies, municipalities and waste management companies. A nationwide separate collection at municipal recycling centres also exists for drainpipes, water pipes, sewage pipes, cable channels, doors and window profiles, wall panels and gutters. The operational costs are covered by 12 main producers/importers according to their product market share including some contributions from VinylPlus initiative (Jensen, 2018). There are also some other actors in Denmark, such as RGS90 and Ragn-Sells collecting the same PVC fractions on behalf of WUPPI (Grøndahl, 2018). The quantities of separately collected PVC waste in Denmark are the highest in the region, but moderate compare to total waste generation in the country (see Table 1, Table 2, Table 3, Table 4).

In Norway, the national legislation considers waste products produced before 2000 to contain hazardous phthalates. In 2017, few thousands of tonnes of PVC waste containing phthalates were reported to the Norwegian EPA (Table 3), the majority of which came from demolition activities and contained largely soft PVC flooring (Larsen, 2018). Municipal waste recycling stations in Norway have limited resources to analyse waste for possible phthalate content, so waste flows from construction and demolition projects are mainly collected as hazardous and treated in a few specialized incineration plants (Akselsen, 2018).

In remaining Nordic countries the collection and treatment are rather similar – no formal collection system for PVC (for C&D sector), although minor plastic waste collection including PVC exist on a business-to-business level. Some (mainly clean pre-consumers) PVC waste products being collected within few industry's take-back initiatives and recycled largely abroad. Meanwhile post-consum (Aar, 2018)er waste mainly ends up in mixed waste flows and goes to either energy recovery (the main option) or landfilling (minor). For instance, the major producer and retailer of PVC flooring in Norway Tarkett AS provides a take-back system for installation flooring waste from its own products and sends the separately collected (mainly pre-consumer) waste to company's sorting and recycling plant in Sweden (Aar, 2018) (Table 3). Similarly, in Sweden, Tarkett AB operates a collection and recycling system for installation flooring waste on behalf of the Swedish Flooring Trade Association. This collection system is provided also to other manufacturers of flooring products who join this voluntary take-back system. The manufacturer typically recycle their own products. However, some of the flooring (e.g. PVC with polyester backside) are complex and difficult to recycle internally and therefore are often sent for energy recovery (Duberg, 2018). However, only around 17% of total flooring installation waste are separately collected and recycled, while the rest ends up in mixed waste fractions and gets to energy recovery (Table 4).

Similarly, some pre-consumer pipe waste is collected by voluntary take-back plastics collection systems in Sweden, Norway and previously in Finland, initiated by Nordic Pipe Association in Sweden and Pipelife Norge AS in Norway. PVC constitutes only a minor part of collected pre-consumer waste, which is mainly sent for recycling abroad and some is incinerated (Table 4, Table 3). Post-consumer pipes from post-demolition materials in Sweden may have up to 70% of PVC, but the collected amounts are minor (Krantz, 2018). Finland has had a rather extended system for clean plastic pipes including PVC monitored by the Finnish Plastic Industries Federation, which was abandoned due to collection difficulties (Pohjakaljio and Punkkinen, 2018). Although there are still some construction companies which collect clean PVC waste from industries and households (Kärhä, 2018), the collected amounts are minor (Vaajasaari, 2018) with small amounts of hard PVC pipes exported to Sweden and Latvia for recycling (Pohjakaljio and Punkkinen, 2018).

4.4.2. PVC in end-of-life vehicles

Management of the PVC material in end-of-life vehicles (ELV's) is rather similar in all Nordic countries (Fig. 5). ELVs are collected and dismantled accordingly to the European Directive 2000/53/EG on end-of-life vehicles (EC, 2000a). Hazardous components and bulk materials such as tires are dismantled and sent to shredding plants (Stenmarck et al., 2017). Although some larger PVC elements (such as e.g. plastic bumpers and gasoline tanks) could be to a smaller extent re-used/sold for re-use, exported for recycling, this is not a common practice according to our interviews. The prevailing practice is that plastics end up in the so-called shredder light fraction (SLF), which is sent either to energy recovery or landfilled (Stenmarck et al., 2017). No official statistics on PVC amounts in SLF are available for Sweden, Finland or Denmark. Based on our assumptions it could vary from 1000–3,000t in Finland to 3000–5000 in Sweden, depending on the number of dismantled ELVs. Norway has official statistics on the SLF management. Here, material and energy recovery is the dominant treatment option with some SLF material sent abroad for recycling (Table 3). Generally, the ratio between landfilling and incineration in the Nordic region is not certain (Table 1, Table 2, Table 4).

Fig. 5

Fig. 54.4.3. PVC in WEEE and cables

All Nordic countries have implemented the EU WEEE directive 2012/19/EU (EC, 2012) which set criteria for separate collection, recycling and recovery for different types of products. The collection, transportation, management and financing are covered by extended producer responsibility (EPR) systems, implemented by several producer organisations. Recycling of WEEE is largely focused on recovering metals and not plastics, especially PVC, which is a rather marginal plastic in WEEE (except in cables) (Fig. 6). Baxter et al. (2014) estimated that in the Nordic countries plastics in WEEE constitute around 20% by weight. According to the European Electronics Recyclers Association (EERA), shredded WEEE residues have is only 1% of PVC (EERA, 2017). This means that 100–300 t of PVC present can be present in WEEE in the Nordic countries (Table 2-Table 4). This part of PVC is too small to be separated from other plastics, although in e.g. Finland some plastic waste from WEEE used to be sent to Asia for recycling (Virtanexn 2018). After China's restrictions on waste imports, plastics now go largely to energy recovery or special energy treatment in hazardous waste plants if they contain flame retardants. Only a minor part goes to landfilling (Virtanen 2018). Landfilling of PVC after pre-treatment of WEEE might be more present in Denmark, due to restrictions on energy recovery, but the landfilling-incineration split is uncertain.

Fig. 6

Fig. 6Cables is probably the main type of WEEE, where PVC recycling (locally or abroad) is more prominent. In Finland, the prevailing approach in the past was exporting non-granulated cable waste to Asia (e.g. China). Today this is largely not possible due to waste import restrictions imposed by China. The only special treatment method available is granulation (or the cable shredding process). For instance, Stena Recycling has its own granulate plant and some cable waste is exported to Sweden. The PVC waste after cable granulation ends up being sent to energy recovery if it remains in Finland (Walavaara, 2018). In Norway, the biggest producers responsibility organisation sells waste cables to recycling companies including Stena Recycling, KMT Gjennvining and Metallco (Dordipour, 2018).

In Sweden, cables often sorted out from WEEE and sent to separate recycling due to high economic value of copper and aluminium. It is estimated that 40,000–45,000 t/year are separately collected, of which 70% contain PVC. The main part of PVC containing cable waste comes from old buildings, but this is likely to shrink in the near future. Today only half of cables produced in Sweden contain PVC and this share is constantly shrinking (Belleza and Youhanan, 2017). Similar situation is also in Denmark.

Metals in cable waste are extracted through cable granulation and separation from plastics. The plastic fraction, mostly containing PVC, has been traditionally sent to energy recovery. Today in Denmark and Sweden some of these plastics are gravimetrically separated using the so called PlastSep process, developed by Watech in Denmark. The process generates a lighter, polyolefin fraction and a heavier “PVC fraction” with further separation of metals and plastics, which allows recovering more metals and a higher purification degree for the plastic fractions (Rasmussen and Boss, 2007). Stena Recycling uses PlastSep and is the only Swedish actor authorised to put recyclate including DEHP on the European market. The share of DEHP in PVC from post-consumer cable waste can be rather high – up to 6–7% of PVC from post-consumer copper cables, and 5–7% of PVC from aluminium cables (Boss, 2014). According to some studies, approximately 2000–3000 tons of cable granulates (mostly PVC) are recycled in Sweden annually, but it is a declining trend (Youhanan et al., 2016). Due to the presence of DEHP in post-consumer cable waste, Swedish recyclers granulating cables send much of the plastic fraction including PVC to energy recovery.

4.4.4. PVC in packaging

PVC content in packaging waste in Nordic countries is rather minor. In Denmark, Lassen et al. (2018) estimated it to be ca. 2% by weight of all PVC annual supply or 1400 tonnes. As packaging has quite short lifespan, it could be assumed that the quantity present in waste is in similar range. Two compositional studies of source-separated plastic packaging waste were carried out in Sweden at recycling stations and from the residual waste–to-energy flows. The analyses showed that the category “other plastics”, including PVC packaging and other types of packaging, constituted only 6% by weight (Stenmarck et al., 2018).

All Nordic countries has producer responsibility for packaging waste collection where producers are taking both financial and physical responsibility for packaging waste collection. Collection occurs mainly throughout bring schemes and/or kerbside collection in some municipalities. In Finland PVC-containing commercial and consumer packaging (including other small PVC-containing waste items) are excluded from the separate collection system. Here PVC packaging is collected in mixed municipal waste stream and treated mainly by energy recovery (Häkkinen, 2018). In the rest of the region, PVC packaging may be collected separately, but generally it is not recycled, but sorted out as a reject fraction and sent to energy recovery. A simplified scheme of PVC waste management is presented in Fig. 7.

Fig. 7

Fig. 74.4.5. PVC in other waste flows

PVC could also be collected alongside other plastics in separate collection for plastics organised by municipalities (Fig. 4). Separate collection of mixed plastic waste (also called “municipal plastic”) for recycling occurs only in a handful of municipal recycling centres in Sweden. Mainly rigid PVC containing plastics, such as buckets, trays, garden furniture, toys and pipes, are collected there (e.g. ca, 7000 t of mixed plastic waste in 2015) and sent to Swerec AB for recycling. However, most of the initiatives do not instruct for a separate collection PVC waste. According to waste analyses PVC constitutes about 7% by weight of this plastic fraction (Fråne et al., 2017).

Similarly, in Norway, PVC waste can also be collected in some municipal recycling stations either as hard plastic together with other types of plastic or as waste for incineration or as hazardous waste. Except for hazardous waste, no information is available regarding how much PVC waste is collected this way.

There are some estimates on the amount PVC containers’ waste (e.g. blood containers) within the Swedish health care sector, that is around 80 tonnes annually, which is sent to energy recovery (Stenmarck et al., 2018). Other PVC waste in health care, depending on how it has been used and the level of contamination, can be sent either to energy recovery or as a part of other hazardous waste from the health care sector and incinerated at 1100 °C. In Finland, PVC used in health care ends up in mixed waste health care fractions and is classified as hazardous waste and subject to incineration for hazardous waste (Vaajasaari, 2018).

5. Discussion

Estimates of the total amounts of PVC waste in the Nordic region are prone to inaccuracies due to variations in the life expectancy and assumptions made about the life spans of different PVC product groups. For some products, such as pipes or window and door frames, it takes a few decades from products’ release on the market until they become waste. However, PVC stock in the society is not possible to detail accurately.

The regional annual average of PVC generation is in the range of 5–5.5 kg/capita (except Denmark). This is in line with the European average by Ciacci et al. (2017) - 5 kg/capita for the EU27 in 2012 or the “available waste” in Europe, some 2.5 million t/year in 2016 or around 5kg/capita by VinylPlus (2018).4 However, the most recent study by Lassen et al. (2018) for Denmark estimates waste generation per capita to be at least twice larger. The difference could be partly explained by the Danish study being more recent (the reported year was 2017) and partly - by potential differences in the methodology and chosen assumptions. Ciacci, Passarini et al. (2017) used a longer and more general lifetime of PVC products (e.g. 50 years for all construction products), while in estimation by Kaysen et al. (2015) and Lassen et al. (2018) PVC products become waste at slower paces, with the majority C&D products peaking as waste after ca. 15–20 years. As PVC supply had its peak in the late 1990s, the model estimates showed a rather large waste generation rate now. Lassen et al. (2018) also recognised that PVC waste available for waste treatment in Denmark may be not accurate and could be only a half of the estimated amount for rigid PVC due to the lifetime of stocks of certain product groups (like sewer pipes), which was not included in the model. Some of the most widely used PVC-containing products, e.g. pipes, might never be collected as a separate waste category if they are left buried in the ground.

In theory, the generated amounts of PVC waste should equal the sum of the amounts recycled, energy-recovered and decommissioned either through landfilling or incineration without energy recovery, plus some amount of littering. However, there are no easily available statistics on PVC waste management in the region and the data are often based on estimates.

The amounts of waste going to recycling are usually relatively easier to estimate as it is often a matter of accounting the separately collected clean waste products. However, for PVC waste only Denmark accounts separately collected PVC waste and its treatment as PVC waste is a part of the official Danish waste statistics, which is not the case in the other Nordic countries. One of the reasons could be the use of European waste catalogue (EWC), which reports the general plastic waste from different sectors and not specific types of plastic waste.5 This means that even though PVC waste could be separately collected or treated, it may not be reflected in national statistics following the EWC. When PVC waste materials are dispersed in mixed waste fractions the estimates are even harder to evaluate and is less reliable and rarely based on waste composition.

For all of the reviewed Nordic countries (except Denmark) finding reliable information on separate PVC collection and treatment is generally difficult. Denmark maintains official statistics, according to which 10–13% of the total PVC waste are recycled. In other countries the recycling rate is likely to be lower than in Denmark. Overall, PVC recycling in the Nordic region seems to be lower than the EU average. A report by VinylPlus (2018) stated that about 695,000 t or 25%6 by weight of “waste available” were recycled in Europe in 2016. However, a direct comparison between different EU countries and the Nordic region is not available.

Most PVC recycling from the Nordic countries seems to occur abroad. Other than the on-site recycling of pre-consumer PVC waste, a minor recycling of own products (such as flooring PVC) or some local recycling of PVC in cables, no other significant local recycling capacities of PVC waste exist. Mainly clean pre-consumer waste from construction industry (e.g. pipes) is separately collected and sent for recycling abroad.

The low PVC recycling rate in the region is influenced by several factors, including low demand on the market, lack of economies of scale, high quality requirements for recycled PVC and relatively low focus on PVC in environmental policies and waste management strategies. Consumption of important PVC-containing products, such as window and door profiles, in the Nordic region is 50–60% lower compared to the European average (Fig. 1, Fig. 3) due to regional preferences for other such as wooden products. According to, PVC profiles were even less popular in the past, which influences today's rate of waste generation. The dominant type of PVC waste today is used pipes and drains, products that may not be easily available for recycling.

PVC recycling in the region is also severely limited by high costs and lack of scale economy. PVC is dispersed among a large variety of geographically dispersed products and the region is relatively sparsely populated, which inflates the costs of waste collection and transfer. The high costs of sorting, management and recycling with a weak market for recycled PVC makes PVC waste collection an unattractive business for most private companies.

High industrial standards for the quality of recycled PVC and restrictions on the of hazardous additives further complicate the recycling of PVC waste. Collected post-consumer rigid PVC contains predominantly lead stabilisers and restricts recycling possibilities in the region. For instance, although the proposal in REACH for restrictions on lead stabilisers from the European Chemicals Agency (ECHA) asks for a 15-year derogation for recycling with lead content of up to 1%, Denmark applies a much lower permissible threshold of 0.01%. This precludes a domestic recycling of separately collected post-consumer rigid PVC waste and results in waste exports. At the EU level, PVC waste containing lead is often recycled incorporating recyclate into new products by e.g. enclosing recycled PVC between layers of new PVC material without lead additives.

Recycling of flexible PVC is even more complicated due to the presence of PVC additives, which make it difficult to achieve the desired quality of recycled products. Historic post-consumer waste may contain DEHP and other phthalates restricted today. Many producers have already phased out use of potentially dangerous phthalates on a voluntary basis. Moreover, DEPH is already on the REACH authorisation list, where a permit is required for anyone willing to produce recycled flexible PVC. The EU is also moving towards restrictions of other phthalates in products that may have prolonged skin contact. Therefore, flexible PVC waste is often down-cycled to industrial grade products. These products still sooner or later become waste with containing undesirable substances and will need to be treated in a special way, probably precluding further recycling.

Separation of PVC from mixed plastics is necessary to both improve recycling and preventing the contamination of other plastic streams by PVC. Such separation could be based on different technologies, such as, for instance, floatation or electrostatic separation-based processes. Recently, more and more research focuses on finding better ways to improve separation processes for plastics, including, e.g. improving PVC floatation by surface modifications, using a heterogeneous catalytic (Zhang et al., 2020), the so-called, response surface methodology (Wang et al., 2016). The efficiency of PVC separation using the electrostatic separation could be improved up to 96 % by, e.g., the so-called three charge-decay pattern approach (Li et al., 2017). Since PVC stream is rather small (but rather detrimental part) in the overall packaging and other waste streams, improving the efficiency of PVC separation is an important technical challenge. More efforts need to be done to increase the efficiency of separate plastic collection in general including separation PVC at source of its generation.

Even relatively clean pre-consumer waste is still not so easy to recycle due to the lack of information about the type and content of PVC material in products. Labelling PVC products indicating their main “ingredients”, e.g. in a similar way food packaging indicates its material, may play an important role in reducing recycling problems. Labelling could also include information relevant to products’ end-of-life treatment.

None of the Nordic countries, except for Denmark, have a specific focus on strategies or legislation for PVC waste issues. Although an environmentally sound management of plastic waste is high on the political agenda in all Nordic countries, it is apparent that Finland, Sweden and Norway have much less specific focus on PVC waste problems. In Denmark PVC has attracted more political debates since early 1990s, especially regarding PVC incineration and the fate of hazardous substances. This led to current Danish legislative framework supporting a nationwide collection of rigid and soft PVC waste.

Waste management hierarchy is the ground for waste management in all Nordic countries. Landfill bans of organic and combustible waste (in Finland and Sweden) and high costs for landfilling facilitated by landfilling tax were among main reasons for diverting PVC away from landfills towards incineration. Denmark is the only country were landfilling of soft PVC is legal, but even here a large share of PVC enters incineration through mixed waste streams.

Most of incinerators in the region use combined heat and power (CHP) technologies with high emissions standards for dioxins and chlorine compounds. According to the EU regulation 1357/2014 (EC, 2014) waste that contains organic halogens exceeding 1% expressed as chlorine equivalents, must be thermally treated in incinerators at least at 1,100 °C to avoid hazardous emissions of chlorines. This is generally the case for homogenous PVC waste streams since they can contain up to 57% of chlorine and are classified as hazardous to be treated in hazardous waste incineration plants. Generally the waste-to-energy sector in Europe is reluctant to accept mono-streams of PVC waste-to-energy recovery, primarily as the chlorine may cause corrosion in the flue gas cleaning system. However, when PVC material ends up in mixed waste streams, the equivalent share of chlorine is much lower and such waste can be subjected to regular thermal treatments. Deliberately mixing PVC waste with other waste streams to avoid excessive chlorine peaks seems to be acceptable practice by incinerators.

Waste incineration with energy recovery is generally seen as a better option than landfilling from the environmental point of view. PVC incineration has been historically a controversial topic and discussed at the EU level since early 2000s (EC, 2000c). The main concerns were that incineration of PVC incineration may cause formation of dioxins, higher levels flue gas cleaning residue to be treated as hazardous, corrosion of cleaning system and presence of heavy metal in the fly ash.

Regarding dioxins high standards are applied in the EU, in relation to the EU Directive 2000/76/EG (EC, 2000b) (limits to 0,1 ng TEQ dioxin per m3). Dioxin emissions and other issues, like flue gas cleaning residues related to PVC is not so seen so high concern in modern, well controlled incineration plants according to Ciotti and Sevenster (2013) or by some PVC industry funded studies (Johnsen, 2016, Buekens and Cen, 2019). In Sweden and Finland, lack of domestic recycling capacities or energy recovery infrastructures within reasonable transport distance results in marginal exemptions from the landfilling bans. In Norway it is legal to landfill PVC waste, but as landfilling is often a more expensive option than the alternatives, it is not carried out to a high extent.