1. Introduction

In offshore Oil & Gas installations severe slug is an undesired flow regime in the well-pipeline-riser systems, as it has proved to have negative impact on the daily production (Havre et al., 2000, Pedersen et al., 2015). The issues related to the severe slugs are numerous (Hill and Wood, 1994): Overload on gas compressors, fatigue in the transporation pipelines, increased corrosion (Sun and Jepson, 1992, Zhou and Jepson, 1994, Kang et al., 1996), production reduction (Isaac et al., 2011), production slop and high pressure and liquid overflow in the downstream gravity separators (Yang et al., 2010). Anti-slug feedback control is one effective solution for changing the slug flow to a stable flow regime (Pedersen et al., 2014). A common approach is to stabilize the fluctuating pressure and/or flow by manipulating the topside choke valve at the riser top (Jahanshahi et al., 2012, Jahanshahi, 2013). However, as the controllers lack robustness to process or condition changes, the operators sometimes manually choke the valves to conservatively low opening degrees to eliminate the severe slugs with the consequence of simultaneously reducing the productions (Jansen et al., 1996).

The traditional upstream separation technology in the North Sea consists of 3-phase gravity separators and de-oiling hydrocyclones. This configuration represents 90% of the existing de-oiling technologies in the North Sea (Cullivan et al., 2004). The outlet of a well-pipeline-riser transportation process is typically physically linked to a 3-phase gas/water/oil gravity separator. The first step in the separation consists of a single or multiple 3-phase separators to completely separate the gas and separate most of the oil in the water. The water outlet of the last 3-phase separator is connected to a de-oiling facility consisting of multiple hydrocyclone liners (Husveg et al., 2007, Husveg, 2007).

The highly fluctuating production rate induced by severe slugs occurring in the riser can cause liquid overflow in the 3-phase separator if the separator's size is designed for a non-slugging buffer time (Yang et al., 2010). Furthermore the study from Husveg et al. (2007) proved that a poor separation in the separator will affect the performance in the rest of the typical produced water separation process. Thus handling the slugs upstream the separator would be preferable as the slugs can reduce the separation efficiency of the separator, ultimately resulting in a limited production rate, reduced production quality, as well as difficulties and challenges for the produced water treatment. The study in Wilhelmsen (2013) proposed control methods for gravity separator outlet valves to handle the large slug disturbances to the separation process. However, the work did only investigate the gravity separator isolated with no downstream de-oiling separation included.

This paper will examine the relationship between different kinds of severe slugs (under different running conditions) and the associated produced water treatment performance. The main contribution of the work is based on experimental data obtained from a laboratory testing facility. The testing facility can test both the transportation well-pipeline-riser transportation and the separator-hydrocyclone separation systems, as well as the entire system running at once in a flow-loop manner (Durdevic et al., 2015, Durdevic et al., 2016, Pedersen et al., 2016). Thus, several testing scenarios will be considered with different operation condition configurations for each individual scenario, respectively. The paper's main objective is to provide some solid experimental evidences that the varying inflow indeed has negative impact on the downstream hydrocylone's separation performance.

The rest of the paper is organized as following: Section 2 briefly describes the testing facility, Section 3 illustrates considered testing scenarios, Section 4summarizes the experimental results and finally a conclusion is carried out in Section 5.

2. Testing facility

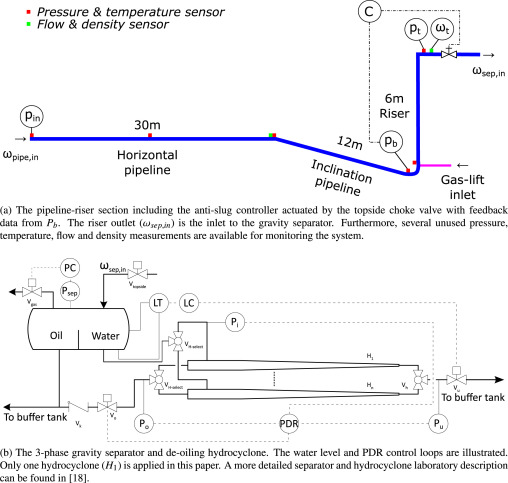

The testing facility described in this section is an extension of the facility examined in Biltoft et al. (2013). Fig. 1 shows P&ID drawings of two parts of the laboratory testing facility where all examined experiments are obtained from. The facility consists of a pipeline-riser-separator-hydrocyclone system in a complete flow-loop. Each individual part of system can be tested respectively. In the this paper's work the configuration consists of the following subsystems will be applied together: Pipeline-riser-separator-hydrocyclone. Fig. 1a shows the pipeline-riser with the anti-slug control configuration examined in this paper, and Fig. 1b illustrates the gravity separator with water level control loop and the hydrocyclone with the pressure drop ratio (PDR) control loop.

Fig. 1. Two illustrations of the linked laboratory-scaled pipeline-riser and separator-hydrocyclone processes, including the respective control loops.

Fig. 1. Two illustrations of the linked laboratory-scaled pipeline-riser and separator-hydrocyclone processes, including the respective control loops.There is a number of transmitters and actuators installed to manipulate and monitor the system. There are temperature and pressure transmitters at all relevant position on the facility, as well as several flow transmitters to measure in- and outflows of each subsystem. In the gravity separator there is also a multi-level transmitter installed to measure the water and oil levels, respectively. The actuators consist of inflow oil and water pumps, gas compressor, with control valves to regulate the gas inflow, a riser gas-lifting valve, a riser topside choke valve, outlet valves on each of the gravity separator's three outlets and control valves on both hydrocylone over- and underflow outlets.

All data acquisition and control is performed using a standard PC running Simulink Real-time (xPC) through a target PC which guarantees real-time simulations. The transmitters and actuators are connected to the target PC through National Instruments (NI) data acquisition and output PCI cards, which are installed in an electrical distribution box.

3. Experimental design

In this section the experimental design is described, as well as an examination of the slug and separation emulation properties.

Some key physical properties are expected to be present for the considered process. The relationship between water in- and outflow of the gravity separator is important as the inflow can be controlled by the topside riser valve and the outflow is transported directly to the hydrocyclone. If all other running conditions are constant, the initial water level is equal to the controller reference (), and a perfect (infinity fast) water level controller is installed in a gravity separator the separator's water mass inflow () will at any point in time be equal to the separator's water mass outflow (). In reality a time delay is also expected to be present.

As the de-oiling hydrocyclone is directly linked downstream the gravity separator's water outlet, the varying water inflow to the separator will simultaneously result in oscillations for at the hydrocyclone's inlet flow, when a water level controller is applied for the gravity separator. As the hydrocyclone's separation performance is highly sensitive to the fluctuating inflow, this can be a problem for the complete separation efficiency (Husveg, 2007, Wolbert et al., 1995, Schuetz et al., 2004). Furthermore, the hydrocyclone's underflow valve is the only applied actuator for manipulating the water level in the gravity separator. The hydrocyclone's overflow valve is normally controlling the calculated pressure drop ratio (PDR) over the hydrocyclone, see Eq. (1), which is used to estimate the flow split between the over- and underflow channels, respectively.(1)

The existence of severe riser-induced slugs require low liquid and gas flow rates (Taitel et al., 1990), which is often observed in mature oil & gas installations where the reservoir pressure has dropped. The longer the riser is, the larger will the region for severe slugs on the flow maps be (Tengesdal et al., 2002). Hence, for longer risers the superficial gas and liquid velocities can be higher while still observing severe riser-induced slugs. However, for the testing facility the riser is only 6 m tall (see Fig. 1a), and the corresponding operating flow rates will be small to emulate the slugs. Scenario 1 has the slugs with the highest possible operational liquid flow rate with atmospheric pressure in the separator. However, as the hydrocyclone is pressure-driven the separator also had to be pressurized for the inclusion of the separation process.

In Ogazi (2011) it was concluded that the gravity separator's gas outlet valve also could be used for anti-slug control purpose. Hence, pressurizing the system forces the inflow superficial velocities to be even smaller. Scenario 2 operates with low inflow rates to create a scenario where it is hard to stabilize the slugs (low open-loop bifurcation point). However, this reduces the amplitude of the fluctuating liquid disturbance to the separator, and is thus not the most severe type of slug according to pressure and flow amplitudes. Scenario 3 investigates a pressurized separator with high gas inflow rate and a liquid inflow which lies in between the two other scenarios. Although the oscillations does not have the cyclic behavior as riser-induced slugs, the scenario has significant pressure and flow amplitudes. These operation conditions are undesired for optimal separation due to the large amounts of inflow gas rates, disturbing the system with high frequency oscillating pressure and flow rates at the gravity separator.

4. Experimental results

Nine different test modes are evaluated, respectively. These include three different test scenarios:

-

1.

Slugs with high liquid production rate, atmospheric Psep

-

2.

Slugs with low liquid production rate, pressurized Psep

-

3.

Irregular oscillation flow (OSC) with medium liquid production rate, pressurized Psep

-

1.

100 topside choke opening, to see optimal operation point during slug flow.

-

2.

Manual slug control: Choking below the to eliminate the slug.

-

3.

Choking with feedback control: Here a trial-and-error tuned riser bottom pressure (Prb) propotional controller is applied.

For each individual scenario the three test modes can be compared. The comparison will cover the production rate, and performance of the anti-slug, level and PDR controllers, respectively. This gives an indication of how efficient the separation will be in realistic operating conditions, although the oil-in-water concentration is not measured directly. Scenario 1 was operating under atmospheric pressure, and thus the pressure-driven hydrocyclone was not able to operate during the tests. Hence, Scenario 1 has not included the level and PDR controllers, but instead bypasses the hydrocyclone and is being fed directly into the disposal water tank. It is included to evaluate the Prb propotional controllers effect on the production rate.

Table 1 gives a detailed comparison between the three scenarios, the related running conditions, slug properties, transient convergence results, resulting production rate and separation process results. In general it is clear that the anti-slug control is more efficient than manually choking in terms of resulting average production rate and settling time. The results will be discussed further in the following.

Table 1. A comparison table describing the different test conditions and results. The results describe the slug elimination with permanent choking and feedback control, as well as the associated produced water separation process.

| Scenario 1 | Scenario 2 | Scenario 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 3 | |||||||

| Nominal avg. * | 0.4 | 0.1 | 0.2 | ||||||

| Nominal avg. * | 1.25 | 0.5 | 3 | ||||||

| Level setpoint | – | 0.25 | 0.25 | ||||||

| PDR setpoint | – | 2.5 | 2.5 | ||||||

| 24 | 18 | 23 | |||||||

| Severity | Strong | Light moderate | Moderate | ||||||

| Test1 | Test 2 | Test 3 | Test 1 | Test 2 | Test 3 | Test 1 | Test 2 | Test 3 | |

| Feedback control | No | No | Yes | No | No | Yes | No | No | Yes |

| Valve opening | 100 | 20 | Controlled | 100 | 15 | Controlled | 100 | 20 | Controlled |

| Flow regime | Slug | Non-slug | Non-slug | Slug | Non-slug | Non-slug | OSC | Non-OSC | OSC |

| Pressure amplitude - Prt | 0.126 | – | – | 0.019 | – | – | 0.062 | – | – |

| Pressure amplitude - Prb | 0.229 | – | – | 0.058 | – | – | 0.141 | – | – |

| Flow amplitude - | 0.69 | – | – | 0.20 | – | – | 0.34 | – | 0.26 |

| Frequency | 1/72 | – | – | 1/58 | – | – | 1/64 | – | 1/10 |

| Settling time ** | – | 120 | 62 | – | 298 | 202 | – | 150 | 30 |

| Rise time ** | – | 42 | 25 | – | 23 | 26 | – | 18 | 8 |

| Overshoot - Prt ** | – | 0.081 | 0.034 | – | 0.026 | 0.004 | – | 0.149 | 0.017 |

| Overshoot - Prb ** | – | 0.154 | 0.057 | – | 0.042 | 0.018 | – | 0.167 | 0.026 |

| Overshoot - ** | – | 0.147 | 0.261 | – | 0.065 | 0.064 | – | 0.143 | 0.089 |

| Steady-state error ** | – | – | 0.012 | – | – | 0.006 | – | – | 0.004 |

| Avg. production rate | 0.415 | 0.306 | 0.418 | 0.098 | 0.081 | 0.106 | 0.185 | 0.181 | 0.182 |

| Water level overshoot peak *** | – | – | – | – | 1.009 | 1.016 | – | 1.008 | 1.009 |

| Water level SS peak *** | – | – | – | 1.006 | 1.001 | 1.001 | 1.014 | 1.006 | 1.007 |

| Water level mean | – | – | – | 0.249 | 0.250 | 0.250 | 0.249 | 0.250 | 0.250 |

| PDR overshoot peak *** | – | – | – | – | inf. | 1.561 | – | 1.339 | 1.555 |

| PDR SS peak *** | – | – | – | 1.353 | 1.054 | 1.061 | 1.854 | 1.478 | 1.543 |

| PDR mean | – | – | – | 2.830 | 3.213 | 3.014 | 3.780 | 2.516 | 4.321 |

| Transient separation performance | – | – | – | – | Low | Moderate | – | High | Low |

| Steady-state separation performance | – | – | – | Low | Very high | High | Low | High | Low |

- *

-

The nominal value is an indicative value for the gas and liquid inflows, as the pump is controlled with voltage to emulate a production well, and the gas is controlled to track a Gas Volume Fraction (GVF) reference.

- **

-

All the slug tests' transient performances are obtained based on steps from 100 topside choke valve opening to either below the bifurcation points or enabling the anti-slug controllers.

- ***

-

These entries indicate the maximum of the peak values normalized relatively to the given steady-state values: .

4.1. Scenario 1: High flow rates and atmospheric separator pressure

In Fig. 2 the open-loop step test is shown. It is clear that the decreased valve opening eliminates the slug, but also increases the back pressure. Besides, the settling time is pretty long, which is undesired. Fig. 3 shows the Prb proportional controller which initially is not enabled, then enabled which successfully eliminates the slug, and then with a increase in the setpoint goes unstable again. Thus, it is important to pick a pressure setpoint below the closed-loop bifurcation point () while enabling the controller. Both the open- and closed-loop control strategies successfully stabilizes Pb, Pt and if the valve is choked below the respective bifurcation point (Zbif). Furthermore, the two tests confirm that the worst production is obtained by the open-loop choking below , while the average production rates are similar for both the fully open valve and the Prb proportional controller. Thus the controller does not improve the production much from the fully open valve, but successfully eliminates the severe riser-induced slug with a better production rate than the open-loop choking.

Fig. 2. A plot of the step test for Scenario 1. Two modes are observed: (1) The slug flow with valve fully open at riser top, and (2) at 400 s the valve is choked below the open-loop bifurcation point () to eliminate the slug. The choking significantly increases the back pressure and decreases the production rate.

Fig. 2. A plot of the step test for Scenario 1. Two modes are observed: (1) The slug flow with valve fully open at riser top, and (2) at 400 s the valve is choked below the open-loop bifurcation point () to eliminate the slug. The choking significantly increases the back pressure and decreases the production rate. Fig. 3. A plot of the controller test for Scenario 1. Three modes are observed: (1) The slug flow with the valve fully open at riser top, (2) at 200 s the Prb P controller is enabled to stabilize the flow with the topside valve, and (3) at 800 s the Prb P controller is given a reference which requires operation above the closed-loop bifurcation point () which causes the slug flow to reoccur.

Fig. 3. A plot of the controller test for Scenario 1. Three modes are observed: (1) The slug flow with the valve fully open at riser top, (2) at 200 s the Prb P controller is enabled to stabilize the flow with the topside valve, and (3) at 800 s the Prb P controller is given a reference which requires operation above the closed-loop bifurcation point () which causes the slug flow to reoccur.4.2. Scenario 2: Low flow rates and pressurized separator

Fig. 4a shows the open-loop step choking for Scenario 2. Here the separator is pressurized to 3 bar, which is the reason for the figure's pressure offset. The settling time for the pressure is significantly longer than for Scenario 1 even though the valve is choked down relatively to below the respective for both tests. The water level, in Fig. 4b, and the PDR, in 4c, both indicate that the nominal operation for the controller is in the non-slugging flow regime. The fluctuations of the water level is insignificant for a optimal operation, however the PDR fluctuations are outside the region desired for good separation performance. It is also clear that the step response induces a minor undershoot for the water level and a much larger overshoot for the PDR. The hydrocyclone's overflow valve saturates during the slugs, which is a clear indication that the PDR controller cannot reject the disturbance induced by the slug mass flow amplitude.

Fig. 4. Measurements from the step test for Scenario 2. The slug magnitude is smaller than for Scenario 1, however the Prb clearly indicate severe slugs for the large valve openings.

Fig. 4. Measurements from the step test for Scenario 2. The slug magnitude is smaller than for Scenario 1, however the Prb clearly indicate severe slugs for the large valve openings.Fig. 5a shows the Prb proportional controller enabled at 100 s. It is clear that the controller struggles to stabilize the pressure, as the controller during the first 300 s saturates the valve opening, but in the end manages to stabilize the reference. Thus, the settling time is not significantly faster with the controller compared to the open-loop choking. During the slug flow, the water level in Fig. 5b is fluctuating in an acceptable region (), but the PDR in Fig. 5c cannot track the setpoint due to a saturated overflow valve. In the non-slug region both the water level and PDR controllers perform acceptably. The saturation of the overflow valve is caused by the dominance of the underflow valve. If the underflow valve opens above a certain point, then the PDR cannot be controlled within the desired region due to the saturation of the overflow valve.

Fig. 5. Measurements from the controller test for Scenario 2.

Fig. 5. Measurements from the controller test for Scenario 2.A comparison between the PDR measurements for scenario 2 is carried out in Fig. 6, where the three modes' (fully open, open-loop choking, and closed-loop choking) distribution during steady-states are compared. Here is it confirmed that both the open-loop and closed-loop choking cause fewer oscillations with much more narrow distributions. Furthermore, the open-loop choking seems to be better than the closed-loop choking with respect to the PDR tracking.

Fig. 6. Steady-state distribution of the PDR in the three considered modes in Scenario 2.

Fig. 6. Steady-state distribution of the PDR in the three considered modes in Scenario 2.The overall result for scenario 2 is that both open- and closed-loop choking significantly improves the overall oil-water separation conditions for the level and PDR controllers. The open-loop choking gives the best PDR and level tracking performance, which is desirable for good separation performance, but also simultaneously gives the worst production rate. The applied closed-loop controller is simple, and a faster controller might improve the closed-loop choking's effect to the separation performance further. Furthermore, experiments with similar running conditions have been carried out with a PDR reference at 4 (changed from 2.5), and the tests confirmed the other results where both the open- and closed-loop choking perform well within the acceptable water level and PDR ranges. Note, however, that in offshore cases this is not considered a good reference point for separation efficiency.

4.3. Scenario 3: Medium flow rates and pressurized separator

In Scenario 3 the separator is again pressurized to 3 bar. Now the liquid mass flow rate is around the double of Scenario 1, and the gas mass flow rate is 6 times higher. The flow variations are more irregular than the previous-examined riser-induced slugs, and is here characterized as irregular oscillation flow (OSC). Fig. 7a shows the open-loop step test for Scenario 3. It is clear that after the open-loop choking at 300 s, is stabilized. However, there are still some oscillating pressure variations. This is expected to be caused by the large amounts of gas inflow. For the separation, this stable region is expected to operate similarly to the two previous scenarios where, contrary to this scenario, the pressures were constant after the open-loop choking. As the pressure in the gravity separation is controlled with a fast operating choke valve, the separator's pressure is close to constant for the entire test (even with an oscillating Pt), which guarantees very ideal running conditions for the downstream pressure-driven de-oiling hydrocyclone. Fig. 7b shows the water level, which is stabilized closer to the setpoint after the valve is choked. However, the water level oscillations are easily kept within the critical lower (20 cm) and higher (29 cm) boundaries even during the slugs, and thus the fluctuations are insignificant for efficient operation. Fig. 7c on the other hand shows that the PDR has large fluctuations in the slugging region, but they are significantly reduced in the non-slug region to an acceptable level.