1. Introduction

Researchers are looking for advanced sustainable and renewable energy resources because fossil fuels are limited and have high CO2 emissions (Bhuiyan et al., 2021a). Great attention is essential to the advancement of novel materials. Recently, TE materials have met the rising global demand for cost-effective, pollution-free energy conversion technologies. It allows heat to be converted into electricity. The perspective research is in cooling devices and waste heat recovery that makes TEG attractive from an environmental point of view. TEG offers an alternative, sustainable power source to alleviate increasing worldwide power demand and concern over environmental issues. High-performance TE materials are a significant topic of concern due to their high figure of merit (ZT). These opportunities for TEGs are supporting a low-carbon economy. TEG is a direct conversion of electrical energy from wasted heat, yet it requires further research and improvement compared to other energy conversion approaches. The performance evaluation of TEG is assessed by the ZT value (dimensionless), which is affected by the Seebeck coefficient, thermal conductivity, electrical resistivity, and temperature, respectively. TE nanostructured materials have an influence on TEG technology for converting electrical energy by using heat management. Development of the nanostructurefeatures might effectively scatter phonons of materials that consequently reduce thermal conductivity. The phenomenon is affecting TE characteristics for ZT enhancement. The maximization of ZT depends on operation temperature and material composition. According to the previous reports, the p-type material compositions exhibit prominent ZT values compared to the n-type materials.

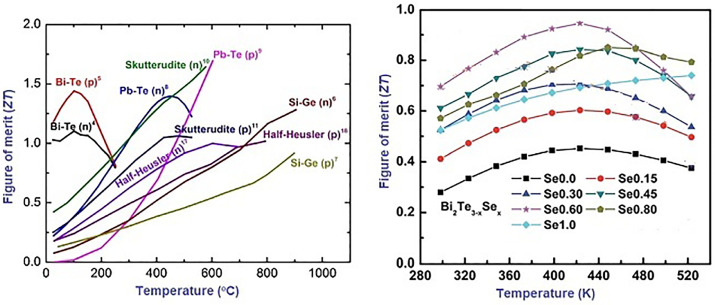

Fig. 1(a) shows the ZT values for various TE materials as a function of temperature. Efficient p and n-type TE materials within different compositions at temperatures up to 300°C may be suitable for TE applications. Fig. 1(b) shows the composition dependence of ZT values for Bi2Te3-xSex (0.0≤X≤1.0) TE materials. The figure demonstrated that both temperature and composition have an influence on ZT values. It has a high power factor and low thermal conductivity. A low-temperature TE material behaves with potentially high performance (Bauer et al., 2021).

Fig. 1. (a) ZT values for various TE materials as a function of temperature (Chen and Ren, 2013). (b) Composition dependence of ZT values for Bi2Te3-xSex(0.0≤X≤1.00) (Zheng et al., 2015).

Fig. 1. (a) ZT values for various TE materials as a function of temperature (Chen and Ren, 2013). (b) Composition dependence of ZT values for Bi2Te3-xSex(0.0≤X≤1.00) (Zheng et al., 2015).Over the previous decade, n-type Bi2Te3-based materials have made significantly less progress in strengthening the TE application at low temperatures than p-type Bi2Te3-based materials. The widespread use of these materials in TEG and other applications is a difficulty. Because of the advanced contribution of TE performance, the Bi2Te3-xSex composition has high electron mobility and expansion electrical conductivity (Chen et al., 2021). It develops a high Seebeck coefficient for energy-dependent carrier scattering. Many researchers have adopted different strategies to realize the high ZT values for these materials. Researchers have attempted to improve TE performance by reducing lattice thermal conductivity through nanostructure form (Deng et al., 2018; Li et al., 2018; Liu et al., 2018; Pan et al., 2017; Wudil et al., 2020), structural texture (Liu et al., 2011; Kim et al., 2017a; Kim et al., 2017b; Zhu et al., 2017a), point defect (Park et al., 2016; Zhai et al., 2017; Zhang et al., 2019b), and different nanocomposition forms (Bisht et al., 2021; Cai et al., 2021; Ibánez et al., 2016; Jabar et al., 2019; Pakdel et al., 2018). In previous reports, we discussed some of the materials, such as AgGaSe2 thin films (Bhuiyan et al., 2007; 2008; 2009a; 2009b; 2011), Bi2Te3 nanostructure materials (Bhuiyan et al., 2021; Mamur et al., 2018a; 2018b; 2021b), ZnO thin films and nanoparticles (Bhuiyan et al., 2021c; Hoq et al., 2014), and CdSe quantum dots(Akter et al., 2020) have been developed for solar cell and thermoelectric applications. In our opinion, nanostructure materials are more cost-effective and simpler than thin-film materials since they can manage the crystalline dimension and shape. Nanostructure materials can reduce thermal conductivity, which has been shown to be very effective in a variety of systems (Li et al., 2010). The material consists of nanosized grain boundaries. It can be scattered primarily by low and intermediate energy phonons. The generation of phonons scattered by nanostructures and point defects in TE materials was established by Toberer et al. (2011) and Chen et al. (2017), who devised a primary technique for decreasing lattice thermal conductivity. Theoretical calculations show that efficient scattering is critical for achieving low overall thermal conductivity. The use of polycrystalline materials has the advantage of being more resilient than brittle single crystals. The TE materials are usually semiconductors. It contains heavy components and possesses limited band-gap energy that exhibits low thermal conductivity within high carrier mobility. The bulk material is shrinking to a crystalline size on the nanoscale to improve the surface to bulk ratio and hence the TE performance. Simultaneously, because of increased phonon scattering events, its lattice thermal conductivity is reduced. This phonon has the potential to have a significant impact on the ZT value. Because of its interconnected structure, the literature on optimizing parameters is exceedingly difficult to navigate. It's important to think about how different compositions should be adjusted. TE research is a topical subject that attracts the notable interest of both scientists and engineers due to its potential to become an alternative solution to a vital problem in the global energy crisis as a sustainable energy source.

The development of Bi2Te3-xSex (0.10 ≤ X ≤ 1.80) nanostructure materials is discussed in this review in order to choose the optimal composition for producing electrical power using TEGs. The primary goals of this review paper are the synthesis and characterization of various compositions of these nanostructured materials. Through this analysis, we hope to establish which composition is best for making TE devices. It might open the door to future investigations into high-performance TE materials with the capacity to generate and transform energy, leading to thermoelectricity. It is a new energy source that is incredibly affordable. This technology is still in its early phases of development, but it may soon be demonstrated to be a superior sustainable energy source.

2. Characteristics of Bi2Te3-xSex materials

2.1. First principle calculations

Calculate physical attributes directly from basic physical quantities using the theory of quantum mechanics, also known as the first principle calculation method. Tsuppayakorn-aek et al. (2021) demonstrated that the van der Waals layered structure of dichalcogenide materials has the lowest ground-state energy. Its dynamical stability is confirmed by the properties of its phonondispersion. Another reporter (Pluengphon et al., 2021) investigated the formation of lightweight ternary polyhydrides and the mechanism by which they store hydrogen. The quasi-harmonic oscillation approximation is used to analyze thermodynamic stability with respect to temperature. It has a high gravimetric hydrogen capacity, making it a potential hydrogen storage candidate. According to this phenomenon, the Bi2Te3 material is dynamically stable within the Se substitution. Density functional theory computations have been shown to be the most effective technique for analyzing the physical characteristics of mixed compounds. Other reports (Pluengphon et al., 2022) are found to be stable compositions. Doping materials mainly reduce the energy barrier of diffusion kinetics in the host materials, leading to an improvement in the performance of the host materials. Mohamed et al. (2018) used first-principle calculations within the Tran-Blaha modified Becker-Johnson (TB-mBJ) exchange potential to optimize the electrical structure and optical performance of Bi2Te3-xSex. In Bi2Te3-xSex (0≤X≤3) materials, they calculated the dielectric function, refractive index, extinction coefficient, energy loss function, reflectivity, absorption coefficient, and optical conductivity, as shown in Fig. 2. To calculate the imaginary parts or real parts of the dielectric function by using the Kramers-Kronig relation (Pluengphon et al., 2019). The imaginary part of the dielectric function ε2(ω) is expressed as follows:(1)

Fig. 2. Calculated the (a) Imaginary parts (b) Real parts of the dielectric function (c) Refractive index (d) Extinction coefficient (e) Energy loss function (f) Reflectivity coefficient (g) Absorption coefficient (h) Optical conductivity from first principle calculations for Bi2Te3-xSex (0 ≤ X ≤ 3) materials.

Fig. 2. Calculated the (a) Imaginary parts (b) Real parts of the dielectric function (c) Refractive index (d) Extinction coefficient (e) Energy loss function (f) Reflectivity coefficient (g) Absorption coefficient (h) Optical conductivity from first principle calculations for Bi2Te3-xSex (0 ≤ X ≤ 3) materials.The real part ε1(ω) can be derived from the ε2(ω)(2)where e is the electric charge, is the unit cell volume, is the vector defining the polarization of the incident electric field, is the frequency of the light, and are the wave functions of the conduction and valence bands, respectively. Their findings reveal that the materials exhibit a straight band-gap and can be controlled from 0.1706 to 0.7819 eV by changing their composition. Conductivity, absorbance, and reflectivity are all desirable optical features in these materials. The performance of TE is critical for its numerous applications. It will be closely connected to topological insulator behaviour.

The first principle transport and defect calculations for Bi2Te2Se in relation to Bi2Te3 materials were reported by Shi et al. (2015). Despite being isostructural and isoelectronic in two compound materials, the authors claim that they have considerable differences in electronic structures. The complex band structures are also favoured by high-performance TE nature. It will be interesting to pursue these potentially useful behaviours from this perspective. Finally, they suggested future searches for such technologically promising materials may be benefited from a consideration of the degree of complexity and anisotropy of the electronic structure of materials studied.

2.2. The crystal structure

Crystal structure is the description of the organized organization of atoms, ions, or molecules in a crystalline material. Požega et al. (2015) used a variety of experimental techniques to investigate a single crystal Bi2Te3-xSex (x=0.12), including light optical microscopy, scanning electron microscope-energy dispersive spectrometry (SEM-EDS), microhardness analysis, x-ray diffraction (XRD), four probe technique, the harman method, and thermogravimetric-differential thermal analysis. The compound was made using the Czochralski process. The chemical composition of the examined alloy was determined via SEM-EDS analysis. The results of the investigation are displayed there. The sample's chemical composition is consistent. The crystal shows in the cracks. Special growth conditions are required to avoid these fissures. The melt and solid composition are necessary at the low-temperature gradient to obtain low dislocation density and strain in the crystal. In the XRD spectrum, only one crystalline phase with a high degree of crystallization is discernible, which is indexed as a hexagonal unit cell. It also reveals that Se has replaced a small amount of Te. The lattice shrinks when a smaller Se is inserted. DTA depicts endothermic heat transfer throughout the material's processing. A single crystal alloy is formed by using different loads through microhardness investigation. Fig. 3 shows the schematic diagram of the Bi2Te3-xSex crystal structure (Yuan et al., 2015).

Fig. 3. Schematic diagram of the Bi2Te3-xSex crystal structure.

Fig. 3. Schematic diagram of the Bi2Te3-xSex crystal structure.A quintuple layer, made up of isotropic layers, is formed by covalently connecting five monoatomic planes. According to the Van der Waals force, the quintuple layer is weakly coupled to each other. The following is an explanation:Whereas AV1 binds to tellurium (Te) or selenium (Se), BV binds to bismuth (Bi). The superscripts (1) and (2) represent the different positions in the five-fold layers. To accommodate AV1(2), which serves as an invention centre, the layer stacks are symmetrical. According to chemical formulas, the primitive cell consists of five atoms, which means fifteen lattice vibration modes. Using the Metalorganic Vapor Phase Epitaxy Method, pure rhombohedral Bi2Te3, Bi4Te5, Bi10Te9, Bi4Te3, Bi3Te2, and Bi2 and hexagonal BiTe phases can be produced (Kuznetsov et al., 2016). In order to get various phases, it was cultivated, and growth parameter ranges were established. It was discovered that distinct phases of the Bi-Te system materialize under the same growing conditions depending on the thickness of the film.

The unit cell dimensions have various compositions of the Bi2Te3-xSex materials. The materials have two kinds of bond length that occupy a middle ground between the ionic and covalent extremes. To explain the distribution and change in bond length, Se atoms preferentially occupy the Bi site, whereas Te is distributed at random in the Bi site. The temperature and charge carrier are the important factors for every atom. Fig. 4 represents the grain boundary scattering of charge carriers' interfacial point defects (Liu et al., 2016). It donates an extra charge carrier into the core of the grain that increases carrier concentration. It also shows the low energy carriers, indicated by the red arrow, that are effectively scattered by the surrounding grain. According to its geometry and thickness, the crystal morphology can be well controlled as well as the stoichiometric ratio of the materials. Different compositions can deliver distinct excitation photon energies. These influences give insight into advancing the higher performance of TE behaviour.

Fig. 4. Schematic diagram of the (a) Grain boundary scattering of charge carriers (b) The presence of positively charged interfacial point defects (c) Conjectured the positively charged grain boundary selectively scattering holes over electrons.

Fig. 4. Schematic diagram of the (a) Grain boundary scattering of charge carriers (b) The presence of positively charged interfacial point defects (c) Conjectured the positively charged grain boundary selectively scattering holes over electrons.2.3. Topological insulator

In its internal part, a material behaves as an insulator, but its external part has conducting modes that allow electrons to travel along the material's surface. The material is known as a topological insulator (TI). The generation of TI phases in specimens with strong spin-orbit interaction is one of the most fascinating issues in condensed matter physics. Different dimensions of TIs are crucial materials for future quantum computing devices. Niesner (2012)investigated the TI Bi2Te3-xSex (0≤X≤3) materials' unoccupied band structure. The authors used angle-resolved two-photon various (photoemission and density) functional theories. Fig. 5 shows the measured and calculated values of the band structure for the Bi2Te2Se material.

Fig. 5. The band structure of Bi2Te2Se material (a, b) Measured (c, d) Calculated values.

Fig. 5. The band structure of Bi2Te2Se material (a, b) Measured (c, d) Calculated values.The linear dispersed surface states can be discovered at the surface's centre. Spin-orbit interaction-induced and inverted local band-gap energy has this property. The character of the local band-gap can be altered by minor structural modifications. The spin-resolved band structure was investigated by Klimovskikh et al. (2017). They used annealed Bi2Te2.4Se0.6 material with a hetero-junction of Bi-bilayer or 3dimentional TI in the quantum size regime. Temperature-induced reconfiguration of the TI's surface quintuple layers, hole-like spin-split Bi-bilayer bands, and the parabolic electronic-like state were discovered by the researchers. Experimental data reveals the development of Bi2 terraces at the surface under annealing. The spin-polarized Bi-bilayer bands interacting with the quintuple-layers-derived states are predicted by the density functional theory calculations, which are supported by experimental results. Other researchers (Tung et al., 2016) studied the structural and electrical properties of Bi2Te3−xSex alloys as topological insulators in a systematic way. The ratio of Te and Se content is used to determine the mixing ratio. The experimental measurements show that the as-grown crystals have a high crystalline quality, and both tests reveal Te substitution by Se. The samples' upper surfaces have terrace-like quintuple layers, and the size of the characteristic triangular terraces reduces monotonically as the Se concentration rises. The Se content is progressively recovered by the triangular terrace structure, allowing for future increases. Other findings revealed Dirac-cone-like surface states in which Bi2Te3−xSex inside Se/Te-substitution results in a tuneable surface state. It shows that these alloys with tuneable topological surface states provide a great platform for researching new device applications based on these compositions under fine-tuned circumstances.

2.4. Optical performance

Optical parameters of a material arise from several different contributions that are associated with various light excitations, such as inter-band transitions, exciton effects, free carriers, and ionic or lattice relaxations (Bhuiyan and Hasan, 2006). The parameters are important due to the particular material and excitation wavelength. The mechanism, in principle, is not different from operating in any inorganic material, except for the role played by the smaller band-gap energy. Peiris et al. (2019) analyzed different optical parameters, such as band-gap energy, carrier concentration, and effective mass. The authors specifically used Kramers–Kronig consistent oscillators to represent the Drude contribution as well as the bang-gap energy of Bi2Te3−xSex ternary alloys. They found the band-gap energy is higher than the binary constituents, Bi2Te3 and Bi2Se3. Akrap et al. (2012) reported the temperature dependence of the complicated optical characteristics of the Bi2Te2Se material for light polarized in the a-b planes at ambient pressure as well as the influences of pressure at different temperatures. Fig. 6 shows the reflectance, transmission, and optical conductivity of a wide energy range of different temperatures for Bi2Te2Se materials.

Fig. 6. (a) Reflectance (b) Transmission (c) Optical conductivity of a wide energy range for different temperatures of Bi2Te2Se materials.

Fig. 6. (a) Reflectance (b) Transmission (c) Optical conductivity of a wide energy range for different temperatures of Bi2Te2Se materials.Their experimental result indicates the presence of an impurity band at 25 meV, well below band-gap energy. The authors identified the numerous in-plane vibrational modes at 5K in the Bi2Te2Se material. In this material, both extra phonon modes and impurity bands are consistent with the presence of disorder and symmetry breaking. Band-gap energy at low temperatures shifts strongly to higher energies. Similarly, several inter-band transitions/absorptions above the band-gap edge show strong thermal dependence. The behavior indicates the band structure is significantly influenced by the temperature contraction. Other researchers (Kovalev et al., 2019) synthesized a set of mono-crystalline Bi2Te3-xSex thin films of various compositions. The authors examined the optical performance of these films within the thickness range of 260 to 1000 nm. The optical performance of these films fluctuates depending on the Se to Te ratio that is displayed, according to the experimental data. Se can be used to quickly determine the needed composition of Bi2Te3-xSex films. The Se atoms are occupied in the internal rows of films.

2.5. Thermoelectrical performance

TE materials such as Bi2Te3 and Bi2Te3-based semiconductors have been used in TE applications for a long time. In recent years, there has been a tremendous improvement in their high performance at low-temperature conditions in nanostructure form. TE technology advancements can be developed by a novel material processing technique. The researchers improved different compositions of Bi2Te3-based nanostructure materials. It easily manipulates the capabilities of electrical and phonon transport properties. Fig. 7 shows the schematic diagram of phonon scattering over a wide range of frequencies by various sources.

Fig. 7. Schematic diagram of phonons scattering.

Fig. 7. Schematic diagram of phonons scattering.The remarkable significance of these TE materials is their low lattice thermal conductivity and relatively easy composition manipulation ability to advance the desired electronic and thermal properties. Improve the TE properties by modifying the Se doping content. It has a lot of fractured crystal planes within specific layer structures that are caused by the different Se content. To obtain the best TE performance, it can readily synchronize electrical and thermal transport characteristics. Finally, it is indicated that combining a low Se doping level with a high-pressure environment can improve the material's figure of merit. TE performance can be enhanced by correctly intercalating and replacing the Se atom in the Bi2Te3 nanostructure. According to Kianwimol et al. (2019), the main factor affecting their TE performance is sputtering power. The sputtering power affected the Te concentration and grain size. Theekhasuk et al. (2021) reported that the Cu-doped Sb2Te3 films were vacuum annealed to improve their TE performance. Structural measurements indicate that Cu atoms occupy the Sb position in Sb2Te3 materials. Other researchers (Daichakomphu et al., 2021) investigated the effect of Bi doping on the photo-TE performance of CuAlO2 materials. Bi doping could potentially improve performance by allowing the proper composition to be adjusted. Similar to this, the authors expected the intercalation and substitution of the Se atom to be the significant rules in the Bi2Te3-xSex composition.

3. Review the performance evaluation

There are at least three reasons why the properties of Bi2Te3-xSex (0.1 ≤ X ≤ 1.80) nanostructure materials are better than Bi2Te3. The Bi2Te3-xSex materials can be used to produce TEGs and other TE devices that are more readily accessible. First, their ZT values significantly decreased because of the bipolar effect. Bipolar conduction is suppressed by widening the band gap. Alternately, to delay the pace at which ZT degrades at relatively high temperatures, synergistic carrier scatterings can be added to weaken the dependency of carrier mobilityon temperature. Second, the power factor is reduced because the Fermi level is located far into the conduction band in pure n-type Bi2Te3 due to the unavoidable Te vacancies. An improved power factor can be attained by tuning the anion vacancies in Bi2Te3 by adding Se. Finally, by adding grain boundaries through nanostructuring, thermal conductivity can be significantly decreased. The present fabrication techniques, such as ball milling and melt spinning, are pricy and comparatively inefficient. Solvothermal synthesis offers greater control over the size, structure, and morphology of the nanograins as compared to ball milling and melts spinning. However, the removal of surfactants is frequently laborious and ineffective, reducing production output. More importantly, the residual surfactants may have an impact on the TE's performance.

The narrow-band semiconductor of the Bi2Te3-xSex families is well known for its exceptional TE properties. These families were discovered within the new context of TIs, in which surface states are very simple. Despite having a huge band-gap, these families' bulk conductivity is relatively high. It makes it difficult to observe TI states. The Fermi level in band theory is found either within the conduction or valence band throughout this series. In these materials, Te or Se content is tuned to different compositions for the remarkable TE performance. Many factors are essential, such as electrical and thermal properties; mechanical and thermal stability; good reproducibility; low toxicity; and the possibility to prepare nanostructured materials on an industrial scale for the commercialization of TE materials. The alarming increase in energy consumption and environmental concerns are the combined advance of technology and scientific progress that led to interest in TE fields. Waste heat management in industrial and power generation processes, reduction of CO2emissions and reliability in low power generation, automobile and electronic technology, make all of them attractive to present technological utilization at many levels through efficient TEG technology. The researcher's search for the following three criteria has emerged in the TEG technology:

-

•

The high-band degeneracy is obtained in highly symmetric crystal structures that enhance the Seebeck coefficient for maintaining good electrical mobility.

-

•

Complex and a large unit-cell formed of the heavy elements and an anharmonic bonding structure that intrinsically lowers the thermal conductivity.

-

•

A covalent framework between the constituent's elements due to significant electro-negativity differences can be developed, resulting in higher carrier mobility.

Promising Bi2Te3-xSex (0.15 ≤ X ≤ 2.85) TE materials for various compositions at different temperature ranges of operation will be briefly reviewed in this section. It is discussed in each case as part of various approaches to improving TE performance. Moreover, chemical and physical routes have been employed to understand the particular effects of the synthesis conditions on the specific features of the different compositions with the ultimate purpose of modifying the different characterizations. The most common growth techniques currently used to prepare Bi2Te3-xSex TE materials are given as follows:

-

•

Spark plasma sintering,

-

•

Hot pressing process,

-

•

Zone melting processes,

-

•

Polyol method,

-

•

Microwave-assisted synthesis

-

•

Mechanical alloying,

-

•

Hydrothermal/Solvothermal synthesis,

-

•

Chemical routes.

There are different factors that would be taken into account in preparing these compositions with the desired characteristics. In every aspect, the significant range of particles that form different compositions makes it necessary to develop synthesis processes that are adequate. We review the different compositions of these materials throughout published articles in journals. Our intention is to find out which composition is suitable for TE device manufacturing purposes. Performance advancement is achievable in Bi2Te3material when compared to normal ingots but not in Se-modified Bi2Te3compositions generated by alternative processing. Electrical characteristics were explored and discussed in connection with the results of various experiments in fine-grained Bi2Te3−xSex specimens treated by various synthesis processes.

Guo et al. (2014) produced Bi2Te3−xSex (x = 0.27, 0.35, and 0.72) materials for improving TE performance. The author successfully synthesized different compositions of this material under high pressure at 1.5 GPa within 30 min. The transport characteristics (electrical and thermal) are heavily influenced by Se doping. The electrical resistivity increases as the temperature rises. This phenomenon can be explained through metal-like conduction or degenerate semiconductor behaviour. It improves as the amount of Se doping in the system increases. It's thought to be due to the carrier mobility being influenced by the usual texture created by Se doping and pressure. The sample's carrier mobility is reduced as a result of the complex texture's increased carrier dispersion. The formation of a negative bipolar effect causes the thermal conductivity to first decrease and then increase as the temperature rises. Second, when the amount of Se doped in the material increases, the thermal conductivity falls. As previously stated an increase in Se content might cause the usual texture to deform and become more complicated, lowering the mean free route of phonons and so improving phonon scattering. Hence, the result indicates reducing the thermal conductivity. They obtained an optimal ZT value by improving the characteristics. At 344 K, the maximum ZT value of the Bi2Te2.73Se0.27 composition is 1.03. The results show that increasing the pressure can enhance the ZT value by adjusting the influence of Se doping content on thermoelectric performance.

Using the melting-grinding method, Park et al. (2018) produced bulk Bi2Te3-ySey(0.3 ≤ y ≤ 0.6) materials. Using different amounts of Se dopant, the authors improved the material's physical properties. They looked at the ZT values of sintered bodies in the temperature range of 298 to 423 K in order to figure out their thermal and electrical properties. Within this temperature range, increasing the Se content reduces thermal conductivity. As a result, alloy scattering is increased, but lattice thermal conductivity is minimized due to crystal grain boundary scattering. Due to a drop in the carrier concentration, electrical conductivity decreased as the Se level increased. It has the potential to increase ZT's total worth. At room temperature, Bi2Te2.70Se0.30 had a ZT value of 0.850. The Se content increases because Bi2Te2.55Se0.45 has a ZT value of 1.15 at 423 K. The best impact of the Se dopant, according to the scientists, changes depending on the temperature range.

Li et al. (2015) investigated the anisotropy of the TE characteristics of Bi2Te3-ySey(0.3 ≤ y ≤ 0.9) prepared by spark plasma sintering (SPS) at temperatures from 300 to 523 K. In this temperature range, normal and parallel to the pressing direction, TE parameters such as electrical resistivity, Seebeck coefficient, and thermal conductivity are measured. Because of the anisotropy in its microstructure in bulk form, the author was able to derive these parameters. According to the JCPDS (29-0247) all of the materials are rhombohedra in structure. So far, no secondary phase peaks have been seen within the detection range of bulk XRD. As observed in the SEM image, the samples are made up of many small particles ranging in dimension from submicron's to a few microns. The surfaces of bulk samples cracked parallel and normal to the pressing direction in a plane. Because the compositions have a lamellar crystallographic structure and a weak van der Waals connection between these layers, the grains are easily oriented when hot-pressed. Plate-like grains that align preferentially in the plane. The author obtained a ZT value of 0.60 for Bi2Te2.60Se0.40 and 0.70 for Bi2Te2.10Se0.90 in the thermal range from 400 to 470 K.

In the other report (Li et. al., 2012), the author successfully synthesized Bi2Te2.55Se0.45 nanocrystals by using a chemical solution route combined with subsequent SPS processes. They obtained a maximum ZT value of 0.70 at 485 K for the Bi2Te2.55Se0.45 composition. In another report (Li et. al., 2013), the author improved the TE performance of Bi2Te3−xSex (0.6 ≤ x ≤ 0.75) nanoplate composites by the simple chemical solution process. The samples were synthesized on a massive scale using a hydrothermal technique followed by spark plasma sintering. At sintering temperatures, they looked into the impact of Se alloying on the TE behaviours of nanostructured bulk materials. The findings of the experiments show that adequate Se alloying at sintered temperatures is an effective technique to modify transport characteristics. The reduction of particle sizes to 10 nm is possible by using this synthesis process. Furthermore, they discovered that as carrier mobility increases and the Seebeck coefficient increases, electrical resistivity decreases. It's thought to be caused by a drop in carrier concentration. Finally, the ZT value has improved dramatically. At 490 K, the author found the highest ZT value of 0.96 for Bi2Te2.25Se0.75.

Pan et al. (2015) studied thermal transport properties within Raman spectra for Bi2Te3-xSex alloys by using a spark plasma sintered process. The authors also looked into the combined effects of point defects and Se dopant content in various compositions. The surfaces perpendicular and parallel to the spark plasma sintered in the pressing direction produce the XRD patterns of these samples. Within low and high Se dopant levels, the peaks can be well indexed as typical of the samples.

It reveals a random layout of grain boundaries by indicating no evident variation in these two directions. In SEM pictures of various compositions, dense formations with an isotropic distribution can be seen. Because of the layered structure of Bi2Te3-based compounds, plate-shaped grains can be found in all compositions. Despite having varied Se dopant concentrations, the materials investigated exhibit similar morphologies, as evidenced by the micro structural form. Changing the Se content in Bi2Te3-xSex causes different point defect compositions. Point defects and associated interactions, such as donor-like effects, alter carrier concentration and mobility while also increasing phonon scattering. The thermal conductivity would be reduced as a result of this event. The schematic diagram of the point flaws is shown in Fig. 8.

Fig. 8. Schematic diagram of the point defects.

Fig. 8. Schematic diagram of the point defects.Because of the samples' significant phonon scattering, it drops dramatically. As a result, Bi2Te2.20Se0.80 is validated as the best composition, with a maximum ZT value of 0.82 at 473K. The Te dopant obtained at optimal Bi2Te2.70Se0.30 is roughly 30% higher than that achieved at optimal Bi2Te2.70Se0.30, which is commonly utilized for ingots. It should be pointed out that the maximum ZT value is 1.0 at this temperature. In other papers (Pan et al., 2016), the authors improved the TE performance of n-type Bi2(TeSe)3 alloys by combining nanoscale homogeneity with a spark plasma-textured microstructure. As a result of the layered microstructure shape, the technique improves electrical transport characteristics within power factors. It increases thermal conductivity by causing highly deformed patches and nanoscopic defect clusters to emerge in nanostructures. Texturing at an optimal temperature can result in the formation of a dislocation loop. Heat-carrying phonons of distinct wavelengths scatter when they come into contact with large nanoscale imperfections, forming phonon transport waves. As a result, the sample's thermal conductivity decreases. Fig. 9 shows the schematic diagram of phonon scattering by nanostructured materials. The researchers created textured n-type Bi2(TeSe)3materials with improved TE performance at low temperatures, with maximum ZT values reaching 1.1 at 473 K.

Fig. 9. Schematic diagram of phonon scattering by nanostructure form materials.

Fig. 9. Schematic diagram of phonon scattering by nanostructure form materials.Han et al. (2016) reported that combining casting, milling, and SPS procedures improved the TE cooling performance of Bi2Te3-xSex compositions. The compositions are widely employed for TE cooling at room temperature, but prior research has shown that their TE efficiency peaks at high temperatures. The author proposes casting, followed by high-energy ball milling and the SPS process, as a viable methodology for developing an effective and well-built material composition for TE cooling at room temperature. They discussed the changes in transport characteristics brought about by the amount of Se dopant content for this methodology. Experimental results showed the irregular trend, power factor, thermal conductivity, and ZT value gradually decrease with increases in the amount of Se content. All compositions exhibited high density regardless of Se content. The carrier concentration has a minor effect on the Se dopant content, but the mobility decreases gradually as the Se dopant concentration increases. The highest ZT value of 0.875 was obtained by the authors for the Bi2Te2.85Se0.15 composition with a high Seebeck coefficient and moderate electrical conductivity. Finally, the authors suggested that the fabrication techniques and material composition be used for the commercial development of TE cooling devices that operate at low temperatures.

Lim et al. (2017) produced n-type Bi2Te3-xSex (x = 0, 0.25, 0.4, 0.7) compositions. Using only oxide powders as starting materials, the authors were able to successfully synthesize these compositions. They used mechanical milling, oxidation, reduction, and SPS procedures to achieve this. Using oxide starting materials, the approach provides a novel route to synthesize these compositions with competitive ZT values. The Se dopant exhibits a variety of structural, electrical, and thermal properties. In the XRD patterns of these compositions, the gradual replacement of Te sites with rising Se content can be seen. It reveals that the oxide reduction technique can successfully generate Bi2Te3-xSexcompounds with controlled Se content. This resulted in a considerable increase in Se, indicating that the compound has a reduced particle size. SEM micrographs of the shattered surfaces of these compounds reveal typical polycrystalline cleavage planes. Grain size tends to decrease as Se level increases, and this trend was clearly observed. These structural results showed that these compounds with regulated Se content can be generated using the recommended oxide reduction process and that the Se content of the compounds has a significant impact on their grain sizes. When Se is present, anti-site defects develop, resulting in a reduction in electrical conductivity. The Se inclusion also induced an increase in the Seebeck coefficient, allowing the power factor optimization to be achieved by this oxide reduction procedure. At 423 K, the authors were able to attain the greatest ZT value of 0.84 in the Bi2Te2.60Se0.40 composition.

Yan et al. (2010) studied the anisotropic TE properties and structures of n-type Bi2Te2.7Se0.3 materials developed by ball milling and hot pressing. There is no substantial grain orientation anisotropy in the XRD patterns of both planes perpendicular and parallel to the press direction. The XRD results are supported by SEM images of freshly broken surfaces in both directions. The grains are haphazard, with no clear preference for crystal orientation. Because of the considerable increase in electrical conductivity, the figure of merit has improved. Thermal conductivity is less changed, and the Seebeck coefficient is not much altered. The reorientation of every plane of the tiny crystals to improve electrical conductivity is the cause of this improvement. The ZT value is projected to be enhanced further by encouraging more reorientation into the planes and reducing the thickness and dimension of the crystal plate. The properties are anisotropic because the crystals are partially orientated; the mechanical performance is good because there are fewer grains; and there is no sign of cleavage in single crystal form. The thermal conductivity was found to be reduced when the grain size was reduced using various pressing techniques, according to the authors. Finally, by compressing the as-pressed samples, the peak ZT value was increased from 0.85 to 1.04 at around 400 K.

Rong et al. (2016) used a microwave activated hot pressing procedure to successfully manufacture n–type Bi2Te3–xSex (x=0.15, 0.3, 0.45, 0.6) compositions in order to find the optimal TE performance. The majority of the XRD patterns are consistent with JCPDS card 15–0863 and may be classified as a rhombohedra lattice crystal structure for sintered samples with varying Se concentration. With a rise in Se concentration, the diffraction peaks move slightly to higher angles. In both axis, the lattice parameters are calculated from XRD using a generic structural analysis system, and they decrease as the amount of doped Se increases. Because Se's atomic radius is lower than that of Te's. This results in the decreased interplanar spacing of the grain boundaries. The SEM fracture images of the compositions indicate the fine grains are distributed disorderly without a preferred orientation. The majority of the grains have a lamellar structure to them. Other irregular grains are interspersed among the giant grains, forming a multi-scale structure. The results of the experiments revealed that the low sintering temperature and short holding time utilized in this study could inhibit grain development. The sintered samples contained fine lamellar grains and irregular granular grains, indicating a typical multi-scale microstructure. In addition, the doped Se has aided grain refining. The variation of Se content, highest power factor, and minimum thermal conductivity were achieved for Bi2Te2.70Se0.30 composition at around 423K. Considering the TE performance, the highest ZT value of 0.73 is obtained for the Bi2Te2.55Se0.45 composition at around 423K.

Zhu et al. (2017b) improved the TE n-type Bi2Te2.7Se0.3 composition characteristics by using zone melting, Bridgman unidirectional, and hot pressing methods to sustain numerous difficult synthesis steps. To attain the requisite TE performance, the liquid condition of the composition doped with potassium iodide (KI) as a bulk specimen can be readily solidified by air cooling within cost-effective equipment. A liquid structural transition is present in the specimen, indicating the liquid's resistivity behaviour. We detected more nanoparticles within a larger density of lattice defects in the structure, indicating the presence of a refined matrix. According to the pseudo-binary phase Bi–Te–Se, the XRD spectrum indexed to the Bi2Te2.7Se0.3 composition is a single phase structure in which the solidified equilibrium phase is only made of this composition. The SEM picture of the sample reveals a greater number of microscale grains. With improved TE performance, the authors were able to achieve a maximum ZT value of 0.80 at 470 K.

Cai et al. (2014) used melt spinning and a resistance pressing sintering technique to improve the TE characteristics of Bi2Te3-xSex alloys. The authors looked at the phases, microstructures, and compositions of the prepared samples. The sample characterization was done using a variety of experimental criteria. This method compacts the samples well within the relative densities of the bulk samples. They detected a moderately orientated lamellar structure in numerous sections of the samples. The lamellar structure's monolayer thickness is the smaller shape. For these compositions, the method is ideal for creating fine microstructures with low lattice thermal conductivity. The findings of the experiments suggest that increasing the Se dopant content to a suitable level will effectively increase the ZT value. For the Bi2Te2.7Se0.3 composition, at 423K, they achieved a maximum ZT value of 0.84.

Kim et al. (2011) used a water-based chemical reaction synthesis procedure under ambient conditions to successfully generate Bi2TeySe3-y nanoparticles of various compositions for TE applications. The compositions are made by stabilizing the bismuth precursor in water with a soluble agent, ethylenediaminetetraacetic acid, and a reducing agent, ascorbic acid, to favor the reaction with decreased sources of Te and Se elements. The final sample has a rhombohedra crystalline structure and is 100 nm in size. An SPS method was used to create a nano-crystalline sample within a sintered body made up of nano-sized grains. For TE performance, the scientists measured the sintered body's essential transport parameters. Experimental results demonstrate a link between the sintered body and the thermal conductivity of nanostructured materials. The temperature dependency of the ZT value is represented by the TE characteristic. For the Bi2Te2.70Se0.30 composition, they got an optimum ZT value of 0.70 at 423K.

Soni et al. (2012a) use the polyol technique to grow Bi2Te3-xSex nanoplatelets for various composites. XRD and Raman spectroscopy tests show the fluctuation in Se content within developing samples. XRD spectra have identified the phase purity and crystal structure; it has a rhombohedral crystal structure with no observable impurities of other phases. The authors used Raman spectroscopy extensively to investigate the vibration properties of electron-phonon interactions in various compositions. For samples that comply by estimating lattice parameters, the high frequency phonon modes show a discontinuity of two mode behaviours. The electrical resistivity exhibits metallic conduction behaviour for intermediate Se dopant contents. The heat conductivity of the bulk material is substantially lower. Within temperature-dependent macrostructural grains, boundary scattering processes dominate the transport data. The TE performance is attributed to the energy filtering of low energy electrons by abundant grain barriers in aligned nanocomposites materials.

The authors concluded the figure of merit is highly dependent on the temperature and Se dopant content. Fig. 10 shows that the ZT value varies with Se dopant and temperature. They estimated the maximum ZT values of 0.54 at 300 K for the Bi2Te2.70Se0.30 composition. In other reports (Soni et al., 2012b), the author declared a high-performance due to grain boundary or interface arrangements for bulk nanoplatelet-composites of Bi2Te2.70Se0.30. These are of interest because of their facile and scalable synthesis with anisotropic properties. The nanoplatelet-composites are sintered at 250°C with the optimal charge carrier filtering effect. The authors estimated the ZT values at 0.55.

Fig. 10. The ZT value varies with Se dopant and temperature.

Fig. 10. The ZT value varies with Se dopant and temperature.