1. Introduction

Rapidly expanding urban areas and increasingly erratic weather patterns due to anthropogenic greenhouse gas emissions demand more resilient and durable structures with minimal environmental footprint. Improving urban infrastructure has been emphasized as a primary challenge to achieve global sustainable development [1]. Extensive research into alternative construction materials and strategies has presented a roadmap of sustainable construction practices that will enable the construction industry to adapt to the challenges in the current millennium. The goal is to create green structures with an extended service life and resilience to various stressors, thus dissociating the expanding construction sector from greenhouse gas emissions [2], [3], [4]. One of the proposed strategies is to use smart self-healing cement composite materials that are affected by changes in the structure and respond accordingly without human mediation.

Concrete self-healing systems have been proposed to resolve the structural and environmental problems encountered by traditional concrete structures. These problems include ① crack formation on structure surfaces due to the low tensile strength of concrete, freeze-thawing, and shrinkage; ② ingress of water and corrosive substances through the cracks and pores on the structure’s surface and dispersion through the interconnected voids of the cement matrix; ③ initiation of extreme structural degradation from an early stage; ④ inadequate capacity of concrete for autogenous self-healing with respect to time and repair scale; ⑤ limitations of manual repair for visible and accessible surface cracks, including time and cost; and ⑥ considerable environmental burden posed by the cement industry [5], [6], [7], [8], [9]. Concrete possesses an autogenous self-healing ability that occurs with ① the carbonation of calcium hydroxide (Ca(OH)2) to produce calcium carbonate (CaCO3), which can block small pores and heal small cracks; ② hydration and swelling of the cement matrix around voids and cracks; and ③ transport of dislodged particles into voids and cracks by water current [10]. However, Ca(OH)2 supply is finite, and the corresponding rate of unadulterated carbonation is slow. Hence, researchers have attempted to improve the self-healing ability of concrete based on a better understanding of the impact of different curing conditions (e.g., curing under wet, wet–dry, or humid conditions) on concrete self-healing [11], [12], [13] and by incorporating autonomous self-healing systems containing chemical [14], [15], [16], [17], biological [7], [18], [19], [20], [21], [22], or mineral [23] healing agents. Note that concrete self-healing systems have been designed and tested on various cement-based materials. In this research field, concrete has been used as a general term encompassing different cement composites.

To overcome the limitations of autogenous concrete self-healing, researchers have developed autonomous concrete self-healing systems based on mineral [24], chemical [14], [15], [16], [17], and biological healing agents [20], [21], [25]. These agents are delivered through ① direct addition [18], [26], ② encapsulation[20], [24], and ③ vascular systems [27], [28], [29]; they may also be immobilized on fibers [30], [31]. Chemical-based systems may include a single healing agent, including cyanoacrylates [14] and epoxy [32], or they may rely on the reaction of multiple chemicals, such as two-component polyurethane foam [33]. Such chemicals may expand upon crack formation to block the entry of corrosive substances through the crack [33], [34]. Chemical concrete self-healing systems offer remarkable advantages, such as a long shelf life for systems based on two chemicals and possibly fast reaction time. However, chemical self-healing systems may pose environmental contamination risks, interfere with future concrete recycling, and possibly result in inadequate cement bonding [35].

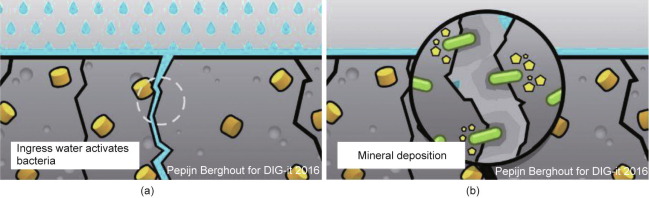

Over the past two decades, researchers have investigated biotechnological strategies to repair concrete structures [9], [36], [37], [38]. Such techniques rely on microorganisms that precipitate CaCO3 to heal cracks and block pores in concrete structures. They involve the manual introduction of bacterial sporesand nutrients to the surface of cracked concrete samples or their incorporation into these samples as a self-healing mechanism. Calcium carbonate is a natural cement-compatible filler present in concrete that poses no adverse environmental impacts. When concrete cracks, water and atmospheric gases seep into the structure and activate dormant biological healing agents, as illustrated in Fig. 1 [26]. The healing agents fill these cracks by microbially induced CaCO3 precipitation (MICP). Most bacteria precipitate CaCO3 when calcium is present in the surrounding environment. The presumption is that bacteria precipitate CaCO3 to strengthen their extracellular matrix and biofilms to better resist environmental stressors, such as high salinity and mechanical force, or simply as a means to store ions or adjust their concentrations [39]. Note that MICP can be achieved through various processes and under different environmental conditions. Bacteria suited for incorporation in concrete self-healing systems must be ① tolerant of the alkaline concrete environment (pH 9–13), ② spore-forming, and ③ capable of precipitating CaCO3 in the cement environment [26], [36], [40]. Spore formation is essential because vegetative bacterial cells cannot tolerate the concrete mixing process and the highly alkaline cement environment.

Fig. 1. (a) Water flow through concrete cracks revives dormant bacteria, leading to (b) CaCO3 precipitation and crack sealing. Reproduced from Ref. [26] with permission of Elsevier Ltd., © 2017.

Fig. 1. (a) Water flow through concrete cracks revives dormant bacteria, leading to (b) CaCO3 precipitation and crack sealing. Reproduced from Ref. [26] with permission of Elsevier Ltd., © 2017.Unlike bacteria, spores can withstand harsh conditions while remaining dormant until favorable conditions (O2, water, and nutrient availability) are achieved. This feature can keep spores from germinating until structural faults in concrete structures allow the penetration of water and oxygen required for spore germination. The bacteria that satisfy the above criteria are categorized based on their utilization of predominant MICP pathways.

Biological concrete self-healing systems can be broadly categorized into two groups based on their underlying MICP pathway. Ureolytic systems use urea and a microbial precursor for CaCO3 precipitation (Eqs. (1), (2)), whereas non-ureolytic systems rely on various nutrients and precursors. Thus far, ureolytic systems have received more research attention than non-ureolytic designs, mainly because ureolytic bacteria have been found to induce rapid CaCO3precipitation under specific conditions [35], [41], [42], [43]. Ureolytic bacteria and urease enzymes are well-characterized, and urea hydrolysis is identified to be an efficient MICP pathway [44]. However, ureolytic bacteria produce NH4+ as a by-product of MICP (1 mol NH4+ per mole of CaCO3) [36]. The pH increase caused by NH4+ increases the CaCO3 precipitation rate in ureolytic self-healing concrete. However, if NH4+ is in contact with nitrifying bacteria or conditions allow for its volatilization as NH3 (g) (Eq. (3)), the dissolution of CaCO3 may occur following a drop in pH, which can damage concrete structures [45]. Moreover, NH4+ is hazardous to the health of various organisms, including humans [46]. The adverse environmental impact of ureolytic concrete self-healing systems can limit their application, hindering their commercialization. Although most MICP studies are based on ureolytic bacteria, these organisms require specific conditions to survive and adequately function, limiting their use in specific environments [41]. Accordingly, non-ureolytic bacteria that do not require urea have been investigated and incorporated into concrete self-healing systems.(1)CO(NH2)2 + 2H2O → 2NH4+ + CO32−(2)Ca2+ + CO32− → CaCO3(3)NH4+ → NH3 (g) + H+

This article reviews the current non-ureolytic systems and their components, research findings, and advances in non-ureolytic biological self-healing concrete development. The remaining challenges that hinder the applicability of these systems and research gaps and unanswered questions are also discussed, and future research directions are highlighted.

2. Non-ureolytic MICP pathways

To date, a wide range of non-ureolytic MICP pathways has been reported. These autotrophic pathways include ① non-methylotrophic methanogenesis [47], ② oxygenic and anoxygenic photosynthesis [48], ③ and heterotrophic pathways, such as conversion of organic salts [36], [49], methane oxidation [50], sulfate reduction [51], and denitrification [52]. Generally, non-ureolytic MICP is influenced by ① Ca2+ concentration, ② dissolved inorganic carbon concentration, ③ pH, and ④ nucleation site abundance [43], [53], [54]. These parameters, alongside bacteria population levels, bacterial strain, and environmental conditions, which alter bacterial activity (e.g., temperature), are primarily associated with the scale of CaCO3 precipitation. The MICP pathways and their applicability to concrete self-healing have been thoroughly reviewed [55], and factors affecting MICP have also been previously examined [22], [54]. Among the non-ureolytic MICP pathways described to date, only organic salt oxidation, denitrification, and photosynthesis-driven MICP are compatible with concrete self-healing. Different problems have hindered the research on other pathways. For example, ammonification-dependent MICP results in significant NH3production; methane-reduction-dependent MICP releases hydrogen sulfide; and the action of sulfate-reducing bacteria frequently results in metal corrosion, posing a serious threat to buildings [56], [57], [58]. Accordingly, researchers have not investigated pathways for concrete self-healing resulting in unwanted by-products. Newly identified non-ureolytic and alkaliphilic MICP-capable bacterial species that can be used for biological non-ureolytic bacterial concrete self-healing research can expand the described MICP pathways [59].

2.1. Oxidation of organic salts

Certain aerobic (AE) bacteria, which rely on the metabolism of organic compounds (e.g., lactate) for energy production, precipitate CaCO3 as a by-product of their metabolic functions. Organic calcium salts, such as calcium lactate (Ca–L) and calcium acetate (Ca–A), provide Ca2+ ions necessary for MICP, whereas bacteria can metabolize organic anions for energy production. Certain AE heterotrophic bacteriahave been investigated as biological healing agents for concrete.

Bacterial species such as Bacillus pseudofirmus (B. pseudofirmus) [20], [36], [40], [49], [60], Bacillus subtilis (B. subtilis) [61], [62], Bacillus cohnii (B. cohnii) [40], [63], [64], [65], Bacillus alkalinitrilicus (B. alkalinitrilicus) [66], Bacillus thuringiensis (B. thuringiensis) [67], and Bacillus halodurans (B. halodurans) [40]are resistant to alkaline cement environment. When applied to concrete, these bacteria successfully precipitate CaCO3, achieving various distinctive features in concrete self-healing. In vitro and in situ studies have reported efficient CaCO3precipitation by alkaliphiles such as B. pseudofirmus from Ca–L [36], [49]. In concrete remediation research, MICP based on the oxidation of organic salts has been used as a surface treatment or self-healing agent. From 1 mol of Ca–L, bacteria can produce 1 mol of CaCO3 and 5 mol of CO2 (Eq. (4)) [68]. The resulting CO2 can react with the abundant Ca(OH)2 in the concrete matrix to yield CaCO3 (Eq. (5)). One mole of Ca–L can result in the precipitation of 6 mol of CaCO3 in the presence of non-limiting Ca2+ ions (Eqs. (4), (5)). The water released during this process contributes to cement hydration and bacterial activity. This pathway has been regarded as a sustainable alternative to ureolysis; it is free of hazardous by-products and can potentially utilize industrial or fermented waste as an organic substrate [69], [70].(4)CaC6H10O6 + 6O2 → CaCO3 + 5CO2 + 5H2O(5)5CO2 + 5Ca(OH)2 → 5CaCO3 + 5H2O

2.2. Denitrification

Unlike ureolysis and oxidation of organic salts, denitrification is independent of atmospheric O2 because denitrifying bacteria utilize NO3− as the final electron acceptor for the oxidation of organic substrates to produce CO2, subsequently hydrated to HCO3− (Eqs. (6), (7)) [71]. Hence, denitrifying bacteria can function in oxygen-deprived environments and precipitate CaCO3 under alkaline conditions when Ca2+ is available. The denitrification pathway involves four enzymes and intermediates, such as N2O, a substance with potential health hazards to vertebrate health that can act as a steel corrosion inhibitor [72]. Under optimal conditions, N2O does not accumulate in the system; however, the alkaline concrete environment may lead to N2O accumulation [73]. Denitrification-dependent MICP has been investigated for concrete repair and is recommended for low-oxygen environments, such as water-logged soils, as it is the only anaerobic (AN) non-ureolytic MICP pathway suitable for concrete self-healing [74]. Calcium nitrate (Ca–N), a source of both calcium and nitrate, is often used in denitrification-dependent concrete self-healing systems [25], [74]. Pseudomonas aeruginosa (P. aeruginosa) and Diaphorobacter nitroreducens (D. nitroreducens) have shown resilience under dehydrated, nutrient-starved, and highly alkaline conditions; accordingly, they have been proposed and investigated for concrete remediation [75].(6)5HCOO− + 2NO3− → N2 + 3HCO3− + 2CO32− + H2O(7)HCOO− + NO3− + H+ → CO2 + H2O + NO2−

2.3. Photosynthesis

Bacteria can facilitate MICP through CO2 uptake via autotrophic and heterotrophic pathways. The precipitation of CaCO3 by cyanobacteria depends on the alkaline extracellular media resulting from the CO2 uptake during photosynthesis [76]. During photosynthesis, CO2 is intracellularly concentrated through a biochemical CO2-sequestering mechanism, creating an alkaline environment around the bacterial cell. In the presence of calcium, CaCO3 can then be precipitated outside the cell (Eqs. (8), (9)). The cyanobacteria capacity to capture CO2 as organic assimilates and CaCO3 precipitates has rendered these bacteria as attractive potential agents for carbon capture and storage (CCS). By abating atmospheric CO2 in heterotrophic bacteria, MICP occurrence has been attributed to the action of the carbonic anhydrase enzyme, which facilitates the hydration of CO2 [77]. Cyanobacteria Synechococcus PCC8806 has shown tolerance to the concrete environment and can precipitate CaCO3 under the environmental conditions of concrete [48].(8)CO2 + H2O → H2CO3(9)Ca2+ + 2H2CO3 → CaCO3 + CO2 + H2O

3. Non-ureolytic biological concrete self-healing systems

Non-ureolytic biological concrete self-healing systems have been less investigated than their urea-dependent counterparts. However, they are among the first biological concrete self-healing systems tested and have been successfully applied in this new scientific field. They offer novel venues for scientific progress and engineering applications. The foundation of their progress could be summarized as follows.

• Non-ureolytic bacteria can precipitate CaCO3 through various metabolic pathways under a wide range of environmental conditions. This property enables the development of versatile healing systems that can rely on different substrates, function under different environmental conditions, and serve various purposes, such as simultaneous concrete self-healing and CCS.

• Non-ureolytic bacterial concrete self-healing systems can contain more than one bacterial species in bacterial consortia (a mixture of different bacterial species). Although the same is true regarding ureolytic bacteria, non-ureolytic consortia can precipitate CaCO3 through different non-ureolytic MICP pathways, exhibiting versatile and flexible self-healing performance. For example, a non-ureolytic consortium consists of organisms that can perform MICP under AE and AN conditions, satisfying the self-healing demands on the concrete surface and oxygen-depleted cracks deep inside a structure.

• Unlike ureolytic bacteria, non-ureolytic MICP is free from harmful and unwanted by-products and does not require urea in self-healing systems. Although the quantity of NH3/NH4+ leaching out of concrete structures containing ureolytic bacteria can seem minute, it may pose a severe threat in the case of large-scale or widespread applications. Concrete is considered the most abundant human-made material. Hence, the large-scale application of novel concrete technologies, such as self-healing concrete, in the future is inevitable. At this point, the presence of NH3/NH4+, which is associated with ureolytic systems, can become a problem. In many ecosystems, NH3/NH4+ is a natural component and is in equilibrium with other chemical and biological components. Alterations to their concentration may prove disastrous for the natural environment because reactive nitrogen species, such as NH3/NH4+, can lead to eutrophication and loss of biodiversity in forests [78], lakes, and streams [79] as well as deplete the stratospheric ozone [80]; overall, they contribute to anthropogenic global warming. Moreover, NH3/NH4+ aggravates numerous health problems, such as cancer as well as respiratory and heart diseases [81].

• Non-ureolytic biological concrete self-healing systems present an opportunity for sustainable production of self-healing systems that can totally rely on recycled or environmentally friendly components. Through this strategy, biological self-healing systems can facilitate the introduction of waste-derived materials into the market. Non-ureolytic systems can be devised locally based on the available resources in a particular region.

The research attention that has been devoted to non-ureolytic bacterial concrete self-healing is driven by the interest in identifying environmentally friendly alternatives to ureolytic MICP. These two biological approaches employ different bacterial strains, and non-ureolytic systems do not include urea. However, the rest of the components, such as nitrogen and calcium sources, carrier materials, and self-healing evaluation methods, are generally similar. The non-ureolytic systems reported to date are subsequently described and discussed.

3.1. Substrates for biological self-healing concrete

3.1.1. Supporting bacterial growth, activity, and CaCO3precipitation

Healthy growth of the bacterial population must be supported before self-healing can commence. Fundamental elements, such as C, H, O, and N, are generally supplied to bio-concrete systems by adding complex media, such as yeast extract. This extract includes the water-soluble remnants of the autolytic digestion of yeast cells mainly composed of singular amino acids or short-chain peptides, nucleic acids, carbohydrates, sugars, vitamins, and salts. Yeast extract is a well-known nitrogen source, rich in B vitamins, and a verified inexpensive and safe microbiological medium that can support the growth of various microbes. Other microbiological medium ingredients, such as nutrient broth, meat extract (e.g., beef extract), and peptone, can also be used to support bacterial activity in bio-concrete systems. Similar to yeast extract, the foregoing ingredients supply N in amino acids and peptides and contain carbohydrates, vitamins, and salts. The exact composition depends on the manufacturer and substrate source. The presence of Ca is essential for MICP because Ca concentration is a major factor that dictates the MICP rate. The abundance of Ca(OH)2 in structures with fresh concrete indicates more bioavailable Ca for biomineralization. Therefore, the presence of a Ca source in bio-concrete systems is not required for early self-healing. As Ca(OH)2 is extremely carbonated and its supply is finite, adding a Ca source to the bio-concrete system is essential for the long-term self-healing of aged carbonated cement-based structures [82]. Non-ureolytic bacteria can perform MICP using a variety of Ca substrates. Organic calcium salts, such as Ca–L and Ca–A, have been used as calcium and energy sources because bacteria can metabolize organic anionsas carbon sources [83].

The impact of different calcium substrates on CaCO3 precipitation and bacterial population growth has been documented. Xu et al. [64] compared the in vitroprecipitation of CaCO3 by B. cohnii (107 cells·mL−1) supplied with 0.1 mol·L−1 Ca–L, Ca–Glut, and calcium chloride as substrates. Both Ca–L and Ca–Glut are organic salts that function as calcium sources, whereas lactate ions provide carbon, and glutamate ions contain carbon and nitrogen. After 28 d of incubation, the authors reported twice as much precipitation in the cultures supplied with Ca–Glut (0.08 mol·L−1) compared with those supplied with Ca–L; the lowest CaCO3 precipitation rates were reported for cultures supplied with calcium chloride. The authors concluded that the choice of calcium source and initial concentration rather than the CaCO3 precipitation rate were the two main factors influencing the total quantity of precipitated CaCO3. Cultures supplied with Ca–L contained higher cell concentrations after one week of incubation compared to cultures containing Ca–Glut (more than 90%). However, after 28 d, cultures supplied with Ca–Glut contained approximately 50% more cells than cultures containing Ca–L; these cultures had the lowest cell survival rate among all cultures up to 28 d. However, after 28 d, they sustained the same population levels as the cultures containing Ca–L. It should be noted that the initial calcium concentration (0.05–0.2 mol·L−1) did not affect the survival results. Bacterial growth was accompanied by media acidification, with pH values dropping from 9.5 to 7.5–8.0 in cultures containing Ca–L and Ca–Glut. Tziviloglou et al. [83] pre-grew three Bacillus isolates in media, with each medium containing 0.1 mol·L−1 of Ca–L, Ca–A, and sodium glutamate. The authors reported that isolates pre-grown on Ca–L and Ca–A could develop a preference for substrates in consecutive generations. The results indicate the formation of a metabolic memory, which may result in the upregulation of certain enzymes in cultures exposed to a nutrient source in previous generations. Metabolic memory can form at different levels of the genetic process and is a phenomenon found across all life domains [84]. Future research can identify the causal genetic factors for the metabolic preference reported by Tziviloglou et al. [83]. Lors et al. [49] investigated non-ureolytic MICP by B. pseudofirmus using Ca–L (0.3 mol·L−1) and yeast extract with and without Ca–N (0.2 mol·L−1). Researchers reported the total lactate consumption in the presence of Ca–N but not without it. A tenfold increase in the population levels of B. pseudofirmus was observed in the presence of Ca–N. However, this did not increase the CaCO3 precipitation, which could be explained by the lack of bioavailable Ca2+ from Ca–N. Population levels can significantly influence the quantity of precipitated CaCO3 [85]; hence, the addition of adequate concentrations of Ca–N for enhanced growth in MICP-based healing systems may be of interest. Moreover, inorganic calcium salts, such as Ca–N, can react with fresh concrete matrix, releasing free Ca2+, contributing to higher CaCO3precipitation and improving self-healing performance. Superior bacterial CaCO3precipitation with Ca–L compared with using Ca–N has also been reported for ureolytic bacteria [69]. Note that at room temperature, the water solubility of Ca–N is considerably higher than that of Ca–L (i.e., 121 and 4.8 g per 100 mL, respectively).

The effect of different organic calcium sources on concrete structures has also been examined; Ca–N and Ca–F are established concrete admixtures that improve the physical properties of concrete and provide anti-freezing protection [74]. Jonkers et al. [36] reported a slight improvement in the compressive strength of concrete samples containing Ca–L. Tziviloglou et al. [83] reported improved compressive strength in mortar samples containing Ca–L (up to 8%) and Ca–A (up to 13.4%) when supplied in 0.56%–2.24% of cement weight after 28 d of curing. Ducasse-Lapeyrusse et al. [86] found that after a month of curing, Ca–L and Ca–Gluc aided in sealing large fresh cracks (> 150 µm) with calcite and ettringite, which were self-healing products derived by increasing calcium and carbonate concentrations, respectively. Both Ca–Gluc and Ca–L had no significant sealing effect on small cracks. Further research into the microstructure of cement and concrete samples supplemented with organic calcium salts can reveal whether the impact of organic calcium salts is due to the increase in Ca2+ concentration or whether organic anions perform a role in settling, gel formation, and cement matrix hydration.

3.1.2. Waste as nutrient or calcium source for non-ureolytic biological self-healing concrete

Non-ureolytic MICP is considered an environmentally friendly alternative to ureolytic MICP; hence, substrates necessary for non-ureolytic MICP must also be sourced through sustainable processes to harness a truly sustainable product. Incorporating waste materials has been suggested to lower the production cost of bio-concrete healing agents and increase the product sustainability factor [26], [87], [88], [89], [90], [91]. For non-ureolytic systems, Ca–L has been a popular calcium substrate because it improves the physical properties of concrete and serves as a calcium and carbon source for non-ureolytic bacteria [36]. Ca–L can be sourced from fermented vegetable waste [70], recycled poly(lactic acid) (PLA) [92], and paper mill waste [93], possibly contributing to the economic feasibility and sustainable nature of non-ureolytic bacterial concrete self-healing agents. Mors and Jonkers [26] tested a non-ureolytic system containing lactic derivatives, such as lactic acid (a calcium source) and non-ureolytic bacterial spores; they reported that significant water tightness was regained by the cracked samples. Lactic acid has been found to improve cement hydration by enhancing the crystalline structure of cement and reacting with Ca(OH)2 from fresh cement to produce Ca–L [94]. The use of Ca–N to sustain denitrifying bacteria has improved bacterial survival; however, it has also resulted in lower quantities of CaCO3 precipitation than when Ca–L is employed [49]. The combined use of Ca–L and Ca–N also improved the functionality of non-nitrifying bacteria through survival preservation. Experts suggest that calcium and nitrate do not fully dissociate from each other and continue to be unavailable to the bacteria to some degree. The structural integrity of concrete is also improved by Ca–A, a known environmentally friendly de-icing agent sourced from vegetable waste conversion into acetic acid [95]. Jin et al. [95] converted more than 22% of the total organic carbon in vegetable waste into acetic acid and used oyster shells as an eco-friendly calcium source to obtain Ca–A. Another organic calcium salt, Ca–F, previously tested as a nutrient source for non-ureolytic bacterial concrete self-healing systems, can be sourced from chlor-alkali industrial waste [96]. Waste incorporation into self-healing systems reduces production costs and keeps hazardous materials from landfills and the environment, further contributing to the sustainability of bio-based concrete self-healing systems. A novel strategy for integrating waste and waste-derived substances into biological self-healing concrete was reported by Vermeer et al. [97]. The technique included refining polyhydroxyalkanoate (PHA)-rich wastewater residue to be used as a bacterial nutrient in a non-ureolytic biological concrete self-healing system. With this approach, the researchers proposed an alternative use for PHAs that lack sufficient quality for conventional bioplastic application. The comparison of self-healing results of specimens with and without waste-derived PHA as bacterial nutrients for non-ureolytic B. cohnii bacteria indicates that the former has higher crack-healing efficiency and reduction in water absorption. It should be noted that B. cohnii produced extracellular enzymes to metabolize the PHA. This research approach utilizes biological self-healing concrete as a niche field for waste-derived products whose use is not economically viable based on conventional applications of concrete. Moreover, it identifies a pathway in which biological self-healing concrete can contribute to sustainable resource management.

Song et al. [92] recycled PLA waste into Ca–L using a reusable inert ionic catalyst, deriving > 70% Ca–L yield [93]. Lactic acid was produced from the mixture of softwood pre-hydrolysate and paper mill waste, obtaining Ca–L as an unwanted by-product. Therefore, concrete self-healing systems can utilize waste materials from other industries, contributing to economic feasibility and sustainable development. Certain industrial waste materials, such as blast furnace slags and waste glass, have become established choices for cement replacement [98], [99], [100], [101]. Research into similar waste materials, including furnace slag from steel, copper, zinc, and iron production, has shown promising results as potential cement replacements as they are rich in cementitious materials such as Ca and Mg oxides, which may be harnessed as biomineralization precursors [89], [102], [103]. Note that when such oxides are employed as a calcium source for MICP, they can cause undesirable cement expansion [104], which can be prevented by immobilizing the biological healing agents. Calcium oxides can also be derived from recycled eggshells [105] and shells of aquatic biomineralizing animals, such as mollusks and oysters [106], [107].

Røyne et al. [108] described the microbial acid digestion of limestone by Bacillus safensis and subsequent re-precipitation by ureolytic bacteria in a process termed “the BioZEment approach” (Fig. 2). This technique sustainably converts limestone into an inexpensive calcium source for MICP (Stage I). the ureolytic bacteria then increase the slurry’s pH and precipitate calcite crystals (Stage II). The pH increase is mainly due to the presence of NH4+ ions resulting from ureolysis. Even in the absence of NH4+, the interaction between slurry and amino acids from the added bacterial nutrients can increase the pH level to 7. The possibility of using this method may depend on which type of non-ureolytic bacteria is used and require a de-acidification step. We further conducted a life cycle assessment and studied the environmental benefits of this technique compared with conventional concrete production by assessing the global warming potential of the process [109]. The findings showed that the BioZEment approach has a lower global warming potential than the conventional concrete production by more than 70%; however, it requires more land area and possibly causes the occurrence of eutrophication and NH3admission problems. The cost of using the BioZEment approach was estimated to be more than 10% of conventional concrete production.

Fig. 2. Schematic of proposed two-stage limestone dissolution–recrystallization process (adapted from Ref. [108] and reproduced based on Creative Commons license).

Fig. 2. Schematic of proposed two-stage limestone dissolution–recrystallization process (adapted from Ref. [108] and reproduced based on Creative Commons license).The investigations described in this section demonstrate the utilization of various waste and by-product materials as bacterial nutrients or calcium sources for MICP of non-ureolytic self-healing concrete. Moreover, research shows how non-ureolytic biological self-healing concrete can be a point of convergence for the construction industry, wastewater treatment sector, and businesses that produce organic refuse or metal-rich waste. This opportunity provides the researchers of non-ureolytic biological concrete self-healing systems with the prospect of expanding their work to include other industrial waste and by-products. Several practical steps that can benefit future research on alternative nutrient sources for non-ureolytic biological concrete self-healing are available. For instance, establishing a clear understanding of the metabolic processes performed by bacteria can aid researchers in predicting the impact of various factors (e.g., bacterial population, temperature, pH, carriers) on metabolism. Furthermore, this can help researchers in identifying the metabolites or remnants left after the digestion of nutrient sources to ensure that harmful by-products, which can damage the concrete structure and carrier material, or inhibit bacterial growth, are not producedover time. Another critical step is a life-cycle assessment of the self-healing system that may be similar to the evaluation performed by Mors and Jonkers [26]; this assessment considers the environmental footprint of the alternative nutrient or calcium source. Moreover, it allows for a more meticulous examination of the system’s sustainability and can aid in determining elements that have not been previously considered in a system’s ecological footprint.

3.2. Immobilization and survival assessment of non-ureolytic healing agents

Although the carrier materials used for biological self-healing between ureolytic and non-ureolytic systems do not differ, the methods used to evaluate bacteria survival after immobilization and application vary. Rajczakowska et al. [110] thoroughly reviewed the impact of different carriers used in biological self-healing concrete on the physical properties of cement/concrete samples. In this study, a review of the techniques employed to evaluate bacterial survival after immobilization is presented. Researchers who investigate ureolytic systems frequently use the urease enzyme activity by the total ammonia nitrogen determination method to analyze ureolytic bacteria activity. As this method is not applicable to non-ureolytic systems, several other methods have been used to determine the bacterial activity in non-ureolytic systems.

3.2.1. Direct enumeration

Direct enumeration of microbial cells involves the quantification of living microbes by growing the cells on specific growth media. Jonkers et al. [36]directly added 2.4 × 108 spores of B. cohnii per cubic centimeter of cement samples and estimated the spore survival by crushing the samples after 9, 22, 42, and 153 d of curing. They used the most probable number technique to measure the bacterial population and reported that the bacterial activity after 9 d was 1% and then decreased to the minimum test detection limit (< 500 cells·cm−3) after four months. There is a possibility that the high mechanical force used to free the bacterial cells from the cement matrix during this test could have altered the results.

Sharma et al. [40] also directly added spores of B. pseudofirmus, B. cohnii, and B. halodurans into cement paste. Less than 5% of the initial B. pseudofirmusinoculum was recovered after 7 d, which decreased to less than 1% after 28 d of water immersion. The spore survival rate of B. cohnii and B. halodurans also decreased in a similar manner as that of B. pseudofirmus; however, their spore loss was more drastic. Overall, the direct addition of spores to cement is related to low spore survivability, which is possibly due to the highly alkaline cement environment, lack of access to nutrients or oxygen, or susceptibility to shear forces during mixing and settling.

Direct enumeration has also been used to assess the survival of bacteria immobilized in/on a solid carrier. A study incorporated B. pseudofirmus in expanded clay particles (ECPs) by vacuum impregnation (2.2 × 107 colony-forming units per gram (CFU·g−1) [111]. The loaded clay particles were then coated with eight different materials and incorporated into concrete specimens. Viability assessment was conducted by direct enumeration of B. pseudofirmusbacteria from powdered biological self-healing concrete specimens of different ages. With this technique, the authors assessed the protective ability of various coatings and reported superior protection by coatings such as MgO and styrene–acrylate, which block the pores of ECPs. They also reported that the sensitivity of this technique was not optimal but was sufficient to distinguish high and low levels of protection.

3.2.2. NO3−/NO2− consumption

The measurement of the consumption of NO3−/NO2− has been a reliable tool for assessing the activity of bacteria with denitrifying ability. Erşan et al. [72]studied the survival of vacuum-encapsulated pure cultures of NO3− reducing P. aeruginosa or D. nitroreducens in diatomaceous earth, expanded clay, and granular activated carbon after addition to mortar. They also performed this test for self-protecting NO3− reducing bacteria mixtures termed as the activated compact denitrifying core. Survival was then assessed by measuring the NO3−and NO2− consumptions of bacteria removed from fractured mortars by resuspension and low-frequency sonication. Among the carrier materials used for pure cultures, expanded clay and activated carbon offered better protection to the bacteria than diatomaceous earth did. The concentrations of NO3−/NO2−were quantified using ion chromatography [72], [112].

3.2.3. Measurement of O2 consumption for bacterial activity

An established method for deducing bacterial activity is the measurement of O2uptake by bacteria. Researchers have used this method to show bacterial activity in self-healing systems and bio-concrete samples. Wiktor and Jonkers [66] vacuum-impregnated ECPs with Ca–L, yeast extract, and B. alkalinitrilicus. By employing O2 consumption measurements, they found that the bacteria remained viable after nine months inside the cement. Sierra-Beltran et al. [63]impregnated lightweight aggregates (LWAs) with Ca–L, yeast extract, and B. cohnii spores and measured the O2 consumption to elucidate the bacterial activity in the mortars. The results indicated bacterial activity after three months of casting the samples. Mors and Jonkers [26] evaluated the O2 uptake of mortars incorporated with a bacterial lactic acid derivative for a non-ureolytic self-healing system. Based on the recorded O2 consumption, they verified that the viability of samples with bacteria was superior to that of abiotic control specimens. From the O2 consumption measurements, they also determined that the nutrient levels had reached a sufficiently low quantity that limited bacterial activity after a week.

The measurement of O2 consumption has also been used to verify the viability of alginate-immobilized bacterial spores [113], [114]. Palin et al. [113] reported lower dissolved O2 concentrations in the 1 mm boundary above the bacterial capsules submerged in artificial seawater at 8 °C compared with those of abiotic control specimens. The dissolved O2 levels reached the lowest recorded concentration on the second day of submersion. This technique demonstrated bacterial activity and metabolism under cold marine conditions. However, the O2 consumption assessment did not allow the collection of precise evidence for the survivability of the bacterial population and evidence regarding whether the bacterial spores remained inside the capsules or ventured out. Furthermore, the immobilization efficiency of the healing agents by calcium-alginate beads was unclear. The porous hydrogel tends to leach the healing agents during the calcium bath stage of capsule preparation and during the suspension. The described instances of O2 measurement demonstrate that this technique can enable researchers to verify the general viability of immobilized healing agents and obtain an estimate of nutrient consumption; however, these measurements do not provide quantitative information regarding the surviving bacterial population. Additionally, no conclusions can be drawn regarding the success of the biological healing agents in the immobilization process (i.e., the extent to which the agents provided immobilization or whether the vacuum encapsulation impacted the spore survival). The above studies have all provided qualitative proof of spore survival after immobilization, indicating that these survival assessment methods do not provide a precise measure of the bacterial survival or the impact of the immobilization process and the concrete environment on the healing agents. They only indicate that a detectable quantity of the bacteria has remained viable for concrete self-healing. Hence, the impact of immobilization processes on spore survival, the germination of viable spores, and the exact degree of protection (e.g., carriers) of bacterial spores remain speculative. The qualitative results offer assurance that spores survive the various immobilization processes. However, for the large-scale production of biological self-healing agents, a quantitative analysis of the impact of immobilization processes is necessary.

To resolve these problems, we attempted to quantitatively assess the impact of hydrogel immobilization on bacterial spores [20]. We immobilized the spores of B. pseudofirmus in calcium alginate capsules using the ionic gelation method, which involved the crosslinking of alginate monomers with a divalent cation (e.g., Ca2+). Then, an optimized de-crosslinking procedure was implemented to dissolve the alginate capsules, and the spores were quantified using direct enumeration. The results suggested that virtually all of the spores had been successfully encapsulated inside the capsules with no loss of viability or occurrence of leaching during the encapsulation process. Furthermore, the presence of nutrients did not impact the efficiency of the immobilization procedure. The de-crosslinking method could not dissolve the alginate capsules removed from cement, possibly due to residual cement. However, the survival of the bacteria in alginate capsules placed in cement can be assessed if the outermost layer can be removed, that is, if the coated alginate capsule is similar to the chitosan-coated alginate capsule described by Gao et al. [60].

The impact of the immobilization procedure on biological self-healing agents can be better understood by thoroughly analyzing the interaction between agents and protective carriers. This analysis can elucidate whether the carrier requires improvement to better retain or protect the healing agents to ultimately fine-tune the protective carriers of the material support and provide long-term functionality to the healing agents. Assuming that a hypothetical system is incorporated with 108 spores·g−1 of a carrier, if 99.99% of the spores do not survive the immobilization or cement casting, 106 spores·g−1 of the carrier can still provide self-healing results in the form of enhanced mechanical performance, crack healing, and CaCO3 precipitation. Moreover, the bacterial samples consume more O2 than the control samples. Nevertheless, the efficiency of self-healing is significantly reduced.

Similarly, if a carrier cannot properly keep healing agents, such as yeast extract, shielded from the cement matrix, the self-healing efficiency and functionality can be reduced, and the cement matrix may sustain the deleterious impact posed by yeast extract or similar MICP precursors. Therefore, researchers cannot ignore the efficiency of immobilization techniques and carrier materials in protecting and holding bacterial spores and other healing agents. Note that the nature of certain carrier materials for protecting non-ureolytic self-healing agents may not allow the precise and direct assessment of the survivability and viability of healing agents. Palin et al. [114] used the O2 measurement data to estimate a possible amount of CaCO3 precipitation; however, they did not report the accuracy of the estimated quantity with respect to the obtained precipitation quantity; nevertheless, this approach can present a strategy for researchers. The correlation of in vitro characterization results (e.g., the relationship between CaCO3 precipitation quantity with estimates of such a performance indicator (e.g., O2 consumption)) can produce a more accurate survivability estimate. Further, the viability of healing agents may even aid in explaining the self-healing behavior of the system after mechanical characterization.

4. Effect of non-ureolytic bacterial concrete self-healing systems on mechanical, physical, and durability properties of concrete

Non-ureolytic biological concrete self-healing systems can protect the biological healing agents and provide the required medium for self-healing action. In contrast, biological healing agents perform the self-healing function following a trigger (e.g., structural fault or crack) that promotes the germination of dormant spores and results in the bioavailability of nutrients and O2. Overall, non-ureolytic biological self-healing systems can reinforce the concrete structure and improve its durability and mechanical and physical properties. Section 3describes the relationship between the biological and carrier subsystems of non-ureolytic biological concrete self-healing systems and the protective function of the systems. This section describes the self-healing functions (e.g., the impact of non-ureolytic self-healing systems on the mechanical and physical properties and the durability of concrete specimens) of non-ureolytic biological concrete self-healing systems.

The self-healing ability of non-ureolytic systems in concrete has been studied by comparing the variations in mechanical parameters (e.g., compressive and flexural strengths) and physical properties (e.g., changes in porosity and crack dimensions) of cement and concrete specimens. Variations in the type and quantity of bacteria, carrier material, nutrients, calcium additive, specimen composition, and curing conditions do not allow a robust comparison of reported results. Nonetheless, similar measurement techniques have been used to assess the durability as well as the mechanical and physical properties of test specimens before and after self-healing. This commonality allows for a meaningful interpretation of the impact of healing agents on the properties of the specimens in their early stages and the self-healing ability of different systems.

4.1. Mechanical properties

4.1.1. Compressive strength

The compressive strength of concrete has an established correlation with the durability of concrete structures. Inadequate compressibility can result in crack formation due to increased sensitivity to loads and pressure. Such cracks then facilitate the concrete structure’s degradation by increasing the exposure of the cement matrix and reinforcements to corrosive agencies (i.e., similar to high-porosity concrete structures) [115]. Hence, the compressive strength of experimental concrete samples containing additives is typically evaluated to determine the impact of additives on the structural strength and concrete durability. This evaluation has been widely implemented to assess the impact of self-healing systems on early concrete properties and the degree to which self-healing systems enhance the structural strength of concrete over time.

Mors and Jonkers [26] showed that the direct addition of 6 × 108 B. pseudofirmusspores has a retarding effect on the cement sample’s initial compressive strength. Over 28 d, the authors reported a decrease in the frequency of larger pores (0.8–1 μm in diameter) in cement specimens containing healing agents compared with that of control specimens in which the microcracks (0.01–0.1 μm) remain unblocked. The compressive strength of biotic mortars was initially 60% lower than that of abiotic mortars. After 14 d, their strengths became similar due to bacterial precipitation and remained unchanged up to 56 d. Mondal and Ghosh [62] incorporated 103, 105, and 107 cells·mL−1 of B. subtilis spores into concrete. They reported higher compressive strengths for all bacterial samples than those of the control specimens after 3 d, continuing up to 28 d. During this time, the highest gain in compressive strength was observed in samples containing 105 cells·mL−1 (a 27% increase compared with those of the control specimens). Lower water absorption rates were also observed, namely, 13%, 23%, and 27%, for the specimens with 103, 105, and 107 cells·mL−1, respectively, compared with those of the corresponding abiotic control samples.

Khaliq and Ehsan [61] incorporated 2.8 × 108 cells·mL−1 of B. subtilis and Ca–L spores either directly or after LWA or graphite nanoparticle (GNP) immobilization and reported improved compressive strengths in bacterial samples compared with those of the control specimens after 3 d and up to 28 d, leading to a maximum compressive strength increase of 12% with LWA-immobilized bacteria and 9.8% with GNP-immobilized bacteria but only a 3% increase with direct bacteria addition. The strength improvement was attributed to the bacterial CaCO3 precipitation and improved matrix packing due to aggregate replacement by LWA and GNP, leading to a decrease in the interfacial transition zone (ITZ) formation. Moreover, the interaction between the bacteria and carrier surface may also affect the healing rate, create nucleation sites, and promote biofilm formation that may possibly affect MICP in a manner resembling the impact of soil particles on CaCO3 precipitation caused by soil bacteria [116]. In vitro MICP evaluation by B. subtilis using Ca–A revealed that B. subtilis promotes CaCO3 precipitation by biofilm formation [117]. Prior research has also noted the importance of biofilm formation for MICP by B. subtilis [118] and B. cohnii [64]. Schwantes-Cezario et al. [117]examined in vitro CaCO3 precipitation by B. subtilis using Ca–A (0.25% w/w). They reported that B. subtilis promotes CaCO3 precipitation by biofilm formation and associated the rise in pH with biofilm development. Hence, attention to bacteria-carrier interactions can lead to beneficial discoveries, especially when the healing agent is a biofilm-forming bacteria. Such an approach may focus on factors affecting biofilm development, including water availability [119].

The reported improved compressive strength upon the direct addition of healing agents by Khaliq and Ehsan [61] differs from the findings of Jonkers et al. [36]; the latter suggests that the retarding effect of bacterial spores on the compressive strength of concrete may be species-dependent. This suggestion is possible because both studies used Ca–L as the primary nutrient source and comparable spore concentrations. Moreover, the data indicates a slight positive impact of 10% by Ca–L on compressive strength [36]. The comparison between the findings of Khaliq and Ehsan [61] and those of Ramachandran et al. [37](who directly incorporated 7.2 × 107 cells·cm−3 of ureolytic bacteria Bacilluspasteurii and found no compressive strength improvement) suggests that B. subtilis is a better choice for direct addition in terms of compressive strength. However, the direct addition of healing agents to concrete can be disadvantageous considering the structural integrity of concrete and self-healing efficiency.

Luo and Qian [120] compared the self-healing capacity of a system composed of non-ureolytic bacterial spores, Ca–L, Ca–N, and Ca–F. The authors reported the impact of bacteria/Ca–F (1% w/w) on the compressive strength of cement samples, namely, decreasing strength with increasing bacteria/Ca–F concentration. The effect of varying levels of calcium substrate on compressive strength was also evident from the reported compressive strength results of bacteria/Ca–L. The best performance was observed when 3% w/w of bacteria/Ca–L was added to cement samples, resulting in an initial loss in compressive strength; however, after 10 d, their compressibility surpassed those of the control samples. Bacteria with Ca–N decreased the compressive strength with increasing Ca–N levels. It was reported that the pore size distribution was associated with the calcium substrate used. The control specimen primarily had pores in the size range of 10–100 nm, but the addition of self-healing agents shifted the pore size distribution to the range of 100–1000 nm. The authors suggested this observation as a possible explanation for variations in compressive strength and reported an adverse impact on the cement’s setting time when bacteria/Ca–L was used; in contrast, bacteria/Ca–N and bacteria/Ca–F reduced the cement setting time. This pattern was also reported for the three substrates regarding their effect on the hydration kineticsof cement. These findings improve the understanding of the impact of self-healing systems and their components on cementitious structures and system optimization.

4.1.2. Flexural strength

The bending of concrete structure due to external forces often lead to crack formation because concrete has low flexural strength (usually 10%–20% of its compressive strength). Accordingly, the impact of concrete self-healing systems on flexural strength has been assessed as a self-healing benchmark.

In an earlier study, Xu and Yao [65] assessed the healing ability of 107 cells·mL−1B. cohnii spores and Ca–L or Ca–Glut when used as a surface treatment. They further assessed the healing system’s impact on the flexural strength of the mortar when applied as surface treatment or when incorporated as a self-healing system. They reported no adverse impacts on flexural strength due to individual system components when incorporated into mortars, even noting a slight improvement in the case of Ca–L addition in an earlier study [36]. After 28 d, the flexural strength of surface-treated mortars was higher than that of mortars with healing agents. Among the samples with incorporated healing agents, the flexural strength of those containing Ca–Glut was two times greater than that of the control samples; the samples containing spores and Ca–L did not perform well. The higher flexural strength recovery of samples with Ca–Glut was attributed to the higher CaCO3 conversion of Ca–Glut by the bacteria. This resulted in a larger and denser transition zone between the biologically deposited mineral layer and cement matrix (Fig. 3 [65]), forming a strong bond between the deposition layer and cement matrix. The flexural strength results were confirmed using grid nanoindentation, and the hardness and modulus of the mortar, the outer precipitates, and the transition zone of different specimens were measured. The highest values of modulus and hardness were observed in the transition zone of the sample with Ca–Glut, and the lowest measurements were observed in the transition zone of the Ca–L sample.

Fig. 3. Scanning electron micrographs of transition zone in (a) Ca–L and (b) Ca–Glut specimens. Reproduced from Ref. [65] with permission of Elsevier Ltd., © 2014.

Fig. 3. Scanning electron micrographs of transition zone in (a) Ca–L and (b) Ca–Glut specimens. Reproduced from Ref. [65] with permission of Elsevier Ltd., © 2014.Sierra-Beltran et al. [63] impregnated LWA with Ca–L and yeast extract, and B. cohnii spores were added to a strain-hardening cement-based composite (SHCC). The presence of bacteria resulted in improved flexural strength compared with that of the control specimen. Further, the healing agents only slightly improved the mechanical properties of the SHCC with an insignificant amount of CaCO3 precipitation compared to that of the control samples. The inadequate nutrition levels was noted as a possible explanation for the lack of distinguishable CaCO3 precipitates in the bacterial samples and suggested further studies. There is a dearth of reported literature on this topic; however, this study can serve as a baseline for evaluating future healing systems for cement variants.

We had previously incorporated calcium alginate-immobilized B. pseudofirmusspores and nutrient broth into cement paste and cement mortar and found initial flexural strength losses of 38.96% and 58.50% for the paste and mortar, respectively [20]. This is expected due to the detrimental impact of superabsorbent polymers (SAPs) on the cement matrix due to excessive water uptake, leading to void formation in the matrix [121]. The analysis of artificially cracked samples after 56 d of wet–dry incubation revealed 32.5% and 39.6% regain levels in the flexural strengths of cement paste and mortar samples, respectively. Compared with those of abiotic control samples, bacterial presence improved the regain levels in the flexural strength of cement paste and mortar by 17.1% and 10.3%, respectively. Although the initial loss in strength was extremely high for the 56 d self-healing action to compensate, the results indicated that calcium alginate was a promising carrier capable of supporting the healing agents up to 56 d. The results further showed that the presence of sand in the mortar accelerated the regain in flexural strength, with 69% occurring in the first 28 d of incubation. In contrast, the regain in the flexural strength of the cement paste specimen was mainly observed in the latter 28 d (67%); this can be attributed to sand particles acting as additional nucleation sites of CaCO3 precipitation. This highlights the potential of calcium alginate capsules for protecting the healing agents over extended periods. Longer incubation periods are necessary to better understand how such a system can be improved for extended self-healing performance and assessed in future research.

Gao et al. [60] coated calcium alginate capsules containing B. pseudofirmus with chitosan and recorded a 3.78% increase in flexural strength compared with that of the capsule-free control specimen; only 1.2%–1.5% (with capsule/with cement) of the capsules were included, which decreased the expected strength reduction. Furthermore, the reduced swelling due to the pH-responsive nature of chitosan and high drying temperature (65 °C) can decrease the swelling and water uptake of capsules. Although the internal curing potential of alginate capsules is severely diminished, the authors have illustrated how hydrogels can be used as bacterial carriers in concrete without initial loss in strength. Future studies on SAP-encapsulated biological concrete self-healing can investigate the impact of MICP-driven self-healing on the drying shrinkage and autogenous shrinkage of cement-based specimens because recent findings suggest that a possible increase in mass loss and shrinkage may be exacerbated by SAP addition [122], [123].