1. Introduction

Use of nanotechnology in oil and gas industry has been improved rapidly over last decades. Adding nanoparticles (NPs), because of their very ultrafine size (<100 nm) and high surface area to volume ratio, allow engineers to modify the drilling fluids rheology by changing the composition, type, or size distribution of nanoparticles that suit desired drilling conditions without using other expensive additives (Abdo and Haneef, 2012). In recent years, numerous studies have been reported on the application of nanoparticles as additives in drilling fluids formulation (Abdo and Haneef, 2012, Amanullah et al., 2011, Sharma et al., 2012, Srivatsa and Ziaja, 2012, Mao et al., 2015a, Mao et al., 2015b, Taraghikhah et al., 2015, Hassani et al., 2016, Shakib et al., 2016). The benefits include improvement of fluids rheological properties, reductions in filtration loss and friction coefficient, increase of the rate of heat transfer, shale stability improvement, and inhibition of gas hydrate formation. A summary of research studies to date is presented in Table 1, Table 2, Table 3, Table 4, Table 5 of this manuscript. Detailed review of the studies with profound outcomes are presented in the following section based on the modification of the drilling fluids property through addition of nanoparticles.

Table 1. Summary of the recent studies evaluating the application of nanoparticles on modification of rheological properties of drilling fluids.

| Author | Types of NPs | Base Fluid | Modified Properties | Experimental Conditions | Summary of Results |

|---|---|---|---|---|---|

| Abdo and Haneef (2013) | Palygorskite | Water |

|

HPHT at 100–392 °F and 100–16,000 psi | 5.9 gr of nano-palygorskite with 10–20 nm diameter in WBFs showed a reduction of fluid rheological properties under HPHT (100-392 °F and 100–16,000 psi) conditions. |

| Abdo et al. (2014) | Nanocomposite of ZnO, montmorillonite and palygorskite | Water |

|

HPHT at 109–370 °F and 150–18,500 psi | Nanocomposite of ZnO, montmorillonite and palygorskite was used in water-based fluid system. 2.3 wt% of the nanocomposite with 5–50 nm diameter resulted in more stable rheological properties under HPHT (109-370 °F and 150–18,500 psi) conditions. |

| Abdo (2014) | Attapulgite | Water |

|

Ambient | 2.0 wt % of attapulgite nanoparticles with 10–25 nm diameter in WBFs increased the rheological properties at ambient condition |

| Abdo et al. (2016) | Sepiolite | Water |

|

HPHT at 77–365 °F and pressure up to 2500 psi | 4.0 wt% of nano-sepiolite with 30–90 nm diameter in WBFs resulted in more stable rheological properties under various HPHT (77-365 °F and pressure up to 2500 psi) conditions. |

| Agarwal et al. (2011) | Clay and silica | Oil |

|

HPHT at 437 °F and 500 psi | 2.0 wt% of nanoclay individually, or mixed with 1 wt% nanosilica can improve the viscosity and gel strength of invert emulsion drilling fluids. |

| Amanullah et al. (2011) | Not specified | Water |

|

LPLT | 0.14 wt% of nanoparticles in water-based drilling fluids showed superior gelling properties under LPLT condition |

| Anoop et al. (2014) | SiO2 | Oil |

|

HPHT at 77–284 °F and pressure up to 6000 psi | 2.0 vol% of nanosilica (SiO2) with 20 nm diameter in OBFs increased plastic viscosity at ambient condition and maintained stable rheological profile under HPHT (77-284 °F and pressure up to 6000 psi) conditions. |

| Ghanbari et al. (2016) | SiO2 | Water |

|

LPLT | 0.5 wt% of silica nanoparticles (SiO2) with 10 nm diameter in WBFs increased plastic viscosity and yield point under LPLT condition. |

| Hassani et al. (2016) |

|

Water |

|

Temperature: 104 °F | Type of NPs: SiO2, Carbon nanotubes, and ZnO. 2.0 wt% of each nanoparticle in WBFs increases rheological properties significantly, however the highest improvement was obtained from silica NPs. |

| Jain et al. (2015) |

|

Water |

|

High temperature up to 203 °F | The studies evaluated the application of (1) composite of polyacrylamide and nanoclay and (2) composite of polyacrylamide-grafted-polyethylene glycol and SiO2nanoparticles. 0.7 wt% of each composite with 20–30 nm particle diameter improved fluid rheological properties. The drilling fluid had also showed a stable rheological profile at 203 °F. |

| Li et al. (2015) | Cellulose nanoparticles | Water |

|

Temperature range from 20 to 176 °F | 0.5 wt% of cellulose nanoparticles with 6 nm width and 228 nm length in WBFs increased rheological properties at elevated temperature range from 68 to 176 °F |

| Mahmoud et al. (2016) |

|

Water |

|

HPHT | Ferric oxide (Fe2O3) and silica (SiO2) NPs were used in water-based system. 0.5 wt% of ferric oxide improved fluid rheological properties while silica at the same concentration that showed the opposite effects on rheology. Fluid with ferric oxide also exhibited more stable rheological properties under HPHT conditions. |

| Mao et al., 2015a, Mao et al., 2015b | SiO2 | Water |

|

LPLT and high temperature (392, 410, 428, 446 °F) | 1.0 wt% of silica nanoparticles (SiO2) in WBFs improved plastic viscosity and yield point under LPLT condition. The formulation also showed stable profiles at high temperature conditions. (392, 410, 428, 446 °F) |

| Nasser et al. (2013) | Nanographite | Oil |

|

LPLT | Nanographite with 40 nm diameter in OBFs increased fluid viscosity at LPLT condition. |

| Needaa et al. (2016) | Sepiolite | Water |

|

LPLT and HPHT (122-356 °F and 500–6000 psi) | 1.4 wt% of sepiolite NPs in WBFs exhibited stable rheological profiles under LPLT and various HPHT (122-356 °F and 500–6000 psi) conditions. |

| Sadeghalvaad and Sabbaghi (2015) | TiO2 | Water |

|

LPLT | 1–14 gr of the titanium oxide (TiO2) NPs were added to the water-based fluid formulation. Results indicated improvement in plastic viscosity and yield point under LPLT condition. |

| Salih et al. (2016) | SiO2 | Water |

|

LPLT and HPHT at 199 °F and 1000 psi | 0.3 wt% of silica nanoparticles with 5.7 nm diameter in WBFs decreased the overall rheological properties under LPLT and HPHT (199 °F and 1000 psi) conditions. |

| Song et al., 2016a, Song et al., 2016b | Cellulose nanoparticles | Water |

|

LPLT | 3.5 wt% of celluloses nanoparticles with 8.2 nm width and 321 nm length in WBFs increased rheological properties under LPLT condition. |

| Srivatsa and Ziaja (2012) | SiO2 | Water |

|

LPLT | 10 wt% of silica nanoparticles (SiO2) in water-based fluids improved viscosity under LPLT condition |

| Taraghikhah et al. (2015) | SiO2 | Water |

|

High temperature at 250 °F | 1.0 wt% of silica nanoparticles (SiO2) improved the overall rheological properties of WBFs both at LPLT and HPHT condition (250 °F). |

| Wagle et al. (2015) | Not specified | Oil |

|

High temperature at 250 and 302 °F | Oil-based fluids (OBFs) containing nanoparticles exhibited stable rheological profiles under HPHT (250 and 302 °F) conditions and maintained barite sag to a lower level. |

Table 2. Summary of the recent studies indicating reduction of filtration loss of drilling fluids by nanoparticles.

| Author | Types of NPs | Base Fluid | Modified Properties | Experimental Conditions | Summary of Results |

|---|---|---|---|---|---|

| Abdo and Haneef (2012) | Material called ATR | Water |

|

Material called ATR | Nanoparticles called ATR were used in water-based fluid system. The results show a decrease API fluid loss and filter cake thickness. |

| Abdo and Haneef (2013) | Palygorskite | Water |

|

HPHT at 100–392 °F and 100–16,000 psi | The study observed palygorskite NPs in WBFs and showed a decreased in spurt loss and fluid loss by 30% at 30 min under API conditions. |

| Abdo et al. (2016) | Sepiolite | Water |

|

HPHT at 77–365 °F and pressure up to 2500 psi | 4.0 wt% of nano-sepiolite with 30–90 nm diameter in WBFs showed reduction of filtration loss under HPHT (77-365 °F and pressure up to 2500 psi) conditions. |

| Aftab et al. (2016) | ZnO | Water |

|

LPLT and HPHT (150 and 250 °F) | 1.0 gr of zinc oxide (ZnO) NPs in WBFs reduced filtrate loss under HPHT (150 and 250 °F) conditions. |

| Akhtarmanesh et al. (2013) | SiO2 | Water |

|

– | 30 wt% of silica nanoparticles with 35 nm diameter in WBfs showed a reduction of fluid filtrate observed through the pore plugging test. |

| Barry et al. (2015) | Fe2O3 | Water |

|

LPLT and HPHT | The results showed an increase in fluid loss with the addition of ferric oxide (Fe2O3) NPs at LTLP conditions. |

| Cai et al. (2012) | SiO2 | Water |

|

LPLT | 10 wt% of silica (SiO2) NPs in WBFs reduced filtrate invasion and improved the ability of plugging and sealing micro-pores and micro-fracks of the shale formations. |

| Contreras et al. (2014) |

|

Oil |

|

LPLT and HPHT | The study tested iron and calcium NPs at concentrations 0.0, 0.5, 1.0 and 2.5 wt% along with lost circulation material (LCM), graphite at 0.5 and 2.0 wt% in OBF. At LPLT, samples with iron based NPs showed higher reduction of filtration loss than samples with calcium based NPs. It also concluded that LCM works better with iron based NPs but not with calcium at HPHT conditions. |

| Halali et al. (2016) | Carbon nanotubes | Water |

|

LPLT and HPHT (248, 302, 347, 392 °F) | 0.8 wt% of carbon nanotubes in WBFs reduced filtration loss under HPHT (248, 302, 347, 392 °F) conditions. |

| Li et al. (2015) | Cellulose nanoparticles | Water |

|

Temperature range from 20 to 176 °F | 0.5 wt% of cellulose nanoparticles with 6 nm width and 228 nm length in WBFs reduced fluid loss under elevated temperature conditions, range from 20 to 80 °C. |

| Liu et al. (2015) |

|

Water |

|

LPLT and HPHT | The study tested spherical latex particles with size distribution 80–345 nm with aluminium complexes in WBfs and concluded they had excellent plugging abilities with API filtrate reducing by 44% |

| Liu et al. (2016) | SiO2 | Water |

|

Low temperature 21–43 °F | 2.0 wt% of silica (SiO2) NPs in WBFs reduced filtration loss at low temperature (21–43 °F) conditions. |

| Madkour et al. (2016) |

|

Oil |

|

HPHT (59–199 °F) | The study tested graphene and multi-walled carbon nanotube (MWCNT) NPs at concentration of 0.5 wt% in an OBFs and showed reduction in filtration loss under HPHT at 302 °F and 500 psi. |

| Mahmoud et al. (2016) |

|

Water |

|

HPHT | 0.5 wt% of ferric oxide (Fe2O3) NPs in WBFs showed minor fluid loss under HPHT conditions compared to silica (SiO2) NPs which showed an increase of fluid loss as due to an increase in porosity and permeability of the filter cake. |

| Mahto and Jain (2013) | Fly ash | Water |

|

LPLT | Experiments using fly ash NPs in WBFs achieved a 30% reduction in filtration loss and about a similar proportion amount again in filter cake thickness. Increasing the concentration of the NPs and the size of the fly ash also decreases filtrate significantly |

| Mao et al., 2015a, Mao et al., 2015b | SiO2 | Water |

|

LPLT and high temperature (392, 410, 428, 446 °F) | 1.0 wt% of silica (SiO2) NPs in WBFs considerably reduced API fluid loss over 80% improved plastic viscosity and yield point while considerably reduced fluid loss. |

| Nasser et al. (2013) | Nanographite | Oil |

|

LPLT | The study tested 40 nm graphite NPs and showed mud filtrate reduction by 50% under LPLT condition. |

| Sadeghalvaad and Sabbaghi (2015) | TiO2 | Water |

|

LPLT | The experiment tested on titanium oxide (TiO2) NPs in WBFs and resulted in the reduction of filtration loss and filter cake thickness by 64%. |

| Salih et al. (2016) | SiO2 | Water |

|

LPLT and HPHT at 199 °F and 1000 psi | Silica (SiO2) NPs at 0.7 wt% in WBFs gave the lowest mud cake thickness (1 mm) and found that filtration reduced as the concentration increased. |

| Song et al., 2016a, Song et al., 2016b | Cellulose nanoparticles | Water |

|

LPLT | 3.5 wt% of celluloses NPs with 8.2 nm width and 321 nm length in WBFs reduced filtration loss at LPLT condition. |

| Taha and Lee (2015) | Graphene | Water |

|

LPLT and high temperature (120 and 351 °F) | The study tested 1, 2, 3, 4 and 5 wt% of graphene NPs in a 10 ppg WBF and resulted in reduced API fluid loss of up to 30%. |

| William et al. (2014) |

|

Water |

|

LPLT and HPHT (T: 158, 194, 230 °F; P: 1450 psi) |

CuO and ZnO NPs were used in the experiments. Both WBF samples have NPs less than 50 nm at concentration of 0.1, 0.3 and 0.5 wt%. The results showed that fluid loss and filter cake thickness decreased significantly under LPLT and HPHT (T: 158, 194, 230 °F; P: 1450 psi) conditions. Overall, at the same concentration ZnO NPs showed a better result |

| Yusof and Hanafi (2015) | SiO2 | Synthetic |

|

HPHT (275, 351, 450 °F) | 40 wt% of silica (SiO2) NPs with 10–20 nm diameter in synthetic-based fluids (SBFs) showed significant reduction of fluid loss and filter cake thickness under HPHT (275, 351, 450 °F) conditions. |

| Zakaria et al. (2012) | Not specified | Oil |

|

LPLT | 0.74 wt% of NPs with 20–40 nm diameter in OBFs reduced filtration loss up to70% under LPLT condition. |

| Zhang et al. (2015) | Not specified | Oil |

|

LPLT and HPHT (194 °F) | 2.0 wt% of NPs in OBFs effectively significantly reduced fluid loss and filter cake thickness under HPHT condition at 194 °F. |

Table 3. Summary of the recent studies evaluating the application of nanoparticles to improve heat transfer properties of drilling fluids.

| Author |

Types of NPs |

Base Fluid |

Experimental Conditions |

Summary of Results |

|---|---|---|---|---|

| Srivatsa and Ziaja (2012) | SiO2 | Water | LPLT | Silica based NPs were mixed with surfactant in WBF system. The results showed that, at 392 °F and 1000 psi, surfactant stability was better when mixed with silica NPs compared to samples without NPs. |

| Abdo and Haneef (2013) | Palygorskite | Water | HPHT at 100–392 °F and 100–16,000 psi | The results on palygorskite NPs showed that the WBF had perfect stability at temperatures up to 392 °F and pressure up to 16,000 psi |

| William et al. (2014) |

|

Water |

LPLT and HPHT (T: 158, 194, 230 °F; P: 1450 psi) |

WBF samples of copper and zinc based NPs showed an increase of up to 53% and 23% in thermal conductivity respectively, with copper having a larger increase in thermal conductivity. The results also showed that using particles at nano level provides superior thermal conductivity than using the particles at micro |

| Barry et al. (2015) | Fe2O3 | Water | LPLT and HPHT | The study tested the filtration and filter cakes at HPHT conditions, 1015 psi and 392 °F, of WBFs. Iron based NPs performed better at HPHT than they did at ambient condition and decreased the filtration. |

| Fazelabdolabadi et al. (2015) | Carbon nanotubes | Water based and oil based | LPLT | 1.0 vol% of carbon nanotubes with 15 nm diameter and 20 nm length in WBFs increased thermal conductivity of drilling fluids |

| Hassani et al. (2016) |

|

Water | Temperature: 40 °C | Some WBF samples were prepared, each containing silica (SiO2), carbon nanotubes (CNT), and zinc oxide (ZnO) NPs. The results showed a 16.9% improvement in thermal conductivity at 2 wt% of sample containing silica NPs. CNT additive on WBF had a 12% increase in thermal conductivity at 2 wt% which is less than the results of silica and zinc at the same concentration, 16.9% and 22%, respectively |

| Needaa et al. (2016) | Sepiolite | Water | LPLT and HPHT (122-356 °F and 500–6000 psi) | The study reported WBF samples containing 1.4 wt% of sepiolite NPs which successfully stabilised the rheological properties up to pressures as high as 6000 psi and temperatures up to 356 °F |

| Mahmoud et al. (2016) |

|

Water | HPHT | The results showed that aging silica (SiO2)-containing WBF to 350 °F and 500 psi had a negative effect and gave a severe gel strength loss of the fluid. When testing iron oxide (Fe2O3) NPs the results displayed that fluid viscosity and yield stress stabilised with the addition of iron NPs at high temperatures up to 200 °F and minor changes to the fluids rheological properties when aged at 350 °F for 16 h. Improvement in filtration properties were also obtained at HPHT condition. The optimum concentration was 0.5 wt%. |

| Halali et al. (2016) | Carbon nanotubes | Water | LPLT and HPHT (248, 302, 347, 392 °F) | CNT NPs were used in WBFs in concentrations up to 0.8 wt% at temperatures 248, 302, 347, and 392 °F. The results indicated that thermal conductivity was enhance by up to 12%. |

| Aftab et al. (2016) | ZnO | Water | LPLT and HPHT (149 and 250 °F) | Zinc oxide (ZnO) NPs were used in WBF at HPHT (65 and 121 °C) conditions for the fluids filtration properties. Filtration reduced slightly at 121 °C, 500 psi, as the concentration of zinc increased from 0 g up to 1 g in a sample of 350 cc of drilling fluid from about 13.5 ml to around 10.5 ml. |

| Krishnan et al. (2016) | Boron | Water | HPHT | The study tested boron NPs in WBFs and showed that, at HPHT (302 °F and 500 psi) condition, the samples could withstand higher temperatures and prevent early breakdown of the polymers in the WBF. A field trial indicated that 2 wt% concentration could go up to 349 °F with no noticeable degradation of the fluid system |

Table 4. Summary of the recent studies evaluating the application of nanoparticles to reduce friction during drilling operations.

| Author |

Types of NPs |

Based Fluid |

Experimental Conditions |

Summary of Results |

|---|---|---|---|---|

| Aftab et al. (2016) | ZnO | Water | LPLT and HPHT (149 and 250 °F) | 1.0 gr of zinc oxide (ZnO) NPs in WBFs slightly increased fluid rheological properties and reduced filtrate loss and friction coefficient under HPHT conditions. |

| Javeri et al. (2011) | Graphene | Water | LPLT and high temperature (120 and 351 °F) | 3.0 wt% of silica NPs in WBFs successfully reduced loss circulation and differential sticking problems resulted from friction reduction LPLT |

| Mao et al., 2015a, Mao et al., 2015b | SiO2 | Water | LPLT and high temperature (392, 410, 428, 446 °F) | 0.5 wt% of silica (SiO2) NPs in WBFs reduced the friction coefficient as high as 93.4%. |

| Srivatsa and Ziaja (2012) | SiO2 | Water | LPLT | The study concluded that silica (SiO2) NPs in a surfactant based fluid benefits horizontal and directional drilling resulted from the low solid content and the ability to form a thin, impermeable filter cake that can reduced friction between the drilstring and the borehole surface. |

| Taha and Lee (2015) | Graphene | Water | LPLT and high temperature (120 and 351 °F) | 5.0 wt% of nano-graphene containing lubricant improved lubricity of the drilling fluids. It also showed a torque reduction of 80% at 199 °C conditions and as high as 50% at 351 °F. |

| Taraghikhah et al. (2015) | SiO2 | Water | High temperature at 250 °F | 1.0 wt% of silica (SiO2) NPs in WBFs reduced friction coefficient significantly from 0.37 to 0.11, and showed mud cake friction factor reduction as the concentration of silica NPs increase |

Table 5. Summary of the recent studies evaluating the application of nanoparticles to improve heat transfer rate properties of drilling fluids.

| Author | Types of NPs |

Base Fluid |

Experimental Conditions |

Summary of Results |

|---|---|---|---|---|

| Aftab et al. (2016) | ZnO | Water | LPLT and HPHT (149 and 250 °F) | 1.0 gr of zinc oxide (ZnO) NPs in WBF slightly increased fluid rheological properties and reduced filtrate loss under HPHT conditions. The fluid formulation was also able to prevent swelling of shale minerals. |

| Akhtarmanesh et al. (2013) | SiO2 | Water | Not specified | 30 wt% of silica NPs with 35 nm diameter in WBFs showed an inhibitive behaviour towards shale minerals indicated from the reduction of mud filtrate observed through the pore plugging test. |

| Cai et al. (2012) | SiO2 | Water | LPLT | 10 wt% of silica NPs in WBFs reduced filtrate invasion and improve the ability of plugging and sealing micro-pores and micro-fracks of the shale formations. |

| Jain et al., 2015, Jain and Mahto, 2015 |

|

Water | High temperature up to 203 °F | The study tested composite of polyacrylamide-grafted-polyethylene glycol and silica nanoparticles. 0.7 wt% of the composite with 20–30 nm diameter in WBF showed a stable rheological profile at 203 °F and exhibit a high inhibition towards clay minerals which can prevent swelling of shale formations during drilling process. |

| Liu et al. (2015) |

|

Water | LPLT and HPHT | The study suggested that novel latex and aluminium complexes with 80–345 nm diameter for WBFs is a potential shale stabilizers that can reduce pressure transmission and improved membrane efficiency to have superior shale stability due to bridging and sealing micro and nano scale pore throats. |

| Østergaard et al. (2000) | SiO2 | Water | Not specified | The study used water based drilling fluid enhanced by silica NPs to improve inhibition of shale materials as compared to a synthetic based mud which is commonly used for when wellbore stability is of importance. Testing 3.0 wt% of silica produced a permeability reduction greater than the water based mud without silica of 20.1% showing its ability at plugging and sealing micro-pores and micro-fracks. |

| Taraghikhah et al. (2015) | SiO2 | Water | High temperature at 121 °C | Study on silica NPs in WBFs to improve shale inhibition found that the optimum concentration is 1.0 wt% compared with other shale inhibitors by preventing the shale from swelling. |

| Zhang et al. (2015) |

Not specified |

Oil | LPLT and HPHT (194 °F) | 2.0 wt% of NPs in OBFs effectively improved shale stability by plugging and sealing micro-pores and micro-fracks. Significant reduction was also obtained on fluid loss and filter cake thickness under HPHT condition. |

2. Modification of rheological properties

The rheology of drilling fluids should exhibit shear thinning characteristics to have less resistance at high shear rates. At low shear rates, (for instance when mud circulation is being stopped) the viscosity should be high enough to prevent transported cuttings from falling back downhole in the wellbore based on Stokes' Law. Apparent viscosity (AV); which is defined as the ratio of stress to rate of strain of liquid, plastic viscosity (PV); the resistance to flow of fluid, yield point (YP); the minimum shear stress required in order to move the fluid, and gel strength at 10 s and 10 min to measure the fluid capability to act like a gel and suspend cuttings and weighting materials when circulation is ceased, are the rheological properties investigated in this study. One of the common models for the rheology of drilling fluid is the Herschel-Buckley model (Eq (1)),(1)where τ is the shear stress (lb/100 ft2), τ0 is the yield point (lb/100 ft2), K is the consistency index, γ is the shear rate (s−1), and n is the flow behaviour index(dimensionless) that needs to be less than 1 for shear thinning fluids.

Nanoparticles can enhance the rheological properties of drilling fluids using various mechanisms which mostly depend on continuous phase of drilling fluids and nanoparticle characteristics. Silica nanoparticles can typically enhance the apparent viscosity of water as the continuous phase of drilling fluids (Mao et al., 2015a, Mao et al., 2015b, Sharma et al., 2012, Taraghikhah et al., 2015) or displacing fluids in enhanced oil recovery processes (Chegenizadeh et al., 2016, Rafati et al., 2016). It has been well established that the viscosity of nanofluids is much higher than the viscosity of conventional dispersions at the same volume concentration of dispersed particles. As viscosity is defined as internal friction between two layers of a fluid under shear stress, once nanoparticles are dispersed in the fluid there is a possibility of increasing friction between layers of the fluid, which results in an increase in viscosity of nanofluid (Sundar et al., 2013, Sharma et al., 2016). This enhancement in viscosity of nanofluids can be estimated through homogeneous solid–fluid interaction models. The available theoretical formulas for the estimation of viscosity of nanofluids have been developed initially from the Einstein model (Einstein, 1906), which is based on the assumption that the fluid contains suspensions of spherical shapes. However, his model was developed based on the simple assumptions and only worked at low concentrations of small nanoparticles. Later, modified models by other investigators have been introduced (Batchelor, 1977, Brinkman, 1952, Godson et al., 2010, Nguyen et al., 2007, Rea et al., 2009) that could be used for larger nanoparticles at higher concentrations, pressure and temperature. In addition, it has been found that the effective viscosity of nanofluids depends not only on the concentration of nanoparticles, but also on their sizes. This results have been confirmed through both molecular dynamics simulations of hard-sphere potential (Rudyak et al., 2008, Rudyak et al., 2009) and experimental studies (Rudyak, 2013, Timofeeva et al., 2010). It should be noted that in designing drilling fluids, different additives can be used to increase the rheological properties into an acceptable and desirable range required for hole cleaning, lubricating and cooling downhole equipment among others. However, these properties may not exceed beyond specific levels, inappropriate increase of properties may have negative effects during fluid circulation in the wellbore such as excessive frictions and weight that impose higher capacity pumps, and sand/cutting removal issues. Therefore, the aim of using nanoparticles is to attain desirable properties with lower cost and improved efficiencies.

Silica nanoparticles can also improve the rheological stability of emulsion based and invert emulsion based drilling fluids as they have a large free energy of adsorption and can attach to the oil-water interface depending on their degree of hydrophobicity (Agarwal et al., 2011, Ghosn et al., 2017). Metal NPs can also improve the rheological stability of drilling fluids due to their high thermal conductivities that can dissipate heat efficiently because of Brownian motion (Einstein, 1956). Therefore, fluid is less affected by the temperature increase and keeps its liquid form, rather than degrading into a solid form. Results from several studies demonstrated that nanofluids have higher thermal conductivities compared to base fluids (Liu et al., 2005, Ding et al., 2006, Aybar et al., 2015). Different investigations on thermal conductivity of nanofluids showed enhancements from 12.4% to 80% can be obtained with carbon nanotubes dispersions in different fluids (Smith et al., 2017). Table 1 lists most of the recent studies on modification of rheological properties of drilling fluids by addition of nanoparticles.

Amanullah et al. (2011) investigated the effect of nanomaterials on several WBFs. They used a number of commercial nanomaterials to overcome challenges associated with conventional drilling fluids. Fluids were prepared with concentration of 0.14 wt% NPs and compared with a base sample. Their results showed no significant changes to the viscosity profile, however superior gelling properties were observed.

Agarwal et al. (2011) used clay and silica nanoparticles to stabilise invert emulsion drilling fluids at HTHP conditions. They found that nanoclay and nanosilica can individually or as a mixture stabilise the invert emulsion drilling fluids. They also indicated that the rheological properties of invert emulsion drilling fluids are functions of nanoparticle's wettability (hydrophobicity). Their results showed addition of barite reduces yield stress but it can be regained by increasing the concentration of silica nanoparticles. They also found that stable invert emulsion drilling fluids can be obtained using organically modified nanoclay and hydrophobic nanosilica. Their analysis of gel strength showed that relatively hydrophilic/hydrophobic nanosilica particles that are dispersed in water, and nanoclay particles that are dispersed in oil phase have significant effect on gel strength capacity.

Sharma et al. (2012) was the first to test a silica based NPs with an average particles diameter of 20 nm as an additive to drilling fluids. They analysed the effects of silica on rheological properties, and found that gel strength and YP were significantly decreased at concentration of 1 wt%, while there was a slight decrease at concentration of 3 wt%. Srivatsa and Ziaja (2012) also showed that the addition of silica increased the drilling fluid viscosity, with one sample achieving 30% increase in viscosity compared to the base drilling fluid. This is consistent with the recent work of Mao et al. (2015b) who also concluded that addition of NPs into drilling fluids cause an increase in viscosity. Taraghikhah et al. (2015) demonstrated similar results for the use of silica with concentrations up to 1 wt%, and Hassani et al. (2016) tested silica NPs, and a hybrid NPs consisting of carbon nanotubes and silica. Hassani and his co-workers showed that both types of NPs can increase the effective viscosity of the drilling fluids significantly, with silica NPs showed a superior behaviour compared to the hybrid NPs. Salih et al. (2016) found that the properties of WBFs containing nanosilica are comparable to the higher performance and stability associated with OBFs. Needaa et al. (2016) tested sepiolite NPs, which contains silica, and showed that there was an increase in PV and YP when compared to a base drilling fluid sample. It can therefore be concluded that enhanced drilling fluid rheologies are common trends amongst WBFs with the addition of silica NPs.

Abdo and Haneef (2013), tested a WBF with a low concentration of Palygorskite(Pal) with particle size between 10 and 20 nm. The samples with low concentrations of Pal displayed significant improvement in rheological properties including a 200% increase in gelling characteristics. And it was noted that all the fluids displayed shear thinning properties.

Abdo and Haneef (2013) tested bentonite with particle size between 4 and 9 nm, as an additive to WBFs and compared the results with API bentonite properties and a sample with local bentonite not at nanosize. The overall rheological properties such as AV, PV and YP decreased due to the addition of bentonite with nanosize diameter, as the solid content of the fluid was decreased.

Kosynkin et al. (2011) were the first who tested carbon-based NPs (graphene oxide) as a filtration additive in water-based drilling fluids at concentrations as low as 0.2 wt% with xanthan gum. Their experimental results showed that a combination of large-flake and powdered graphene oxide in a ratio of 3:1 can provide the best filtration results, having an average fluid loss of 6.1 mL over 30 min and leaving a filter cake of about 20 μm thick. This was promising compared to a standard suspension of clays and polymers that are used in the oil industry which showed an average fluid loss of 7.2 mL and a filter cake of 280 μm thick.

Later in 2013, Nasser et al. also tested the rheological properties of carbon-based NPs (graphite) in WBFs. They showed for NPs with the size of 40 nm, the drilling fluid viscosity was increased, and as temperature and shear rate increase, the viscosity decreases. In 2014, Ismail et al. examined the use of multi-walled carbon nanotubes (MWCNT) in drilling fluids. They found that adding low concentrations of MWCNT with the size of 30 nm, at normal temperature made no significant difference in the rheological properties compared to the base sample. However, in ester-based drilling fluids, gel strength and emulsion stability slightly were increased with addition of MWCNT. Later, Taha and Lee (2015) examined the use of carbon-based NPs graphene in WBFs, and similarly their observations showed improved rheological properties of drilling fluids.

Madkour et al. (2016) tested the use of MWCNT based biodegradable composites in oil based drilling fluids, and showed a significant increase (in some cases up to double) in AV, PV and YP as well as gel strengths over the commercial viscosifier that is used as a comparison, and found that the fluid followed the Herschel-Buckley model. Overall, carbon based NPs have been demonstrated to be effective rheological modifiers at HPHT (High Pressure, High Temperature) conditions, and provide stable drilling fluids (Liu et al., 2005, Ding et al., 2006, Farbod et al., 2015). Mahto and Jain (2013) is, so far, the only study have tested the rheological properties of WBFs with the addition of fly ash NPs. Fly ash is small dark flecks and is composed of silica, alumina, magnetite and other components, and is produced from the burning of powdered coal. Fly ash is currently the world's fifth largest raw material resource, with India producing up to 130 Mt of fly ash per year. Fly ash NPs with the size between 1 and 100 nm, were added in concentrations of 1, 2 and 3 wt% and resulted in a stable rheology without any major changes in AV, PV, YP or gel strengths.

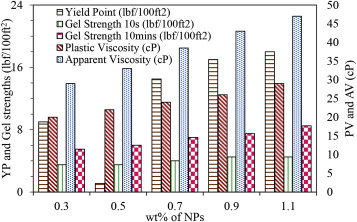

Sadeghalvaad and Sabbaghi (2015) tested a mixture of TiO2/polyacrylamide NPs with size between 10 and 15 nm and observed increases in rheological properties. Jain et al. (2015) used polyacrylamide-grafted-polyethylene glycol/silica nanocomposites, and their results showed an increase in rheological properties for NPs with the size between 20 and 30 nm, with increasing concentration from 0.3 to 1.1 wt% as shown in Fig. 1.