1. Introduction

In recent years, global awareness has prompted humanity to take action to preserve nature against various threats. These threats include air pollution, which contributes to global warming, water pollution, and the depletion of natural resources. As a result, many individuals are advocating for a different type of development and behavior through various laws that aim to increase the effectiveness of alternative fuels. This movement has led to the emergence of the concept of sustainable development [[1], [2], [3]].

Sustainable development is a widely recognized concept internationally, even though there is a lack of consensus on the means and methods of its development [4]. The concept emphasizes the need to consider both the current and future generations when making decisions. Eco-materials have been defined as a set of materials that should help reduce the environmental impact of human activities, and many researchers are working within this framework to develop eco-friendly materials that can play a leading role in promoting sustainable development [5,6].

The concept of eco-materials encompasses a wide range of materials, including both traditional and innovative options and their various uses. Developing and utilizing eco-materials is essential to achieving sustainable development and reducing the impact of human activities on the environment.

Composites, due to their advantageous mechanical characteristics and light weight, are continually evolving towards products that are the most efficient and least expensive possible. They are widely used in various industries, such as the automobile, aeronautics, marine, and sporting goods sectors, among others [7,8]. To promote environmental protection and public health, composites are now being designed with an ecological character to reduce the use of materials made from fossil resources. The reduction of global warming gases also requires lighter materials and lower carbon emissions.

As a result, there has been a shift towards using “environmentally friendly” and lighter materials, such as biocomposites, replacing conventional composite materials. Researchers focus on composite materials reinforced with natural fibers, as these composites combine good mechanical properties with low density [[9], [10], [11]]. These compounds offer several advantages, such as cost, availability of renewable natural resources, and biodegradability [12]. Moreover, many of these composites based on natural fibers exhibit mechanical properties suitable for technical fields [13]. The use of plant fibers as reinforcement of composite materials is increasing in various sectors of activity, like the automotive industry, where textiles have been used for years to reinforce the plastics used in cars, as they offer excellent insulation and are based on cellulose [14,15].

The use of natural plant fibers as reinforcement in polymer materials has limitations due to certain drawbacks, such as water absorption [16]. Plant fibers consist of lignocellulose, which contains hydroxyl groups, making them hydrophilic and unsuitable for use with hydrophobic thermoplastics such as polyolefins, resulting in poor moisture resistance. Furthermore, natural fibers can exhibit low dimensional stability, non-reproducible physical properties, and challenging processing methods that can lead to suboptimal final properties [[17], [18], [19]].

The main limitation of using natural fibers as reinforcement is the lack of compatibility between fibers and the matrix. Natural fibers' polar and hydrophilic properties are not compatible with the non-polar properties of most commercial polymers, such as unsaturated polyester [20]. When subjected to external stresses, composite materials undergo various types of degradation, leading to reduced mechanical properties. The degradation mechanisms are influenced by factors such as the tensile strength of the fibers, the matrix's energy absorption ability, the fiber-matrix interfacial properties, the volume fraction of fibers, and the applied mechanical stress conditions. Therefore, modifying the fibers' surface is crucial to improve their adherence to the matrix and reduce moisture absorption [21]. It has been demonstrated that appropriate physical or chemical treatments applied to the fibers can increase their compatibility with the polymer, enhancing the performance of the composites [22]. Several techniques, including alkaline, silane, and chemical treatments, have been utilized to increase the fibers' compatibility with the matrix. While composite materials reinforced with natural fibers are still in development and have limited applications, they are expected to play a crucial role in future industries, especially in construction [15].

The main objectives of this study are to provide an overview of natural fibers, their physical characteristics, chemical composition, and mechanical properties. It also explores the compatibility of natural fibers with different matrix, including thermoplastics, thermosets, ceramic resins, biodegradable polymers, bioplastics, and polymers derived from fossil resources. Furthermore, the performance and potential applications of natural fiber composites will be discussed in detail.

To better understand the bonding between natural fibers and matrix, the section on fibers/matrix bonding explores various chemical and physical treatments used to enhance adhesion. Chemical treatments such as alkaline treatment with soda, enzymatic treatment, acetylation treatment, and permanganate treatment are discussed, along with physical treatment methods like heat treatment drying, electric shock, addition of coupling agents and silane treatment. Additionally, the impact of fiber surface treatment and the type of fiber reinforcement on the mechanical properties of composites are explored. The effects of hygrothermal conditions on these materials are also addressed. Finally, a comparison between natural and synthetic fiber composites is presented by highlighting the differences in their properties. The potential applications of natural fiber composites, such as in the automobile industry, construction applications, and biomedical applications are discussed by showcasing their versatility and promising future.

By understanding the characteristics and properties of natural fiber composites, researchers, engineers, and industries can make informed decisions regarding material selection and design, promoting sustainable, and environmentally friendly solutions.

2. Natural fibers

Synthetic-reinforced composite materials, such as aramid, carbon, and glass fibers, have numerous applications in various fields, including automobile, construction, and aeronautics [23]. Among these materials, glass fibers are the most popular due to their unique mechanical properties and low production cost. However, using synthetic fibers can harm human health and the environment, causing issues such as skin allergies and lung cancer [24].

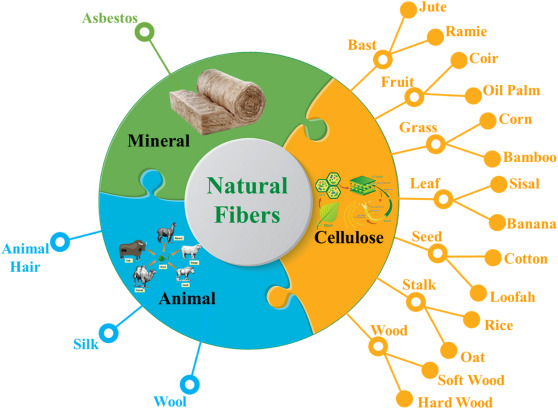

As a solution to these issues, environmentally responsible materials such as natural fibers are gaining popularity in the composites industry [25,26]. Natural fibers can come from various sources, including plants (such as linen, hemp, jute, and cotton), animals (like wool and silk), and minerals (such as asbestos) [27]. However, some types of natural fibers have been banned in many countries due to health concerns, such as cancer caused by asbestos [28,29].

Despite these concerns, natural fibers are still widely used in the composites industry, with a variety of types available, including bast (such as flax, jute, ramie, hemp, and kenaf), seed (like cotton, coconut, and kapok), leaf (such as pineapple, abaca, and sisal), grass and reed (like corn, rice, and wheat), kernel (such as hemp, jute, and kenaf), and even roots and wood (Fig. 1) [27,30]. Table 1 shows the most commonly produced and sold natural fibers worldwide.

Fig. 1. Classification of plant fibers according to the origin.

Fig. 1. Classification of plant fibers according to the origin.Table 1. The most commercially natural fibers world production.

| Fiber source |

World Production ( × 103 ton) |

Country | Reference |

|---|---|---|---|

| Sugar can bagasse | 75,000 | India, Brazil, China | [[30], [31], [32], [33], [34], [35], [36], [37], [38]] |

| Bamboo | 30,000 | India, China, Indonesia, Malaysia, Philippines | [[30], [31], [32], [33], [34], [35], [36], [37], [38]] |

| Jute | 2300 | India, China, Bangladesh | [10,[30], [31], [32], [33], [34], [35], [36], [37], [38]] |

| Kenaf | 970 | India, Bangladesh, United States | [[30], [31], [32], [33], [34], [35], [36], [37], [38], [39]] |

| Flax | 830 | Canada, France, Belgium | [[30], [31], [32], [33], [34], [35], [36], [37], [38], [39], [40]] |

| Grass | 700 | [32,33] | |

| Sisal | 378 | Tanzania, Brazil, Kenya | [10,19,[30], [31], [32], [33], [34], [35], [36], [37], [38],41,42] |

| Hemp | 214 | China, France, Philippines | [[35], [36], [37], [38], [39], [40],[43], [44], [45]] |

| Coir | 100 | India, Sri Lanka, Philippines, Malaysia | [[30], [31], [32], [33], [34], [35], [36], [37], [38],[43], [44], [45], [46], [47], [48]] |

| Ramie | 100 | India, China, Brazil, Philippines | [[30], [31], [32], [33], [34], [35], [36], [37], [38],40,42] |

| Abaca | 70 | Philippines, Ecuador, Costa Rica | [[30], [31], [32], [33], [34], [35],41] |

| Oil palm | 40 | Malaysia, Indonesia | [30,31,34,35,49,50] |

| Pineapple | 74 | Philippines, Thailand, Indonesia | [30,31,[34], [35], [36], [37], [38],42] |

| Rice husk | 160,000 | China, India, Indonesia, Malaysia, Bangladesh | [51,52] |

| Rice straw | 579 | China, India, Indonesia, Malaysia, Bangladesh | [[36], [37], [38],43,53] |

| Wood fiber | 1,750,000 | Canada, United States, China | [ [[36], [37], [38], [39],54] |

| Palm date | 4200 | [32,33] |

The primary group of fibers comprises jute, hemp, kenaf, and sisal, which are predominantly cultivated for their fiber yield [35]. However, the secondary group consists of pineapple, oil palm, and coir, which are utilized as by-products [25]. Bast fibers can be obtained from the outer layer of plant stems through a process called retting, where the fibers are separated more easily under the influence of bacteria and moisture [55,56]. The fiber can also be extracted from the plant leaves either by hand-scraping or through mechanical extraction [57].

The fibers obtained from various sources have different characteristics and can offer unique benefits. Leaf fibers such as sisal, pineapple, and banana are particularly strong and perform better than bast fibers [30,31,45]. Coconut fibers are obtained from the fruit's exterior and shell [58]. Seed fibers, conversely, are produced from the capsules or corn of plants such as cotton and kapok. Stem fibers are obtained from plants such as sugar cane, corn, wheat, rice, and barley straws, which are thick, tough, and low-density [56,57,59]. Grass fibers from tall grasses such as elephant grass and bamboo also offer unique properties. Finally, trees are a source of softwood and hardwood fibers commonly mixed with virgin or recycled fibers as presented in Fig. 2 [34,57].

Fig. 2. Source of different types of natural fibers.

Fig. 2. Source of different types of natural fibers.Extracting natural fibers from their source is a key step in the production of fiber-based composite materials. Different methodologies are used to extract natural fibers, and each has its own advantages and limitations. Here is a detailed explanation of some of these methodologies, along with specific references.

-

•

Decortication method: Decortication is a common method used to extract natural fibers from plants with fibrous stems, such as flax, hemp and jute. It involves removing the outer part of the stem, called the bark, to reveal the inner fibers. Decortication can be done mechanically or chemically, depending on the plant and the processing conditions [60].

-

•

Retting method: Retting is a microbiological treatment method that detaches the plant fibers from the stems. It involves exposing the rods to microorganisms, such as bacteria and fungi, which degrade the pectic matter that holds the fibers together. Retting can be performed in the open air, in water or using specific chemical agents [61].

-

•

Blow molding method: This method is used to extract bamboo fibers. It involves using a screw extruder to heat and soften bamboo fibers, which are then blown through a cooling chamber to form continuous fibers. This method makes it possible to obtain high quality bamboo fibers with good mechanical strength [62].

-

•

Enzymatic method: The extraction of natural fibers can also be achieved by using specific enzymes to break down the non-fibrous components of plants. This method is effective for fibers such as sisal and kenaf, and it achieves high quality fibers with low impurity content [63].

The choice of extraction method will depend on the type of fiber, the end application and the specific constraints of the manufacturing process.

2.1. Types of naturals fibers

2.1.1. Cotton fiber

The cotton plant, known scientifically as Gossypium arboretum and a member of the Malvaceae family, is a small annual shrub that grows up to 1.5 m high. It is primarily cultivated in hot climates in America, Africa, Asia, and Europe (Spain) for its cotton fibers, called linters, originating from the seeds. Cotton linters, which have a length of 2–5 mm and a diameter of 18 μm, are highly valued for their excellent mechanical and physical properties [64,65]. They are often used to make luxury papers and are widely used in the textile industry [66].

2.1.2. Ramie fiber

Ramie is a shrub native to East Asia, belonging to the Urticaceae family and scientifically known as Boehmeria nivea [67,68]. The fibers derived from ramie have an average length of 40–250 mm and an average diameter of 45 μm, making them longer, stronger, and stiffer than flax fibers [56]. In recent years, there have been numerous studies on using ramie fibers as reinforcing elements in composite materials, such as in PP/ramie [69] and PLA/ramie [70,71] composites.

2.1.3. Sisal fiber

Sisal, a perennial plant with large triangular leaves that can grow up to 2 m in length, belongs to the Agavaceae family and has the scientific name Agave sisalana [30,53]. It is native to the tropics and subtropics of North and South America [72]. Each sisal plant has around 200 to 250 leaves containing 1000 to 1200 bundles, with an average length of 3 mm per elementary fiber [34,57]. Sisal is widely cultivated in the West Indies, the far east, and Africa due to its short planting cycle and resemblance to a large pineapple [19,44]. It can also be found growing wild along railroad fields [35,73]. Sisal fibers are used to make mats, twines, ropes, and other products that are commonly used in marine and agricultural industries. They are also used to reinforce cement matrixes in construction, as well as in the automotive industry and furniture manufacturing [19,30,74]. Consequently, many researchers have focused on developing, characterizing, and improving composites based on sisal fibers, such as PE/sisal [75], polyester/sisal [76], HDPE/sisal [77], and PS/sisal [78].

2.1.4. Alfa fiber

The warm Mediterranean region of North Africa commonly cultivates the “Esparto Grass or Stippa Tenacissima plant,” an alfa fiber source. Alfa can also be found in central and southeastern parts of Spain and the Balearic Islands of Iceland. In addition to making high-quality paper, Esparto is used to manufacture ropes, sneakers, coarse fabrics, rugs, baskets, and more. However, there are few reports on the characteristics of esparto fibers and their use in reinforcing composite materials in the literature [79,80].

2.1.5. Kenaf fiber

The kenaf plant, scientifically known as Hibiscus cannabinus and belonging to the Malvaceae family, originated from the Hibiscus genus. It is commonly used to strengthen composites [30,81]. Kenaf has a rapid growth rate in certain climatic conditions, reaching heights of up to 3 m and a diametric base ranging from 3 to 5 cm in just three months [18,34,55]. Originally from Africa, kenaf is now found in Bangladesh, India, and America [34,39]. The kenaf plant's filament comprises distinct, separate fibers of 2–5 mm in length [18,35,82], while its stem is made up of bark and core. The bark is densely structured with a high arrangement of crystalline fibers and represents 30–40% of the stem's weight [34,82], while the wood makes up the remaining 60–70% [34,82]. The kenaf plant's noyau exhibits an isotropic amorphous pattern [12]. Kenaf fibers have unique mechanical properties, good recyclability, and low-density levels, making them suitable for producing ropes, bags, canvas, and twine [35,55,81].

Currently, kenaf is used as a raw material in the paper, textile, and automobile industries. Its versatility makes it a valuable resource with the potential for further applications.

2.1.6. Diss fiber

“Diss” (Ampélodesmos Mauritanicus, Poaceae family) is a herb widely found in North Africa and dry regions spanning Greece to Spain. Due to its mechanical and hydration qualities [83], it is commonly used to construct traditional houses in these regions. There has been a growing interest in using dissing fiber in composites in recent years, as evidenced by several published reviews [84,85].

2.1.7. Flax fiber

Flax, known scientifically as Linum Usitatissuim, is an annual plant whose stems and seeds are used to produce fiber. The plant can grow to heights of 0.6–1.2 m, with stem diameters ranging from 1 to 3 mm. Flax fiber is highly prized due to its superior quality and yield compared to other available fibers [86]. It is primarily cultivated in moderate regions such as the Mediterranean (Europe and Egypt) and the Indian subcontinent [30,41,42,87].

Flax fiber possesses several advantages, including its long length (averaging 33 mm), good mechanical properties, low density, high toughness, and strength [35,58,88]. Flax fiber is highly versatile, with tensile and compressive strengthsof 1500 and 1200 MPa, respectively [85,86]. It is commonly used in clothing, composites, and cigarette papers [89]. Additionally, flax fibers are utilized in the automotive industry for reinforcement, specifically in the production and development of hidden interior parts like door panels, rear seat shells, rear shelves, dashboards, etc., as well as structural components such as floors and parts under the hood, such as degassing box plugs [[90], [91], [92], [93]]. Furthermore, research has focused on using linen as a reinforcement for polymer matrix [94].

2.1.8. Hemp fiber

Hemp is an annual plant from the cannabis family, belonging to the bast fiber category. The cultivated species is Cannabis sativa L., which has two distinct categories: Cannabis sativa L. var. Vulgaris (also known as fiber hemp) is found in moderate regions, while Cannabis sativa L. var. Indicia (or drug hemp) is located in tropical regions [34,35,41]. Hemp fiber is considered to be one of the oldest natural fibers, cultivated for over 12,000 years, and is known for its eco-friendliness. China currently produces about half of the world's industrial hemp, even though it originated from Central Asia [40,72,95]. The plant can grow very quickly, reaching over 3 m in height in as little as three months. However, for seed production, it requires a longer growing period [96].

Studies have shown that hemp fibers gain significant resistance (about 150 MPa) in a growth period ranging from 99 to 109 days, with an optimal duration of approximately 114 days. Without retting, hemp fibers can reach an average of 800 MPa, showing great potential [95]. The long bast fibers, which make up 70% of the hemp stalk, have a higher cellulose content (55–72%) and lower lignin content (2–5%) than other fibers, contributing to their high-strength mechanical properties and water resistance [35,55,58]. Hemp fibers have been widely used in the textile and paper industries, as well as in the automotive and rigging sectors [34,40,42,87].

2.1.9. Jute fiber

Jute is a tropical plant from the Tiliaceae family, scientifically known as Corchorus Capsularis. It is mainly produced in countries such as India, China, and Bangladesh, making it one of the most affordable natural fibers [30,39,41]. The stem has a diameter of about 3 cm and can grow to a height between 4 and 6 m [15]. Jute production ranges from 2.3 to 2.8 million tons, and its fibers remain stable even at high temperatures of up to 200 °C [87]. Jute fibers are biodegradable and can withstand humid environments. India accounts for 60% of the world's production, with Bangladesh producing almost all the rest [97].

Jute fiber is used as reinforcement in composites, and it has various applications such as packaging bags, ropes, yarns, and wall decorations [44]. Additionally, it is used in the manufacturing of furniture, water pipes, and transportation applications such as in the doors and roof panels of automobiles [72]. Jute can be combined with polypropylene (PP) [98], polyester [99], and polylactic acid (PLA) [100,101] to form composite materials.

2.1.10. Abaca fiber

Abaca, also known as banana fiber, is derived from the Musaceae family's banana tree, one of the oldest cultivated plants [72,95]. Abaca is primarily grown in Southeast Asian countries such as the Philippines but is also commercially cultivated in other tropical and subtropical regions such as Ecuador and Costa Rica, with an annual crop of 70 million metric tons [34,72,95]. Of the 300 species of banana plants, only 20 are suitable for consumption [42,72,95]. Abaca fiber is commonly used in the production of ropes, twines, and mats [30,35], and it is also used to produce floor panels in automotive manufacturing [39,102,103].

2.1.11. Wood fiber

Wood is a natural fiber widely used in the manufactablturing of pulp and paper products [45]. There are two main types of wood fibers: hardwood and softwood. Hardwood fibers are obtained from deciduous trees, such as aspen and birch, that shed their leaves annually. Softwood fibers, on the other hand, are mainly obtained from conifers, such as pine and spruce, that do not shed their leaves. Softwoods like pine and spruce usually grow faster than hardwoods. While hardwood is thicker and has a more complex cellular structure than softwood, softwood is typically preferred for composite applications due to its larger aspect ratio [34,104,105].

2.1.12. Nanocellulose

Nanocellulose is a material based on natural fibers of nanometric size. It is mainly extracted from cellulose, which is the main structural component of plant cell walls. Nanocellulose comes in different forms, including nanocrystalline cellulose (NCC), amorphous nanocellulose (NCA), and nanofibril cellulose (NFC). Each shape has unique properties that make them suitable for different applications.

One of the main characteristics of nanocellulose is its high mechanical resistance. Despite their small size, nanocellulose fibers have exceptional strength, making them suitable for reinforcing composite materials. When incorporated into a polymer matrix, nanocellulose fibers add strength and stiffness to the material, making it an attractive choice for a variety of structural applications [106]. Nanocellulose fibers have a large specific surface area. This means that they can interact significantly with other materials, such as polymers, metals and nanoparticles. This property provides opportunities for adsorption, liquid retention, catalysis, and other chemical processes [107]. Another advantage of nanocellulose is its lightness. Nanocellulose fibers have a low density, which makes them ideal for manufacturing lightweight materials. This makes them suitable for applications where weight reduction is a key criterion, such as in the aerospace and automotive industries [108].

In terms of applications, nanocellulose is used in many fields. In the composite materials industry, it is incorporated into polymer matrix to improve mechanical properties, such as tensile strength, stiffness, and toughness. In the packaging industry, nanocellulose is used to strengthen packaging films, improve gas and liquid barrier, and extend the shelf life of packaged products. It is also used in coatings to improve abrasion resistance, moisture protection, and antibacterial functionality. In medicine, nanocellulose is being studied for its potential use in biomaterials, such as cell culture media, tissue regenerationmatrix, and drug delivery devices [109].

Due to its exceptional properties, nanocellulose offers many opportunities to develop advanced, sustainable, and environmentally friendly materials. However, there are still challenges to overcome, such as scaling up production, compatibility with other materials, and reducing manufacturing costs. Despite this, the importance of bio/biodegradable polymers cannot be overlooked.

2.2. Physical characteristics of natural fibers

In terms of reinforcement, natural fibers are a viable eco-friendly alternative for both common applications and technical parts [7]. Due to their carbon balance and recyclability, natural fibers offer several advantages, and their inherent characteristics can provide additional properties to composites, particularly in terms of vibration resistance and weight reduction [[13], [110]]. Table 2 outlines the physical properties of various natural fibers.

Table 2. Physical characteristics of bio fibers [10,15,67,68,[111], [112], [113], [114], [115], [116]].

| Fibers | Fiber length (mm) | Fiber diameter (mm) | Thickness of single cell wall (micron) | Width of lumen (micron) |

|---|---|---|---|---|

| Sugar can bagasse | 0.7–2.8 | 10.0–40.0 | 1.4–9.4 | 1.0–19.1 |

| Coconut coir | 0.3–1.0 | 12.0–14.0 | 0.06–8.0 | – |

| Sisal | 0.8–8.0 | 7.0–47.0 | 8.0–25.0 | 8.0–12.0 |

| Pineapple leaves | 3.0–9.0 | 5.9–80.0 | 1.8–8.3 | 2.4–3 |

| Jute | 0.8–6.0 | 5.0–30.0 | 5.2–11.3 | 3.4–7.6 |

| Banana | 0.1–4.2 | 12.0–30.0 | 1.2–1.5 | 13.4–22.4 |

| Areca | 10–60 | 396–476 | ||

| Flax | 10.0–65.0 | 5.0–38.0 | 10.0–20.0 | – |

| Oil palm | 0.6–1.4 | 8.0–25.0 | – | 6.9–9.8 |

| Palm | 150–500 | |||

| Ramie | 30.0–60.4 | 7.0–80.0 | 2.8–3 | 12.8–13.0 |

| Kenaf (bast) | 1.4–11.0 | 4.0–36.0 | 1.6–12.6 | 5.4–11.1 |

| Kenaf (core) | 0.4–1.1 | 0.27–37.0 | 0.5–11.5 | 14.8–22.7 |

| Rice | 0.4–1.2 | 8.0–15.5 | 2.0–5.6 | 1.1–8.7 |

| Bamboo | 2.0–3.0 | 14.0–17.8 | 3.0–9.0 | 3.8–8.6 |

| Cotton | 15.0–56.0 | 10.0–45.0 | 3.6–3.8 | 15.7–16.4 |

| Corn | 0.4–1.4 | 12.1–26.7 | 2.4–6.5 | 2.4–20.1 |

2.3. Chemical composition of natural fibers

Fibers or cells in plants are comprised of two walls: the primary wall and the secondary wall. The primary wall contains hemicellulose, pectins, proteins, and disordered cellulose microfibrils, giving it some flexibility. This wall allows for cell growth while also acting as the fiber's skeleton. In contrast, the secondary wall is much stiffer and is responsible for the fiber's high mechanical properties. It is much thicker than the primary wall and has three parts: the outer wall S1 (100–200 nm), the central wall S2 (0.5–8 nm), and the inner wall S3 (70–100 nm). Like the primary wall, the secondary wall contains the same constituents but is richer in cellulose and also has lignin. It is made up of concentric layers of tightly packed cellulose microfibrils arranged helically with respect to the fiber's axis as modeled in Fig. 3. Each fiber is a multilayer biocomposite in which lignin acts as a matrix coating the structuring element of cellulose, which is very rigid (see Fig. 4). Cellulose chains form basic structures called microfibrils, with diameters ranging from 2 to 20 nm. Each microfibril consists of chains of cellulose crystals connected by amorphous zones [117]. The composition of natural fibers varies according to their botanical origins, climatic conditions, maturity, and method of extraction [118,119] detail is listed in Table 3.

Fig. 3. Microstructure of natural fibers: flax stalk [120].

Fig. 3. Microstructure of natural fibers: flax stalk [120]. Fig. 4. Schematic representation of the structural hierarchy in a plant fiber [121,122].

Fig. 4. Schematic representation of the structural hierarchy in a plant fiber [121,122].Table 3. Chemical characteristics of bio-fibers.

| Fiber | Cellulose (wt%) | Hemicellulose (wt%) | Ligning (wt%) | Micro-fibrillar angle [°] | Reference |

|---|---|---|---|---|---|

| Bamboo | 22.8–56.7 | 17.2–43.8 | 21–31 | [[30], [31], [32],[36], [37], [38],64,[123], [124], [125]] | |

| Canary | 3 7.2–41.7 | 19–22.9 | – | [10,64] | |

| Corn | 41.7 | 46 | 7.4 | [64,126] | |

| Sugar can bagasse | 41.1–55.2 | 16.8–31.8 | 22.3–25.3 | [[30], [31], [32],64,123,124,127] | |

| Jute | 61–71 | 13–20.4 | 5–13 | 8 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,59,64,67,73,82,113,123,124,128] |

| Kenaf | 31–72 | 20–33.9 | 8–21.2 | 2–6.2 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,64,67,68,82,123,124,129] |

| Kudzu | 33 | 11.3 | 14 | [64,130] | |

| Nettle | 79–83.6 | 6.5–12.5 | 3.5–4.4 | [64,131] | |

| Roselle | 70.2 | 7.21 | 14.91 | [64,132] | |

| Flax | 64.1–75 | 10.37–20.6 | 2–5 | 5–10 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,64,67,73,82,88,115,126,128,133] |

| Sisal | 60–78 | 10–38.2 | 8–14 | 10–25 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,59,64,73,74,82,123,124,134,135] |

| Hemp | 68–75 | 15–22.4 | 3.7–10 | 2–6.2 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,64,67,73,82,116,123,124,136] |

| Coir | 32–43 | 0.15–0.25 | 40–45 | 30.45 | [18,[30], [31], [32],[34], [35], [36], [37], [38],41,45,57,59,64,67,68,82,123,124,136] |

| Kapok (fruit) | 35 | 22 | 21.5 | [64,137] | |

| Cotton | 82.7–92 | 0 | [64,65] | ||

| Kapok (seed) | 64 | 13 | 23 | [64,65] | |

| Oil palm | 47.91–65 | 19.06 | 24.45–29 | [[30], [31], [32],64,123,124,138] | |

| Ramie | 61.85–85 | 3–7.58 | 0.5–9.06 | 69–83 | [[30], [31], [32],36,37,64,67,68,123,124,139] |

| Abaca | 56–63 | 20–25 | 7–12.4 | 20–25 | [[30], [31], [32],[34], [35], [36], [37], [38],41,57,64,82,123,124,140] [65,67,114] |

| Pineapple leaf | 70–82 | 18 | 5-12 .7 | [[30], [31], [32],36,37,43,64,123,124] | |

| Henequen | 70–77.6 | 4–20 | 8–13.1 | [64,65,141] | |

| Cuaua | 73.6 | 9.9 | 7.5 | [[30], [31], [32],123,124] | |

| Wheat straw | 33–45 | 15–32 | 12–20 | [32,123] [30,31,43,64,124] | |

| Rice straw | 36–57 | 33 | 8–19 | [[30], [31], [32],[34], [35], [36], [37], [38],41,43,64,123,124] | |

| Rice husk | 35–45 | 19–28 | 20 | [ [[30], [31], [32],[34], [35], [36], [37], [38],41,123,124] | |

| Hard wood | 31–64 | 25–40 | 14–34 | [37,45,95] [36,45,64] | |

| Softwood | 30–60 | 20–30 | 21–37 | [[36], [37], [38],45,64,95] | |

| Banana | 60–65 | 10–24 | 5–10 | 11–12 | [36,37,64,67,116,142] |

| Mesta | 60 | 15 | 10 | [10,36,37] | |

| Sun hemp | 70–78 | 18–19 | 4–5 | [10,36,37] |

2.3.1. Cellulose

Cellulose is a crucial component of the plant cell wall and serves an important structural role in its architecture. It is also the most abundant organic compound in nature and a major constituent of natural fibers. The degree of polymerization in cellulose is about 14,000 in its native state and 2500 after purification as shown in Fig. 5 [143]. It is a natural polysaccharide with a chemical formula of C6H10O5. Cellulose is a semi-crystalline homopolymer that is abundant in plant cell walls, consisting of chains of cellobiose molecules (two d-Anhydroglucopyranose (AGU) linked by covalent β 1 → 4 glycosidic bonds) [143]. The polymer has a high degree of polymerization, close to 10,000 repeat units [144]. Cellulose has many hydroxyl groups along its chain that create hydrogen bonds, resulting in crystalline zones known as crystallites. This unique structure gives cellulose high rigidity and a significant modulus of elasticity [15].

Fig. 5. Molecular structure of cellulose [120].

Fig. 5. Molecular structure of cellulose [120].Hydrogen bonds are responsible for the cohesion between the cellulose fibrils, resulting in the formation of semi-crystalline microfibrils (Fig. 5). The degree of crystallinity depends on the origin of the cellulose. Crystalline cellulose has a high modulus of elasticity, around 136 GPa, larger than fiber glass, around 75 GPa [118]. Cellulose macromolecules are assembled into microfibrils, which make up the fiber [119]. In these structures, the macromolecules are held together by hydrogen bonds. Two types of cellulose are distinguished based on the organization of molecular chains: native cellulose (cellulose I) and regenerated cellulose (cellulose II) [145]. Cellulose II is produced when native cellulose is chemically treated with sodium hydroxide (NaOH) and then dried. The semi-crystalline structure of native cellulose changes and forms other allomorphic structures through chemical treatments [146,147].

2.3.2. Hemicellulose

Hemicelluloses are a group of complex polysaccharides with low molecular weight (DP of 200 to 10,000 for cellulose [144]), which play a crucial role in strengthening the cell wall of natural fibers by interacting with the lignins and cellulose that make them up. Hemicellulose is a heterogeneous branched polymer composed of chains of various sugars. These hydrophilic and adhesive molecules act as a reinforcing matrix between cellulose microfibrils [54,82,105,148]. Hemicelluloses can be made up of different sugars, including d-xylose, d-mannose, d-galactose, d-glucose, l-arabinose, D-4-0-methylglucuronic acid, d-galacturonic acid, and d-glucuronic acid, which are most commonly found in bark plants [149,150]. The chemical structure of hemicellulose monomers is shown in Fig. 6. The presence of a multitude of monomers gives hemicelluloses a branched and disorganized structure, which makes them amorphous and less resistant to hydrolysis. Hemicelluloses can be extracted from plant cell walls using alkaline solutions. Their degree of polymerization is 100 times smaller than that of native cellulose, and they have a helical structurethat gives them some flexibility [151]. Hemicelluloses are soluble in water, which makes them [76]susceptible to Ref. [12] biodegradation, moisture absorption, thermal degradation, and an increase in the degree of flammability of fibers [148,152,153].

Fig. 6. Structure of a type of xyloglucan [120].

Fig. 6. Structure of a type of xyloglucan [120].2.3.3. Lignin and pectins

Lignin, which is the second most abundant renewable organic substance on earth after cellulose, constitutes 15–30% of plant material [154]. Lignins are three-dimensional amorphous phenolic polymers that result from the polymerization of three phenylpropanoid alcohols, namely p-coumaryl, sinapyl, and coniferyl alcohols with short chains (Fig. 7a and b) [151].The density by weight of lignin is about 20,000 monomer units . The density varies depending on the origin of the natural fibers and whether it is the lignin of the walls of the fibers or that of the lamella [155].

Fig. 7. (a) Structure of the proposed lignin with its different types of bonds; (b) primary alcohols (monomers) of lignin [[156], [157], [158]].

Fig. 7. (a) Structure of the proposed lignin with its different types of bonds; (b) primary alcohols (monomers) of lignin [[156], [157], [158]].Lignin provides plants with water resistance due to its hydrophobicity and contributes to the rigidity and hardness of wood and plants. It is highly resistant to biological degradation and creates a morphological barrier against the penetration and growth of pathogens, thereby protecting plants from chemical and bacterial attacks in nature [146,159]. Lignins are present in the secondary wall of natural fibers as well as in other parts of the stem or bark.