1. Introduction

In the petroleum industry, sanding can occur due to rock failure in the process of producing reservoir fluid [1]. This process is typically common in porous sediments [2], and poorly consolidated rocks with low strength [3]. As a result of this phenomenon, hydrocarbon production is adversely affected and can affect oil and gas flow within a reservoir as well as production equipment performance. Over 70 % of petroleum reservoirs in the world are affected by formation sand production [4], with about 20 % of the oilwells permanently shut-in due to significant loss of well productivity [5]. These losses have a significant fiscal effect in the petroleum industry.

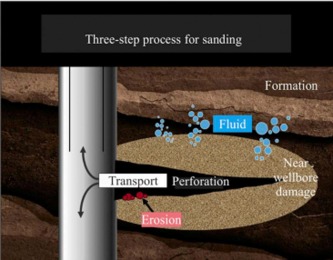

Sanding happens when there is a weakening of the grain bonding materials [6], resulting to a reduction in the rock’s strength or steady degradation [7]. This may be because of mechanical processes or chemical-rock interaction [8], and transport of the grain particles by the reservoir fluid [9]). During well cementation, well drilling, well shut-in and start-up, reservoir treatment, and workover all exert pressure on the formation, and when this pressure surpasses the strength of the rock, the rock will fail [10], [5], therefore leading to sand production and loss in well productivity [11], [12], [13]. The disaggregation of rock grains and consequent transport to the wellbore may be caused by reservoir factors such as reservoir strength, cement-cement bonds, reduced pore pressure, weak cements, and heterogeneity [14], [5]. Fig. 1 shows a graphical presentation of a well producing sand. To predict and describe sanding in weak oil formations, sand production models have been proposed, including geomechanical models, erosional models, and poromechanical models. Analytical models to predict the onset of sanding are developed by considering the borehole pressure which causes the maximum effective tangential CS (compressive stress) to exceed the strength of the rock (failure criteria), also recognized as the critical pressure borehole pressure (CBHP) [15]. It was found that calculating Uniaxial Compressive Strength (UCS) using different correlations revealed that this parameter is necessary for the mechanical earth model since, choosing an inadequate correlation or selecting a correlation without validating the data can cause differences within the interval of producing sand. In contrast, a numerical model discretizes simulated rock into grid blocks, and sanding in the model occurs as discrete jumps, reducing the resolution of the sanding profile. In addition, a numerical model was presented that combines the formations deformation and fluid flow in weak reservoirs for the prediction of volumetric sanding [16]. Using numerical and theoretical models to address sanding as an erosion problem combined with geomechanical -and hydro effects, Wang et al. [17] proposed a numerical model coupled with reservoir-geomechanics. According to this study, sanding is a function of time, stress, and fluid rate. However, sand erosion is strongly interconnected with geomechanics with an intimate connection between sand erosion and the deformation of the rock grain. In 2018, ANN (Artificial Neural Network) was utilized to model and predict sand production due to failure of the formation using synthetic logs obtained to generate values for missing sonic and density data [18].

Fig. 1. Sand production mechanisms [37].

Fig. 1. Sand production mechanisms [37].Increasing reservoir productivity requires the proper management and control of sanding [19]. To correctly ease the negative impact of sanding or the likelihood of sanding, a realistic approach must be given to changes in reservoir fluid characteristics and the rocks stress. This review covers the causes and mechanisms of formation failure, and sand production predictions.

2. Failure mechanisms and causes of rock failure

Sanding in rock formation during production has been investigated in an attempt to explain and predict it [20], [21], [22], [23], [24], [25], [26], [27], [28], [29]. The most common failure mechanisms of rock have been classified by failure mechanisms caused by cohesion, shear, tensile, and compressive or pore collapse [30]. A rock may fail compressively when the volume decreases because of the increase in stress, such as pore collapse. Whereas Cohesion refers to the cohesive force between formation grain, it is a function of the rock's consolidation and cement content. The rock fails tensile criteria when the tensile forces are large enough to overcome the rock's strength. Three main factors contribute to this effect: the regional in-situ stress, tensile strength, and the pore pressure. Sanding which is the degradation of rock due to of stress (e.g., shear, tensile, compressive and cohesive) and fluid flow, is common in the course of hydrocarbons production from weak sandstone formations [31]. It is the stress level that typically causes a rock to fail. There are three stages for the sanding process to develop progressively [32], [33], these include; rock failure around perforated zone from where sand particles are produced, an open hole or disintegration of rock grains from failed rock, and the transportation of the disintegrated rock particles by the fluids inside the wellbore to the surface [4]. Fig. 1 shows a graphical presentation of sand production mechanisms.

To predict sanding onset, it is significant to correctly evaluate the sanding mechanisms which are either due to chemical processes or mechanical failure developments [34], and its contributory parameters [35]. The two key mechanisms that influence the sanding processes are tensile and shear failure. These mechanisms are associated with increased production rates [36]. Tensile and shear stresses are significant conditions which aide rock particle disintegration and failure or sand production. Other mechanisms for sand production include capillary cohesion, water sensitivity of the rock strength, pore pressure gradient and multiphase flow [37]; producing time and fluid viscosity [38]; depletion, seepage, water-cut, erosion and material weakening [39]; triaxial stress conditions [40]; water breakthrough, production rate or changes in the gas–liquid ratio [41], [42]. Also, rock failure due to chemical and rock interface [43], [44].

Chin & Ramos [38] established a model to predict and manage sanding, this model incorporates bean-up in the depletion phase, fluid flow during drawdown and geomechanics. The study demonstrates that in a weak formation, sanding is influenced by oil viscosity, the strength of rock, producing time and flow rate. At the same time, Han & Dusseault [45] stated that the various likely mechanisms for sanding may be categorized as: chemical reaction between solid–fluid-cementing material dissolution might deteriorate the rock; change in capillary force and surface tension lowers cohesive strength; a decrease in the relative permeability with an increased water saturation may develop which may lead to a high pressure gradient; thus, a higher drag force and fluid velocity may weaken the rock; and grains that have been detached from the rock by the fluid and the swell of clay body’s may obstruct pore throat thereby increasing pressure gradient within the vicinity and increasing the weakening force. In another report, Sunday Isehunwa et al. [4] in their attempt to study sand production mechanisms in reservoir formations in the Niger-Delta, identified formation weakening possibly as a result of fatigue effects connected to repeated well shut-ins, loss in cohesion strength in the reservoir due to work-over and completions, fluid losses in drilling as key contributory parameters to sanding. The authors identified the formation failure mechanisms as mostly both cohesive and compressive. The consequences of sanding have become a routine activity more than ever before to analyze rock failure and evaluate reservoir rocks for sand production potential. Papamichos et al. [37]reported the rate of sanding in three sandstone rock samples at varying saturation and fluid flow. The authors credited the possible mechanisms for sanding to the formation strength weakening impact of water, pore pressure gradient in water breakthrough and capillary cohesion in failed zone. The authors noted that the strength weakening impact of water is observed in early sanding initiation stress, water saturation and water breakthrough which led to an increased rate of sanding. Sanding is a phenomenon that occurs in three stages. These stages are initiated by reservoir rock failure, the detachment of the failed rock particles and transport of the rock particles by the flowing fluid. The authors [46], [47] indirectly associated the cyclic influence of start-up and shut-in, formation pressure depletion, operational conditions, and drilling operations to the reasons for rock failure. Therefore, sanding involves numerous factors such as production parameters, drilling operations, formation mechanical properties and rock mineralogy or composition [48]. The development of rock failure and mechanisms for sanding under true triaxial stress to study the influence of stress state and fluid flow have also been reported [40]. A minimum drawdown pressure is required to instigate sanding, irrespective of the boundary stress state (see Fig. 2). Furthermore, it was discovered that the developed failure region in the borehole is dependent on the state of stress.

Fig. 2. Sand production with increasing drawdown [39].

Fig. 2. Sand production with increasing drawdown [39].Lately, Dehghani [35] reported the mechanisms for sanding in a reservoir, the main sanding parameters and evaluated their influence on sand production. The results gotten proves that mechanisms for sand failure and their contributory parameters were identified as sand strength, grain movement, tensile strength, and shear strength with cohesive stress as the main sand failure mechanism. Al-Awad [10] noted an increased sand production after shutting in a well at simulated bottom hole stress-fluid flow conditions in a sandstone reservoir. The modelled bottom-hole stress-state test was set-up to allow the determination of sand movement and fluid flow under modelled in-situ stresses. It was noted that, when a well is shut-in, the pore fluid pressure gets to an initial (maximum) value which results to a reduction in the effective confining stress. Though, repetitive variations in the pore fluid pressure can really impair the cement material that bonds sand particles together, resulting to increasing the quantity of sand produced. As a precedence, saline water may damage sandstone cement bonding material, this may lead to increased quantity of sand grains prepared to flow into the wellbore when related to the light oil situation [34]. The fluid used is not a chemical normally used in oilfields for treatment operations and therefore cannot be inferred since the chemistries would be different. Though, the studies of Kuncoro et al. [49], Aborisade [50], and more lately Ahad et al. [51], recognized factors such as degree of consolidation or cementation, production rate, reduced pore pressure, pressure drawdown, increase in water cut and reservoir fluid viscosity may be the basis for rock failure, detachment and particle transportation.

3. Failure prediction

Oil wells produce sand for a variety of reasons, including fluid flow, geological and geographic influences, rates of production, natural particle association, porosity, and a reduced relative permeability. Sand failure prediction is a significant part of reservoir formation analysis and evaluation [52]. Physical principles can be used to describe fluid flow in a reservoir, such as constitutive and Darcy law, Erosion Law, Equation of state, or conservation of mass law. Various types of mechanical failures exist: tensile failure occurs once the tensile stress exceeds the strength of the formation, while in erosion failure, the hydrodynamic force overcomes frictional resistance, causing sand grains to separate. However, water-induced sand production involves the weakening of the inter-granular cementation of the rock formation (Young’s modulus of saturated rock is about 20–30 % lower than dry rock) and water sweeping the reservoir, breaking through into the producer. It is therefore imperative to evaluate the risk of reservoir rock failure and the possibility for sanding in oil wells. As a consequence, sanding prediction models are being advanced with the capability of knowing the onset of sanding. The prediction of sanding may help to recognize the utmost economical technique of sand management with the desired production rate [53]. This is significant due to the environmental, safety and operational fears associated when produced sand grains fill the pore holes, obstructing the wellbore, wear of downhole and surface equipment’s, thereby increasing the cost of operation. Due to the negative effect, a dependable sand production prediction study therefore offers a foundation for a design that may realize a suitable approach to sand management. Currently, no one method of sanding prediction is generally considered to be precise and consistent in the industry [54]. However, predicting onset of sanding in real time from a production standpoint is important, as it permits timely formation control decisions on methods for sand control.

The approach to sand control as emphasized by Oyeneyin et al. [55], considers sanding risk evaluation through a predictive tool, downhole sand grain, produced amount monitoring and topside management, selection of suitable sand control options,. Although predicting the onset of sand production is crucial to sand control and management, adequate knowledge of sanding mechanisms and failure behavior are necessary to accurately predict the onset of sanding. The failure of rock grain and the subsequent evaluation of sanding can be predicted using a variety of mathematical models. The models which are built on various failure mechanisms [56], may be grouped into numerical models [57], [58], [59] and analytical [60], [61], [62]. The analytical models offer a base for flow rate which is crucial in inducing tensile failure. An analytical model has limitations in its general constraints, which are constrained by boundary conditions, geometry, and complex material behavior. The numerical models, however, are able to overcome many of the limitations of the analytical models [63]. A previous attempt to develop numerical and statistical models involved the analysis of sand strength logs, mechanical properties logs, and cores. Most times, individual efforts to develop a predictive model were definite on the type and location of the formation being studied, i.e., water production, perforation geometry, pressure drawdown caused by skin influence, pore pressure depletion, and variation of other critical parameters were not always measured [64].

Tixier et al. [65] implemented a ratio of shear modulus to bulk compressibilitywhich the authors obtained from acoustic log data as a signal for sand production risk. A ratio which the authors posited if greater than 0.8 × 1012 psi2showed a lower likelihood of sand influx. While values below 0.7 × 1012 psi2 indicated a higher possibility of sand production. This process depended on using collated field data. Nevertheless, it should be noted that if one is modeling the physical processes in engineering, such as predicting the onset of sanding due to rock failure in fluid-rock interfaces, there may be some level of uncertainty in the model input parameters, such as the use of the Mohr failure criterion, which assumes the quality of rock mass to be 100 percent whole and does not consider the different stages of disturbance in terms of rock strength [48]. Weissenburger et al. [66] developed a sanding\prediction system. The developed system synergizes log analysis, reservoir characterization and rock strength test to predict the stability of cavity perforation. In coupling rock strength with a reservoir simulator makes it possible to model stability of the cavity at preliminary stages all through the life of the well. The conditions for failure or stability of an unconsolidated and weakly consolidated rock were investigated by Perkins & Weingarten [67]. By applying confining pressure to the formation, a shear failure round the cavity was induced. As fluid flowed through the cavity at an increased rate, there was a rise in the shear failure zone at the outer boundary, causing grains to disaggregate and the region to dilate. The model collapses, causing a large amount of sand to be produced. Application of a Sand Production Management System (SPMS) to successfully evaluate, predict, resolve, and control sand production problems have been reported in literature [68]. By incorporating a geomechanical model, the SPMS method determines the properties and stress of in situ rocks, and then predicts alterations that may occur as a consequence of formation exhaustion. In the study, the results presented an increased drilling and production performance while minimizing sand production complications. Based on empirical data, Fig. 3 illustrates the finite element simulation of sand production coupled with hydraulic erosion and reservoir matrix mechanical behavior [69]. The developed model defined the empirical data approximately well (Fig. 1). Though, the empirical result obtained shows the borehole diameter of weakly consolidated sandstone increased after erosion for a time and formations with lower strength tend to produce larger volume of sand.

Fig. 3. Simulation and empirical results for sand production [69].

Fig. 3. Simulation and empirical results for sand production [69].The rock erosion criterion applied in the finite-element model is the criterion as proposed by Papamichos [70], which is mathematically stated as:(1)(2)(3)(4)

Given vw pore fluid velocity, c transport concentration, ve is erosion velocity, critical strain ϕ porosity and λ as the sanding coefficient. λ is dependent on the equivalent plastic strain εp.

Additionally, researchers have applied elastoplastic models in sanding analysis [71], [72], [73], [74]. By combining the pore-mechanical behavior of fluid–solid systems with erosion of rock grains caused by fluid flow, Papamichos and colleagues established a sanding prediction model [75]. The model considers the impact of fluid flow and external stress. Though the model accounted for fluid-rock interface, it involves additional input data in addition to the use of oil, which does not exhibit comparable reactivity of oilfield chemicals for fluid-rock interface. A model that captured fluid-rock interaction in addition to a finite-difference method was used to analyze the impact of uniaxial strain conditions on synthetic rocks [76]. Nevertheless, the role of volumetric failure and the fluid-rock interface on formation strength impact was not sufficiently integrated. The sanding prediction model should capture the essential mechanisms of rock failure reactive to fluid and rock interface system. Additionally, Wu et al. [77] performed an empirical investigation of water-cut impact on sanding, in which result showed that sanding depended on the configuration of the rock minerals and the degree of residual water saturation. Depending on the flow velocity, a reactive fluid may carry away sand particles as well as reacting with the reservoir medium. More so, if the stress acting on the consolidated rock is high enough, the formation may collapse as a result of compressive failure, with consequent particles being released into the flowing fluid. With this perspective, Isehunwa & Olanrewaju [78] established an analytical model to predict sanding. the assumptions includes sand particles are spherical and are submerged in a fluid in motion; during flow, sanding will lead to the radius of a cylindrical cavity to increase until an equilibrium is achieved; drag and buoyant forces are continually acting on grains; fluid flow is described by Darcy’s law. The variables flow rate, density, fluid viscosity, and grain size exhibited certain level of impact on sanding rates. Kim & Sharma [79] sand production prediction models for onset and volume of sand that is produced after failure, combined formation failure and flow-driven sand production mechanisms. However, Suez & Subbiah [80] sand prediction model was developed relying on the mechanical earth model (MEM) to measure key properties that govern rock failure and distortion such as internal friction angle, young modulus, poisons ratio, UCS, overburden stress and pore pressure. The results validating the model confirms that when the BHP is below the reservoir pressure, the oilwell will produce sand-free if drawdown pressure is maintained at a precise safe zone.

On the other hand, a technique that combines shear modulus, bulk compressibility, and the ratio of shear modulus to bulk compressibility was adopted by Khamehchi & Reisi [81]. The shear modulus to bulk compressibility ratio was experimentally linked to sand influx. In later investigation by Gholami et al. [82], the authors developed an elliptical model based on the shape of the wellbore to predict sand production in a carbonate formation. The authors presented a shape factor parameter based on various failure criteria to assess variations in the borehole geometry due to shear failure. Furthermore, Gharagheizi, et al. [83] utilized the least square support machine (LSSVM) to find the circumstances in which sanding may arise. The model considers various sand production parameters like transmit time (TT), cohesive strengthof rock (COH), drawdown pressure (DD), bottom hole flow pressure (BHFP), total vertical depth (TVD), gas and water flow rates (Qg, Qw) etc. Li et al. [84]offered a finite element-based method to simulate a precise sanding process. The method considers coupling hydrodynamic erosion and mechanical failure of the rock. The outcome from the numerical analysis showed sand production is influenced principally by flow velocity around the wellbore and plastic strain. Further parameters such as in-situ stress, perforation orientation, and drawdown pressure, were shown to have significant effect on sand production rate. More lately, Abbas, et al. [85] performed a sanding prediction analysis with a combination of quantifiable log data, laboratory data, analytical and empirical calculations that are supported by results from previous advanced numerical codes. The results show that the method was capable of correctly predicting the sanding onset and agrees with field observations and the sanding history. Oluyemi and Oyeneyin [77] used the HOEK and Brown failure criterion in developing a failure model for predicting sanding in real time. The developed model when compared to field data was discovered to have a correlation coefficient of 0.9123. The authors [77] confirm that predictive tools such as INSIM as used in their study can provide very good history matching for field cases. Studies show that fluid-rock interaction process may lead to rock formation failure, and therefore, result in wearying formation grain fabrics as well as its UCS decrease resulting to sand production. Summarized in Table 1are some sand failure prediction models. Using models, one can characterize, predict, qualify, and quantify the amount of sand produced from oil and gas reservoirs.

Table 1. Summary of existing sand failure prediction models.

4. Effect of chemical interaction

There are two components that make up rock strength: friction between grains and cohesion between adjacent grains. As the formation fluids are being produced, sand may also be produced due to sand failure. It occurs when the sand grain and cohesive forces are not strong enough to withstand the induced stresses on the rock formation. Based on mechanical strength, elastic properties, and cementation materials, sandstone formations can be grouped into unconsolidated, poorly consolidated, and consolidated [34]. Sand production may result from the failure of reservoir rocks [84]. Sands can fail due to cohesive, shear, tensile, and pore collapse mechanisms. Various modeling techniques are used to model various failure mechanisms, they comprise of compressive strength /pressure drawdown, failures due to specific failure criteria such as cohesive strength failures, Mohr Coulomb, viscoplastic modeling, empirical correlations, and elastoplastic failures around a perforation [34]. Thus, cohesive strength, tensile strength, Uniaxial Compressive Strength (UCS) are therefore mechanical properties important in characterizing rock/sand formations and sand production. summarily, the sanding process is more likely to occur in rocks with low mechanical properties. On the contrary, as a result of chemical interaction with rock formation, cementation materials (e.g., carbonate, clay, etc.) can deteriorate causing a weakening effect. Hence, rock/sand formations can fail as a result of mechanical or chemical effects.

Typically, sand production comprises two stages, the first being the rock failure that occurs because of stress acting on the rock due to chemical flow interactions. The second stage involves transporting failed sand grains in the fluid. These transported sand grains may be deposited in the reservoir or transported to the surface. During drilling, completion, and stimulation, stress is distributed in the rock near the borehole wall rock. As a result, the rock grains under stress can yield and disassociate. In other words, the rock formation may either yield (weak formation) or respond elastically (strong formation). A shear failure generates small and large solids at the failure plane, and the formation begins to deteriorate, which may be projected by the Mohr-Coulomb failure criterion [84]. The Mohr-Coulomb criterion can also be used to predict critical drawdown pressure due to UCS and shear failure. The geomechanical properties of the rock such as UCS can be altered as a result of chemical interaction during well stimulation process such as chemical enhanced oil recovery (EOR), acidizing, and water flooding. Through chemical-rock interaction, precipitation and dissolution occur, altering the permeability and porosity of reservoir rocks [85]. Therefore, chemical interactions can weaken the cementing materials, causing failure of sand or rock formation. To predict the failure of rock formation and therefore the production of sand. Several mathematical models have been reported in literatures. The following are common mathematical models used to describe and predict the influence of chemical-rock interaction on rock properties:(5)

Critical drawdown model [77] Where Pri and Prc is initial and current reservoir pressure, n is the ratio of changes in critical pressure drawdown with reservoir depletion, poro-elastic constant UCS is uniaxial compressive strength,.(6)(7)

A poro-elasto-plastic, failure and sand erosion models [84] where p is pore pressure, incremental displacement , intrinsic permeability k, fluid viscosity , M and is Biots modulus and coefficient, shear modulus , Lames constant and incremental plastic strain .(8)(9)

Rock weakening and sand production models [84] where mole fraction in gas is , water vapor pressure , friction factor , is friction drag, interstitial velocity phase .

The process of injecting chemical fluid into a reservoir for the purpose of simulating production, or enhanced oil recovery, is also fraught with a number of operational problems, one of which is the precipitation and deposition of inorganic minerals in the reservoir formation and near the wellbore. As a result of chemical-rock interactions in the reservoir, the rock strength and permeability are altered, complicating the chemical injection process. Therefore, predicting the effects of chemical-rock interaction during fluid injections can be done through modeling and numerical simulations, in order to develop preventive measures to avoid rock failure. Similarly, for reducing operational costs, a good reactive fluid flow simulation is essential for predicting and optimizing the impact of chemical injection on reservoir formation rock. Chemical-rock interactions, for example, might result in the precipitation and deposition of minerals, lowering well injectivity and productivity. Researchers have recently become more interested in geochemical software packages, such as PHREEQC, since these packages can simulate a wide variety of chemical reactions in the aqueous phase during reactive fluid flow through a reservoir rock. A combination of geomechanical, petrophysical and analytical methods was used to assess how rock formation interact with scale inhibitors, biocides and corrosion inhibitors oilfield chemicals to determine their effects on reservoir rock strength and failure mechanism [87]. As a result of these oilfield chemicals interactions like precipitation, adsorption, dissolution, and ionic substitution, the Cementous material was weakened and the UCS decreased, resulting in sand failure. The influence of brine–CO2—formation interaction on fracture mechanical properties of reservoir rocks was investigated by Major et al. [89], due to CO2 injection into the subsurface long-term (102–104 years) storage. It was found that carbonate and hematite cement dissolution in Entrada Sandstone by Carbon dioxide-rich brine reduces fracture toughness by around 40 %. Likewise, the precipitation of carbonate mineral cement causes alteration of interconnected fracture networks of the rock. They concluded that the geomechanical properties of the rock and seal rock may be altered as a result of chemical Carbon dioxide–brine–rock interactions. The fracture network observed in the field match those projected by numerical simulations under various fracture mechanical parameters and can therefore, reflect alterations in the fracture mechanical properties caused by brine-CO2- rock interactions [89]. This proves that brine-CO2-rock interactions over geologic time affects the mechanical properties of formation and seal rocks. Additionally, it has been examined and reported in the literature how calcite interacts with CO2-saturated brine when it is in reservoir conditions and validated with geochemical a model, PHREEQC to simulate and evaluate the equilibrium state [90]. This study investigated precipitation and dissolution of minerals to evaluate how they affect formation properties like as porosity. The result from the PHREEQC modelling showed an estimated a reduction in the volume of the mineral by 2.3 %, resulting in increased porosity depending on the concentration of SO42− in the original brine. As a result of the dissolution reaction occurring during chemical-rock interaction, the rock's grain-to-grain bond deteriorated, allowing grains to disintegrate and enter the fluid streams. Sand failure and likely sand production may result from the release of grains and an increase in porosity and decrease in UCS in the rock formation. Conversely, precipitated minerals may fill pore spaces, thereby reducing permeability and porosity, and consequently damage the formation.

Wang et al. [91] used a numerical model of sand production to explore the difference in sanding onset and the quantity of produced sand using different types of fluid and conditions for flow and in-situ stress conditions. Mechanical failure as well as sand erosion caused by fluid flow are sanding criteria considered. It was found that the onset of sanding in gas wells differ from oil wells, as this is noticed at higher compressive stress for gas reservoirs. Experiments have shown that different stress and flow conditions lead to distinct failure patterns and cavity shapes [92]. It is critical to identify the physics of the formation of cavities during sanding so as to precisely predict the onset of sanding and the rate in which sand is be produced. In 2018, Wang and Sharma [92] reported the results of using a poro-elastoplastic, 3D-sanding model for predicting sanding around perforated wellbores within a formation weakly consolidated. It was found that sanding criteria relies on the combination of tensile and shear failure, compressive failure from the Mohr‐Coulomb theory and strain‐ softening/hardening. In the study, the common shear failure mechanisms that resulted in sand failure include dog-ear cavities, spiral-shear-band cavities, and V-shaped cavities. In other words, by using this model, not only can the mechanisms accountable for the various cavity shapes be explained, but also the cavity shape that is formed at a certain condition can also be predicted. Nevertheless, as a result of a pressure pulse, which is also called a “water hammer”, chemical injection wells can be shut in for emergency or operational reasons, and this can affect wellbore integrity, causing sand-face failure and sand production. An investigation by Wang et al. [92] quantified the effects of well shut-ins and water hammer pressure on rock properties, well geometry and sand production using numerical simulation. It was discovered that because of their amplitude, period, and attenuation, water hammer events contribute to the failure of unconsolidated sands near the wellbore.

5. Conclusion

A reservoir rock can be sanded during the production of reservoir fluids when pressure exerted on it exceeds the rock's strength. The negative fiscal inference of sanding in the petroleum industry therefore makes it very significant to manage and control sanding to reestablish reservoir fluid production at an economically tolerable rate. This paper analyzed and reported work done on sanding due to chemical-rock interactions in the oilfield, sand production mechanisms, and prediction. To manage sand production, it is therefore recommended to use a 3D geomechanical model which incorporates well data and integrates in situ flow distribution, chemical-rock interaction, and mineral transport. Chemical effects on sand failures should be evaluated by closely examining the cementing materials. Hence, one way of controlling sanding is selecting chemicals that do not deteriorate the rock formation cementing materials. For instance, clay minerals have a large surface area and are very reactive in nature; they therefore possess a high adsorption capacity for oilfield chemicals. The results prove that oilfield chemical-rock interactions impact geomechanical properties of reservoir rocks, which weakens formation grain fabrics and reduces UCS, resulting in sand failure. This can be attributed to the occurrence of sulfate dissolution, carbonate, Fe-bearing phases, and precipitation of minerals in the rock formation. A decrease in UCS of sandstone was found to occur with increased porosity as a result of dissolution/precipitation caused by chemical-rock formation interactions. Also, chemical-rock interactions cause changes in cementing materials, resulting in disintegrated grains being released into fluid stream, increasing porosity of rock and decreasing UCS, and thus causing the occurrence of sand failure. Therefore, a further investigation of the impact of alterations in the diagenetic composition, volume, and the morphology of detrital particles and pore minerals on mechanical properties of the rock formation due to chemical-rock is needed. Similarly, precipitated minerals may fill the pore space, reducing permeability and porosity, leading to formation damage. As a consequence, for field operators to appropriately evaluate the failure of rock and sanding potential of reservoirs. It is imperative to take into account the mechanical impact of these oilfield chemicals on the reservoir rock.

Declaration of Competing Interest

The authors recognize the Tertiary Education Trust Fund (TetFund) Nigeria, for funding the research study from which this paper originated and declare that they have no other known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

No data was used for the research described in the article.