1. Introduction

Nanotechnology applications have pierced through oil industry in the four general petroleum disciplines: exploration, drilling, production and reservoir. The possibility to produce tailor-made nanomaterials with specific properties is expected to play a leading role in dealing with challenges encountered in different areas of the oil industry (Li et al., 2013). For example, nanoparticlesmay provide sophisticated measuring and imaging tools to improve field characterization techniques in oil exploration (Krishnamoorti, 2006, Pourafshary et al., 2009). Nanosensors compatible with hostile environments in deep wells are being developed for reservoir management (Zhang et al., 2011). Also, there has been a great focus on Enhanced Oil Recovery (EOR) using nanotechnology. Application of nanoparticles such as oxide nanoparticles, polymeric nanoparticles and nanoemulsions have demonstrated improved and cost-effective EOR processes (Del Gaudio et al., 2007, Morales et al., 2003, Zargartalebi et al., 2015). Nanotechnology has also led to the introduction of a new generation of smart fluids for drilling and completion applications. These smart fluids contain nanoparticles and provide advantages like wettabilityalteration, advanced drag reduction and sand consolidation, enhancing the drilling process (Matteo et al., 2012). Among others, nanopalygorskite has been found to deliver stable drilling fluid providing excellent penetration rates, enhanced lubricity, and improved wellbore stability at high temperature high pressure (HTHP) environments (Abdo and Haneef, 2013).

Nanotechnology is being increasingly introduced to improve the well cementing process. Conventional cement-based materials are naturally brittle, display low tensile strength and bulk shrinkage. These features result in poor performance in bottomhole condition and finally, costly repair operations, reduction in production capacity, environmental issues, and in worst case loss of the well (Jimenez et al., 2016). Application of nanotechnology in well cementing is a promising approach to convert conventional cement system into multifunctional, durable system to deal with imposed stressful conditions for entire life of the well. From cement sheath perspective, as hydrocarbon resources are becoming gradually depleted in easy-to-recover environments, hostile downhole conditions are more common (Jimenez et al., 2016). Additionally, thermal and stress cycles created by well events such as hydraulic fracturing, production, completion, steam injection, or remedial treatments during the well's life, poses significant challenges to the cement sheath integrity (Shadravan et al., 2014). Therefore, taking new approaches are required to design a cement system to withstand the potential severe conditions during well's life cycle. In order to enhance cementing process, nanospacer based on nanoemulsion technology has been introduced as a new method for enhancing mud displacement efficiency, resulting in better mud removal, wettability change and better casing/formation adhesion of the cement sheath (Maserati et al., 2010). In addition, nanomaterials have been applied in the oil well cementing industry to accelerate the cement hydration (Pang et al., 2014), improve the mechanical properties of the cement sheath (Mercado et al., 2012, Roddy et al., 2010, Roddy et al., 2013), control fluid loss, reduce the probability of casing collapse, and prevent gas migration (Roddy et al., 2013). In summary, nanotechnology has been applied by the oil well cementing industry to solve problems which cannot be solved by conventional approaches.

There are several reviews of nanotechnology application in construction materials, e.g. (Andersen and Geiker, 2009, Hanus and Harris, 2013, Pacheco-Torgal and Jalali, 2011), in concrete, e.g. (Antonovič et al., 2010, Mukhopadhyay, 2011, Pacheco-Torgal et al., 2013, Sanchez and Sobolev, 2010) and oil industry in general, e.g. (El-Diasty and Ragab, 2013, Esmaeili, 2011, Kong and Ohadi, 2010, Li et al., 2013, Matteo et al., 2012, Ponmani et al., 2013). The present review supplementing these reviews, focuses on the application of nanotechnology for preventing cement sheath failure thereby improving long-term zonal isolation of oil wells. The factors affecting zonal isolation are introduced in Section 2, and the factors compromising long-term zonal isolation are further dealt with in Section 2.1. The required properties of a cement system to provide the desired long-term performance are discussed in Section 3. The impact of nanoadditiveson the tensile properties and the bulk shrinkage of cement systems is reviewed in Section 4 and Section 5, respectively. This review is applicable for oil well cement sheaths in particular and cement-based materials in general.

2. Factors influencing zonal isolation

Primary cementing is the process of placing cement slurry in the annulus between the casing and the formation (Nelson and Guillot, 2006). The principal goal of primary cementing is to provide a complete zonal isolation in the well to ensure safety and prevent environmental problems while the well is operating economically (Hunter et al., 2007). The economic longevity of a producing oil and gas well is directly linked to the quality of the cementing job, and without complete isolation in the wellbore, the well may never reach its full production potential (Nelson and Guillot, 2006).

Numerous factors may contribute to loss of zonal isolation. The physical state of the cement system develops initially from a liquid slurry during placement, through a permeable and weak solid, to an (almost) impermeable solid after hardening (Nelson and Guillot, 2006).

The physical process of gas migration, the most common and most dangerous form of annular flow, is convenient to categorize according to when it happens during the cementing operation. Immediate gas migration (during placement), short-term gas migration, and long-term gas migration are the three major categories of gas migration during the life of the well (Nelson and Guillot, 2006). Immediate gas migration occurs from the start of the cementing job to the end of cement placement. It is essential to control the thickening time and viscosity during placement to preserve the flowability of the slurry and ensure a complete placement of slurry in the annulus. Short-term gas migration can occur anytime between a few minutes to a few days after the end of cement placement. Properties impacting zonal isolation in this period include fluid loss (filtration), free fluid development (bleeding), gel strength development, chemical shrinkage, and permeability (Nelson and Guillot, 2006). The required short-term properties are summarized below (Nelson and Guillot, 2006, Ravi et al., 2002, Shadravan et al., 2014, Williams et al., 2011):

-

•

-

-

Non-settling under static and dynamic condition

-

-

Limited free-fluid (bleeding) (<0.25 vol %)

-

-

-

•

Limited fluid-loss (filtration) (<50 ml/30 min)

-

•

Static gel strength development (time to transition from 48 Pa (100 lbf/100 ft2) or critical static gel strength to 240 Pa (500 lbf/100 ft2) less than 45 min)

-

•

Low permeability

-

•

Limited chemical shrinkage during the transition phase from slurry to final set

Usually, short-term properties have been in focus by industry rather than the long-term properties. However, even when the cement slurry is placed properly and its short-term properties provide adequate zonal isolation, the long-term zonal isolation can be compromised. In general, the required long-term properties of a cement system are:

-

•

Volume stability

-

•

Chemical stability

-

•

Mechanical stability under static/cyclic loads

-

•

Thermal stability under static and cyclic thermal condition

In addition to optimal cement system performance, long-term zonal isolation requires that the drilling and cement placement procedures are done ideally, i.e. proper casing centralization, adequate mud removal, complete cement placement, adequate cement-formation/cement-casing bond, and no cement slurry contamination.

2.1. Factors compromising long-term zonal isolation

In order to identify the origin of factors leading to loss of long-term zonal isolation in cemented oil wells, the causes of problems are analyzed from the time when the cement slurry is placed in the annulus. Initially cement hydration is the main cause of distress inside the cement sheath; later the different well operations affect the stresses in the cement sheath.

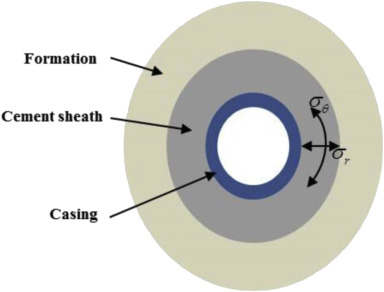

Typical operations during a well's lifetime and the main influencing parameters for each operation are listed in Table 1. When designing the cement system, it is important to consider depth dependent temperature and confining pressure during and after placement (ISO10426-1, 2009) and the temperature and pressure conditions during possible later operations. All loads have a direct influence on the radial, axial and tangential stresses to the cement sheath (Ramos et al., 2009), see Fig. 1. Most of the operations listed in Table 1 can be expressed as cyclic loading with different frequency and amplitude; thus, the cement sheath performance under cyclic loading is critically crucial compared to the case of static loading. In HPHT cyclic loading situations, tensile failure of cement sheath occurs according to the theoretical and preliminary tests (Teodoriu et al., 2013).

Table 1. Possible main operations/events during the life of an oil well after cement placement, after (Hunter et al., 2007).

| Operation/events | Typical time of occurrence after cement placement | Typical duration | Main affected property/load | Range of variation/example value |

|---|---|---|---|---|

| Cement hydration | Start earlier | Months | Autogenous (bulk shrinkage) | Volume reduction: 1–5% (Reddy et al., 2009) |

| Pressure testing | Hours | Hours | Pressure | 50 MPa in a 244 mm, 69.9 kg/m casing results in a strain in the casing-cement interface of 1.25 millistrains (James and Boukhelifa, 2008) |

| Subsequent drilling | Days | Week | Mechanical load (shock wave), pressure, temperature |

Drill string rotating at 100 rpm for 50 h Pressure variation if the mud weight has been changed to drill the next section (Thiercelin et al., 1998) Temperature increase of the cased section when the mud, which has been heated by the formation being drilled, returns to the surface via the annulus (Thiercelin et al., 1998) |

| Well completion | Weeks | Weeks | Pressure, temperature | |

| Perforation | Weeks | Day | Pressure, mechanical load (shock wave) | Pressure increase to values in excess of 40 MPa (Thiercelin et al., 1998) |

| Hydraulic fracturing | Years | Day (x times) | Pressure |

Differential pressure: (7–55) MPa (Shadravan et al., 2014, Williams et al., 2011) Pressure increase is more damaging because the fluid injection lasts from minutes to hours (Thiercelin et al., 1998) |

| Hydrocarbon production | Year | Years | Pressure, temperature |

Depends on production zone depth Pressure and temperature fluctuation mainly concerns the near-surface casing sections (Thiercelin et al., 1998) |

| Fluid injection | Years | Months (x times) | Pressure, temperature |

Steam injection: a temperature increase of 250 °C results in a strain in the cement sheath at the casing interface of 3.25 millistrains (James and Boukhelifa, 2008) Injector well: Max. results in 420 pressure cycles from (0–8) MPa (Pedersen et al., 2006) |

| Formation movement | Decades | Hours | Mechanical load | Dependent on formation creep-characteristics |

Fig. 1. Cross-section through formation, cement sheath and casing. Radial stress , and tangential stress , are indicated, after (Thiercelin et al., 1998).

Fig. 1. Cross-section through formation, cement sheath and casing. Radial stress , and tangential stress , are indicated, after (Thiercelin et al., 1998).The potential failure of cemented oil wells compromising zonal isolation can be divided into three groups: formation-cement debonding (outer microannulus), casing-cement debonding (inner microannulus), and failure of cement sheath itself (Liu and Vipulanandan, 2012). Formation-cement debonding, can be caused by bulk shrinkage, incomplete mud removal, stiffness difference between formation and cement sheath and/or temperature and pressure change inside the casing. Casing-cement debonding can form due to stiffness differences and/or pressure and temperature fluctuation inside the casing. Failure of the cement sheath itself can be due to pressure and temperature fluctuations and bulk shrinkage causing tensile failure; or cyclic loads, formation pressure and formation subsidence and movement, which can lead to shear failure (Liu and Vipulanandan, 2012, Nelson and Guillot, 2006, Teodoriu et al., 2013). In general, cement sheaths fail to perform as designed mainly because of too low tensile properties and volumetric instability (McCulloch et al., 2003, Nelson and Guillot, 2006).

3. Requirements to cement systems to provide long-term zonal isolation

The ability of a cement system to provide long-term zonal isolation depends on the mechanical properties of the cement sheath, the formation, geometry of the cased wellbore and the well condition (Thiercelin et al., 1998). As described in the previous section, cement sheaths typically fail because of volumetricinstability and imposed tensile stresses beyond the tensile strength of the cement sheath.

Several have suggested requirements to tensile strength, Young's modulus, and other mechanical properties of the cement sheath to provide a long-term zonal isolation through long-term stress evaluation (Bois et al., 2011, Bois et al., 2012, Roy-Delage et al., 2000, Saint-Marc et al., 2008, Stiles and Hollies, 2002). Thiercelin et al. (1998) analyzed different stress conditions in oil wells which were applicable for most types of loading. They considered wellbore pressure increase and decrease, formation pressure increase, and well temperature increase; a summary of the qualitative requirements are shown in Table 2. Due to special- and varying-conditions of each well, quantitative requirement are not generally applicable.

Table 2. Typical loading modes, stress type, stress value, max. stress location, failure mechanisms, and cement system requirement to prevent failure, after (Nelson and Guillot, 2006, Teodoriu et al., 2013, Thiercelin et al., 1998).

| Loading mode | Stress value | Stress type (Fig. 1) | Max. stress location | Failure mechanism | Requirements to cement system | |

|---|---|---|---|---|---|---|

| Radial | Tangential | |||||

| Wellbore pressure increase | Linear function of wellbore pressure | Compressive | Tensile | Casing-cement interface | Tensile radial crack | Low Young's modulus |

| Wellbore temperature increase | Function of exposure time | Compressive |

Compressive (near the casing-cement interface) Tensile (near the formation-cement interface) |

Formation-cement interface | Debonding, cement sheath failure | |

| Wellbore pressure decrease | Linear function of wellbore pressure | Tensile | Compressive | Casing-cement interface | Debonding (location depends on the bonding strength of the two interfaces) | High tensile strength, more flexible than the formation, expansive |

| Wellbore temperature decrease | Function of exposure time | |||||

| Formation pressure increase | Dependent on formation creep-characteristics | Compressive | Compressive | Formation-cement interface | Buckling of the casing, shear failure under compression | High compressive strength |

The tensile strength requirement strongly depends on the loading during the life of the well and the mechanical properties of the formation. The Young's modulus of the cement sheath should be lower than that of the formation to mitigate the tensile strength requirement when the wellbore pressure or temperature increase. For flexible cement sheaths, the tangential stress is less tensile and more compressive near the casing-cement interface. This reduces the required tensile strength to prevent cracking (Thiercelin et al., 1998, Williams et al., 2011). In contrast, in case of wellbore pressure decrease, the tensile strength requirement increases with increasing Young's modulus of the formation, and debonding is more likely to occur when the cement system is placed in a stiff formation because it constrains cement deformation (Thiercelin et al., 1998). As all types of loading might be encountered in a well's life, it's important to consider an optimum Young's modulus for the cement sheath according to the formation's mechanical properties.

Each well has its special condition and a custom made design is needed. Therefore, it is necessary to determine the stresses that can occur in a well during the entire service life and identify the risks of cement sheath failure (McCulloch et al., 2003). In Table 2, it can be observed that during different loading modes a cement system with low Young's modulus is needed to survive under the imposed stresses. Moreover, the Young's modulus affects the requirements to tensile and compressive strengths, and a reduction of Young's modulus will decrease the required tensile strength to maintain zonal isolation. Consequently, two common mechanical characteristics of a cement system which can survive in oil and gas wells stress conditions are as below:

-

1.

The ratio of cement sheath-to-formation Young's modulus: A suitable value would be 0.5 (Williams et al., 2011).

-

2.

The ratio of tensile strength to Young's modulus σt/E, of cement sheath: A higher ratio is more favorable for elevated stress environments. The requirement is well-specific. (Nelson and Guillot, 2006, Williams et al., 2011)

Fig. 2 illustrates schematic load-extension curves for a target system and cement system with and without fibrous or flexible material. The target system presents a high strength and low Young's modulus illustrating the potential combined impact of fibrous and flexible additives. The target system has the potential to prevent cement sheath failure.

Fig. 2. Schematic load extension curve of a target system (see text) compared to the response of a reference system and systems containing fibrous or flexible particles (Own data).

Fig. 2. Schematic load extension curve of a target system (see text) compared to the response of a reference system and systems containing fibrous or flexible particles (Own data).In addition to mechanical properties, the short-term and long-term shrinkage should be compensated effectively. Conventional cement systems without compensation for bulk shrinkage have a high risk of failure during all phases of the well operation. However, when the volume reduction is compensated without significantly modifying the mechanical properties, the risk of damage to the cement sheath is considerably reduced. Increasing the tensile strength of a conventional system without compensation for shrinkage will slightly reduce the risk of failure (McCulloch et al., 2003). As an example, for the wells located in Marcellus shale (Williams et al., 2011), application of a flexible expanding cement system providing adequate flexibility and expansion as listed in Table 3compensates both short-term and long-term shrinkage and provides zonal isolation during and after simulation-related stress events.

Table 3. Required mechanical properties of the cement sheath providing reduced SCPa to prevent potential damage to the cement sheath for wells located in Marcellus shale (Williams et al., 2011).

| Property | Required range |

|---|---|

| Bulk expansion (%) | 0.2–0.5 |

| Flexibility (Young's modulus, GPa) | 2.4–6.2 |

- a

-

SCP=Sustained Casing Pressure, caused by hydrocarbon fluid migration from the formation to the surface through communication pathways in the annulus.

4. Improvement of tensile properties

To create a long-term zonal isolation, a flexible cement system exhibiting high σt/E with high resistance to fatigue and low shrinkage is required. The impact of nanofibers, nanoparticles, flexible particles and hybrid addition of these additives on tensile properties are discussed.

4.1. Nanotubes and nanofibers

4.1.1. Tensile strength

Addition of fibers is one of the most common and effective methods to improve the tensile behavior of cement-based materials. The impact of discrete macro-to microfibers on controlling crack growth in cement-based materials has been studied over the several decades (Berndt and Philippacopoulos, 2002).

The impact of fibers on the mechanical properties of cement-based materials primarily depends on the fiber dimension because the fracture indeed has a multi-scale nature e.g. (Metaxa et al., 2010). Macrofibers (typically defined as fibers with diameters greater than 500 μm) can improve post-peak toughness by bridging macrocracks. Fine microfibers (typically defined as fibers with diameter less than 50 μm), on the other hand, bridge the microcracks and delay microcracks coalescence to form macrocracks (Metaxa et al., 2010). However, cracks in cement-based materials initiate from the nanoscale where microfibers are not effective (Metaxa et al., 2010). Consequently, nanoscale fibers have attracted researchers over the last years (Konsta-Gdoutos et al., 2010, Li et al., 2005, Nochaiya and Chaipanich, 2011, Tyson et al., 2011).

Literature data on the impact of different nanofibers and nanotubes on the tensile strength of cement paste is summarized in Table 4. In the majority of the studies, the flexural strength was tested, but on specimens with different sizes. As discussed in Section 3, the tensile strength is the property to evaluate for assessment of the performance under induced stresses. Several equations and correlation factors have been proposed to estimate the tensile strength from the flexural strength (Balbo, 2013, Bhanja and Sengupta, 2005, Thiercelin et al., 1998). In the present paper the tensile strength of the system is determined from the flexural strength according to Eq. (1), which also includes the impact of the size of the tested specimen (Beverly, 2010).(1)where is the mean value of the uniaxial tensile strength; is the mean value of the splitting tensile strength; is the mean flexural strength; is the beam depth; and has been chosen as a compromise (Beverly, 2010). is tensile strength measured using splitting tensile test, Brazilian test or calculated from flexural strength according to Eq. (1).

| Fiber | Content (wt. %) | Size | w/ca | Curing time (d) | Flexural strength (MPa) | E(GPa) | σt(MPa) | σt/σt.Ref | E/ERef | Ref. | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter (nm) | Length (μm) | ||||||||||

| Short-MWCNT | 0 | 20–40 | 10–30 | 0.3 | 28 | 9.3 | 16.4 | 3.1 | 1.00 | 1.00 | (Konsta-Gdoutos et al., 2010) |

| 0.048 | 10.8 | – | 3.5 | 1.13 | – | ||||||

| 0.08 | 12.7 | 21.9 | 4.2 | 1.35 | 1.34 | ||||||

| 0.1 | 11.5 | – | 3.8 | 1.23 | – | ||||||

| Short-MWCNT | 0 | 9.5 | 1.5 | 0.4 | 28 | 3.3 | 14.5 | 0.6 | – | – | (Abu Al-Rub et al., 2012) |

| 0.04 | 3.8 | 12.2 | 0.7 | 1.17 | 0.84 | ||||||

| 0.1 | 4.5 | 15.2 | 0.8 | 1.33 | 1.05 | ||||||

| 0.2 | 11.9 | 17 | 2.2 | 3.67 | 1.17 | ||||||

| Long-MWCNT | 0 | 20–40 | 10–100 | 0.3 | 28 | 9.3 | 16.4 | 3.1 | 1.00 | 1.00 | (Konsta-Gdoutos et al., 2010) |

| 0.025 | 11.5 | 21.9 | 3.8 | 1.23 | 1.34 | ||||||

| 0.048 | 11.5 | 20.2 | 3.8 | 1.23 | 1.23 | ||||||

| 0.08 | 10.2 | – | 3.3 | 1.06 | – | ||||||

| Long-MWCNT | 0 | <8 | 10–30 | 0.4 | 28 | 3.3 | 14.5 | 0.6 | 1.00 | 1.00 | (Abu Al-Rub et al., 2012) |

| 0.04 | 5 | 15.2 | 0.9 | 1.5 | 1.05 | ||||||

| 0.1 | 5.3 | 13.0 | 1.0 | 1.67 | 0.90 | ||||||

| CNF | 0 | 60–150 | 30–100 | 0.5 | 28 | 5.5 | 8.8 | 1.8 | 1.00 | 1.00 | (Metaxa et al., 2010) |

| 0.048 | 7.2 | 13.2 | 2.4 | 1.33 | 1.5 | ||||||

| MWCNT | 0 | 13–18 | 3–30 | 0.54 | 7 | – | 7.2 | 2.6 | 1.00 | 1.00 | (Santra et al., 2012) |

| 0.1 | – | 7.1 | 1.8 | 0.69 | 0.99 | ||||||

| 0.2 | – | 7.2 | 2.5 | 0.96 | 1.00 | ||||||

- a

-

Water-to-cement mass ratio.

Among fibers in nanoscale, carbon nanotubes (CNTs) and nanofibers (CNFs) have attracted the most interest due to their extraordinary strength with Young's modulus in the order of TPa and tensile strength in the range of GPa (Sanchez and Sobolev, 2010). There are several studies on the impact of CNTs and CNFs on cement-based material properties, especially, mechanical properties as given in Table 4.

In the application of CNTs and CNFs in cement-based materials, one of the main challenges is the proper dispersion of CNTs and CNFs, partly due to their high hydrophobicity and partly due to their strong tendency to agglomerate owning to high surface area-to-volume ratio. Incorporating CNTs or CNFs in cement systems has been proven to be rather complex and inconsistent mechanical properties of the composites have been obtained (Sanchez and Sobolev, 2010). As presented in Table 4, addition of 0.1% multi-wall CNTs (MWCNTs) to oil well cement paste without surfactant reduced the tensile strength about 30% compared to the control system (Santra et al., 2012); while well-dispersed CNTs resulted in significant increase in flexural strength, stiffness and deformation ability (Abu Al-Rub et al., 2012, Li et al., 2005, Metaxa et al., 2010). Addition of 0.2% MWCNTs led to 260% increase in the tensile strength (Abu Al-Rub et al., 2012). Studies on CNTs and CNFs emphasize that resolving the issues related to dispersion is a key issue for the application of CNTs or CNFs in cement-based materials (Sanchez and Sobolev, 2010).

4.1.2. Flexibility

Addition of fibers into cement paste will change the Young's modulus, which characterizes the flexibility of a material. In most studies, addition of fibers was found to increase the Young's modulus, tensile strength, and toughness of the cement system, see Table 4. Addition of CNTs and CNFs showed mixed result; in a few cases a small decrease in Young's modulus was observed while in most of the systems Young's modulus increased. Addition of 0.2% by weight of cement, fibrous nanoclay resulted in about 50% and 20% increase in tensile strength and Young's modulus, respectively (Jafariesfad et al., 2015).

Tensile strength and toughness improvement are favorable for oil well cement system. However, as discussed in Section 3, Young's modulus also affects the tensile strength requirement. For the wells located in the Marcellus shale, the preference is to reduce the Young's modulus to the values in the range of 2.4–6.2 GPa, depending on well and formation requirements (Williams et al., 2011). This range values is unreachable by addition of only very stiff fibers like CNTs and CNFs.

4.2. Nanoparticles

Nanoparticles having a very high surface area-to-volume ratio can act as nuclei for cement hydrates promoting cement hydration (Lindgreen et al., 2008, Pang et al., 2014). As reinforcement and as filler, they are densifying the microstructure resulting in a reduced porosity (Sanchez and Sobolev, 2010). Distribution of nanoparticles in cement slurry also increases the matrix viscosity (Choolaei et al., 2012), which might impair the homogeneous dispersion of nanoparticles in the slurry. For all nanoparticles, the most significant problem is to achieve a homogeneous dispersion, which depends on a few critical factors such as concentration, matrix viscosity and attractive forces (Parveen et al., 2013). High nanoparticle concentration leads to relatively high agglomeration tendency (Sanchez and Sobolev, 2010) and increased viscosity of the cement slurry. Potential properties of nanocomposite can only be achieved by an effective dispersion of nanoparticles in the matrix (Parveen et al., 2013). It has been observed that addition of 5% (Stefanidou and Papayianni, 2012) and 3% of nano-SiO2 and 5% of TiO2 (Li et al., 2006) decreased the flexural strength of the concrete. This was attributed to the weak zones caused by agglomeration of nanoparticles.

The impact of addition of nanosized particles on tensile strength of cement mortar and paste are summarized in Table 5. Addition of 5% nanosized bentonite to oil well cement paste resulted in 54% increase in tensile strength compared to a reference mixture with microsized bentonite (Roddy et al., 2013). Fig. 3 illustrates the impact of various metal oxide nanoparticles with the same size, on tensile strength of concrete with water-to-binder mass ratio (w/b) of 0.4 after 28 days of curing. System containing 4% nano-SiO2 showed significant enhancement in tensile strength (Nazari and Riahi, 2011c). SiO2 (Nazari and Riahi, 2011c), TiO2 (Nazari and Riahi, 2011d) and ZnO2 (Nazari and Riahi, 2011e) nanoparticles performed similarly in concrete. Up to 4% increase in nanoparticle content resulted in tensile strength enhancement, but beyond 4% led to tensile strength reduction. The optimum concentration for system containing Al2O3(Nazari and Riahi, 2011a) and Cr2O3 (Nazari and Riahi, 2011b) was 1%. In almost all of the studies, addition of nanoparticles in relatively low concentrations resulted in noticeable tensile strength improvement. However, still there is lack of information about their impact on Young's modulus (Nazari and Riahi, 2011a, Nazari and Riahi, 2011b, Nazari and Riahi, 2011c, Nazari and Riahi, 2011d, Nazari and Riahi, 2011e).

| Particle | Content (wt. %) | Size | w/b | System type | Curing time (d) | Flexural strength (MPa) | σt(MPa) | σt/σt.Ref | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Bentonite | 5 | 32-38 μm | – | Paste | 3 | – | 1.1 | – | (Roddy et al., 2013) |

| Nanobentonite | 5 | – | – | 1.7 | 1.54b | ||||

| Nanoclay platelets | 0 | – | 0.48 | Paste | 56 | 5.4 | 1.5 | – | (Hakamy et al., 2014) |

| 1 | 7.2 | 2.1 | 1.40 | ||||||

| 2 | 7.1 | 2.0 | 1.33 | ||||||

| 3 | 6.8 | 1.9 | 1.27 | ||||||

| Nano- SiO2 | 0 | 15 nm | 0.5 | Mortar | 28 | 4.9 | 2.2 | – | (Li et al., 2004) |

| 3 | 5.8 | 2.6 | 1.18 | ||||||

| 5.2 | 6.2 | 2.7 | 1.23 | ||||||

| Nano-MgO | 0 | 30 nm | 0.5a | Mortar | 28 | 3.0 | 1.1 | – | (Moradpour et al., 2013) |

| 1 | 5.1 | 1.9 | 1.73 | ||||||

| 3 | 3.5 | 1.3 | 1.18 | ||||||

| 5 | 3.2 | 1.2 | 1.09 | ||||||

| Nano-Fe2O3 | 0 | 30 nm | 0.5 | Mortar | 28 | 4.9 | 2.2 | – | (Li et al., 2004) |

| 3 | 5.8 | 2.6 | 1.18 | ||||||

| 5.2 | 6 | 2.7 | 1.23 |

- a

-

w/c.

- b

-

Reference system contained the same content of bentonite in microscale (32–38 μm).

Fig. 3. The impact of nanoparticles with average size of 15 nm on tensile strength of concrete with w/b of 0.4, at the age of 28 days of curing, data from (Nazari and Riahi, 2011a, Nazari and Riahi, 2011b, Nazari and Riahi, 2011c, Nazari and Riahi, 2011d, Nazari and Riahi, 2011e).

Fig. 3. The impact of nanoparticles with average size of 15 nm on tensile strength of concrete with w/b of 0.4, at the age of 28 days of curing, data from (Nazari and Riahi, 2011a, Nazari and Riahi, 2011b, Nazari and Riahi, 2011c, Nazari and Riahi, 2011d, Nazari and Riahi, 2011e).In addition to long-term properties, presence of nanoparticles in cement slurry has a major impact on its short-term properties which should be considered in designing cement system. Thickening time, slurry stability (free-fluid, sedimentation and fluid-loss), rheological properties, gel strength development, porosity and permeability are strongly influenced by concentration and type of nanoparticles. Incorporation of nano-SiO2 to oil well cement slurry resulted in zero free-fluid, significant reduction in dormant period, and reduced porosity and permeability (Choolaei et al., 2012).

4.3. Flexible particles

Flexible particles have been used to increase the flexibility of the cement-based system. Suggested characteristics of flexible particles eligible to be used in cement system are (Roy-Delage and Thiercelin, 2004):

-

1.

Particle size ≤500 μm

-

2.

Density less than 1 500 kg/m3,

-

3.

Young's modulus <5 GPa, preferably <2 GPa,

-

4.

0.3 < Poisson's ratio <0.45

Several polymeric materials conform to these performance criteria. Examples are thermoplastics like polyamide, polypropylene and polyethylene, styrenedivinylbenzene or styrene butadiene (Roy-Delage and Thiercelin, 2004). While these materials can provide flexible cement systems resistant to induced stresses due to pressure and temperature fluctuations, problems can occur if the well is also exposed to high temperatures like what can be encountered in steam injection wells or geothermal wells. The mentioned polymeric materials are not suitable for high temperature applications as they either melt or deteriorate at high temperatures. There are several thermoplastics (PEEK, Ryton, PTFE) which are stable at high temperatures and in highly alkaline environments (as occur in cement slurry), but their cost is prohibitive for massive applications in well cementing (Roy-Delage and James, 2008).

Addition of conventional microsized flexible particles into cement system results in reduction of the Young's modulus, but also the tensile strength. It is necessary to find materials which improve both flexibility and tensile strength, or at least increase σt/E so that cement system is capable of maintaining zonal isolation under extreme stress condition. Such materials could be flexible particles in nanoscale. Epoxy resin exhibit inherent brittle nature and poor crack resistance somehow similar to cementitious materials. Incorporation of microsized rubber particles used as a method to improve the toughness of epoxy composites, but also they lead to significant loss of tensile strength (Thomas et al., 2008). Compared to the microrubber, the nanorubber particles produce an impressive toughening effect, while preserve the tensile properties of epoxy (Tang et al., 2013). It has been observed that incorporation of performed nanoscale powdered rubber particles (PR) into epoxy resin resulted in increased or almost unchanged tensile yield strength of the cured epoxy/PR composites (Guan et al., 2015, Tang et al., 2013). Therefore, partial or total replacement of conventional flexible particles by their nanoscale version can be the promising solution to improve the flexibility while keeping the tensile strength of cement system.

In addition to flexibility improvement, incorporation of rubber particle into both concrete and oil well cement systems is a common method to improve resistance to shocks and cyclic loads (Dargaud et al., 2003, Nelson and Guillot, 2006, Sukontasukkul and Chaikaew, 2006). Thus, improvement of the cement system flexibility can result in a system which is capable of standing under cyclic loads.

4.4. Hybrid additives

In a hybrid, two or more different types of additives are combined to create a composite that derives benefits from each of the individual additives and exhibits a synergistic response. Addition of fiber-toughening agents is a common way to improve tensile strength and toughness of cement systems. However, the Young's modulus is barely decreased and the flexibility is hardly improved (Yao and Hua, 2007). Therefore, it is necessary to develop additives that are able to improve flexibility, tensile strength and toughness, while not negatively affecting the other engineering properties of cement systems.

Table 6 presents different hybrid composites in an attempt to produce a flexible cement system while keeping the tensile strength unaltered. It could be found that addition of flexible agents such as rubber particles or latex resulted in Young's modulus reduction and flexibility improvement, but reduced tensile strength as well. A hybrid use of flexible agents with fibers in most of the cases led to simultaneous improvement in tensile strength and flexibility. Recently, the combination of nanoparticles/nanofibers with polymeric materials in cement-based materials has been used to improve ductility and provide high mechanical properties. Metaxa et al. (2010) used CNF, polyvinyl alcohol (PVA) microfibers and their combination aiming to improve tensile strength and toughness in cementitious matrix. By addition of only 0.048 wt % CNFs, the flexural strength and the Young's modulus of cement matrix increased up to 40% and 75%, respectively. Conversely, adding 0.54 wt % PVA microfibers enhanced only the post-peak behavior of cement paste resulting in a highly ductile behavior. Interestingly, the combination of CNFs and PVA improved the flexural strength up to 50% and toughness up to 33 times (3 350%) of the cementitious matrix. It resulted in stronger and tougher material compared to the singly-reinforced composites or plain cement paste (Metaxa et al., 2010). Incorporation of modified polypropylene fibers with well-distributed nanosilicainto the cement paste showed excellent mechanical properties and crack resistance (Yang et al., 2011); while a hybrid CNF and silica fume cement composite did not show any difference compared to neat cement paste. The CNFs embedded in the paste offset the effect of defects generated by pockets of CNFs and silica fume agglomerates, resulted in no net change in the compressive and splitting tensile strengths of the composites (Sanchez and Ince, 2009). Performance enhancement of cement composites was expected if better dispersion of the CNFs in the cement paste could be achieved by surface treatment of CNFs, optimum physical blending, and/or the use of surfactants (Sanchez and Ince, 2009).

Table 6. The impact of separate or combined use of fibers and polymers on tensile strength and Young's modulus of cement paste.

| Additive | Content (wt. %) | w/c | Curing time (d) | Flexural strength (MPa) | E(GPa) | σt(MPa) | σt/σt.Ref | E/ERef | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Reference | 0 | 0.44 | 2 | – | 6.3 | 1.9 | 1.00 | 1.00 | (Morris et al., 2003) |

| Polymer fiber (PF) | 0.4 | 0.44 | – | 2.6 | 3.2 | 1.68 | 0.41 | ||

| Styrene-butadiene latex (L) | 10 | 0.34 | – | 2.6 | 1.8 | 0.95 | 0.41 | ||

| Hybrid | 0.4 PF+10 L | 0.34 | – | 2.5 | 3.4 | 1.79 | 0.40 | ||

| Reference | 0 | 0.44 | 2 | 8.3 | 12.6 | 1.9 | 1.00 | 1.00 | (Yao and Hua, 2007) |

| Carboxylated nitrile rubber (CNR) | 6 | 6.5 | 7.8 | 1.5 | 0.79 | 0.62 | |||

| Polypropylene fiber (PP) | 0.25 | 8.4 | 14.5 | 1.9 | 1.00 | 1.15 | |||

| Hybrid | 5.5 CNR+0.2 PP | 8.2 | 8.1 | 1.9 | 1.00 | 0.64 | |||

| Reference | 0 | 0.35 | 14 | – | – | 3.3 | 1.00 | – | (Brothers, 2005) |

| Carbon fiber (CF) | 5 | – | – | 3.5 | 1.06 | – | |||

| Rubber particle (R) | 20 | – | – | 0.4 | 0.12 | – | |||

| Hybrid | 5 CF+20 R | – | – | 2.1 | 0.64 | – | |||

| Reference | 0 | 0.5 | 28 | 5.5 | 8.8 | 1.8 | 1.00 | 1.00 | (Metaxa et al., 2010) |

| CNF | 0.048 | 7.2 | 13.2 | 2.4 | 1.33 | 1.50 | |||

| Polyvinyl alcohol (PVA) | 0.54 | 5.8 | 8.9 | 1.9 | 1.05 | 1.01 | |||

| Hybrid | 0.048 CNF+0.54 PVA | 7.3 | 14.6 | 2.4 | 1.33 | 1.66 |