1. Introduction

There are three different categories can be used to classify the approaches taken to enhance heat exchangers' performance. These categories are the passive, active, and hybrid approaches [1,2]. Within the framework of the hybrid technique, the passive and active methods can be subdivided into various categories. Numerous strategies for amplification have been the subject of a considerable quantity of research, focusing spiral ribs, transverse fractures, spirally corrugated tubes, straight fins, lock fins, and annular fins on rough surfaces. The edge of the tube of a double-pipe heat exchanger, raised areas were made in order to increase the surface area. This was achieved by adding dimples along the heat exchanger's tube [1]. Enhanced surfaces can create one or further mixtures of the following conditions who are favourable for increasing the heat transfer coefficient in a based improve in the friction measure due to, firstly, the interruption of the development of the limit layer and expansion of the degree of turbulence [2]. The existence of rotating and secondary flows was the third change, followed by an increase in the effective heat transmission area. More than thirty previously published studies on the impacts of various helical tapes used in heat exchangers on pressure drop and the transmission of heat were reviewed and analysed by Ali et al. [3]. These experiments cantered on how different helical tapes affected heat transmission and pressure drop. More specifically, the study was conducted between 2001 and 2012. The findings demonstrate that the modified twisted tape configuration's heat transfer rate is significantly higher while still keeping a friction factor that is suitable for both laminar and turbulent flow [[4], [5], [6]]. Jesumathy et al. [7] looked at more than ten various published works to investigate the strategies for improving heat transfer in straight pipes. The square duct had a significantly greater rate of heat transmission than the circular tube, according to their comparison of the two. The square pipeline's large quantity of surface area in comparison to its capacity is the main cause. When used on square and rectangular pipes, the short-length twisted tape performs worse than the total-length crooked tape. The version of complete-length twisted recordings, however, is noticeably inferior to the version of routinely spaced twisted cassettes when compared to that version. Nakate et al. [8] developed and conducted experiments to ex-amine the effects that introducing crooked tape has on the transmission of heat and flow friction qualities of a cylindrical double-pipe heat exchanger. A circular tube fitted with either plain tape with twists or U-cut twisted videos was used in an experiment devised by Murugesan et al. [9] to compare the heat transmission and friction factor characteristics. Both varieties of contorted media were present inside the tube. An experimental study of a fully developed turbulent flow in a dimpled tube in conjunction with a twisted tape was carried out by Promvonge et al. [10]. This study was displayed as a twisted piece of tape. Khalil et al. [11] conducted an experiment to examine the effects that swirling flow had on the transmission of heat, the characteristics of pressure drops, and the increase in efficiency that happened when the flow was channelled through a suddenly larger conduit. By perching a test tube atop a number of cylindrical cylinders that served as tabula-tors. Promvonge [12] carried out several experiments. The majority of the enhancement techniques used in the study that was published were successful. In improving heat transmission on the side of the tube where it was applied. Because the design of the tube had a dual effect on both sides in certain applications, there on both sides, there was a substantial decrease in pressure. This penalty was severe in scope. On the contrary hand, the majority of the improvement devices discussed in the books needed additional materials, which increased the cost of production. In contrast, no extra materials will be used in the manufacturing process of the suggested tube. The impact that a dimpled tube's geo-metrical features possess on the amount of heat transmitted and the drop in pressure in turbulent water flow is not well-documented in the published research. There is a dearth of information regarding how a dimpled tube affects the rate of heat transfer and the drop in pressure that occurs in a turbulent flow. Mousa et al. [13] used the water as working fluid in heat exchanger with dimpled tube for a wide range of Reynolds number from 5000 to 20,000 is investigated and analysed. More so, the effect of geometrical characteristics, such as dimple arrangement (staggered or inline), distribution angle and pitch ratio was studied. Also, the thermal performance factor concept is correspondingly discussed by several studies [[14], [15], [16]]. The studies concluded the extent of the effect of the use of dimples in the tubes of heat exchangers, as shown in Fig. 1.

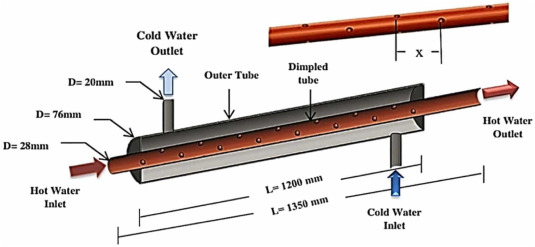

Fig. 1. Section view of the heat exchanger tube geometry [16].

Fig. 1. Section view of the heat exchanger tube geometry [16].In this work, it will focus on the main geometrical properties, such as the arrangement of the dimples (staggered as well as inline), their size, and their overall number. The relationship between the thermal performance and the hydraulic version should also be taken into consideration using the concept of the overall improvement ratio. This ought to be something that should be thought about.

2. Observations made on a surface containing dimples

By employing a wide variety of distinct geometric variables in various permutations, it is possible to designate a solid wall covered with dimples. Some examples of these characteristics include the covering ratio, structure, and relative geographic distribution of the dimples. In addition, these characteristics can be broken down further into subcategories. One more illustration of this can be seen in the arrangement of the dimples. (Ratio of the entire surface area to the area of the non-planar surfaces) [17,18]. In the beginning, dimples were conceived of as depressions in the shape of spheres. They left a spherical indentation on the wall when they were no longer present. Because of how common this misconception is, dimples are frequently called “dimples.” This is because of how commonly it is used. Because of the parametric nature of a specific class of circular dimples, which was initially outlined by Chen et al. [19], the dimples have acquired a lot of prominence over the past few years. They originally outlined this particular class of circular dimples. They first identified this specific variety of circular dimples in their study. De-scribing this particular variety of dimples was one of the earliest tasks undertaken by Chen et al. who was among the pioneering researchers in this field. This design is an ex-citing combination of an indentation in the shape of a sphere and a torus that has connections that follow a consistent tangential pattern. It is the intention of this design to dispel the notion that it contains any sharp corners in any way. A cylindrical indentation is combined with a torus to create the design. The torus also plays a role in the design. When viewed in cross-section, it is possible to see that the dimple has axial symmetry. This can be seen when the dimple is inspected. This is shown in Fig. 2, which is an illustration of the indentation. This demonstrates the point. Taking a brief minute to examine that picture will make the significance of this point exceedingly clear (see Fig. 4) (see Fig. 3).

Fig. 2. The stream wise displacement of the deepest point can be seen on the right (right), and cross section of the parametric dimple geometry can be seen on the left (left) [20].

Fig. 2. The stream wise displacement of the deepest point can be seen on the right (right), and cross section of the parametric dimple geometry can be seen on the left (left) [20]. Fig. 3. Illustrates some common variations of the indentation outline [20]..

Fig. 3. Illustrates some common variations of the indentation outline [20].. Fig. 4. The two most common configurations for dimples: flow oriented (right) and scattered (left) [20].

Fig. 4. The two most common configurations for dimples: flow oriented (right) and scattered (left) [20].The geometry of this dimple is determined by a combination of four distinct parameters, which are as follows:

The radius of curvature at the boundary, The depth of the spherical cover, The measurement D circular subdivision at the wall, The radius of curvature, r, at the boundary of region, and The radius of curvature R of the spheroid that covers it.

The circular component's width of the wall is measured D, and this dimension also establishes the scale and depth of the dimple. d of the tip of the cylindrical body; r, the radius of curvature at the While the spherical cap's penetration depth d determines how much space is filled by the circular area at the wall, the circumference D circle cross section at the wall establishes the size and its spherical cross section at the border. The depth d of the spherical cap is the measurement that is most exact among the four qualities. The largest of the four parameters is, however, the circular area at the border, diameter D. Because each of these four characteristics is connected to the others through a unique analytical relationship, it is impossible to think of them as being independent of one another. It is therefore impossible to think of them as living independently of one another. This leads to the limitation of the total number of degrees of freedom that can be used to just three. Due to the following geometrical properties, we are required to say the following as a matter of obligation:(1)

Additionally, some studies expanded this fundamental circle geometry by including a brand-new element known as s. The name for this parameter was chosen to be the letter s. This parameter describes how the area with the greatest depth is traveling in the same way as the water flow (either The geometry of this dimple is determined by a combination of four separate parameters, which are as follows: the dimension D the cylinder section at the wall; the sphere's diameter, d, includes; the bending radius r at the perimeter; and the shape radius R of the sphere cover. d of the wall-facing cylinder portion. d of the sphere cover. Each of these factors, which all contribute, influences the shape of the dimple in some way. D is the circumference of the spherical area at the border can be used to calculate the size circle cross section, while the depth d of the elongated top can be used to calculate the size of the wall's spherical portion. The size D of the cross-section of the circle at the boundary is the most important of the four features, while the width d of the elliptical cover is the least significant. Because each of these four characteristics is connected to the others through a unique analytical relationship, it is hard to think of them as being separate from one another. It is therefore impossible to think of them as living independently of one another.

Because this is the case, the overall amount of degrees of freedom that can be employed is capped at just three. As a matter of obligation, we are compelled to state that in regards to fact, due to the following elements of geometry.

3. Background on the use of structures with dimples for facilitating heat transfer

Numerous studies have been done on different heat transfer enhancers, such as pin fins, louvered fins, offset strip fins, slit fins, ribs, protrusions, and dimples, in order to in-crease the thermal effectiveness of heat exchangers [[21], [22], [23], [24]]. The use of these heat transfer enhancers has been the primary objective of this study. The purpose of this study was to increase the efficiency of heat exchangers. Some of these advancements in heat transfer have also, at various times throughout history, been referred to as split fins, another name for the characteristic. Despite this, the chance that dimples will improve heat transmission in internal cooling passages has drawn much more attention in recent years. This is due to the fact that dimples can greatly increase the amount of heat transfer that can take place. This is because earlier studies have shown that, in comparison to other kinds of augmented heat transfer devices, dimples can enhance heat transmission in constrained channels with a relatively low-pressure loss cost. Basically, this is what happens as a result of dimples. This was achieved as opposed to the numerous techniques that sped up the rate of heat transfer. Dimpled surfaces show a high heat transfer capacity with com-pared low-pressure loss penalty when compared to other types of heat transfer augmenters that have been accessible according to studies conducted by Ligrani et al. [25], who compared several different techniques for enhancing heat transfer. According to Ligrani et al. [25], the central and edge vortex pairs which are periodically shed from each wrinkle (as well as the resulting shear layer reattachments, border layer re-initializations, and induced local unsteadiness) are vital ingredients in augmenting local and spatially-averaged turbulence transport levels, and the associated appear heat transfer rates. The speed of passing on heat is increased on dimpled surfaces because the existence of swirling structures makes it easier for fluids to combine. Compared to the rate during which heat is transferred by projecting tabulators, this process proceeds much more slowly. The amount of heat transmitted via convection as well as the total amount of heat transmitted increase when “cold” fluid from outside the thermal boundary layer is brought into con-tact with a wall. As a result, a significant quantity of research has been done to identify the pressure loss and heat-transfer properties that are a direct result of the dimpled surface. The fact that this was the situation in issue led directly to the decision to take this action. Moon et al. [26] conducted several tests to study and analyse surface dimples to ascertain whether a convex-patterned surface could increase the heat transferred. At comparatively low Reynolds numbers, it was discovered that improving heat transmission by using a convex-patterned surface was more efficient thermally than doing so with a smooth channel. Moon and colleagues, who conducted the study, came to this conclusion. This discovery served as the basis for the researchers' findings. The researchers came to the conclusion they did as a result of this finding. Silva et al. [27] examined the flow pattern in a rectangle micro channel with dimples on one side of the wall during this time. They also tried to increase the channel's ability to transmit heat. According to the measurements, there was a noticeable rise in the drag coefficient as well as the rate of heat transfer. Wei et al. [28] and Lan et al. [29] conducted the study to find out how the presence of dimples in micro channels affects fluid flow and heat transfer. However, some of the discrepancies found between the calculated results and the actual flow in the experiment conducted by Wei and coworkers [28] may have been caused by incorrect use of boundary conditions. These differences were noticed when comparing the calculated flow to the occurred flow. These discrepancies were discovered when the actual flow was compared to the predicted flow. Using a micro channel heat sink with a dimple and a projection may lead to a lessened pressure penalty and a greater heat transfer coefficient in the laminar flow regime, the studies' results suggest. The situation that was looked into was this one. This might be the case if the point is noticeably bigger than the depression [30]. Recent experimental studies by Suresh et al. [31] looked at how CuO-water Nano fluids flowed and transferred heat inside a dimpled tube. This research was carried out in laminar and turbulent conditions in India. The results show that using Nano fluids in a helically dimpled channel results in a rise in the rate of heat conduction.

4. Principle of design dimples

The design of the best arrangement to accomplish the most significant reduction in drag has yet to be discovered because there have not been any systematic investigations that consider the impact of each geometric component. This precludes the creation of the configuration that would be optimal from being accomplished. This is one of the reasons why this is the case. Because of this, the optimum configuration has not been able to be designed. As a result of this, it is not possible to construct a structure that's optimal and will achieve the most significant reduction in drag that is possible, given the circumstances. In this section of the article, the meagre amount of information that we have is broken down into two distinct groups: first, the geometrical features of the dimples them-selves, and minute, the configuration of the dimples.

4.1. The characteristics of the dimple and internal organization

A plot of the data for the variance in drag that was established by a number of works that followed the baseline circular geometry can be seen in Fig. 5 [32]. These works were completed as part of the investigation that was being carried out.

Fig. 5. The six flow structures found in spherical dimples in order of increasing dimple depth and Reynolds number [32].

Fig. 5. The six flow structures found in spherical dimples in order of increasing dimple depth and Reynolds number [32].Fig. 6 shows cross-sectional geometry of a rounded spherical dimple. Depth is exaggerated for clarity. The illustration shows how the proportional difference in drag changes as an expression of all three variables. Independent mathematical quantities, d/D, r/D, and R/D. To achieve this goal, research was conducted on the publication that demonstrated the greatest reduction in trash, and the results were published. (Or the least significant increase in drag) [32]. It is of the foremost importance to remember that, in general, different locations compatible to simulations or investigations that vary for other, often extremely significant, design characteristics. Keeping this fact in mind is of the utmost importance. This is something that must not be forgotten under any circumstances. It is also important to keep in mind that this is the case. It is essential to remember that this is the situation in every instance. Always bear this in mind because it is very significant. This is something that must not slip your mind at any time. Instead, dashed lines connect the locations where the only difference is that a parameter on the abscissa has been altered. This is done in place of the traditional solid lines. The findings of previous studies on the enhancement of heat exchange point to the very logical conclusion that this is one of the most important variables that influences drag [[32], [33], [34], [35]].

Fig. 6. Cross-sectional geometry of a rounded spherical dimple [32].

Fig. 6. Cross-sectional geometry of a rounded spherical dimple [32].Several writers have contributed to this article with their findings after researching the impact that d/D has on the fluctuation of the drag force. Their results are presented in Table 1. However, according to the findings of some researchers, shallower dimples with a d/D ratio of under 0.1 should be taken into account to lessen total drag. To avoid an excessive punishment caused by the pressure drag produced. This is because the optimal d/D range for the best heat exchange is in the range of 0.1–0 [35,36]. This is done to ensure that an excessive punishment will not be incurred as a result of the heat exchange. This is due to the fact that dimples of a shallower depth result in a pressure decrease of a lower magnitude. The data are extremely inconclusive and make it abundantly clear that the difference in the drag generated by a surface with dimples not solely dependent on the d/D relationship. This is demonstrated by the fact that there is a large amount of inconsistency in the statistics. For instance, According to Vervoort and Veldhuis [37], there was a decrease in drag of almost 15% for d/D = 0.05, whereas the analysis by Tay et al. [38] an increase in drag of approximately 6%. Both of these studies were conducted using the same d/D value. These experiments were carried out using a d/D value of 0.05, which was the same throughout them. Both teams of researchers arrived at the same answer when calculating the ratio of d/D by using the same integer. The results presented in Ref. [39] were obtained by recreating a turbulent channel flow using disconnected eddies, with a covering ratio of 90% and a Reynolds number of 3000. The experimental observations in the case of a turbulent boundary layer over an area with dimples taken from reference number [38] have a covering ratio of sixty percent and a free-stream velocity that varies from zero to 29 m per second. Additionally, the boundary layer has a covering ratio of sixty percent. On the other hand, it is comforting to be aware that a local optimal can be discovered for intermediate levels, at the very least within some of the databases in which dotted lines connect the data points. This is an important fact to keep in mind. This discovery offers some solace to those affected by the situation. This is because it is reasonable to anticipate that there will be no changes in drag when d is less than zero and that there will be an increase in drag comparable to that of conventional k-type roughness when d is greater than. The rationale for this is that when d is greater than, there will be no changes in drag. Although they both agree that there is a decrease in achievement with an increasing d/D (in the range 0.015 d/D 0.05), Van Nesselrooij et al. [40] pinpoint the rate at which this decrease occurs as differing. On the other hand, Tay et al. [38] research suggests that Velshis and Vervoort [37] and others reported a marginal performance improvement. Tay et al. [38] was raised up to d/D = 0.12, and the researchers discovered that when d/D is greater than 0.05, the d/D ratio causes an increase in the average drag. This was discovered after the researchers expanded the first study to its maximum capacity. This was un-covered when the initial research was expanded to d/D = 0.05 in scope and scale. The radius of curvature r, located at the edge of the depression, has been designed to eliminate or prevent flow separation to the fullest extent possible to minimize the harmful impacts of pressure flow to the greatest degree possible. This was done to maximize the potential for minimizing the negative impact of pressure drag. The second component of the discussion of Fig. 6 demonstrates that the data are also widely dispersed in this particular in-stance: for a ratio of 0.5 to r/D of 1.5, the obtained change in drag ranges from 4% to 4.8% [41]. This shows that the data are not consistent in any way. [Note: The experiments carried out by Tay et al. [38] demonstrate that the border curvature's effect on the change in drag is negligible after a certain number, particularly after r/D > 4. To provide evidence for this claim, the investigations above were carried out. During these experiments, a total of Reb 32,100 was spent on verifying the premise. Through a Reynolds number, Spalart et al. [42] conducted a DNS on a chaotic boundary layer. (Based on the thickness of the boundary layer) of Re = 7.5103 and Re = 3,104, and they extrapolated that r/D = 0.5 throughout the operation. This allowed them to determine that the turbulent boundary layer had a Reynolds number of Re = 7.5103 and Re = 3104. The thickness of the boundary layer was used to determine the value of the Reynolds number. The Reynolds number was deter-mined by using the ratio of the Reynolds number to the thickness of the boundary layer and multiplying that by the thickness of the boundary layer. The Reynolds number was found by dividing the thickness of the boundary layer by the thickness of the turbulent boundary layer and using that percentage as the basis for the calculation. Fig. 7 does not contain the plotting of their data values. Because the information that they provide in their article is insufficient. To determine r and therefore cannot be quantified. This is the reason why their data values are not plotted. On the other hand, they demonstrated that making the dimple boundary as smooth as possible is to everyone's advantage. A portrait of the dispersion is revealed when the statistics are presented in comparison to the R/D ratio. As shown in the centre quadrant of Fig. 5 in this example. This provides additional evidence that it is not possible for a single mathematical component to provide what is required for this particular configuration, a comprehensive description of the dimples' effect on the fluid's movement. This is because the dimples are shaped to prevent the fluid from moving in a circular motion. The experiments that carried out by Ng et al. [41] presents the rate of pressure increase is very rapid whenever the change instead takes place in the upstream direction, which is also referred to as s 0. This is because upstream is located downstream from the location at which the shift takes place. The number 0 in the state represents the beginning point of the change, which is why this is the case. 2800 is the value for the Reynolds number in these calculations. Which is a substantial reduction when compared to the Reynolds number of the investigations, which ranged from greater than 4300 to less than 4300. It is of the utmost importance that this point is brought up because it is essential to emphasize that as measured by the models' Reynolds number is much smaller overall. According to Tay and Lim [43], a shift equivalent to the axisymmetric requirement is downstream of 0.2 D. when Reb = 7000 is implemented. Even though this results in a 1.5% increase in drag, Tay and Lim [43] claim that this condition can be achieved. This is in spite of the reality that there is a greater amount of friction. This is the inference one can make after considering both aspects of the similarity. This conclusion was arrived at after an investigation into the aforementioned facts. This is because the in-creased resistance to flow caused by the flow impinging on the steepest downstream wall makes up for the diminished resistance to flow the shallower upstream wall receives be-cause of decreased flow separation. The reason for this is that the passage of water is hit-ting the more vertical downstream wall, which is the cause of the problem. This is because the flow impinges on the steeper downstream wall. This is because the upstream wall is lower to the ground than the downstream wall. Put another way, the circumstance in solving a greater amount of friction can be compared to the axisymmetric condition. Ng et al. [41] point out that a downstream shift has no impact on the reattachment point be-cause they can use DNS to separate the contributions made by friction and pressure. Identifying friction drag is almost unaffected by a change in the downstream orientation. Other contributors to total drag include pressure. This is because the reattachment point is not affected. They come to this realization because of their discovery that a change down-stream has almost no effect on the friction drag. They have arrived at this conclusion be-cause of their discovery that the drag brought on by friction can be broken down into two components: the component brought on by pressure and the component brought on by friction. Tay et al. [44] looked into whether or not it would be feasible to use trapezoidal dimples as an alternative to the more traditional designs. They were successful in producing dimples through their experiment. by sculpting the bottom surface of the triangular depression so that it sloped upward from where the depression was the deepest, which was at the vertex of the triangle, near the bottom of the triangular indentation, where it converged with the level surface of the waterway. It was necessary to do this to ensure that the bottom surface of the triangular depression would reach the surface of the flat channel. The product was a framework that was shaped exactly in the opposite way that a wedge would be. It was found that the drag was greater for triangles pointing upstream in addition to triangles pointing downstream across the entire measured range of Reynolds figures, and this can be described as 5180 to 28,600. Additionally, it was found that the drag was greater for triangles pointing upstream than for triangles pointing downstream. This was the situation irrespective of the direction in which the triangles were oriented, either upstream or downstream. In addition, the increase in drag practically does not change as Re is increased for the triangle pointing downstream. On the other hand, the drag increase for the triangle pointing upstream as Re increases. Tay and Lim [24] looked into the tear-drop depression and evaluated a drop in drag for the two types of teardrops pointing up-stream and the teardrops pointing downstream, which came to a total of 4500 Reb 44,000. The teardrops that were pointing upstream produced a drag reduction of up to 6%, while the teardrops that were pointing downstream produced a drag reduction of up to 5%. Re-searchers led by Tay and his associates [43] found that the diamond depression can reduce drag by as much as 7.5%. Their findings can be found in the article. Ng et al. [41] conducted a computational study investigating the formation of teardrop and diamond shaped dimples, and spherical ellipsoids within a turbulent channel flow. Recent years have seen the completion of this investigation. They found that the diamond dimple reduced the amount of drag by 7.4%, the elliptical dimple reduced it by 4.9%, and the up-stream-pointing shape lowered it by 3.1%. All of these figures are percentages.

Table 1. Summary of the main parameters and results of the literature.

| Num/Exp | Authors | Re | Flow | Shape | Dz/L(Dx/L) | R/Dz | d/Dz% | r/Dz | s/Dx | Cov% | Layout | ΔDrag% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. DNS | Lienhart et al. [45] | 10,000 | CF | Circle | 0.6 | – | 5 | – | 0 | 22.5 | A | 0 |

| 10, 935 | CF | Circle | 0.6 | – | 5 | – | 0 | 22.5 | A | +1.99 | ||

| EXP | Veldhuis et al. [37] | – | BL | Circle | – | – | 5 | – | 0 | 60 | S | −14 |

| EXP | Tay et al. [38] | ≈17,500 | CF | Circle | 5 | 1.68 | 5 | 0.84 | 0 | 90 | S | −2 |

| EXP | Tay et al. [39] | ≈32,100 | CF | Circle | 5 | 8.45 | 5 | 4.2 | 0 | 90 | S | −2.8 |

| EXP | Nesselrooij.et al. [40] | ≈1500 | BL | Circle | 26.67 | 4.51 | 2.5 | 0.5 | 0 | 33.3 | S | |

|

EXP – EXP |

Tay et al. [44] |

≈5625 +0.5 ≈50,350 |

CF – CF |

Triangle – Circle |

−(4.67) s 5 |

– – |

5 S 5 |

– +2.8 – |

−0.5 +0.1 |

– 90 |

S S |

+4.8 −3.6 |

| Exp | Tay, J.et al. [43] | ≈42,850 | CF | Circ | 5 | 0 | 5 | – | – | S | −3.5 | – |

| Exp | Campenhout.et al. [46] | ≈30,140 | CF CF | Tear Up Tear Dp | 5 (7.5) | +0.17 | 5 | – | 84 | S S | −6 | – |

| DNS (FVM) | Spalart et al. [42] | ≈22,270 | BL | Circ | 5 (7.5) | −0.17 | 5 | – | 84 | S/A/H | −5 | – |

| Exp | Tay, Jet [47] | – | BL | Circ | – | 0 | 2.5 | 0.5 | – | S | +1 | 0.5 |

| LES (FVM) | Prab et al. [48] | ≈6121 | HCF | Circle | 5.7 | 4.51 | 2.5 | 1.5 | 0 | – | S | −3.6 |

| DNS (SEM) | Ng et al. [41] | 2800 | CF | Circle | 5 | 1.68 | 5 | 0.84 | +0.1 | 90.7 | S | +4.6 |

Fig. 7. Change in drag measured with circular dimples plotted against depth (top) [20].

Fig. 7. Change in drag measured with circular dimples plotted against depth (top) [20].4.2. Fundamentals of dimples arranged

When referring to the pattern of the dimples on the surface and their placement about one another, once the other characteristics have been established, the asymmetrical con-figuration results in less drag when contrasted with the flow-aligned one. This is because the dimples are arranged in a pattern that is not parallel to the flow [45]. This is the case regardless of whether the dimples align with the flow. This is the situation irrespective of whether or not the dimples are oriented in the same orientation as the flow. The flow-aligned design is less efficient than the staggered configuration, which is why the asymmetrical arrangement is the one that is utilized the majority of the time. The flow-aligned design does not come close to matching the efficiency of the staggered setup. Staggered dimples, which have the same morphological evaluations, coverage, and Reynolds number as flow-aligned dimples, can result in a 4% reduction in drag. In contrast, flow-aligned dimples can result in a three percent rise in a breath. Flow-aligned dimples can result in a 3% increase in pain. These results are based on research conducted by Weng et al. [49]. According to Spalart et al. [42], the flow-aligned dimples caused an in-crease in drag that was almost twice as high as the increase in pain caused by the scattered dimples. On the other hand, it was discovered that both configurations had the same increased level of drag. Research on the variation in pain caused by a broad variety of different non-standard designs has been carried out by Lashkov and Samoilova [50] as well as by Campenhout et al. [46]. Earlier research found that employing a hexagonal dimple arrangement significantly raises drag—up to fifty percent more than what it would be otherwise. This is because the hexagonal dimple arrangement increases the surface area of the dimples. According to the most recent investigation's conclusions, each of the configurations considered had a continuous drag increase of approximately 1%. This information was derived from analysing the data collected in the study. Tay et al. [43,47] considered the impact of the coverage ratio in their research. They investigated the effects of circular depressions in the passage of a waterway combined with covering varying from forty percent to ninety percent and discovered that the greater the coverage, the more pronounced the effects of the dimples were. This was the case regardless of whether the results were positive or negative. An investigation into the impact of covering on a boundary layer was the focus of an experiment that Nesselrooij et al. [46] conducted. They found that a coverage of 33.3% is always within the same range of Reynolds numbers; this leads to a diminution in the amount of drag experienced, in contrast to a coverage of 90%, which always results in an increase in pain for a wide range of Reynolds numbers. They discovered this. It was found that increasing Re led to a performance increase for both of the system's configurations, regardless of which one was used. Spalart et al. [42] found that having a lower coverage ratio in their boundary layer DNS resulted in approximately one percent less drag, whereas having a higher coverage ratio resulted in roughly two percent more pain. This was discovered by looking at how the two percentages compared to one another. This fact was uncovered as a result of an investigation into they found two coverage rates in their boundary layer DNS.

5. The real efficiency of dimples

Even though it should not arrive as a surprise that our limited understanding of the science involved contributes to the uncertainties regarding the real efficiency of dimples in decreasing turbulent drag, this is something that should still be brought up because it is important to note. However, it does come as a surprise that our comprehension is so restricted. There is still a lack of widespread agreement surrounding the various ideas and hypotheses that have appeared due to the many computational and experimental investigations that have been carried out up to this point. This lack of agreement is because so many studies have been carried out up to this point. You will find a description of both of these methods in this section. These are the two most common ways of describing how dimples affect turbulent flow.

5.1. The self-organizing circulation causing secondary hurricanes

Kiknadze et al. [51] made the first attempt at understanding the reduction in drag produced by dimples, even though similar observations had already been proposed in earlier numerical discussions [52] and experimental [53] studies. Their explanations were founded on video recordings and photographs, two kinds of evidence not utilized by any other explanations. The writers of reference [54] are employed at the research and production facility in Moscow that is known as “They assert that the action of dimples is what causes tornado-like jet technologies is best exemplified by an occurrence known as Tor-nado-like jet self-organization,” which describes the behaviour precisely. To put it another way, this is the way the flow distributes itself and acquires on top of the double-curved concavity that makes up a depression, which is also referred to simply as a dimple. At the leading edge, a circular the movement that originates upstream, dimple flat portion picks up speed, and as it attempts to follow the curved wall, it is raised off the surface. As a direct outcome of this, there is a decrease in the amount due to the abrasion of the epidermis in the front half of the depression. After the flow has passed the stream-wise midpoint, it will begin to converge toward the centreline, and ultimately it will meet the smooth wall positioned behind the trailing edge. As a direct result of this, there will be a rise in the level of friction that occurs between the outer layer of skin and the object. An additional pressure drag component can be seen here because of the depressed construction of the dimple. This can be seen in this instance. Therefore, to reduce drag, the general reduction of the increase in pressure drag must outweigh the rise in skin friction drag. This condition must be met for success. This condition must be met before drag reduction can be achieved. This is the requirement that needs to be satisfied to be successful. This description, on the other hand, does not specifically discuss the sudden decrease in drag; rather, it demonstrates an attempt to simplify the local flow modifications generated by the dimple. In other words, this description does not specifically discuss the observed sharp decrease in drag. As the previous sentence implies, it is essential to note that this description does not directly address a sharp drop in drag. This is a crucial point to keep in mind. The steep walls that surround the dimples in the upstream section of the recess have the potential to cause the flow to become segmented, which is an outcome that would be undesirable. This may lead to the development of slantwise vortices and the recirculation of the fluid within the channel if the dimples are sufficiently big. There is a beneficial impact on the drag due to the change in the flow direction, which results in lower pressure at the surface in the first part of the passage of the dimple. This is because the flow has changed its direction. It creates a powerful impingement of water on the back incline of the dimple when the flow re-attaches to the dimple, which results in an approximate amount of skin friction. This occurs as a direct consequence of the indentation that was created in the ground. Additionally, Flow separation evidently produces a substantial increase in pressure drag, which has the potential to nullify the beneficial impact of the skin-friction drag. This is because pressure drag the square of the distance between the two objects being dragged. This is because pressure drag is a form of drag measured in Newton's. This is because the force of pressure drag is directly proportionate to the cube of the speed of the fluid. The friction between the epidermis and the object's surface is what causes this drag to occur. It is important to use designs that are more effective than the traditional spherical one to prevent separation, which would increase pressure drag. Separation would lead to increased resistance to pressure. These patterns are available in a wide variety of iterations and formats. The area of depression that is the most profound. Moves downstream, which changes. The wall sways and exerts pressure. The pressure drag to change the overall flow, while the friction drag tends to remain the same. This movement of the point of the dimple's greatest depth alters the atmospheric drag; the overall drag will be affected. This movement the deepest part of the promontory of the dimple affects the total drag by altering the pressure drag. This change in the location of the dimple's point of greatest depth affects the total drag. This shift in location affects the pressure as a whole. One way to mitigate the negative effects of separation to a significant degree is by employing a (moderate) downstream shift, which also results in less drag than the conventional spherical topology. This adjustment can potentially reduce the negative effects of the separation to an acceptable level to make it more bearable. Usually, the shift has little to no impact on where the reattachment spot is. This is due to the vast bulk of the situations. The one and only time this does not apply is when the change is extraordinarily significant. Flow reversal can be completely suppressed for huge shifts; however, this comes at the expense of a significant impingement onto the steeper rear wall, which has a detrimental effect on the drag caused by the situation. It is possible to suppress flow reversal completely when dealing with substantial changes. It is possible to suppress flow reversal completely when dealing with huge shifts. If the shift in direction is substantial enough, it is possible to avoid the flow reversal that would otherwise occur completely. Non-circular dimples generate different drag discrepancies [40]. When it comes to elliptical dimples, upstream pointing, and diamond-shaped, there is no evidence of flow division or reversal. In comparison to a smooth wall surface, this results in a reduced drag coefficient. This can be understood by looking at the gentler incline that is located upstream as well as, the longer leading edge that is directed more toward the stream. Both of these features are directed more toward the centre of the stream. Both of these characteristics face more toward the stream than any other direction. Other experiments, such as [55,56], which, even for a circular shape, fail to capture movement reversal, calculate a maximum drag reduction of three percent and one and a half percent, respectively, when compared to the drag value recorded in the original experiment. This is a significant improvement. This discovery is in direct contrast to the findings found in the studies discussed previously. In addition as this, during their investigation, they did not discover any flow reversal. Tay et al. [38] detect flow divergence for spherical dimples in the analysed traffic scenarios for d/D = 0.06 but not they quantify an increase in the quantity of drag in each of the tested cases for d/D = 0.01 despite this. Watch for flow separation in circular movement dimples across the complete spectrum of flow conditions evaluated for d/D = 0.01. When d/D is equivalent to 0.06, flow separation is observed for spherical dimples across the board for the entirety of the spectrum of flow conditions. Flow separation is observed for circular dimples across the entire surface when d/D is equivalent to 0.06, and this holds for the entire spectrum of flow conditions that were measured. Flow separation was observed for d/D = 0.06 across the board for the entire spectrum of flow conditions that were evaluated for circular dimples. This observation was made for all of the flow conditions. This was true despite the various forms the indentation could take.

5.2. Forcing span wise span

Both the research group at TU Delft [46] and the group at NUS [44] have independently suggested a more modern theory about the mechanisms by which dimples reduce the quantity of drag they produce. Both of these hypotheses have been presented in written form in scholarly publications. These hypotheses have been described in detail in written articles published in academic journals. Flow visualizations show that stream-lines flowing in straight from a smooth surface near the wall curve. The water flows in a converging-diverging pattern, bending toward the dimple centreline in the upstream part of the recess and away from it in the downstream portion. This pattern causes the depression to have a connecting–diverging design in the flow, and it does so because of the way the flow is directed. The development of a dimple occurs due to the streamlines in the up-stream portion of the recess curving pivoting to face the dimple centreline away from it in the downstream part of the recess. This takes place in the pieces of the hollow that are up-stream as well as the sections that are downstream as shown, For instance Ref. [36]. A span -wise velocity distribution with a shifting sign along the dimple length is suggested by this meandering shape [57,58]. This is because the span-wise velocity continues to be restricted very near the wall. And as a result, there is a rotating stream wise vortex [59] because the span-wise velocity changes across the dimple length. The typical span-wise speed of a boundary layer is approximately two to three percent of the free-stream rate, as stated in Ref. [60]. This knowledge was derived from the results of the research.

On the other hand, the research mentioned in the source [53] discovered that the channel had a span-wise velocity between 3.5 and 8% as fast as the centreline velocity. This was found to be the case. The conduit was employed to gather both of these observations that took place in that location. Both of these observations took place in that location. During their investigation of the DNS, Spalart et al. [42] discovered indications of a span-wise motion; however, the amplitude of this motion was significantly less significant than what was anticipated when they began their research. Fig. 8, which portrays a spherical dimple, illustrates a span-wise velocity vector in real time. The dimple defines this field. This figure, representing a choppy channel movement over circular dimples, was obtained from one of our DNS simulations and can be found here. You can watch the simulation as it was initially run here. Because there is a discernible alternation in the pattern of span-wise velocity, the hypothesis that a depressive disorder The fact that there appears to be an alternation in the way of span-wise rate, which both generates a span-wise motion component direction and causes the streamlines to operate in a fashion that is both converged and diverging, lends credence compared to the notion that the latter creates a velocity component in the span-wise direction. This is because the structure of the span-wise velocity pattern displays a distinct alternation, which is the reason for this result. When the instantaneous measurements are taken when they are in their most prominent position, they can reach up approximately 40% of the mass velocity [61].

Fig. 8. The immediate span-wise velocity element won a surface that is parallel to the wall and at an angle of y + = 1.3 away from the horizontal section of the wall [17].

Fig. 8. The immediate span-wise velocity element won a surface that is parallel to the wall and at an angle of y + = 1.3 away from the horizontal section of the wall [17].