1. Introduction

Growing concerns over the effects of climate change, emphasized by the latest report from the IPCC [1], [2], [3], call for a rapid reduction of greenhouse gas emissions (GHG) in all sectors and parts of our society. According to the IEA, the transport sector alone accounts for 24% of direct CO2 emissions from fuel combustion, even though the increase in emissions slowed somewhat during the Covid-19 pandemic [4]. Considering the growing demand for air transport with an annual increase of 5% as of 2019 globally, aviation is considered as the most rapidly growing industry in the transportation sector by moving over 4.4 billion passengers in 2018 with 120 thousand daily operated flights with a projected passenger throughput of 7.2 billion in 2035 [5,6]. This growth is desirable from an economic standpoint, but aviation is predicated on fossil fuels, which increase greenhouse gas and air pollutant emissions [7,8]. Together with some industries and other heavy transport, aviation is sometimes referred to as one of the “hard-to-abate” sectors, meaning that the route to zero emissions is not as straightforward as in some other sectors [9]. As other sectors are decarbonized, the relative share of emissions from these “hard-to-abate” sectors is set to increase in the decades to come. Presently, aviation accounts for approximately 2.5% of global CO2 emissions. It is projected to rise to 11% if new technology is not advanced in the next two decades to cope with the projected annual growth of the aviation industry [10,11]. To mitigate the impact of air transport on the environment, the European Commission and the Advisory Council for Aviation Research and Innovation in Europe (ACARE) flightpath 2050 strategy [12] and the NASA N + 3 programs [13] have set challenging and ambitious goals that will require new technology and its rapid implementation to enhance aircraft design and operations. These differing goals are summarized in Table 1.

Table 1. Summary of NASA N + 3 and ACARE flightpath 2050 goals.

| Environmental factor | EU ACARE flightpath 2050 strategy. (Up to 2050), [12]. | NASA N + 3 Program. (2010 to 2035) [13, 14] |

|---|---|---|

| Greenhouse gas emissions (GHG) | 75% CO2 emission reduction | 25% CO2 emission reduction within 10 years and 50% reduction within 25 years |

| Nitrogen oxides NOx | 90% NOx reduction | 70% reduction in NOx emission within 10 years and 80% within 25 years |

| Noise | 65% reduction in noise | Perceived noise reduction by a factor of 2 in 10 years and by a factor of 4 in 25 years. |

| Safety | 80% reduction in aviation accidents using the year 2000 as a baseline and accounting for growth in air traffic. | Reduction in aviation fatal accidents by a factor of five within 10 years and by a factor of 10 within 25 years. |

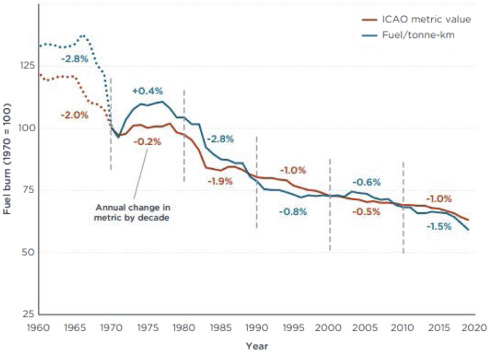

Achieving these goals requires disruptive innovation in the propulsion system of aircraft. The first measure taken by the aviation industry to achieve this goal is by continuously improving the efficiency of aircraft engines. Fuel efficiency improvement averaged 2% per annum, corresponding to a 40% fuel burn reduction between 1960 and 1995, but reached a plateau between 1995 and 2005 [15,16]. As illustrated in Fig. 1, significant fuel burn reduction picked up again from 2010. The rapid improvement from 2010 was as a result of the introduction of new and more fuel-efficient engines with high BPR that were utilized in narrow-body aircraft such as the Airbus A320neoand Boeing 737 Max, and also the introduction of the more electric widebody aircraft such as the Boeing 787 in 2010 and Airbus A350–900 in 2015. Kharina et al. [17]propose that the rate of fuel-burn reduction could be accelerated to 2.2% per annum by 2034 by adopting more cost-effective technologies. However, ACARE proposes that radical technological solutions and innovative propulsion and airframe design concepts will be the basis for reaching emission-free aviation [18].

Fig. 1. Average fuel burn for new jet aircraft, 1960–2020 [16].

Fig. 1. Average fuel burn for new jet aircraft, 1960–2020 [16].To support NASA's N + 3 program, NASA proposes a four-phased aero-propulsion research approach enabled by technological revolutions that characterize their vision for 21st-century aviation [13]. Fig. 2 depicts the various revolutionary levels specified by NASA. A detailed explanation of the various technological revolutions can be found in [13].

Fig. 2. Aviation propulsion power revolution proposed by NASA N + 3 program [13].

Fig. 2. Aviation propulsion power revolution proposed by NASA N + 3 program [13].Several published review articles discuss different aspects of electric aviation. Brelje and Martins [19] discussed electric fixed-wing aircraft models' electrical fundamentals and concepts. Gnadt et al. [20] provide a technical and environmental assessment of all-electric narrow-body aircraft compared to conventional aircraft. Their results indicated that an improvement in batterypack energy density up to 800 Wh/kg is required to make flying an electric Airbus A320 feasible.

Alrashed et al. [21] review the feasibility of the turboelectric distributed propulsion (TeDP ) concept in commercial aviation. The authors established that TeDP could increase aircraft efficiency by up to 24%, with a corresponding 50% reduction in emissions compared to conventional aircraft. Xie et al. [22] provide a detailed review of hybrid-electric aircraft. The authors identified that small-scale hybrid aircraft had been widely studied and implemented. In contrast, large-scale hybrid aircraft remain at the conceptual level unless a significant improvement in energy storage technology is achieved. Rendón et al. [23]studied hybrid-electric propulsion for aviation applications using present technology levels. Their study concluded that all-electric aircraft are well suited for unmanned aerial vehicles. In contrast, series and parallel-hybrid aircraft best fit smaller airplanes designed for short-duration flights with varying power requirements.

Despite all the works cited, it is unclear from the literature how much advancements in various technologies contribute to electric aviation. This review aims to provide an in-depth understanding of different electric aviation technologies and identify the most feasible technological mix required to achieve significant aviation emission reduction in the short term. Up-to-date progress in academia and industry is surveyed, taking into account the amount of technology integration required in several electric aircraft concepts to establish a three-point technology improvement approach that significantly defines the success of electric aviation. The paper is structured as follows: After a detailed introduction in Section 1 establishing the need for decarbonization and technological advancement in aviation, Section 2 discusses the various classifications of electric propulsion and highlights the opportunities each class presents. In Section 3, a comparative analysis of electric propulsion and conventional aircraft is carried out to identify the main technological areas required to make electric aviation feasible. This is identified as battery technology, electric-motor technology, and airframe design. Each of these technologies is extensively reviewed to identify their state-of-the-art levels, future projections, potential, challenges, and measures taken to mitigate these challenges. Section 4 discusses some proposed electric aircraft concepts and the degree of technology integration in these concepts. These concepts are compared to the state-of-the-art technology and projections in Section 3 and their challenges to identify the most feasible technological mix and concepts capable of implementation in the short term. Lastly, Section 5 concludes the review and highlights the study's key findings.

2. Classification of electric propulsion architectures

Brelje and Martins [19] classify electric aircraft by the degree of hybridization of their powerplant. This refers to using one or a combination of different energy sources to provide propulsive power for the aircraft. Isikveren et al. [24] provide a more detailed definition of hybridization in terms of battery energy and motor power, which is valid for electric aircraft and applicable for hydrogen-powered aircraft. Based on the topology of the powertrain, electric aircraft can be classified into turboelectric, hybrid-electric propulsion (HEP), and all-electric aircraft, as summarized in Table 2.

Table 2. Classification of electric propulsion architectures based on definitions from references [19,24].

| E-Architecture | Hybridization |

|---|---|

| Turbo-electric | A gas turbine engine drives an electric generator which provides propulsive power. No energy batteries are required. |

| Hybrid electric | Uses both gas turbine engines and batteries for propulsion. |

| All electric | Propulsive power is produced only by batteries. |

2.1. Turboelectric aircraft

Turbo-electric configuration focuses on the incremental electrification of gas turbine engines [25]. In this model, one or more gas turbines drive an electric generator to produce electrical power. The power is distributed using DC busses and electronic converters to drive an electric motor to which a propeller is attached [26,27]. As shown in Fig. 3, the gas turbine is directly connected to an electric generator that generates the necessary power to drive the motors, thereby utilizing 100% of the gas turbine's output power to generate electrical energy. There are no energy storage devices (batteries) onboard such an aircraft. Although the ICE operates to its maximum power vs. speed condition, stand-alone turboelectric architectures suffer from power loss due to energy conversion from mechanical to electrical energy, and back to mechanical energy. Espein and O'Flarity [26] estimate the efficiency penalty of turboelectric compared to direct mechanical drive to be 10%. However, the benefit of turboelectric can be duly observed when it takes advantage of the synergy provided by propulsion/airframe integration techniques such as Distributed Propulsion (DP) and Boundary Layer Ingestion (BLI). Since the only role of the ICE is power generation, this configuration is best suited for DP where the generated power can be distributed to several electric motors. This approach results in an increased effective Bypass ratio (BPR) with a corresponding reduction in fan pressure ratio [23]. Increasing BPR increases propulsive efficiency. When combined with BLI, the propulsive efficiency is increased by re-energizing the wake and reducing airframe-induced drag [28]. DP and BLI are explained in detail in Section 3.

Fig. 3. Turboelectric layout.

Fig. 3. Turboelectric layout.2.2. Hybrid-electric aircraft

The success of HEP applications in the automobile industry is transferrable to aviation. Hybrid automobiles benefit from increased range, noise reduction, low emissions, and minimal fuel burn, thereby spiking a significant interest in research into HEP technology for aviation applications. Hiserote and Harmon [29] suggest that small-scale aircraft could benefit from HEP by decreasing fuel burn, emissions, and increased range. However, the authors question the applicability of HEP to larger aircraft. Glassock et al. [30] confirm this claim by stating that HEP configuration is much more feasible for short-duration high-power missions, such as skydiving than conventional long-duration flights.

Contrary to these claims, Voskuijl et al. [31] modified the Breguet range equation to suit hybrid-electric aircraft. Using range limitation and aircraft performance as a function of battery technology, the authors achieved a 70-passenger aircraft with a design range of 1528 km using batteries with an energy density of 1000 Wh/kg. Based on the variant of HEP configuration chosen, the required thrust may be delivered by a gas turbine and a battery, only by a battery, or only by the gas turbine during specific phases of the flight [32]. During different flight phases, the energy sources onboard the aircraft is balanced such that an optimal operation of the system can be achieved [33]. Two types of hybrid configurations are considered: series-hybrid and parallel-hybrid configurations.

2.2.1. Series-hybrid configuration

In a series-hybrid configuration, the gas turbine is decoupled from the propeller, and the propeller shaft is driven only by the electric motor [32]. This system is similar to the turboelectric architecture, except that a battery stores energy and contributes to the propulsion. As illustrated in Fig. 4, a generator converts the mechanical energy from the gas turbine into electrical energy. The electrical energy can then be used to drive the electric motors directly or be stored in a battery through a charging process. This configuration is best suited for aircraft with distributed propulsion as the only role of the gas turbine engine is to produce electricity [11].

Fig. 4. Series-hybrid layout.

Fig. 4. Series-hybrid layout.Since there is no direct linkage between the propeller and the gas turbine, the gas turbine can operate at its optimal operating condition during all phases of the flight leading to a significant reduction in fuel burn compared to the parallel-hybrid configuration. Also, this configuration is simple, offers higher flexibility in positioning the internal combustion engine, and requires less space [11,22]. However, the need for a generator in addition to a battery in this configuration means that it is heavier than the turboelectric and parallel-hybrid configurations. Also, in analyzing the hybridization factor of hybrid systems, Economou et al. [34] further proved that series systems suffer from power losses compared to parallel systems due to the use of power converters in transforming the generator's output before supplying power to the motors. This process results in significant efficiency penalties for the series configuration. Lastly, there is no redundancy with this configuration in the event of a motor failure.

Siemens, Diamond Aircraft, Austro Engine, and Airbus demonstrated the first series-HEP manned aircraft at the Paris Air show in 2011. The two-seater DA36 E-Star aircraft featured a 70 kW electric motor from Siemens and a 30 kW internal combustion engine from Austro Engine and achieved a 25% emission reduction and fuel burn [35]. The manufacturers claimed the DA36 E-Star was scalable to 100 passengers and, based on this claim, considered series-HEP to be the future of commercial air transport. However, the manufacturers gave no technical basis for scalability.

2.2.2. Parallel-hybrid configuration

In a parallel-hybrid configuration, the gas turbine engine and the electric motor are connected through a mechanical coupling to the propeller, enabling both powertrains to contribute to the propulsion energy simultaneously or separately [22]. This configuration causes extra mechanical complexity, and the engines do not operate at a constant maximum efficiency speed resulting in a higher fuel burn. Therefore, Bravo et al. [11] consider parallel-hybrid less efficient than the series architecture. The resulting advantage of this configuration is that weight-saving may be achieved by downscaling either the electric motor or the gas turbine and still achieve the same performance [32]. Comparing the series and parallel-hybrid configurations, Finger et al. [36]considered parallel-hybrid superior in decreasing global weight and fuel weight. Supporting this claim, Boggero et al. [37] achieved a 46 kg reduction in empty weight and a 10 kg reduction in fuel weight when they retrofitted a Piper PA-38 aircraft with a 22.6 kW electric motor and a 54.6 kW IC engine. Having two-propeller driving mechanisms installed also provides redundancy in the system, making it much safer. Also, when the aircraft is operating in engine mode, the electric motor can act as a generator that charges the battery [11]. In addition, power loss due to energy conversion is reduced since this configuration does not require power converters on the gas turbine. Fig. 5shows the layout of the parallel-hybrid architecture.

Fig. 5. Parallel-hybrid layout.

Fig. 5. Parallel-hybrid layout.2.3. All-electric aircrafts

All-electric aircraft configuration is the simplest of all the electric architectures in terms of layout (Fig. 6). The only power source in this architecture is the rechargeable battery, connected directly to an electric motor through a power management system that drives a propeller. Unlike the hybrid architectures, this configuration does not allow for an inflight charging of the batteries; therefore, the batteries need to be charged on the ground before any flight mission.

Fig. 6. All-electric aircraft layout.

Fig. 6. All-electric aircraft layout.Although all-electric aircraft have many advantages, including zero-emission, low noise, and operating cost reduction, the enabling battery technology has not achieved sufficient maturity to cover the same distances as jet fuel-driven aircraft [26]. This limits current electric aircraft designs to light aircraft and short-distance ranges. All-electric propulsion is currently viable for a wide range of aerial vehicles. This includes vertical take-off and landing (eVTOL) aircraft, powertrain retrofits of conventional fixed-wing aircraft, and new fixed-wing aircraft concepts using electric motors. Publicly announced all-electric aircraft models include Velis Electro from Pipistrel [38], Alia-250 by Beta Technologies [39], Alice by Eviation [40], and Lilium Jet [41]. While turboelectric and hybrid aircraft configurations reduce CO2 emissions by a fraction, all-electric configuration eliminates CO2 emissions along with GHGs such as NOx and water vapor, making it the most sustainable form of technology capable of zero emissions during flight operations.

Although battery-driven architectures, including hybrid and fully electric systems, can significantly reduce aviation-related emissions, the net CO2 effect will largely depend on the source of electricity used in charging the batteries. According to World Energy Data [42], cleaner energy generation accounts for 38% of the global energy mix. This implies electric airplanes will be over 30% cleaner over its life cycle using present energy generation mix levels. Achieving the carbon neutral goals the aviation industry sets will indirectly depend largely on advancement and investment in sustainable energy generation.

3. Enabling technologies for electric aviation

Although electric aviation possesses several benefits to the environment, the primary concern that inhibits its development is range limitations due to the low energy density of the state-of-the-art battery technology, which results in heavier battery packs. Caset et al. [43] argue that to match the electrical energy equivalent required to power an Airbus A320 using present technology, the batteries' weight will exceed the maximum take-off weight by a factor of 38. Epstein and O'Flarity [26], on considering the possibility of aviation CO2emission reduction using electric propulsion, identified that 92% of the current global fleet could not take off using present battery technology due to increased weight. For this reason, NASA proposes that the threshold of energy densities of batteries to enable the full implementation of electric aircraft for general aviation and regional aircraft are 400 Wh/kg and 750 Wh/kg, respectively [44]. Viswanathan et al. [45] confirm these figures by specifying that batteries of energy densities of 600 Wh/kg and 820 Wh/kg are required for commercial regional and narrow-body aircraft, respectively.

On the other hand, Moore and Fredericks [46] state that it is misleading to compare electric propulsion and conventional aircraft based on the energy density of batteries and jet fuels. Electric propulsion will not only be defined by advancements in battery technology. However, it will also largely depend on other weight-sensitive and energy-efficient technologies such as electric motor designs and advanced airframe design concepts. By comparison, state-of-the-art Li-ion batteries with an energy density of approximately 250 Wh/kg are 48 times less than jet fuels, which possess a staggering energy density of 12,000 Wh/kg [26]. However, according to Åhman [47] and, Haung and Zhang [48], the fuel-to-wheel efficiency of an internal combustion engine averages ∼28%, while electric motors are ∼90% efficient. This reduces the ratio of batteries to aviation fuels from 1:48 to 1:15. Considering an average improvement of 600 Wh/kg battery energy density, the ratio is further reduced to 1:6.2. In addition, it has been proven through research that efficient aerodynamic designs such as distributed propulsion and boundary layer injection which are much more practical with electric aviation can reduce the overall energy consumption during flight by a factor of 3 to 5 [49]. Using the mean value of 4 reduces the ratio of batteries to aviation fuel to 1:1.5. In summary, the development approaches towards electric propulsion can be described as a three-point approach predicated on: 1. battery chemistries of minimum 600 Wh/kg, 2. advancement in electric motor design for high power applications, and 3. efficient aerodynamic design. Fig. 7 shows a comparative analysis of electric propulsion and conventional aircraft.

Fig. 7. Comparative characteristics of electric propulsion to conventional aircraft for general aviation and regional jets based on values from [46], [47], [48].

Fig. 7. Comparative characteristics of electric propulsion to conventional aircraft for general aviation and regional jets based on values from [46], [47], [48].The following sections discuss developments in these three technological areas, where they currently stand, and their potential to make electric aviation viable in the medium and long term.

3.1. Battery technology

Research in battery technology is advancing rapidly, mainly due to the growing popularity of electric vehicles [50]. The successful application of batteries in powering aviation has been demonstrated by the trainers Pipistrel's Velis Electro and Bye Aerospace's eFlyers with batteries with specific energy densities between 250 and 270 Wh/kg [51]. However, the Uber-Elevate white paper published in 2016 [52] cited that energy densities of 400 Wh/kg and above are required for electric aviation to take off fully. Tesla and SpaceX founder Elon Musk also echoed that batteries with an energy density of 400 Wh/kg with a high cycle life could be realized within 3 to 4 years [51]. Therefore, it is evident that significant improvement in battery technology will characterize the possible application and time-to-market of electric aircraft. Armand and Tarascon [53] specify that the ideal battery for use in airplanes should be light, rechargeable, safer, have long durability, and have the highest energy density possible. Fig. 8 compares the theoretical, expected, and state-of-the-art energy densities of lithium-based battery chemistries, demonstrating their significant potential in aviation. These battery types are further discussed in this section.

Fig. 8. Comparison of cell-level energy densities of potential battery chemistries for aviation applications based on values from [54], [55], [56], [57], [58].

Fig. 8. Comparison of cell-level energy densities of potential battery chemistries for aviation applications based on values from [54], [55], [56], [57], [58].3.1.1. Lithium-ion batteries

Li-ion batteries are becoming increasingly popular in research and development for electric aviation due to their higher specific power and demonstrated success in portable electronic devices and the automobile industry [53,[59], [60], [61]]. Comparing Li-ion to other high-quality rechargeable battery technologies such as nickel-cadmium (Ni-Cd) or nickel-metal-hydride (Ni-MH), Li-ion cells have higher energy densities as well as higher cell voltage up to 3.6 V, which is three times greater than these battery technologies [61]. This implies that they can produce a large amount of current for high-power applications.

However, despite the technological success and promise of Li-ion technology, several challenges restrict their application and raise numerous concerns regarding safety and lower specific energy compared to jet fuels. Li-ion batteries can overheat at higher voltages, resulting in battery damage leading to thermal runaway and explosion [62,63], which led to the grounding of the Boeing 787 fleet when onboard battery fires were reported. Solving the issue of lower specific energy in Li-ion cells requires a further increase in the energy density of the cathode and anode material. However, the electrochemical stability window of the currently available electrolyte does not allow an increase in cathode voltage above ∼4.3 V [64]. Also, the graphite anode capacity is limited to ∼370 mAh g–1. Therefore advanced cathode and anode materials that allow for higher capacity need to be developed [65]. Li-ion battery technology has achieved specific energy densities over 250 Wh/kg [54] and is currently the technology to which all other potential battery technologies for aviation and automobile applications are compared.

3.1.2. Lithium-Sulfur

Li-S batteries consist of a lithium metal anode and a sulfur-based cathode and possess a high theoretical energy density of 2600 Wh/kg, making it the most promising choice for energy storage for large-scale grids and aviation applications [55,56]. Moreover, sulfur is abundant, cheap, nontoxic, and light in nature, making it suitable for weight-sensitive applications such as aviation [66], [67], [68]. Lighter cell assemblies may be achieved with the relatively lightweight nature of both lithium and sulfur elements. However, Cerdas et al. [54] indicated that lighter cell assemblies imply a lower volumetric density which implies more space is required per unit of energy stored.

Although Li-S battery demonstrates higher specific energies, several problems restrict their practical utilization and large-scale production. Firstly, sulfur is non-conductive and requires conductive additives such as carbons into its electrodes [65]. The addition of conductive additives leads to slow electron migration, limited utilization of active substance, and poor reaction kinematics [69], limiting Li-S batteries to a lower discharge rate of 0.2 C and shorter cycle life between 180 and 300 cycles [67].

Moreover, sulfur expands significantly in volume by approximately 80% during discharge, which may lead to detachment of active components and electrical disconnection [56,65,66]. Lastly, the discharge intermediates (lithium polysulfides) formed during the conversion reaction can dissolve in the electrolyte producing a shuttle effect which results in a low sulfur utilization [56,65]. To address the issue of shorter cycle life and lower discharge rates, Zhang et al. [66] developed a graphene-oxide cathode and successfully improved the cycle life up to 500cycles. Song et al. [67] improved it further by developing a sulfur-graphene-oxide nanocomposite cathode and an ionic liquid-based novel electrolyte. The authors achieved a Li-S that could achieve a discharge and charge rate of 6C and 3C, respectively, with 1500cycles.

Li-S batteries with energy densities higher than 500 Wh/kg, about two times greater than the state-of-the-art lithium-ion battery, have been successfully demonstrated [70]. It is currently the only rechargeable battery technology to have reached such high energy density and 1350 cycles [71]. The application of Li-S in aviation was successfully demonstrated by the Airbus Zephyr aircraft (a solar-powered UAV), which made the longest endurance flight of 14 days [72,73]. In 2019, Oxis Energy and Bye Aerospace collaborated and developed a 500 Wh/kg Li-S battery, which offered a two-fold reduction in battery weight [74].

3.1.3. Solid-state batteries

Solid-state battery technology presents a perfect solution for the intrinsic shortcomings of current lithium-ion batteries’ poor cycle performance, electrolyte leakage, flammability, and limited voltage [75]. Extensive research on developing battery technologies has led to the development of solid electrolyte, which provides high lithium conductivity at room temperature while providing high processing flexibility and stability [76]. The unique feature of this battery is a solid-state ceramic separator (solid electrolyte) and a pure lithium metal anode [77]. The highest theoretical capacity (3860 mAh g − 1) and lowest potential (−3.04 V) of lithium metal make it the ultimate anode material for all-solid-state batteries [78]. The advantage of solid-state technology is reflected in its shorter charging time, higher energy density, and inherent safety compared to aqueous Li-ion battery electrolyte. These qualities put solid-state batteries ahead of conventional Li-ion batteries and is currently envisioned as the future battery technology for energy storage.

In 2020, NASA launched the Solid-state Architecture Batteries for Enhanced Rechargeability and Safety for Electric Aircraft (SABERS) project [79]. The preliminary results showed a carbon-sulfur cathode capable of achieving 1100 Wh/kg at a discharge rate of 0.4C and 804 Wh/kg at 1C discharge rate. In July 2021, Quantum Scape also unveiled a 10-layer solid-state battery with 390–500 Wh/kg energy density. This battery could charge from 0 to 80% of its capacity in 15 min and achieved 800 cycles to meet the current automobile standard [80]. The real challenge with solid-state batteries lies in developing methods for mass production. However, Quantum Scape has mentioned entering mass production by 2025.

3.1.4. Lithium-air batteries

Based on the electrolyte used, Li-air batteries are classified into the non-aqueous electrolyte, aqueous electrolyte, hybrid electrolyte, and solid-state electrolyte [81,82]. Although a complete description of the various Li-air chemistries is beyond the scope of this paper, the non-aqueous Li-air battery is considered the most advantageous since it has the highest specific energy density and can sustain a reversible cycle [83]. For the charged state, 1 kg of lithium metal oxidation produces 11,680 Wh/kg without oxygen. The discharge reaction produces an energy density of 3460 Wh/kg (usable energy) [57,58]. However, Li-air batteries are confronted with several challenges, including lower electrical efficiency in the range of 60% to 70% compared to other battery chemistries, lower specific power, and low discharge rates [58]. At present, no practical application of a Li-air battery exists. To demonstrate the feasibility of utilizing Li-air batteries in aviation, NASA built a 5-cell battery pack that consisted of a lithium-metal anode, a porous carbon cathode, and an ether-based electrolyte [84]. However, this demonstrator achieved only 200 Wh/kg, representing 5% of the calculated energy density, and could only achieve 5–25 cycles. NASA further explained that the battery pack could reach 700–800 Wh/kg energy densities when optimized. Girishkumar et al. [58] predict that Li-air batteries with an energy density of 1700 Wh/kg may be achieved, while Thielmannl et al. [85] predict that Li-air batteries may be market-ready by 2030. For this reason, Airbus and EADS are considering a Li-air battery to power the Voltair aircraft they estimate to enter the market in 2035 [86].

3.2. Electric motor technology

Electric motors convert the magnetic and electric field energies into mechanical energy, which translates into propeller motion in an aircraft [87]. Conventional electric motor technologies are not designed for weight-sensitive applications, are limited by heat generation in the copper windings, are heavier, and have a specific power of 1–5 kW/kg, which is very low compared to gas turbines[88,89].

For this reason, current research into motor technology for high power applications has mainly focused on using high-temperature superconducting materials (HTS). HTS motor design utilizes a permanent magnet such as Neodymium-Iron-Boron (NdFeB) as its rotor material. To ensure a constant interaction between the rotor poles and the electromagnetic field of the stator windings, active power control and management unit (PMAD) is employed to control the current in the stator windings [90,91]. Fig. 9 shows a basic layout of an HTS motor with a superconductive rotor.

Fig. 9. A basic layout of an HTS motor with a superconductive rotor [92].

Fig. 9. A basic layout of an HTS motor with a superconductive rotor [92].Superconductivity is an effect that causes the ohmic resistance of a particular group of materials to be lost at specific temperatures, usually at extremely low temperatures (between −192 °C and −246 °C) [49,[91], [92], [93]]. This effect can increase the armature's electric field capability and electric field intensity in electric motors. Since superconductors can carry high current density with no resistive losses, very light machine assemblies with high specific power can be achieved by replacing either the stator and rotor windings with high-temperature superconductive coils [88].

Sivasubramaniam et al. [92] studied HTS motor design for aerospace applications where they replaced the stator with HTS coils. Their preliminary results showed a significant increase in specific power up to 10 kW/kg, which meets the power output of the modern internal combustion engine. On the other hand, Luongo et al. [88] conducted a study on the potential application of HTS motors for aviation. They concluded that replacing both rotor and stator windings with HTS coils could produce a staggering 40 kW/kg specific power at efficiencies greater than 99%. This is over three times more power per unit weight than gas turbine engines. However, the authors specified that it would take 20–25 years for the first fully HTS motors to be implemented. To meet the Flightpath 2050 objectives, the EU sponsored the Advanced Superconducting Motor Experimental Demonstrator (ASuMED) project [94] led by the German electric motor manufacturer Oswald Elektromotoren. The ASuMED motor presented in Fig. 10 is a 1MW motor with a power density of 20 kW/kg. It uses HTS material for both its stator and rotor and operates at an efficiency of 99.9%.

Fig. 10. Mockup of the ASuMED motor presented at the 2019 Hannover Fair [94].

Fig. 10. Mockup of the ASuMED motor presented at the 2019 Hannover Fair [94].