1. Introduction

In terms of climate change mitigation efforts, an overarching goal at the global level is needed to control the temperature intensification due to human activities below 2 °C by mid-century (United Nations, 2015). The main sources of greenhouse gas (GHG) emissions leading to temperature rise are categorized into the energy- (heat and power producer (40%)), building (9%)-, transport (24%)-, and industry (24%) sectors (IEA, 2020f, 2019a). In recent decades, the building-, transport-, and energy sectors have attempted to develop distinct decarbonization pathways (Fischedick et al., 2014). In contrast, as one of the most challenging sectors that significantly impact global warming, the industry needs to make more efforts to clarify its decarbonization roadmap. The industry consumes about a quarter of the world's total primary energy,1 of which almost 70% comes from fossil fuels (IEA, 2020f). Globally, the industry is also responsible for over 24% of total anthropogenic GHG emissions due to fossil fuel consumption and manufacturing process, without including indirect emissions from purchasing electricity and heat (IEA, 2020i). The difference between the industrial subsectors regarding energy consumption and GHG emissions is noteworthy. While the iron and steel (I & S); chemical and petrochemical; cement; aluminum, and pulp and paper (P&P) industries, as energy-intensive industrial subsectors (EIIs), are responsible for more than two-thirds of industrial energy demand and sectoral emissions; the rest of energy consumption and emissions are accounted by other industrial subsectors such as textiles, food and drink, wood and wood products, machinery, etc. (IEA, 2020f).

To transition the industry to a low-carbon economy, decarbonization of EIIs is critical. However, specific factors such as high-temperature heat demand, process emission results from chemical reactions, and the long life of the industrial plants make it challenging to mitigate emissions from EIIs (IEA, 2020f; Pee et al., 2018). This study, performed within the framework of NEFI- New Energy for Industry (NEFI), a consortium of Austrian companies, research institutes, and public institutions, aims to develop an integrated approach for deep decarbonization of EIIs toward being sustainable, efficient, and a low-carbon economy and examines the Austrian EIIs as a case study.

1.1. State of research

In recent years, studies have started to look at ways to save energy and reduce emissions in the industry. The literature covered within the systematic and comprehensive literature review of this work includes policy documents, roadmaps, technical reports, journals and conference publications, and forecast studies on the transformation and decarbonization of the energy system focusing on the industrial sector, divided into two groups: the integrated industry sector and individual industrial subsectors.

1.1.1. State of research on the Integrated Industry Sector

The first group of references has proposed energy savings and emissions reduction in the industry as an integrated sector. This group is almost top-down in its approach. Their main goals are to find possibilities to reduce GHG emissions and analyze the industry's overall emission reduction strategies at the national and international levels. European Commission studies (European Commission, 2018c) and International Energy Agency (IEA) reports (IEA, 2021c, 2020f) have addressed the transformation of emissions and energy in the industrial sector, likewise the other sectors, such as buildings, transport, and energy in the EU and international contexts.

Some references in this group were more industry-specific, focused on EIIs, and sought to highlight emissions reduction opportunities (Chan et al., 2019) and present decarbonization pathways (Bataille et al., 2018). In addition to providing a compilation of possible key solutions, numerous publications also discussed the barriers and challenges facing the industry. Wesseling and his colleagues (Wesseling et al., 2016) pointed out costs, availability of renewables and electricity, and lack of infrastructure as major bottlenecks to the adoption of new technologies (Wyns and Axelson, 2016). presented the crucial conditions and frameworks. They stated that the exciting or new obstacles like the development and cost of new technologies, energy constraints, circular economy and material efficiency, etc., must be overcome to decarbonize the EIIs. Beyond the reflection on possibilities and obstacles, a group of references provided recommendations for policymakers, such as improving emissions monitoring and benchmarking and converting the existing plan to BAT as fast as possible (Napp et al., 2014), providing stimulus and technical support, and promoting a market for low-carbon technologies (Whitlock et al., 2020), etc.

Although industrial emissions, and EIIs specifically, are hard to abate, industry decarbonization is technically feasible. In the following the options that have been widely discussed in the literature are divided into five pillars:

-

•

Energy efficiency improvement (I) is seen as the most technologically mature option (European Commission, 2018b). However, energy efficiency improvement using the Best Available Techniques (BAT) or Best Practice techniques (BPT) cannot reduce emissions by more than 15–30% for the industry sector (Chan and Kantamaneni, 2015; European Commission, 2018c). They are fundamental in the first step for near-term transformation to a low carbon economy (Fischedick et al., 2014). They can immediately and simultaneously reduce emissions and provide additional cost reduction benefits in the next step (IEA, 2021e).

-

•

Electrification (II) of industrial processes' heat (steam) demand is one of the key pillars of decarbonizing the industrial energy system (IEA, 2020f). Electrification offers a wide range of opportunities to reduce emissions in the industrial sector. Industrial manufacturing requires fossil fuels for heating at low, medium, and high temperatures, which can be replaced by electrification across a broad spectrum. At low to medium temperatures (up to 400 °C), the heat demand for space heating, cooling, steam generation, and drying can be fully electrified with commercial electric boilers, infrared, microwave and heat pumps (close to ready to use for medium temperatures), etc. (Lechtenböhmer et al., 2016; Madeddu et al., 2020). Such technologies are mature and have adequate capacity for industrial applications (Madeddu et al., 2020). Nonetheless, the main challenges are the high-temperature heat requirements. Electrification of this group is technically feasible, but the technologies are not yet fully developed (e.g., electric furnaces and thermal plasma for the cement sector (Vattenfall, 2019), electrowinning, and electrolysis of hydrogen (H₂) in I&S (Lechtenböhmer et al., 2016)). Electrification of industrial sites usually does not expect a fundamental change in the production process; instead, it requires replacing equipment such as boilers or furnaces. It also has other manufacturing benefits, such as reducing maintenance costs and, in some cases, capital costs (e.g., industrial boilers) compared to traditional equipment (Roelofsen et al., 2020). Electrification diminishes GHG emissions substantially where zero-emission electricity is utilized; otherwise, it boosts GHG emissions. Nevertheless, the availability of sufficient renewable resources for power generation, the electricity price (Lechtenböhmer et al., 2016), and the readiness of the essential technologies in high-temperature demand (Bruyn et al., 2020) are obstacles facing electrification.

-

•

Fuel switching (III) by replacing fossil fuels with biofuels (biomass, biogas, H₂, etc.) as an energy source or feedstock is a crucial option that can significantly reduce emissions in EIIs (European Commission, 2018c). The substitution of fossil fuels as feedstocks in the I&S as well as the chemical industry requires converting production processes and adopting alternative technologies (Bruyn et al., 2020; Pfaff et al., 2018). A few industries have started to transition to alternative fuels, although some technological options for moving energy-intensive processes away from current fossil fuels are not yet commercially available and require further optimization to become technically viable (Lyons et al., 2018). The replacement of fossil fuel as an energy source is dependent on the temperature and the direct or indirect purpose of fuel use. Traditional bioenergy sources such as biomass and biogas would be employed at low to medium temperatures, where fossil fuels are indirectly used (Honore, 2019). For high-temperature heat, which is usually direct combustion with fossil fuels, solid biomass, biomethane, and H₂ can be burned directly instead of fossil fuels (Honore, 2019). H₂ (Dolci, 2019)and biomethane are the most attractive renewable sources and can be used 100% or combined with other fuels (IEA, 2019b). The comparative similarity between H₂ and biomethane with natural gas (NG) means they are likely suitable for many processes currently powered by NG (Lyons et al., 2018). The main obstacle to fuel substitution that must be overcome before any particular technology can be considered a realistic option is the reliability of biomass and H₂ supply in sufficient quantities and the impact on product quality for direct heat applications (Lyons et al., 2018).

-

•

Carbon Capture and Storage (CCS) or Carbon Capture Utilization and Storage (CCUS) (IV) are up-and-coming abatement options. They may play an indispensable role in some subsectors such as cement (non-metallic minerals), chemical, and I&S (Pfaff et al., 2018). In these subsectors, the process-based emissions, an inherent part of production processes, can be heavily decreased using CCS/CCUS with no or less modification of existing production processing (Bruyn et al., 2020). The widely used and under considering separation technologies are chemical absorption, physical separation, oxyfuel separation, membrane separation, and calcium looping (IEA, 2021a). The collected carbon dioxide (CO₂) from the exhaust gases, after purification and compression, is transported for permanent storage in an underground storage facility (Alcalde et al., 2018; IPCC, 2005) or used in another industrial subsector as a feedstock (Pee et al., 2018; Pfaff et al., 2018). The chemical industry and fuel manufacturing are interested stakeholders in using captured CO₂ to produce cost-effective, low-carbon products (IEA, 2020c, 2019d). Combining CO₂ capture technology with renewable energy sources - the promised goal for the next decades - will represent a profound transformation towards net-zero emissions (IEA, 2021d). Notwithstanding the benefits of CCS/CCUS in bringing the technology to existing industrial sites, some barriers to deployment need to be addressed. Currently, the high cost of CCS/CCUS techniques, the lack of the enabling infrastructure to transport captured CO₂ to the storage site, and insufficiently available geological reserves for CO₂ capture, which are essential for reducing the risk of carbon leakage and storing carbon for a long time (Alcalde et al., 2018; IPCC, 2005), are obstacles that need to be overcome (IEA, 2020c, 2019c).

-

•

Circular economy (V) (Material Economics, 2018) and raw material efficiency (Material Economics, 2019) are also remarkable options for emissions reduction in the future. Track the industry value chain from raw material production to end-use consumption can limit the waste of materials. By improving the waste management system, materials will be able to return to the economic cycle and decrease primary materials production, which is energy and emission-intensive (e.g., primary steel production, primary paper production, etc.) (European Commission, 2018c). The production of recycled materials such as secondary aluminum, secondary steel, paper making by recycling fibers, etc., is considerably less energy and emission-intensive than the extraction of the same tons (t) of new materials. The objective of the circular economy is achieved by minimizing waste throughout the supply chain and optimizing material use (Material Economics, 2018; Sen et al., 2021). Combining the circular economy with a material efficiency strategy-that improves material production and reduces material consumption-provides a great occasion to decarbonize EIIs. However, some hurdles must be overcome in implementing the circular economy strategy than the current system, which uses less recycled material. Lack of knowledge and specific framework conditions to make the industry take a step in this direction, uncertainty about consumer acceptance, technical feasibility, and production costs are some issues that need to be explored (McKinsey & Company and World Steel Association, 2021a; Sen et al., 2021). Furthermore, most of all, this concept requires close collaboration throughout the value chain.

In addition to the technologies and pillars mentioned above, the industrial transition to a low-carbon economy cannot be an isolated affair (Wyns and Axelson, 2016). Instead, it must be coordinated with other important shifts in other sectors, such as transportation and energy, during the coming decades. In particular, in connection of the industry sector with the energy sector, manufacturers face supply and price fluctuations of natural gas (currently imported from Russia to Europe), which could significantly affect the costs transferred through the supply chain, industrial demand, technical problems, and fuel prices. Overall, a sustainable transition will require a concerted effort by the public and private sectors, industrial companies, government, and policymakers (European Commission, 2018b, 2018c).

1.1.2. State of research on the individual industrial subsector

The most recently emerging literature in this group has put forward an in-depth analysis of the various technology options in EIIs separately. They usually have taken a bottom-up approach and focused on each subsector's specific information and mitigation options. In addition to the scientific papers, the well-known technical reports published by the European Commission, the Joint Research Center (JRC), and the IEA on I&S (EUROFER, 2013; Pardo et al., 2015), P&P (Moya and Pavel; Suhr et al.) cement (European Cement Research Academy and Cement Sustainability Initiative, 2017; IEA, 2018), and aluminum (Cusano et al., 2017; Moya et al., 2015) subsectors were consulted.

Table 1 shows some cutting-edge technologies (excluding BAT) of the literature considered in Sections 1.1.1 State of research on the Integrated Industry Sector, 1.1.2 State of research on the individual industrial subsector. categorization by subsectors and technology pillars. The Technology Readiness Level (TRL) is also introduced to characterize the maturity levels of technologies.

Table 1. Decarbonization Technology from the literature research for the considering EIIS.

| Technology option (pillar) | TRL | Description | application | References |

|---|---|---|---|---|

| Electrification (II) | 4–5 | Use of electricity to reduce the iron ore in two ways Electrolysis (ULCOLYSIS) and Electrowinning (ULCOWIN) | Ironmaking | (Moya and Pardo, 2013; Siderwin, 2018; World Steel Association, 2021a; Yan Junjie and Junjie, 2018) |

| Smelting reduction process (HIsarna) (III) | 7 | Reduce directly injected iron ore at the top and coal powder at the bottom by using purified oxygen to replace the air in the smelting reduction process. The process will produce CO₂-rich waste gas and is suitable for combination with a CCS plant. | Ironmaking | (Abdul Quader et al., 2016; EUROFER, 2013; IEA, 2021b; Yan Junjie and Junjie, 2018) |

| Top gas recycling (TGR) (III) | 7 | recycle the CO and H₂-containing blast furnace exhaust gas (BFG) and utilize it as a reduction agent to replace coke or coal | Ironmaking | (Feiterna et al., 2014; Pardo et al., 2015; Pfaff et al., 2018; Yan Junjie and Junjie, 2018) |

| Direct reduction with Natural gas (ULCORED) (III) | 9 | Use of natural gas as a reducing agent in direct reduced iron (DRI) replacing coke. To increase the emission reduction efficiency process can be integrated with CCS. | Ironmaking | (EUROFER, 2013; Keys et al., 2019; Yan Junjie and Junjie, 2018) |

| H₂ plasma direct reduction (III) | 4 | Use of H₂ plasma to melt the pre-reduced fine or pelletized iron ore as reductant. | Ironmaking | (IEA, 2020f; Naseri Seftejani et al., 2019; Sabat and Murphy, 2017) |

| Direct reduction iron with hydrogen (DRI-H₂) (III) | 5 | Use of H₂ (renewable) instead of coal for the reduction of iron ore pellets in the shaft furnace or fine iron powder in the fluidized bed | Ironmaking | (Bhaskar et al., 2020; Da Ranzani Costa et al., 2013; IEA, 2020f, 2019b; Thyssenkrupp, 2021; Vogl et al., 2018) |

| CCS/CCUS (IV) | 6–7 | CO₂ separation of other produced gases (BF gas containing up to 60% CO₂) in the iron-making process and capture it. The captured CO₂ can be used in other industrial processes such as the chemical industry. | Ironmaking | (IEA, 2019d; IEAGHG, 2013; McQueen et al., 2016) |

| Black Liquor gasification (BLG) (I) | 8–9 | BLG is a new technology capable of efficiently recovering energy from the black liquor's organic content using a recovery boiler and gasification process. | Pulping | (Bajpai, 2016b; Moya and Pavel; Rogers, 2018) |

| Direct electric heating (II) | 7–8 | Fossil fuel emissions could be eliminated by replacing fossil fuels with electricity and using an electric boiler instead of a fossil fuel boiler (natural gas boiler) to generate heat (steam) demand. If the electricity is supplied from renewable sources, net-zero emissions could be reachable. | Papermaking | (Marsidi et al., 2018; van Berkel, 2018) |

| Heat pump - recovering waste heat (III) | 6–7 | The heat pump can convert the arising low-temperature waste heat from process to medium temperature by consuming electricity. Reusing the waste heat at an acceptable temperature would drastically reduce fossil fuel emissions and improve energy efficiency. | Papermaking | (Marsidi et al., 2018; van Berkel, 2018) |

| Deep eutectic solvents (DES) (I) | 3 | DES are produced naturally by plants and can break down wood and selectively extract cellulose fibers required in the papermaking process. DES has the potential to be used in pulp production using wood and waste paper with minimized energy demand and CO₂ generations. | Pulping | (Cepi, 2013; Rogers, 2018) |

| Flash Condensing (I) | 3–5 | The concept of this technology is to produce waterless paper using high turbulent steam combined with dry fibers. The technology can be applied to any pulp (chemical, TMP, RCF) and reduces energy consumption and fossil fuel CO₂ emissions. | Pulping | (Cepi, 2013; WSP Parsons Brinckerhoff, 2015) |

| Carbon capture and storage or Biomass-based CO₂ CCS (BECCS) (IV) | 6 | CO₂ emissions from combustion processing, the recovery boiler, and the lime kiln, particularly at the kraft pulp mill, can be captured and stored, allowing the industry to be a negative emissions site. | Pulping | (Jönsson and Berntsson, 2012; Kuparinen et al., 2019; Moya and Pavel; Sagues et al., 2020) |

| Superheated steam drying (I) | 3–5 | Replacing the air needed to remove water from the paper in the drying section with superheated steam can improve heat recovery (full recovery) and increase energy efficiency. The recovered steam can be used in the next steps of paper production. | Papermaking | Cepi (2013) |

| Gas-fired dryers (I) | 6–7 | Dryers are heated with hot gases from gas combustion (which may occur in the drum) instead of steam. This dryer technology improves energy efficiency by 75–80% compared to the 65% of the usual system. | Papermaking | (Cepi, 2013; Kong et al., 2012, 2016) |

| Microwave Drying (I) | 3–4 | Paper is dried by exposure to microwave radiation. This technology increases the drying rate and reduces the total energy consumption. | Papermaking | (Cepi, 2013; Kong et al., 2012, 2016) |

| Waste heat recovery (I) | 8–9 | Recovery of waste heat from the kiln and clinker cooler and converted to electricity using available technologies such as Organic Rankine Cycle, Single Flash Steam Cycle, Duel Pressure Steam Cycle. | Clinker making | (Pardo et al., 2011; Wang et al., 2009) |

| Advanced grinding (I) | 6–9 | New grinding technologies such as ultrasonic grinding and non-contact grinding are more efficient grinding processes that can be applied to both raw materials and fuel grinding | Cement making | (European Cement Research Academy and Cement Sustainability Initiative, 2017; IEA, 2021b, 2018) |

| Electrification (II) | 4 | Instead of fossil fuels, electricity can be used to meet the clinker kiln's high temperature (1400 °C) heat demand. Electrification is achieved by adapting plasma technologies, microwave heating, and induction heating, which are not commercially available. | Clinker making | (Cembureau, 2019b; IEA, 2020f; Lechtenböhmer et al., 2016) |

| New binder- carbonate calcium silicates | 7–8 | Carbonated calcium silicate is a new alternative clinker with little lime compared to conventional clinker. It can be produced in the same kiln as Portland cement with a lower burning temperature. | Clinker making | (Gartner and Sui, 2018; IEA, 2020f; Lehne and Preston, 2018) |

|

New binder- Magnesium Silicates (MOMs) |

3 | Magnesium oxide, which is produced by calcining natural magnesite rock, can be used instead of limestone for clinker production and leads to negative emissions in cement production, as the CO₂ produced during the process is returned to the process. | Clinker making | (Gartner and Sui, 2018; IEA, 2020f; Lehne and Preston, 2018; Taylor, 2013) |

| New binder- Alkali activated binders (geopolymers) | 9 | the alkali-activated material, a source of soluble base activator (alkali), and aluminum-rich materials produce the cement with lower energy and carbon intensity than Portland cement. | Clinker making | (Gartner and Sui, 2018; IEA, 2020f; Lehne and Preston, 2018; Luukkonen et al., 2018) |

| CCS- Oxyfuel (IV) | 6 | Using oxygen instead of air to produce CO₂-rich exhaust gas that can be easily captured after purification. | Cement making | (Jordal et al., 2019; Voldsund et al., 2019) |

| CCS- Calcium looping (CaL) (IV) | 7 | In CaL technology, part of the captured CO₂ from production processing is used in a reversible carbonation reaction to produce the CaO. The remaining CO₂ is stored. CaL can be implemented in tail-end or integration configuration. | Cement making | (Lena et al., 2017, 2019; Rodríguez et al., 2012; Voldsund et al., 2019) |

| Inert anode (I) | 5 | New electrolytic technology utilizes an inert anode instead of a conventional carbon anode. The inert anode is a non-consumable anode that produces O₂ instead of CO₂ and increases energy efficiency by 25% during the primary AL production. | Primary Aluminum making | (Chan et al., 2019; Elysis, 2021; Solheim, 2018) |

| New decoating equipment (I) | 8–9 | Decoating technology removes the contaminated material and cleans the surface of recycled aluminum. This technology improves the process and reduces raw material loss. | Secondary Aluminum production | (Chan et al., 2019; Evans and Guest Graham, 2000; Moya et al., 2015) |

| Recuperative or regenerative burners (I) | 8–9 | These burners can be installed in primary and secondary ways and save energy (fuel consumption) by 30–50%. | Primary/secondary Aluminum making | (Chan et al., 2019; Moya et al., 2015) |

| CCS/CCUS (IV) | 4 | Application of CCS in primary aluminum smelting process with CCS absorbent. | Primary Aluminum making | (Chan et al., 2019; Mathisen et al., 2014) |

The extended description of related technologies is discussed in the other sections.

1.2. Objective and structure

To evaluate how future production demands in the EIIs might affect CO₂ emissions and support the net-zero transition, this study aims to close the gap between current climate strategies and the long-term goal of deep decarbonization. This essay examines decarbonization strategies for EIIs globally and analyzes them using the Austrian case study as the primary focus. So the objectives of the present paper, intending to take into account the less mentioned issues in the previous works, are organized as follows:

-

•

Whereas previous research, as cited in Sections 1.1.1 State of research on the Integrated Industry Sector, 1.1.2 State of research on the individual industrial subsector, employs a top-down approach for the integrated industry sector or a bottom-up approach for individual subsectors, the present work intends to assess the impact of abatement options using a mix of bottom-up and top-down perspectives on individual subsectors. Therefore, prepare an energy flow Sankey diagram for each subsector to identify the source and type of energy consumption and emissions for today's process chain.

-

•

Conduct an extensive inventory of technology options for four EIIs: I&S, P&P, cement, and aluminum, based on the energy-saving and emission abatement potential and maturity of the technology, using valuable knowledge gained from other literature through the process- and energy-system analysis, and divide the important options into two main groups: short/medium-term and long-term reduction.

-

•

Introduce a comprehensive and convenient framework for selecting technology for decarbonization pathways that has received little attention in the literature so far.

-

•

Determine the most important subsector-specific technology pillars and propose broad decarbonization pathways for Austrian EIIs. It is noticeable that in recent years some research has paid attention to Austrian industry (Karl-Heinz Leitner et al., 2014; Sejkora et al., 2018), such as I&S (Dock et al., 2021; Raupenstrauch and Pulm, 2014), cement (Haider and Werner, 2014), P&P (Rahnama Mobarakeh et al., 2021; Steinmüller, 2014), and aluminum (Pulm and Raupenstrauch, 2014) but has mainly focused on improving energy efficiency and less focus has been given to emissions reduction. Consequently, the primary intention of the present work is to compensate for this.

The following qualitative structure provides the following subjects throughout this study: Section 2 presents a systematic methodology used in the framework for identifying and categorizing relevant technology options. Section 3 gives a broad overview of the Austrian industry, concentrating on EIIs. Section 4provides a global perspective of each subsector's manufacturing processes, energy consumption, and carbon footprint. The investigation of the current situation for the Austrian case study is then continued by giving an energy flow Sankey diagram for each subsector. This section also analyzes emission reduction technologies for each subsector in two groups: short/medium-term and long-term, based on the literature review results. Eventually, the qualitative bottom-up method examines the Austrian case's possible decarbonization pathways. Section 5 discusses the potential decarbonization pathways for Austrian EIIs, including opportunities and barriers. Finally, the key findings are summarized in Section 6. This groundbreaking study helps policymakers, industry analysts, and especially energy modelers better understand the climate change policy gap and take a step toward making a sustainable transition to a zero-emissions economy.

2. Methodology

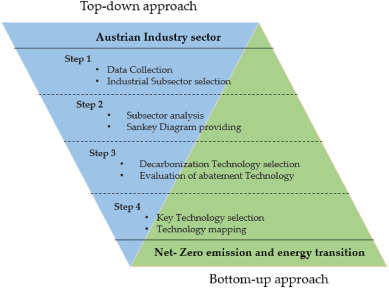

In this paper, we apply a mixed top-down and bottom-up approach with the following steps (Fig. 1):

-

•

A top-down approach was used to identify key industrial subsectors based on energy consumption, emissions footprint, and economic data in the first step. This was done using available national and international statistical data. The latest Austrian statistical information is used for the subsectors.

-

•

In the second step, a bottom-up approach was applied to evaluate technology pathways for decarbonization. This approach starts with the analysis of the individual industrial subsectors. The production process and energy consumption are assessed using an energy flow Sankey diagram. Analysis of the Sankey diagram helps determine the type of energy source, distinguishes between total energy : Eq. (1) and final energy consumption, and leads to an understanding of the source of GHG emissions in each subsector.

-

•

In the third step, an extensive literature review was conducted to identify technology options to enhance energy efficiency and reduce emissions. Various resources such as the latest scientific papers, reports, books, conference proceedings, and web materials have been studied. Each industrial subsector has created a list of related technologies to the respective BAT and IT. This technology database (only a part of the database is presented in this essay- Table 1) collects the data on energy-saving potential, emission reduction potential, investment cost (CAPEX), operating cost (OPEX), market entry, and TRL of each technology. In this step, the technology options were benchmarked on the technical indicators, and a shortlist of the most relevant technologies was selected. The selected technologies are out of the emerging technology listed. Mainly, technologies that will have a massive impact on energy savings and emission reduction in the subsector by 2050 and are the most promising according to EU, and worldwide benchmarks will be assessed in two approaches: short/medium-term and long-term. This study's short/medium-term vision focuses on routes and technologies that are ready to deploy or have already been deployed at an industrial scale and will have an immediate mitigating effect by 2030. They may not significantly influence deep decarbonization but are necessary to pave the way for long-term goals. In contrast, the long-term strategy prioritizes complete decarbonization in the second phase. It addresses technologies and methods that are not yet commercially accessible but have the potential to be proven beyond 2030. Various Key Performance Indicators (KPIs), such as Specific Energy Consumption : Eq. (2), and Specific CO₂ emissions : Eq. (3) served to select the technologies in each subsector.

Fig. 1. Review of the methodology employed in the study.

Total energy consumption is based on Eq. (1), and total CO₂ emission is the sum of direct emissions from fossil fuel burning and process emissions : Eq. (4) . However, there is another source of emission (indirect emission) from electricity supplied to the industrial subsector . This emission is computed upon the amount of electricity purchased for the subsector and the electricity grid emission factor . Due to some restrictions and uncertainty, such as the future share of renewable sources for electricity production, import or export policies, and emission reduction strategies in the energy and electricity sector that are beyond the control of industry, a detailed analysis of indirect emissions (based on the type of fuel used for electricity production in Austria) is outside the scope of this study's system boundaries. Nevertheless, for a more precise analysis of the emission reduction target, the indirect emission is calculated using the electricity demand for each subsector and the European electricity grid emission factors in the base year 2019 (European Environment Agency, 2020), in the short/medium term in 2030, and for the long-term approach in 20503 (European Commission, 2020)(4)

These indicators are used particularly for Austrian industrial subsectors to aid in analyzing each subsector's current energy performance and emissions footprint compared to EU benchmarking data, as well as to determine the next step and opportunities for energy improvements and emission reductions.

-

•

Finally, for the Austrian case study, this work proposes a decarbonization technology mapping for each subsector based on two short/medium- and long-term approaches that comprise important alternatives and technologies and estimate a technological demonstration rate. This technology mapping is crucial as input for energy system modeling and assessing the future performance of various technologies and routes for scenario creation in order to accomplish the Austrian industrial transition to a low carbon economy in the 2030 and 2050 timeframes.

However, selecting the most promising technology-based decarbonization option for each subsector requires close collaboration between energy policy, the research community, and the industry. This collaboration can be accomplished by direct interviews with industry representatives and discussing the technology list with experts. This approach ensures that both industry and researchers take advantage of the same possibilities.

3. Overview of Austrian energy-intensive industry

In Austria, industry accounts for about 35% of total energy consumption (Sejkora et al., 2018) and 28% of final energy consumption (Statistik Austria, 2019a), with more than 66% of this energy consumed by EIIs (Fig. 2). The required energy is drawn from various sources, renewable and mainly fossilfuels resources (Table 2), to provide the necessary thermal energy (heat and steam) and electrical energy (for pumps, motors, dryers, etc.) or to be used as a reducing agent in the chemical reaction of the production process.

Fig. 2. Total and Final energy consumption by EIIs compared to energy consumption by industry sector in Austria (Statistik Austria, 2019a; 2019b).

Fig. 2. Total and Final energy consumption by EIIs compared to energy consumption by industry sector in Austria (Statistik Austria, 2019a; 2019b).Table 2. Overview of material production volume, energy-using, CO₂ emission, SEC, and SCe of the EIIs considered in this study in 2019. yr (AMAG Austria Metall AG, 2020; Austropapier, 2021; Mauschitz, 2021; Statistik Austria, 2019a; 2019b; Umweltbundesamt GmbH, 2021).

| industry Sector | Main Production | Production [Mt/yr] | Energy Consumption | CO₂ Emission [Kt] | SEC [MWh/t product] | SCe [t CO₂/t product] | |||

|---|---|---|---|---|---|---|---|---|---|

| Total Energy [TWh] | Fossil Fuel [%] | Electricity [%] | Renewable/alternative fuel [%] | ||||||

| Iron and Steel | Crude Steel | 7.4 | 35.1 | 88 | 11 | < 0.05 | 11,755 | 4.7 | 1.58 |

| Pulp and Paper | Paper (graphic, Packaging, Special | 5 | 22.5 | 30 | 20 | 50 1 | 1,943 | 4.5 | 0.38 |

| Chemical and Petrochemical | Ammonia | 0.508 | 3.18 | 97 | 3 | – | 469 | 6.26 | 0.92 |

| Olefin | 1.286 | 6.25 | 96 | 6 | – | 1,175 | 4.86 | 0.91 | |

| Non-Ferrous Metal | Secondary Aluminum | 0.788 | 0.950 | 70 | 30 | – | 138 | 1.21 | 0.18 |

| Non-Metalic Mineral | Portland Cement | 5.23 | 4.4 | 18 | 14 | 68 2 | 2,653 | 0.84 | 0.51 |

- 1

-

Renewable sources like: Black liquor, waste wood, biomass, biogas.

- 2

-

Alternative fuels include old tires, plastic waste, waste oil, agricultural residues, and paper fiber residue.

Based on Austrian national CO₂ inventory data, industrial processes and their product uses are responsible for about 34% of total national emissions (Umweltbundesamt GmbH, 2021), of which 38% are from direct fossil fuel use, and 62% are from production processing. As is shown in Fig. 3, more than 60% of direct fossil fuel emissions and 75% of process emissions are due to energy-intensive subsectors' activities (Mandl et al., 2021).

Fig. 3. Share of total CO₂ emission by industrial subsector (Mandl et al., 2021; Umweltbundesamt GmbH, 2021).

Fig. 3. Share of total CO₂ emission by industrial subsector (Mandl et al., 2021; Umweltbundesamt GmbH, 2021).In recent decades especially from 1990 onwards, the Austrian industry has caused to improve the process through measures such as energy efficiency enhancement, use of BAT and BPT, replacement of fossil fuels with renewable and alternative fuels, and the setup of internal combined heat and power plants (CHP) (Umweltbundesamt GmbH, 2021). These activities influenced in some subsectoral emission reductions, such as chemicals - 45% and minerals by - 9.2% compared to 1990 (Umweltbundesamt GmbH, 2021). In contrast, the overall GHG emission trend has risen by 21% since 1990, mainly due to the production of metal (I&S) (Umweltbundesamt GmbH, 2021). Consequently, fundamental changes in emissions reduction must be made to achieve the Paris Agreementtarget and be in line with Europe's ambitions for deep decarbonization by 2050.

To reduce emissions and lead the industry to a zero-emissions economy, this study has identified the source of emission contribution and determined the reason for fossil fuel consumption for each subsector by using a top-down approach. The outcome of this analysis is used together with the sectoral Sankey diagram developed in the next step to identify sector-specific decarbonization options. As outlined in Table 3, fossil fuels are classified into three categories: Fossil fuel use as a reducing agent, heat demand in industrial furnaces and space heating, and medium temperature demand (steam production). The CO₂ emissions (Eq. (4)) are also divided into process-related emissions, an inherent part of production processing for some subsectors such as I&S and cement, and fuel-related emissions due to the direct combustion of fossil substant in industrial furnaces or their use to generate steam in boilers or CHP. However, the CHP units currently being used at the industrial site contribute to reducing fuel-related emissions by generating heat and electricity from high-pressure steam.

Table 3. Share of fossil fuel consumption and CO₂ emission by categories for Austrian EIIs in 2019. yr (Statistik Austria, 2019a; 2019b; Umweltbundesamt GmbH, 2021).

| Industry Sector | Unit | Fossil fuel consumption | Source of CO₂ emission | ||||

|---|---|---|---|---|---|---|---|

| Reducing agent | Steam production 1 | Heat generation 2 | Process-related | Fuel related | |||

| Industrial furnace | Space heating 3 | ||||||

| Iron & Steel | [%] | 54 | < 0.01 | 44 | 1.5 | 87.6 | 12.4 |

| Pulp & Paper | [%] | – | 82 | 9 | 9 | 3 | 97 |

| Aluminum | [%] | – | – | 90 | 10 | – | 100 |

| Cement | [%] | – | 3 | 90 | 7 | 66.7 | 33.3 |

1,2. Data is generated based on the final energy consumption (except for P&P is based on total energy) (Statistik Austria, 2019a).

- 3

-

A small share is used in stationary engines (Statistik Austria, 2019a).

According to the analysis in Table 3, the emission reduction path of each subsector can be determined based on the purpose of fossil fuel consumption and the scope of CO₂ emissions. In general, the following approach seems to be recognizable:

-

•

Innovative technology must be investigated for process-related emission reduction, which is an integrated part of the chemical reaction for material production in I&S, cement, and chemicals. Replacing the current production processing with a new production system, using the recycling-based route, utilizing low carbon resources as, for instance, H₂- based reduction or carbon capture storage or utilization can be seen as solutions for process-related emission reduction.

-

•

To eliminate the emission-related fuel consumption for heat (space heating) and steam generation at low/medium temperatures, possible options for energy efficiency improvement such as waste heat recovery systems and electrification of steam generation by heat pumps (up to 200 °C) or direct electric boilers (200 °C < t < 400 °C) instead of fossil fuels boilers is investigated.

-

•

Abatement of emission-related fossil fuel combustion for high-temperature heat generation (>400 °C in the furnaces) can be achievable by replacing fossil fuels with high calorific value biofuels like bio methane, H₂, biomass, and biogas.

Nonetheless, the influence of material production with a recycling route instead of the primary path (circular economy), which can considerably impact total energy consumption and the associated CO₂ emissions, should not be ignored.

Section 4 defines the process analysis and associated abatement technologies based on this study's approach for four EIIs.

4. Energy-intensive industrial subsector

4.1. Iron and steel industry

4.1.1. Structure of the Iron and steel industry

In the past few years, global steel demand has grown significantly and is forecasted to increase by more than a third by 2050 (IEA, 2020g). Steel is made from iron ore, one of the most common materials in the earth's crust. In the world, there are two main routes to produce steel. The primary route involves steel production from iron ore via blast furnace /basic oxygen furnace (BF/BOF), and a secondary way using recycled scrap in an electric arc furnace (EAF) (Chan and Kantamaneni, 2015).

In primary steelmaking, the raw material contains coke; transferred from coal pyrolysis to coke ovens; sinter/pellets and lump ore are injected into BF/BOF to produce crude steel (CS). During this process, some by-product gases such as coke oven gas (COG), blast furnace gas (BFG), and BOF gas are generated, which are collected and used as energy sources after purification (Chan and Kantamaneni, 2015; Pardo et al., 2015).

The secondary steelmaking process using EAF involves directly melting ferrous materials, usually from scrap and recycled iron, as source material from waste streams. In this process, scrap iron is smelted and upgraded in an electric furnace under a high electric current, producing CS (Chan and Kantamaneni, 2015).

Another commercial method of manufacturing CS from iron ore is Direct Reduction Iron (DRI) (Wörtler et al., 2013). It takes place in a shaft furnace and generates sponge iron. The sponge iron, which has lower carbon content than pig iron (Ecofys, 2009b), and steel scrap are then fed directly into an EAF and melted to produce CS. This process uses natural gas (rich in CO and H₂) as a reducing agent. Therefore, this technology is more feasible for the region with lower NG and electricity prices (Pardo et al., 2015). In 2019, the CS production by BF/BOF was about 71.9%, and by EAF 27.7% worldwide (World Steel Association, 2020).