1. Introduction

Current research has indicated the transportation sector as a key contributor to global warming since it has generated approximately one-third of greenhouse gases (GHG), including carbon dioxide (CO2) emissions from fossil fuels combustion [1,2]. The environmental concerns associated with global warming have led the automotive industries to employ alternative fuels, which must be renewable and economically viable, particularly for large-sized adaptation plans, in addition to being able to meet the power and fuel economy demands of end-users [3,4].

Of the currently available alternative fuels, biodiesel is a suitable substitute for fossil diesel owing to several attributes, including its biodegradability, non-toxicity, recyclability, and compatibility with existing fuelling infrastructure and diesel engine hardware setup as well as a more straightforward manufacturing process [5]. In employing biodiesel fuels and their blends, positive effects on emissions have been reported with relative decreases in CO2, sulphur dioxide (SO2), particulate matter (PM), and unburned hydrocarbons (UHCs) [5,6]. Meanwhile, inconclusive findings on nitrogen oxides (NOx) emissions from biodiesel combustion have been obtained [7]. Nevertheless, the abovementioned potential of biodiesel fuels in lessening toxic exhaust pollutants comes with a trade-off in the lower heating values of biodiesels which may adversely affect engine power output [6]. Additionally, biodiesel combustion is associated with potential spray atomisation and mixing issues since biodiesel is typically more viscous and less evaporative. As a consequence, carbon deposition, soot formation, adhesion of piston ring, and most importantly, poorer combustion characteristics may take place that ultimately bring about lower engine performance, reduction in service intervals and increased tailpipe emissions [8,9].

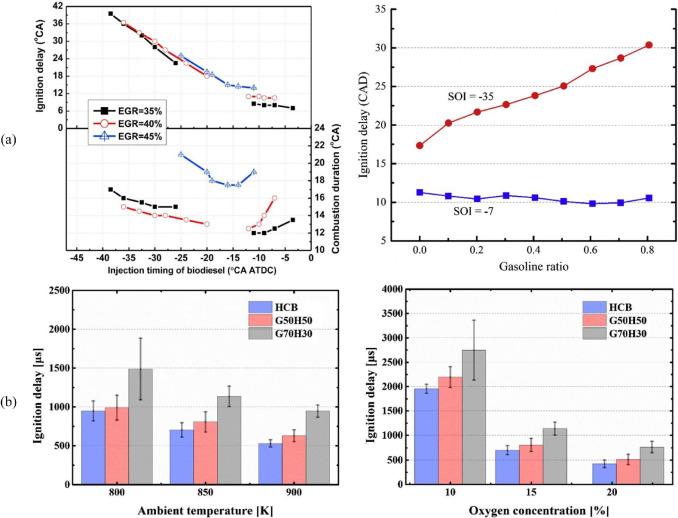

To address the aforementioned problems, certain approaches have been introduced such as fuel preheating and fuel additives, but their implementation is more likely to encounter increased costs and commercial feasibility issues [10]. Recently, the addition of gasoline as a blending component with biodiesel fuel has proven promising to alleviate the combustion concerns of diesel-biodiesel mixtures [11]. This newly introduced blending strategy is capable of altering the overall engines/fuels combusting behaviour provided that suitable controls are adopted [11,12]. For instance, previous research has revealed that the incorporation of gasoline normally causes elongated ignition delay (ID) periods [11]. This feature allows more extended air-fuel mixing and the formation of more premixed regions that eventually reduces emissions. Also, it has been ascertained that the longer ID period in conjunction with multiple injections and the recirculation of exhaust gas can facilitate a simultaneous decrease of both NOx and PM productions [13,14]. Despite the promising aspects of gasoline addition in either biodiesel or diesel blends, the controlling effects of such mixtures on the combustion characteristics for the respective blends have not yet been well-established. In fact, the combustion of gasoline-biodiesel blends in diesel engines lacks a thorough understanding of fundamental physics, which govern gasoline combustion, on both experimental and theoretical grounds.

Given the variability associated with the gasoline combusting behaviour under various operating conditions and mixing ratios [11,15], in-depth analyses are necessary to elucidate the application of gasoline addition into diesel/biodiesel mixtures. To this end, computational fluid dynamics (CFD) modelling will serve as a useful tool for this purpose. Nonetheless, a comprehensive computational insight into the in-cylinder combustion process requires combustion kinetic mechanisms to be coupled with CFD simulations. As far as the combustion kinetic mechanisms are concerned, there have been a myriad of studies to develop chemical kinetic mechanisms along with their corresponding thermodynamic data to simulate the kinetic behaviour of the intended fuel blends with acceptable accuracy [16]. Despite the abundance of such kinetic mechanisms, there remains a lack of a thorough understanding into the applicability domain of the available kinetic mechanisms which can be utilised for combustion modelling of gasoline-biodiesel blends. Thus, this work aims to provide a comprehensive review into the available kinetic mechanisms for each individual fuel and their applicability in CFD combustion modelling. This is followed by a discussion on the combustion characteristics and emissions formation for gasoline-biodiesel mixtures as attained through coupled chemical kinetics-CFD simulation studies. Furthermore, the review will identify current research limitations and recommend strategies for further development of this field.

2. Chemical kinetic mechanisms of gasoline

Gasoline fuels are multiplex mixtures encompassing hydrocarbon components and molecules such as branched and linear chains, aliphatic constituents, aromatics, olefins, paraffins and naphthenes [16]. Due to the discrepancies in primary sources and refinery processes, gasoline formulations are considerably variable worldwide [17,18]. Thus, the sheer number and variety of components within the gasoline fuel makes it unpractical to develop chemical kinetic mechanisms for each of its constituents and ultimately utilising them in CFD simulations [19,20]. Therefore, surrogate mixtures have been extensively applied to numerical modelling; as such, the combustion behaviour of the primary fuel can be mimicked using simplified representatives of the components. The formulation of surrogate models must live up to the expectations of generating essential targets such as emissions, compositions and bulk burn timing up to reasonable extents [18,19]. These targets which also define the validity of the surrogate model are dependant on the engine applications. Since they vary according to the operating conditions, engine types and in-cylinder abnormalities, it is imperative to particularly define which targets should be chosen to inspect the correspondence of a surrogate model with the primary fuel [16,18,20,21].

2.1. Gasoline surrogate mechanisms

In the field of gasoline surrogate fuels, the Pitz et al. [18] study is deemed a comprehensive review covering chemical kinetic mechanisms as well as experimentally obtained data. Battin-Leclerc [22] presented a thorough review into the kinetic models suitable for the combustion of gasoline equipped diesel surrogate blends under low temperature circumstances, in conjunction with summarising the available experimental results for validation purposes. Unlike the work of Battin-Leclerc [22], the study by Simmie [23] appraised the chemical kinetic mechanisms for oxidation, ignition, and combustion for a wide-reaching class of hydrocarbons as well as the experimental data to validate their fidelity.

2.2. Detailed chemical kinetic mechanisms

The surrogate mixtures development is mainly carried out by integrating the pure component chemical kinetic mechanisms. In doing so, they must retain a commonality or share a common mechanism, known as the core mechanism. Moreover, the reactions between the pure components, which are called cross reactions, must be taken into account upon merging the mechanisms. Previous analysis has revealed that the importance of cross reactions for mixtures comprising aromatics/alkanes is not as profound that it must be considered. Although neglecting influences of cross reactions in mixtures may cause inaccuracies in surrogate mixtures’ chemical kinetic modelling, their impacts are noticeable only in the reactions associated with intermediate radicals [20]; this fact clarifies the significance of the core mechanism developments.

The selection of pure components to be incorporated into the gasoline surrogate blend is dependant on the intended gasoline properties. Early on, n-heptane and isooctane binary blends were the main constituents of gasoline surrogate mixtures known as the primary reference fuels (PRF). The PRF blends were employed to emulate gasoline fuels with varying octane number, by simply varying the quota of binary blends [16]. Subsequently, it was discerned that for the sake of gasoline surrogate blends correspondence with the real fuel in terms of motor octane number (MON) as well as research octane number(RON), additional components must be imperatively integrated. To be more exact, the real gasoline fuels comprise hydrocarbon components that come with varying RONs and MONs. Fuel sensitivity, which is the variance between RON and MON, is zero for conventionally used PRFs and not for practical gasoline fuels [24]. Henceforth, these challenges led to the development of an alternative surrogate called the toluene primary reference fuels (TPRF). Nonetheless, further advancements showed that the implementation of TPRFs could not serve the purpose of complex combustion modelling. Therefore, multicomponent blends that include other gasoline pure components and fuel characteristics which are of utmost-importance such as molecular weight and hydrogen carbon ratio were proposed. The following subsections present and discuss the developments of detailed mechanisms of gasoline surrogate mixtures.

2.2.1. PRF and TPRF surrogates

The proliferation in detailed kinetic mechanisms for PRF surrogates concurred with the development of n-heptane and isooctane low-temperature oxidation models [[25], [26], [27], [28]]. The primary infrastructural notion lying behind the PRF mechanisms development was grounded on the oxidation of alkane [29]. The PRF models specifically facilitated the further understanding of engine-relevant phenomena such as knocking tendency and auto-ignition features. They were also utilized in some other methodologies such as octane rating [30,31]. Later, with the advent of technology and the need for more advanced surrogates that can resemble the real gasoline fuel, particularly in terms of RON and MON, TPRF surrogate mixtures were introduced. A list of chemical kinetic mechanisms for PRF and TPRF blends is summarised in Table 1. These detailed chemical kinetic mechanisms can be implemented to model a broad range of engine-relevant phenomena, however, as will be explained in the following parts, they must undergo a reduction mechanism process to lower down their complexity to allow feasible CFD modelling.

Table 1. Compilation of gasoline surrogate chemical kinetic mechanisms.

| Mechanism | Species | Reactions | Validation criteria | Reference |

|---|---|---|---|---|

| PRF | NA | NA | ID time, flow reactors, perfectly stirred reactors, and homogeneous charge compression ignition engine (HCCI) | [[25], [26], [27],28,35] |

| NA | NA | ID time, flow reactors, perfectly stirred reactors | [36] | |

| 188 | 233 |

ID time [600–1800 K] Perfectly stirred reactor & jet stirred reactor Pressure [up to 4 MPa] Equivalence ratio [0.5–1.5] |

[37] | |

| 150 | 3000 |

ID time [550–1250 K] Shock tube & motored engine Pressure [up to 2 MPa] Equivalence ratio [1] |

[38] | |

| 134 | 1006 |

ID time [650–1200 K] Shock tube Pressure [0.65–4.5 MPa] Equivalence ratio [0.5–2] |

[39] | |

| 107 | 723 |

ID time [above 950 K] Jet stirred reactor & shock tube &flow reactor Pressure [1.5 MPa] Equivalence ratio [broad range] |

[40] | |

| 101 | 479 |

ID time [600–1400 K] Homogenous charge compression ignition engine Pressure [1–4 MPa] Equivalence ratio [0.33–2] |

[41] | |

| 69 | 406 |

ID time & flow reactor & laminar flame speed Pressure [0.1 MPa] Equivalence ratio [0.1–1.7] |

[42] | |

| 58 | 120 |

ID time [672–760 K] Jet stirred reactor & shock tube Pressure [2.5–5.8 MPa] Equivalence ratio [0.5–1] |

[43] | |

| 41 | 130 |

ID time [700–1200 K] Shock tube & homogenous charge compression ignition engine Pressure [4 MPa] Equivalence ratio [0.5–2] |

[44] | |

| 41 | 116 |

ID time [650–900 K] Rapid compression machine & shock tube |

[45] | |

| TPRF | NA | NA | ID time, flow reactors, jet stirred reactors, species profile, HCCI engine | [46,47] |

| 2021 | 8688 | ID time, flow reactors, laminar flame speed, soot calculation and PAH counter-flow diffusion flame | [48] | |

| 109 | 543 |

ID time [580–1280 K] Shock tube Pressure [2 & 5 MPa] |

[49] | |

| 173 | 689 |

ID time [450 K] Perfectly stirred reactor & laminar flow speed Pressure [0.1–2 MPa] |

[50] | |

| 199 | 1011 |

ID time [1000–1600 K] Auto-ignition Pressure [0.1–2 MPa] |

[50] | |

| 276 | 936 |

ID time [300 K] Perfectly stirred reactor & laminar flow speed & HCCI Pressure [0.1–2 MPa] |

[50] | |

| 386 | 1591 |

ID time [700–1600 K] Auto-ignition Pressure [0.1–2 MPa] |

[50] | |

| 226 | 2121 |

Premix conditions Pressure [0.1 MPa] |

[51] | |

| 782 | 3631 |

ID time [490 K] Perfectly stirred reactor & laminar flow speed Pressure [0.1–2 MPa] |

[52] | |

| 1161 | 4961 |

ID time [690–1200 K] Shock tube Pressure [1–5 MPa] |

[53] | |

| 1087 | 4639 | Shock tube & HCCI | [54] | |

| 1083 | 4635 |

ID time [8,591,138 K] Shock tube Pressure [1.6–5.89 MPa] |

[53] | |

| 783 | 2883 |

ID time [500–1700 K] Shock tube & flow reactor Pressure [0.2–5 MPa] |

[55] | |

| Multicomponent | 1833 | 8764 |

ID time [650–1800 K] Laminar flow speed, perfectly stirred flow reactor Pressure [1–50 bar] |

[56], [57], [58] |

| 2315 | 10,079 |

ID time [650–1200 K] Pressure [3–50 bar] |

[59], [60], [61], [62] | |

| 1769 | 5722 | ID time | [63] |

The composition of PRF blends plays a significant role in controlling certain engine-related characteristics such as the heat release rate (HRR). A previous study revealed that the occurrence of low-temperature HRR could not be noticeably detected for the case of PRF mixtures with zero proportion of n-heptane, or in other words, pure isooctane [32]. This was attributed to the inability of isooctane to predict low-temperature oxidations. As the proportion of n-heptane incorporated in the PRF surrogate blend was elevated, the existence of low-temperature HRR became more pronounced. As such, PRF with 30% of n-heptane could perfectly exhibit the low-temperature HRR. The competency of n-heptane in predicting such phenomenon could be traced back to the presence of huge fragments of CH2 while the low-temperature HRR corresponded to the magnitude of utilised n-heptane in the PRF blend [20,33].

Conversely, it was reported that TPRF blends can replicate the ID time for various RONs [34]. It must be noted that since n-heptane possesses low-temperature reactivity, the ID time for the case of largely incorporated n-heptane (70% in TPRF) was the shortest amongst other tested cases. By increasing the proportion of toluene in the blend, the ID time increases commensurably. T explain this, the inclusion of n-heptane in the mixture brings about the production of OH radicals, but the rise in the toluene proportion acts as an eliminative component that lowers the content of OH radicals and gives rise to the formation of resonantly stabilized benzylic radicals [34].

2.2.2. Multi-component blends

Gasoline surrogate blends that comprised more than the previously explained constituents of PRF and TPRF are deemed as multicomponent blends. The PRF and TPRF models cannot accurately replicate the distillation profiles of practical gasoline fuels due to the lack of comprehensive coverage of real gasoline fuels’ boiling point range. Furthermore, PRF and TPRF mixtures do not incorporate other gasoline pure components, which retain important characteristics of gasoline fuels, such as olefins and naphthenes. Moreover, to have the surrogates demonstrating other properties like chemical functional groups, hydrocarbon class distribution, molecular weight and octane sensitivity, it is imperative to include components that are representative of these features.

Table 1 contains the chemical kinetic mechanisms developed for multicomponent gasoline surrogate blends. amongst the presented detailed multicomponent gasoline surrogates, the research carried out by Nail et al. [58]and Puduppakam et al. [56] are considered major works since they have integrated the largest possible detailed chemical kinetic mechanisms representing most of the practical gasoline fuels. However, their developed mechanisms come in large sizes, and hence, they cannot be imported to numerical simulation unless they are reduced. Meanwhile, the Lawrence Livermore National Laboratory (LLNL) research team [21,64] has dedicated years of practice to develop multicomponent gasoline surrogate chemical kinetic mechanisms. Their mechanisms incorporate TPRF components in conjunction with alkene groups. Their proposed mechanisms are grounded on the base chemistry developed by the NUI Galway [[65], [66], [67], [68]].

Recently, NUI Galway, LLNL, and King Abdullah University of Science and Technology (KAUST) research teams collaborated to propose a surrogate model for gasoline that was comprised of 10 components to represent different hydrocarbon classes [20,59,60]. In a comparative study of ignition properties of gasoline fuels (ID timing), it was shown that the implementation of previously mentioned PRF and TPRF mechanisms could replicate the experimentally determined ID timing of practical gasoline fuels under high-temperatures circumstances while the utilisation of multicomponent gasoline surrogates reproduced more accurate results for the low/intermediate temperature regimes [59,60]. Moreover, Singh et al. [69] found that the composition of multicomponent gasoline surrogates can affect some engine-relevant phenomena, particularly ignition aspects. They reported that the amount of aromatics and olefins in a blend of isooctane, n-heptane, toluene, 1,2,4-trimethybenzene and 1-hexene was proportional to the octane sensitivity. They also revealed that under high-temperature engine environment, different multicomponent compositions reproduced almost the same ID time, in contrast to low/intermediate temperature conditions where significant differences were observed for mixtures with varying compositions. This indicates that the influence of composition modification in multicomponent surrogates differs according to the temperature domain. Despite the recent developments in multicomponent gasoline surrogates, there is still a need for more advanced gasoline surrogate blends with a broader coverage of practical gasoline boiling points.

3. Chemical kinetic mechanisms of biodiesel

Biodiesel comprises long-chained fatty acid methyl esters (FAME) components. Likewise to gasoline, implementation of detailed chemical kinetic mechanisms to represent all these components is deemed unfeasible [70]. Employing simple yet well-demonstrated chemical kinetic mechanisms for biodiesel surrogates with simpler alkyl ester groups has proven a solution to model the combustion kinetics of biodiesel [71]. The development of biodiesels’ chemical kinetic mechanisms typically integrates critical species and reactions to precisely replicate the combustion-related phenomena of ignition, combustion and extinction stages.

3.1. Biodiesel surrogate mechanisms

Table 2 presents a thorough compilation of biodiesel surrogate mechanisms. The key features in developing a biodiesel surrogate chemical kinetic mechanism are the unsaturation degree, length of the alkyl ester chain and oxygen (O2) content, all of which impacts the combustion characteristics and emissions formation. For the same temperature regime, the ID timing was reportedly extended as the level of unsaturation increased [72]. Additionally, the soot and NOx emissions tendency of biodiesels in conjunction with ID timing are controlled by the saturation level of biodiesel components [[73], [74], [75]]. It has also been noted that the alkyl ester chain length significantly affects the ignition behaviour [76]. Moreover, under low-temperature circumstances, ID timing and reactivity rate is influenced by the O2 proportion in biodiesels [77,78].

Table 2. Compilation of small- and large-sized biodiesel surrogate mechanisms.

| Mechanism | Species | Reactions | Temperature | Pressure | Validation criteria | Reference |

|---|---|---|---|---|---|---|

| Small-sized mechanisms | ||||||

| Methyl-butanoate | 295 | 1498 | 800–1350 K | 1 bar |

Species profile JSR Equivalence ratio [1.13] |

[82] |

| NA | NA | 500–900 K | 12.7 bar |

Species profile Pressure flow reactor Equivalence ratio [10.35–1.5] |

[82] | |

| 264 | 1219 | 541–741 K | 40.5 bar |

Static reactor [DI timing] Equivalence ratio [0.5] |

[83] | |

| 41 | 150 | 650–1350 K | 40 & 60 bar |

Auto-ignition [ID timing] Equivalence ratio [0.4–1.5] |

[84] | |

| 88 | 363 | 600–1400 K | 10–60 bar |

Sock tube [ID timing] Equivalence ratio [1] |

[85] | |

| MBBio | 113 | 399 | 650–1350 K | 13.5 & 41 bar |

Sock tube [ID timing] Equivalence ratio [0.5–1.5] |

[86] |

| 301 | 1516 | 850–1400 K | 1 bar |

Species profile JSR Equivalence ratio [0.375–0.75] |

[87,88] | |

| 80 | 299 | 750–1350 K | 40 & 60 bar |

Sock tube [ID timing] Equivalence ratio [0.4–1.5] |

[89] | |

| Large-sized mechanisms | ||||||

| Methyl-hexanoate | 435 | 1875 | 500–1000 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.5–1.5] |

[90] |

| 401 | 2440 | 500–1000 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.5–1.5] |

[91] | |

| Methyl-heptanoate | 1087 | 4592 | 550–1150 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.6–2] |

[92] |

| 531 | 3236 | 550–1150 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.6–2] |

[91] | |

| Methyl-octanoate | 383 | 2781 | 800–1350 K | 1 bar |

Species profile JSR Equivalence ratio [0.6–2] |

[93] |

| Methyl-decanoate | 1251 | 7171 | 500–1100 K | 1.1 bar |

Species profile JSR Equivalence ratio [1] |

[91] |

| 648 | 2998 | 900–1800 K | 1 & 10 bar |

Species profile OPPDIF Equivalence ratio [0.25–2] |

[94] | |

| 125 | 713 | 900–1300 K | 1 bar | Auto-ignition [residence time] | [95] | |

| 435 | 1098 | 350–390 K | 0.67–1.91 bar |

HCCI [peak pressure, HRR CA50*] Equivalence ratio [0.71–5] |

[96] | |

| 2276 | 7086 | 653–1336 K | 16.2 bar |

Shock tube [ID timing] Equivalence ratio [0.5–1.5] |

[97] | |

| 530 | 2396 | 403 K | 1 bar |

OPPDIF [flame speed] Equivalence ratio [0.7–1.5] |

[97] | |

| 238 | 1244 | 403 K | 1 bar |

OPPDIF [flame speed] Equivalence ratio [0.7–1.5] |

[97] | |

| 3012 | 8820 | 800–1400 K | 1 & 10.1 bar |

Species profile JSR Equivalence ratio [0.25–1.5] |

[98] | |

| 1247 | 7775 | 500–1100 K | 1.06 bar |

Species profile JSR Equivalence ratio [1] |

[99] | |

| Methyl-5-decanoate | 2649 | 9247 | 800–1400 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.25–1.5] |

[79] |

| Methyl-9-decanoate | 3298 | 6904 | 800–1400 K | 10.1 |

Species profile JSR Equivalence ratio [0.25–1.5] |

[79] |

| Methyl-decanoate +Methyl-9-decanoate + n-heptane | 3299 | 10,806 | 800–1400 K | 10.1 bar |

Species profile JSR Equivalence ratio [0.5] |

[100] |

| 123 | 394 | 700–1800 K | 1–101.3 bar |

Auto-ignition [ID timing] Equivalence ratio [0.5–2] |

[101] | |

| NA | NA | 80–1250 K | 1–101.3 bar |

Species profile JSR Equivalence ratio [0.5–2] |

[101] | |

| 118 | 837 | 1000–1800 K | 1–101.3 bar |

Auto-ignition [ID timing] Equivalence ratio [0.5–2] |

[102] | |

| NA | NA | 700–1100 K | 1 bar |

Species profile JSR Equivalence ratio [0.5–2] |

[102] | |

| 77 | 216 | 700–1300 K | 40, 60, 80 bar |

Auto-ignition [ID timing] Equivalence ratio [0.5–2] |

[103] | |

| 69 | 192 | 700–1300 K | 40, 60, 80 bar |

Auto-ignition [ID timing] Equivalence ratio [0.5–2] |

[104] | |

| 112 | 498 | 700–1800 K | 1, 10, 100 bar | Shock tube [ID timing] | [105] | |

| Additional Large-Sized Mechanisms | ||||||

| Methyl-laurate | 2012 | 13,004 | 500–1100 K | 1.06 bar |

Species profile JSR Equivalence ratio [1] |

[99] |

| Methyl-myristate | 3061 | 20,412 | 500–1100 K | 1.06 bar |

Species profile JSR Equivalence ratio [1] |

[99] |

| Methyl-palmitate | 4442 | 30,425 | 500–1100 K | 1.06 bar |

Species profile JSR Equivalence ratio [1] |

[99] |

| Methyl-stearate | 6203 | 43,444 | 500–1100 K | 1.06 bar |

Species profile JSR Equivalence ratio [1] |

[99] |

- ⁎

-

crank angle where the accumulated heat is half-released.

Compared to fossil diesel, the oxygenated compounds in biodiesel leads to increased O2 content, which accounts for the commencement of the chain-branching stage (particularly under low-temperature conditions) in addition to the primary production of carbon monoxide (CO) and CO2 emissions [72,79]. Other investigations have also revealed that the oxidation of soot precursors is the concomitant result of additional O2 content. Additionally, the soot deposition propensity is also governed by the unsaturation degree of biodiesel fuels whereby the higher the unsaturation level, the more the soot production [80]. Nevertheless, it was ascertained that the soot precursors’ oxidation process is brought to a halt once the CO2 component is produced at the initial phase of the combustion process [81]. This signifies the imperativeness of robust development of biodiesel surrogate chemical kinetic mechanisms which accurately replicates the different combustion phases under varying conditions.

3.2. Biodiesel surrogate mechanisms (small-sized carbonyl chains)

Within the context of CFD simulations, biodiesel surrogate mechanisms that come in small sizes which entail low computing power with reasonable accuracy are favourable. For this purpose, alkyl esters small kinetic mechanisms (comprising up to five carbons) viz. methyl-butanoate (MB) is a widely preferred choice [83]. Additionally, the availability of comprehensive experimental data to validate these mechanisms has advanced their applications [[87], [91], [106], [107], [108]]. Despite these advantages, these mechanisms have their limitations, for instance, their reactivity intensity under low-temperature engine-related environments is poor, and their combustion phenomena such as auto-ignition features are observed to exhibit dissimilar behaviours [109].

3.2.1. Methyl-butanoate chemical kinetic mechanism

Methyl-butanoate is the first developed biodiesel surrogate mechanism aimed to replicate biodiesel reactivity intensity and ignition behaviour [83,110]. Chain propagation and branching developed by the decomposition of uni-molecules and the additional reactions of O2 molecules, respectively are deemed critical parameters which affect the reactivity intensity of methyl-butanoate [83]. Concisely, the reaction rate is generally governed by the chain-branching development, but under high-temperature conditions, the chain propagation mechanisms take precedence over the chain branching reactions that ultimately bring about the reduction in the reactivity intensity of methyl-butanoate [83]. It is worthy to highlight that the surrogate mechanism of methyl-butanoate lacks ample carbon chains that lowers its fidelity to emulate the combustion-relevant phenomena of biodiesels [109].

The work of Brakora et al. [84] is considered one of the primary studies with the focus of integrating small-sized reduced surrogate mechanism for biodiesel in CFD modelling. Their surrogate mechanism characteristics were analogous to methyl-linoleate, which is a common FAME constituent of biodiesels. Moreover, throughout their surrogate mechanism development, the sub-mechanisms of methyl-butanoate and n-heptane were utilised. The idea of integrating the n-heptane in biodiesel surrogates was to match the O2 proportion of the developed surrogate mechanism to the intended diesel-biodiesel mixture. This was in line with the work of Brakora and Reitz [111,112], in which the incorporation of n-heptane was found to give a better approximation of the C:H:O ratio found in practical diesel-biodiesel blends. Furthermore, the validation of the developed surrogate mechanism was carried out using CHEMKIN software considering the ID timing of detailed mechanisms as the benchmarking parameter (0-Dimensional modelling). The outcomes of their modelling revealed an acceptable degree of agreement (local errors of less than 20%) with experimental data, and subsequently, KIVA-3 V software was employed with the reduced model to emulate the combustion process under diesel engine-like conditions. It must be noted that typically for validating the accuracy of the developed reduced surrogate mechanisms in simulating combustion phenomena such as HRR, peak pressure and emissions concentration profile, the results of previously conducted modelling and experimental investigations under the same operating conditions are employed [109].

Likewise, there have been a myriad of other attempts to develop small-sized biodiesel surrogate mechanisms with further incorporation of other components in addition to methyl-butanoate. As such, the amalgamation of phenyl-methyl ether to methyl-butanoate has been examined by Golovitchev and Yang [85]. The authors reduced the developed biodiesel surrogate mechanism using the sensitivity analysis approach and compared its prediction ability for combustion phenomena under low-temperature regimes. Their suggested small-sized surrogate mechanism revealed satisfactory agreement to the reactivity behaviour of the real biodiesel fuel. As stated earlier, the methyl-butanoate mechanisms suffer from the downsides of unclear negative temperature coefficient (NTC) region and poor reactivity intensity under low-temperature conditions owing to its short-length carbon chain [82,108]. Hence, there have been several efforts to mitigate these shortcomings by adjusting the reaction rate [108], broadening the combustion applications scope of methyl-butanoate [84] and using supplementary validation [85].

Given the fact that biodiesel fuel comprises unsaturated components in addition to saturated ones, some researchers sought to develop more comprehensive surrogate mechanisms representing these two components. As an example, in a study carried out by Gail et al. [87], methyl-butanoate and methyl (E)−2-butenoate, shortly MBBio, were combined to be the representatives of the saturated and unsaturated components, respectively. The outcomes of their analysis showed that the production of soot precursors was incremented due to the presence of extra double bonds in the surrogate mechanism of MBBio. A similar work into the integration of both saturated and unsaturated components can be found in [113]. Nonetheless, the examination of such simultaneous consideration of saturated and unsaturated components for surrogate mechanism development is still limited due to lack of adequate research, particularly for the integration of the unsaturated components.