1. Introduction

World Health Organization (WHO) and the United Nations Development Program (UNDP), from 1.5 billion people around one-quarter of the total global population has no access to the basic usage of electricity (Gwénaëlle et al., 2009). According to the reports, there are two billion people who require the latest services of energy to fulfill the development goals of the United Nations Development Program (UNDP) (Nathanial, 2009). Apart from the absence of access to the usage of electricity, there has been disproportionality in the transportation of liquid fuels and thus affects the under-developed or developing nations having high population densities and few resources. Approximately, two billion of the population is reliant on solid fuels like crude oil by burning biomass, and coal (Gustafsson et al., 2009). The costs associated with the health issues arising due to the burning of such solid fuels in poor and inappropriate ventilated homes in women and children, precisely (Nathanial, 2009). Thus, such nations have a dire need to look for an alternative that can behave as a renewable source of energy as a motivation to reduce the carbon dioxide emissions along with the security of energy of numerous domestics (Tilman et al., 2009). Concerning this, intensive work has been done on the dedicated energy crops which produce lignocellulosic biomass in high amounts like Miscanthus (Heaton et al., 2008), which can replace the food crops and will aid in maintaining the equilibrium of the food and fuel security (Rosamond et al., 2007).

Despite the significant and noticeable merits regarding the usage of numerous residues of agricultural practices (Kim and Dale 2004), eradication of certain residues of agriculture highlights various notions and concerns (Tilman et al., 2009) like the frequent practice of harvesting total biomass obtained from the annual cereal crops which result in the reduction of organic matter of the soil at the end and thus depletion of the fertility of the soil for long periods which will further accentuate the carbon dioxide (Lal 2005). Keeping in mind this concern, there has been an instance to remove the superficial residues of grain husks of rice (Oryza sativa) in India (Bornstein 2011). This particular approach has been gasified on a small scale and an environment-friendly unit which will further generate electricity for the users that will spend around $2 per month for energy (Bornstein 2011). Such a unit can be considered as a cost-effective mechanism to decentralize energy all over the globe. Side by side, numerous factors like temperature, rainfall, and the altitude that affect the environment display the type of crops to produce in a particular and suitable atmosphere (Mendu et al., 2012).

Biomass consists of forests, wastes from agriculture, residues of numerous crops, clippings of yards, wood chips, and municipal solid wastes (MSW). is one of the biggest sources of renewable energy. Plant-based biomass consists of polymers of carbohydrates, cellulose (40–43%), hemicelluloses (28–35%), and lignin (22–29%). There are various monomers of sugars in plant-based biomass which is bounded tightly with the lignin. Both cellulose and hemicelluloses belong to the class o carbohydrates whereas lignin is a non-sugar substance (Xu et al., 2012). Lignocellulosic materials are made up of approximately 30% of lignin (Beauchet et al., 2012)concerning weight and provide 40% of energy (Perlack et al., 2005).

Lignin is an essential part present in the cell walls of plants. It holds the gap in-between the walls of the cells among other components like cellulose, hemicelluloses, and pectin which render mechanical strength to the cell wall. Lignin is present in bulk amounts in wood and thus considered as a magnificent raw material and thus imparts better durability. Lignin, when employed as a fuel, generates more energy while burning in comparison with cellulose. Around 26.6 kJ/g heat is produced during the combustion process of lignin and hence has a high amount of energy because of reactive groups in lignin for all-natural substances made up of polymers. Since lignin is a derivative of biomass from the combustion process, thus there will be no or negligible release of carbon dioxide (Caidong Qin 2009). Lignin is a natural hydrophobic substance with a phenolic macromolecule. It consists of three major phenylpropane units called monolignols and they are (i) coniferyl alcohol (G), (ii) sinapyl alcohol (S), and (iii) p-coumaryl alcohol (H) (Beauchet et al., 2012). Because of the complex structure of lignin, there have been certain impacts of the pre-treatment processes on lignin. To identify and extract the materials from lignin, there is a requirement of intense characterization investigations to comprehend the polymeric characteristics of lignin, polymeric networks, and features of the functional groups associated with the aromatic ring of lignin (Azadfar et al., 2015). The fundamental structure of lignin implies that lignin has the capacity and significant role to play majorly during the formation of supramolecular materials and aromatic chemicals (Akriti et al., 2014).

This chapter provides insights into the structure, source, characteristics, and biosynthesis of the lignin. This review also discusses the pre-treatment methods and certain methods to determine the amount of lignin. Additionally, discussions also hold environmental, ecological, and economic considerations for bio-energy and numerous policies associated with that.

2. Energy crops and their bio-energy yields

From the forecasted reports considering the needs of biomass, it has been estimated that there will be an increase in the demands at higher levels in near future due to a major focus on the bio-economy all over the globe. Hence, to meet such urgent demands researchers are performing extensive investigations on the concept of energy crops along with their ramifications on the topsoil and surroundings at a universal level (Guragain et al., 2015). Currently, feedstocks based on the lignocellulosic materials to produce biofuels and biochemicals are one such significant material that is obtained from the various residues of crops like corn stover and wheat straw. whereas eliminating such residues in bulk has adverse effects on the fertility of the soil, water transfer properties, stability of the structure of the soil, and activities of microbes present in the soil (Evers et al., 2013). Additionally, the extensive utilization of fertilizers into the crops has resulted in the hiked emissions of nitrous oxide (N2O) which is considered as one of the potential greenhouse gas (Mathews 2009). All the greenhouse gases must consider to figure out the impact of bio-energy concerning the changes observed in the climate. Contradicting to this, the dedicated energy crops such as perennial warm-seasons grasses (WSGs) such as switchgrass (Panicum virgatum), miscanthus (Miscanthus spp.), big bluestem (Andropogon gerardii) and short-rotation woody crops (SRWCs) such as poplar (Populus species), eucalyptus (Eucalyptus species) and willow (Salix species) acquire numerous profits over the residues of annual crops which will help in reducing the detrimental impacts on the fertility of the soil and environments (Fig. 1). Hence, such aforementioned crops can be considered as a potential alternative for lignocellulosic feedstocks for their utilization in various energy industries (Blanco-Canqui 2010). Above mentioned dedicated energy crops require less preservation, aids in reducing the emissions of greenhouse gases, quick growth with increased yields in the mass, less requirement of water, enhances the fertility of the soil. Furthermore, it is possible to sow and grow such dedicated energy crops in marginal, degraded, and abandoned lands to avert the competition for land for prime crops (Evers et al., 2013). Millions of hectares of potentially arable land are available in sub- Saharan Africa, South and Central America, and many other parts of the world that are not presently under cultivation. These lands could be used for the production of dedicated bio-energy crops (Mathews 2009). The yield of bio-energy per unit of land is defined as the amount of dry matter or biomass which is available to transform into bio-energy such as bio-ethanol, bio-diesel, and electricity (Karp and Shield 2008).

Fig. 1

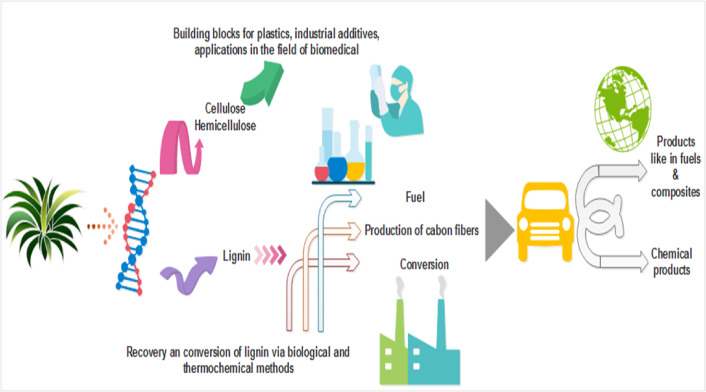

Fig. 1With improved and sophisticated methods and a better understanding of the structure of lignin renders potential opportunities to transform lignin into suitable products like carbon fibers, fuels (bio-energy), and chemicals. Below are certain dedicated energy crops which are considered to produce bio-energy by various energy industries (Ragauskas et al., 2014).

2.1. Wheat (Triticum spp.)

It is a cereal with small-sized grains arising from the fertile lands of the Middle East. With the evolution of earlier agricultural practices, wheat is selected and modified with various breeding techniques and have been converted into hexaploid condition, that is 2n = 6x = 42, for example, bread wheat (Triticum aestivum) and tetraploid condition, that is 2n = 4x = 28, for example, durum wheat (Triticum durum). The straw obtained from the wheat is further combusted for the production of heat and power, for instance, at Ely in the United Kingdom, and the setting up of various bio-refineries which will utilize the grains of the wheat for the production of bio-ethanol. The yield is derived from the three young leaves present on each shoot. The estimation of yields is an amalgamation of genetics, agronomy, and genotype, particularly in Japan (USDA, 2006). With the amplification in the utilization of nitrogen-based fertilizers approximately 240 kg N ha−1 in the United Kingdom (Maff, 2000), there has been an observation of an increase in the yields during the era of the green revolution. Due to this, there has been an upright position of straws of short height and results in the generation of high yields as compared to the varieties of straws with long height which are sensitive to water lodging. During the 1990s, in winters the cultivars of wheat were introduced (Calderini et al., 2007) and increased the biomass present aboveground due to excess radiation use efficiency (RUE) at a stable harvest index (HI) (Sylvester-Bradley et al., 2002). When 1BL.1RS wheat-rye chromosome translocation was introduced, there has been a high pre-anthesis radiation use efficiency (RUE) and enhanced grain number per meter square with better storage of water-soluble formaldehyde (CH2O) in the stem for its exploitation during the formation of grains (Foulkes et al., 2007). With the increase in the number of grains there has been an increase in the post-anthesis radiation use efficiency (RUE) by managing a strong sink and thus assuaging the feedback inhibition being initiated through photosynthesis (Reynolds et al., 2005).

2.2. Maize (Zea mays)

It belongs to the category of cereals with large–size grains with a condition of 2n = 2x = 10 arising from Central America. As for wheat, maize is one of the staple food crops, but in the recent past, there has been increased production of bio-ethanol from maize or corn in the United States of America as compared to the production of bio-ethanol from sugarcane in Brazil. Though the plantation of maize is on the lands where areas are less as compared to the wheat, there has been increased yields since it exploits the C-4 pathway of photosynthesis which has better efficiency. The advantages of C-4 plants are various like they fit very well in a biochemical, physiological, and morphological environment which promotes the concentration of carbon dioxide in the bundle sheath. The results obtained were two-fold on the activity of the bulky and nitrogen-rich enzyme called Rubisco. Also, C-4 plants have better nitrogen use efficiency (NUE) and water use efficiency (WUE) in comparison to the C-3, for example, wheat (Karp and Shield 2008).

The physical segregation of maize is somewhat like there is an origin of a 2-m tall single stem. In this very stem, the female cob is situated around halfway up whereas the male tassels are present at the top of this stem. This structure aids in exploiting the heterosis and generates F1 hybrids seeds at a commercial level in a very simpler way. With the evolution of genetic tools, there have been approximately 50–60% of contributions concerning the overall yield in the case of maize. With numerous advancements in the traits of maize when compared to the wheat such as resistance towards pests and diseases, and water lodging by decreasing the height of the stem (Duvick and Cassman 1999), Since, it has been observed that the maize species have shown very less response for nitrogen-based fertilizer, the dwarf genes were not that much important in comparison to the wheat species. Also, drought stress and mutual shading in maize varieties expand the duration between anthesis and silking and the emergence of barren spikelets. The time interval between anthesis and silking is the origin of a receptive female floral structure (Campos et al., 2006). Modern varieties with better power to tolerate drought stress are due to a decrease in the duration of anthesis−silking (Duvick and Cassman 1999). Furthermore, such reductions render the cultivation of two-fold to three-fold more plants per unit area (Uribelarrea et al., 2002).

2.3. Sugarcane (Saccharum officinarum)

It is a large perennial grass that is more than 2 m tall of C-4 class which originates particularly in South-East Asia. Numerous advanced cultivars have been made from the concept of inter-specific hybridization originating from breeding programs. Such advanced cultivars are flourishing all over the tropical and sub-tropical regions. It has been reported in Hawaii that sugarcane being the significant and productive terrestrial plant, generates a yield of 80 t dry matter ha−1 in a twelve-month season of growth (Elawad et al., 1980). But, there has been an observation of decreased yield due to the attack of pathogens on roots of the plant (Magarey et al., 1997) and the reduction of minerals in the soil. Consequently, the crops were continuously eliminated after five years (Bell and Garside 2005). There is approximately 20 percent sucrose in the stems of the sugarcane which requires rapid processing after the process of harvesting to extract in the maximum amount. Additionally, the radiation use efficiency (RUE) and harvest index (HI) of the sugarcane with extreme management is high which can be considered as an appropriate goal for breeding practices instead of biomass present in bulk amounts (Inman-Bamber et al., 2002). Alternatively, high sucrose concentration may be strongly associated with low cane yield, resulting in selection against high sucrose in breeding programs in the past (Jackson 2005). When sugarcane is associated with endophytic diazotrophic bacteria, there is an observation of a better and increased supply of nitrogen into the plant particularly through the exploitation of nitrogen present in the soil instead of fixation present in the atmosphere (Andrews et al., 2003).

2.4. Miscanthus

The origin of miscanthus is from East Asia. In the majority, the significant species for bio-energy are Miscanthus sacchariflorus with a condition of 2n = 4x = 76, Miscanthus sinensis with a condition of 2n = 2x = 38, and Miscanthus × giganteus-a sterile triploid hybrid of Miscanthus sacchariflorus and Miscanthus sinensis, that is 2n = 3x = 57. The specimen, Miscanthus sacchariflorus is comparatively better acclimated into warmer environments and also, has a wide creeping rhizome with thick stems whereas Miscanthus sinensis is better acclimated into winter environments having rhizomes that can form tuft with thin stems. The Miscanthus × giganteus, a product of rare and the natural process of hybridization, has rhizomes and features of the stem of both Miscanthus sacchariflorus and Miscanthus sinensis. The hybrid is comparatively is more intense with high yields (Lewandowski et al., 2003).

Miscanthus × giganteus is sterile with the possibility of propagation as rhizomes or through tissue culture. Generally, it requires three to five years to grow before their yield. The harvesting of cops takes place when the stems are completely dried whereas, in a completely dry state, the yield reduces to 25 percent which allows the re-immobilization of nutrients onto the rhizome. Being a C-4 plant, Miscanthus has a very high water use efficiency (WUE) but still requires water in sufficient amount to maintain the growth in full form. From various experiments, it has been found out that both Miscanthus × giganteus and Miscanthus sacchariflorus reciprocated to water stress through senescence and loss of leaf area, whereas Miscanthus sinensis decrease the leaf conductance and remain in the green condition during water stress conditions (Karp and Shield 2008).

2.5. Switchgrass

Switchgrass (Panicum virgatum L.)-a perennial energy crop is present in North America. It adapts properly to the marginal productive croplands (Pamula et al., 2021). It has the potential to grow in diverse regions of the country (Sanderson et al., 1999) such as regions with feeble quality of soil (Sesmero et al., 2021). Switchgrass exhibits better tolerance towards cold stress, disease, and insects. The biggest benefit of exploiting these energy crops is that it has a relatively cost-effecting seeding process and flourishes very quickly via obsolete or traditional farming equipment and harvesting processes. It is a significant source of biofuel production and yields nearly15 Mg/ha with quick integration into numerous farming practices (Boateng et al., 2006). Other advantages of using switchgrass include eco-friendly energy crop (Flint et al., 2021) due to very less requirement of nutrients and water (Keshwani and Cheng 2009) for growth (Larnaudie et al., 2021), significant reduction of soil erosion (around 95%) in comparison to other annual row crops (Dien et al., 2006), approximately 90% decrease in the usage of pesticides (Casler et al., 2020) carbon sequestration owing to the intensive root system (Bahulikar et al., 2019) which further increases the storage of carbon in the soil (Moore et al., 2020) Considering bioenergy production, the prime objective of all the researchers is to maximize the yield of dry matter during the harvesting process (Lovell et al., 2021). It has been reported with increasing biomass till anthesis, there has been a reduction in the yield of biomass by 10–20% until damaged by frost (Vogel et al., 2002). The optimal yields obtained from a single harvest ranges from 10.5 to 12.6 Mg/ha/year (Mitchell et al., 2012). The only disadvantage of switchgrass is its slow growth (Alexander et al., 2020). It takes nearly two years to grown completely (Bouton 2007). In the scientific community, switchgrass has received very little attention particularly in plant breeding (Onovo et al., 2021). As a consequence, the germplasm of switchgrass cultivars is not distant from the native genomes. Based on the genetic profile, there are very few varieties of switchgrass that can be differentiated from natural populations. Hence, switchgrass holds significant potential for improving the genetic profile (Rose IV et al., 2008) for enhancing the yield of biomass and hence the large-scale production of diverse biofuels (Yadav et al., 2019).

2.6. Poplars

Populus genus constitutes 25–35 species of deciduous plants which are native to the Northern Hemisphere (Thakur et al., 2021). The common names of various species are poplar, aspen, and cottonwood. There are significant genetic diversities within this genus and respective hybrids have been produced (An et al., 2021) intending to yield favorable traits (Pancaldi and Trindade 2020). The breeding process of poplar species majorly focuses on three native species, namely Populus deltoides (eastern cottonwood), Populus balsamifera (balsam poplar) and Populus trichocarpa (western black cottonwood), and two non-native species, namely Populus maximowiczii (Asian black poplar) and Populus nigra (European black poplar) (McNeil Technologies Inc. 2005). The hybrid poplars are advantageous as they are fast-growing trees in North America and are well adapted for numerous applications (Tuskan et al., 2006) like the production of biofuels, paper and pulp industries, and production of various chemicals and adhesives (Stanton et al., 2021).

The hybrid poplars come under the category of short-rotation woody crops and can be grown easily on forest lands and economically marginal lands (Schiberna et al., 2021). Hybrid species of poplars are considered as a promising feedstock for producing bioethanol, and thermal energy (Gómez-Martín et al., 2020). The complete illustration of the genomic sequence of poplar and easy manipulation of the genetic profile (Niemczyk et al., 2021) has resulted in the significant development of transgenic poplar clones with better chemical characteristics for their effective conversion into a variety of biofuels (Rodrigues et al., 2021).

In North America, hybrid poplar has high productivities, even in the case of marginal lands. Their growth in the large area renders them as an ideal candidate for their cultivation in different regions of America. As a consequence, they are flexible enough to locate crops standing close to the biorefineries (Mellor et al., 2021). Generally, poplar has a high content of cellulose, fewer ash and extractives, and marginal contents of lignin and hemicellulose. Such characteristics have been designated as favorable feedstock for biofuel production particularly bioethanol. Through an appropriate pre-treatment approach, resulting in reduce degradation, the lignin content in poplar species is considered as a valuable product apart from the source of energy (Sannigrahi et al., 2010).

3. Fundamental characteristics of the production of bioenergy from residue/biomass

Concerning the year 2012, the global basic supply of energy has reached 560 EJ, which corresponds to approximately 19,000 Mtce (IEA CCC 2014). Considering this supply of energy, more than 2/3rd is formed of fossil fuels, 5% from nuclear power, 3% from the renewable source of energy which consists of hydropower, geothermal energy, solar energy, wind energy, and tidal energy (Mohammed and Alade 2018). This particular equilibrium is comprised of biomass and waste, which accounts for 10% of the global market which renders approximately 56 EJ/y of the energy supplies (Ben-Iwo, Manovic, and Longhurst 2016). This is equivalent to three times of renewable source of energy in total (Barz and Delivand 2011).

In the report of the Food and Agriculture Organization (FAO) of the year 2012 (FAO 2016), it has been documented that numerous greenhouse gases (GHGs) emissions have been produced by agriculture, the utmost importance of synthetic fertilizers which contribute about 12%, rice cultivation nearly 10.1%, residues of crops, about 3.5%, cultivation of organic soils about 2.8%, and burning of crop residues roughly 0.5% (Caicedo et al., 2016). The greenhouse gases (GHGs) emissions from crop residues comprise of direct and indirect emission of nitrous oxide (N2O) gas due to the presence of nitrogen in the residues of crop and renewal of forage or pasture which was left on the agricultural fields by the farmers. Precisely, the production of nitrous oxide (N2O) is due to microbial processes of nitrification and de-nitrification which takes place on the deposition site (termed as direct emissions), and after volatilization or re-deposition and leaching processes (termed as indirect emissions) (Tubiello et al., 2015). Trace gases like nitrous gases (N2O) are of utmost priority for the greenhouse effect due to the absorbance of infrared radiation (IR) much more as compared to the carbon dioxide despite they are present lower concentrations in comparison to carbon dioxide (Levander 1990). Concerning the production of greenhouse gas (GHG) emissions produced through agricultural wastes all over the globe in the year 2012 (Table 1), carbon dioxide equivalent (CO2eq) emissions were approximately 300 times higher in comparison to the nitrous oxide (N2O) emissions for the five major crops as scrutinized. Among them, wheat has the highest carbon dioxide equivalent (CO2eq) emissions and oxide (N2O) emissions, following rice and maize, respectively (FAO 2016). The practices associated with the agricultural approaches indirectly results in the generation of biomass which is usually not exploited and hence the production of such kind of agricultural residues do not exhibit any further environmental and the economic cost to the agricultural activities primarily focused on the production of food. The utilization of the numerous types of agricultural residues for producing energy results in curbing the greenhouse effect arising from the generation of the residues from atmospheric carbon dioxide (Caicedo et al., 2016).

| Crops | CO2eq Emission (Gg) | N2O Emission (Gg) | ||||

|---|---|---|---|---|---|---|

| Direct | Indirect | Total | Direct | Indirect | Total | |

| Wheat | 42,510 | 9565 | 52,075 | 137 | 31 | 168 |

| Rice paddy | 42,114 | 9476 | 51,590 | 136 | 31 | 166 |

| Maize | 35,455 | 7977 | 43,432 | 114 | 26 | 140 |

| Potatoes | 3795 | 854 | 4649 | 12 | 3 | 15 |

| Dry beans | 1652 | 372 | 2023 | 5 | 1 | 7 |

Bioenergy is the exploitation of bio-based materials which consists of plant materials, and manures for the production of renewable fuels for the transportation and generation of sustainable electricity. This bio-based fuel is characterized by low-carbon emission in comparison to fossil fuels. Apart from low-carbon emission, it also renders immense benefits to the respective community through the sale of bio-energy resources along with the reduction of dependence on the utilization of fossil fuels (Ghosh 2016). Agricultural residues are the primary field-based byproducts of crops (maize, wheat, sunflowers) during the process of harvesting and processing the crops. Agricultural residues show heterogeneity with varied bulk density, moisture content, and particle size, and particle distribution analogous to operational handling. Usually, there are fibrous with low nitrogen and changes with the demographic locations (Caicedo et al., 2016). Such residues have the potential to exploit as fertilizers, a cure for soil erosion, as fodder for livestock. One of the biggest merits of the exploitation of agricultural residues is that there is no such competition with food production and results in food with low prices. Also, it has economic importance in the case of energy production of energy. It has been estimated that approximately one ton of residue has been produced for each ton of grain being harvested (Virmond et al., 2013).

Exploring special crops that are the source of energy might replace the food crops that render food-energy feud (Battisti and Naylor 2009). Issues like food security, energy from such crops can be assured with the utilization of destroyed farmland for growing crops after deforestation. This results in carbon dioxide emission with the excessive usage of land (Fargione et al., 2008). Thus, the dual cropping process allows better agricultural productivity through the generation of bioenergy from agricultural wastes in the combination with the assuring of the production of food. Even though there are numerous merits of exploiting agricultural residues as a waste stream (Koltermann et al., 2014), a team of researcher's states that clearing the farm of certain types of agricultural residues might results in certain grievous environmental matters such as (Tilman et al., 2009). For instance, periodic continuous harvesting of total above-ground biomass from annual cereal crops can degrade the organic matter of soil and thus affects the fertility of the soil, and more carbon dioxide emissions (Lal 2005).

A demonstration has been provided by the scientists in whom they have removed the partial residues of grain husks of rice (Oryza sativa) in India following their gasification in small-scale and eco-friendly units for the producing electricity for those users that spend nearly $2 per month for energy (Bornstein 2011). Such type of renewable energy model can curb the expenses associated with energy all over the world. When synthesizing biofuels, lignin exhibit better energy content in comparison to the cellulosic biomass (Raveendran and Ganesh 1996). A group of researchers has studied the demographic distribution of particular horticultural crops such as coconut (Cocos nucifera), mango (Mangifera indica), olive (Olea europaea), walnut (Juglans spp.), pistachio (Pistacia vera), cherry (Prunus cerasus, P. avium), peach (P. persica), plum (P. domestica, P. salicina), apricot (P. armeniaca), and almond (P. dulcis) and their capability to produce bioenergy (Dutta et al., 2014). The anticipation regarding biomass feedstock for bioenergy production and as starting materials for industrial applications cannot be overestimated. The experts have predicted the strength of residues (particularly agricultural residues) in intensifying the need for energy all over the globe in the coming future (Mohammed and Alade 2018).

4. Structure, composition, and biosynthesis of lignin

Lignin is considered the second most abundant polymers in lignocellulosic material. Lignin is located on the cell walls of some plants which can perform the biosynthesis of the secondary cell wall (Bhuiyan et al., 2009). Lignin has a major role in rendering mechanical strength to the sap-conducting xylem cells, renders a defensive system to plants during the dispersal of seeds, forms an apoplastic diffusion barrier in the roots of the plants (Nawrath et al., 2013). Furthermore, lignin also protects against numerous biotic and abiotic stresses (Uzal et al., 2009). From the structure point of view, lignin is a complex heteropolymer that consists of three major recognized monomers and they are (i) p-coumaryl (H), (ii) coniferyl (G), and (iii) sinapyl (S) monomers (Boerjan et al., 2003). These monomers are obtained from the phenylpropanoid pathway. All these monomers have varied degree of methoxylation of the aromatic ring at the three positions which is ortho-position, meta-position, and para-position, respectively (Ragauskas et al., 2014). Phenylalanine is a significant and prime substrate in the biosynthesis pathway of lignin. The phenylalanine is obtained from the shikimate pathway which was further modified through the enzyme called phenylalanine ammonia-lyase (PAL) which will form cinnamic acid. After their synthesis, the subunits of monomeric lignin are further transported to the apoplastic space through the plasma membrane with the help of transporters. To date, from all the discovered transporters, adenosine triphosphate binding cassette (ABC) transporter has been well reported with context to the transportation of para-coumaryl alcohol transport (Alejandro et al., 2012). The composition and structure of lignin are dependent on the (i) availability of the aforementioned monomers and (ii) the type of bonds generated during the process of polymerization. Additionally, the generation of condensed and non-condensed bonds is dependent primarily on the spatial restrictions of the nearby polymers, the availability of the monomers present in the lignin, and the reactive ends present on the subunits of lignin monomers (Terashima et al., 2012).

A recent study has been performed on Arabidopsis thaliana through the use of Transfer-DNA (T-DNA) mutants. In this study, researchers exploited one of the monomers of lignin namely coumaryl monomer units by the enzyme laccase (LAC) 17 in the sclerenchyma cells of the stems still in a developing stage (Berthet et al., 2011). Another study has suggested that in the case of Brachypodium distachyon, laccase 5 (LAC 5) was responsible for the lignifications of culm (Wang et al., 2015, Wang et al., 2015), and thus there is the significance of phenol oxidases in the case of lignification. Instead of enzyme laccases, another class of oxidizing enzymes is called peroxidases with non-redundant behavior with enzyme laccase during the generation of free radicals (Zhao et al., 2013). In general, the biosynthesis of lignin utilizes numerous enzymes, transporters, and phenol oxidases which help in the determination of the final composition of lignin polymer. The presence and absence of genes or variations in the expression of genes influence the deposition of lignin at a large scale at the cell level and further to the organism level (Weng and Chapple 2010) (Table 2).

Table 2. Composition of lignin in various species and divisions.

| Divisions | Occurrence and composition of lignin | Ref. |

|---|---|---|

| Algae | Absence of lignin but there are certain exceptions such as Calliarthron cheilosporioides, certain sea weeds, etc. Varying composition of lignin monomers (H:G:S) over the time. Green algae do not constitute lignin monomers where as in red algae (Calliarthron cheilosporiodes) all three monomers are present. | Lewis and Yamamoto (1990) |

| Bryophytes | Presence of intermediate compounds like 1,3,5-hydroxybenzene. Mostly there is absence of lignin in bryophytes and thus absence of lignin monomers (H, G, & S) but in Dawsonia sp. and Dendroligotrichum sp., 6–10% of gametophyte axes consist of lignin. Physcomitrella patens constitutes only H monomer. | Wilson et al. (1989) |

| Pteridophytes | Occurrence of lignin in the vascular system (tracheary elements). Approximately, 14 percent of lignin is present in the cell wall. Majorly, H and G lignin monomers are present (Phyllitis scolopendrium, Pteridium aquilinum, Dryopteris affinis, Equisetum telmateia) and very few amount of S monomer is present. | Silva et al. (2011) |

| Gymnosperms | Occurrence of lignin in the vascular system (tracheary elements). Approximately, 30 percent of lignin is present in the cell wall. G and H monomers are majorly present in the cell walls of gymnosperms. There are very less or few S monomers. | Jouanin and Lapierre (2012) |

| Angiosperms (Monocots) | Occurrence of lignin in vascular system (tracheary element and fibers). Approximately, 30 percent of lignin is present in the cell wall. There is presence of all three lignin monomers (G, S, and H) in significant amount. | Saulnier et al. (1999) |

| Angiosperms (Dicots) | Present in vascular system (tracheary element and fibers). Approximately, 30 percent of lignin is present in the cell wall. Two lignin monomers namely, G and S are majorly present whereas very few amounts of S subunits are present. | Woolhouse (1981) |

The analysis of the structure of lignin needs accurate extraction with no alternation in the native structure of the polymer but there should be a full breakdown of the polymer into respective monomers during the compositional analysis. Destructive methods like oxidation, reduction, hydrolysis, thioacidolysis, and acidolysis are employed for analyzing the composition of lignin whereas non-destructive methods like thioglycolic acid (TGA), and acetyl bromide (ACBR) are exploited to analyze the composition of lignin (Fig. 2). Following the composition of the lignin, there are chances that end products may vary. To scrutinize the end products numerous techniques have been utilized like gas chromatography (GC), mass spectroscopy (MS), and proton nuclear magnetic resonance (1H-NMR) spectroscopy (Welker et al., 2015).

Fig. 2

Fig. 2(Du et al., 2021; Jiang et al., 2018; Magrini et al., 2002; Moreira-Vilar et al., 2014; Welker et al., 2015).

(Thioglycolic acid (TGA) and Acetyl bromide (ACBR) are significantly exploited for quantification and solubilization of lignin at specific absorbance values (280 nm). TGA method results in the formation of thioesters of benzyl –OH groups present in the lignin which further solubilizes lignin in alkaline environment. In the ACBR method, there is formation of acetyl derivatives in non-substituted –OH groups for complete solubilization of lignin in acidic reaction conditions. The Klason lignin method-a gravimetric assay which directly quantifies the lignin content. Initially, an insoluble lignin fraction was extracted from the plant tissues following digestion with 72% sulfuric acid and partial solubilization of cell wall polysaccharides. Nuclear Magnetic Resonance (NMR) is another non-destructive method for analyzing the structure of lignin. This analytical method helps in investigating the biosynthesized lignin chemistry in detail through its high resolution. The pyrolysis-molecular beam mass spectrometry (py-MBMS) is a rapid characterization method. The method deals with the rapid heating of lignin samples in an inert atmosphere of helium (He) at extremely high temperature (500 °C). The process occurs in an ambient pressure environment which is further connected with molecular beam mass spectrometer. The chemical structure of lignin is retained and hence is significant to analyze complex molecules present the lignin).

5. Sources and characteristics of lignin

Lignin can be found in all the plants with vascular properties and thus entitles them as a second-most (cellulose being the first one) abundant polymer in nature. The generation of lignin is through the process of photosynthesis and thus renders them renewable with an approximate production of lignin annually within a window of 5–36 × 108 tons. The amount of lignin present in woody plants (gymnosperms and angiosperms) is approximately 15–40% (Fengel and Wegener 1984) whereas it is around 15% in the case of herbs (Dos et al., 2013). Additionally, annual plants have a very low amount of lignin. Considering Table 3, certain values depicting the amount of lignin in numerous plants with commercial importance have been mentioned (Belgacem and Gandini, 2008).

Table 3. Amount of lignin in various commercially important plant species.

| Plant Species | Amount of lignin (%) | Ref. |

|---|---|---|

| Picea abies (Norway spruce) | 28 | Önnerud and Gellerstedt (2003) |

| Picea abies (Compression wood) | 39 | Önnerud (2003) |

| Pinus radiate (Monterey pine) | 27 | Sjöström (1993) |

| Pinus sylvestris (Scots pine) | 28 | Sjöström (1993) |

| Pseudotsuga menziesii (Douglas fir) | 29 | Sjöström (1993) |

| Tsuga canadensis (Eastern hemlock) | 31 | Sjöström (1993) |

| Acasia mollissima (Black wattle) | 21 | Sjöström (1993) |

| Betula verrucosa (Silver birch) | 20 | Önnerud and Gellerstedt (2003) |

| Eucalyptus globules (Blue gum eucalyptus) | 22 | Sjöström (1993) |

| Hibiscus cannabinus (Kenaf) | 12 | del Rio et al. (2006) |

| Oryza species (Rice straw) | 6.1 | Belgacem and Gandini (2008) |

| Saccharum species (Bagasse) | 14 | Belgacem and Gandini (2008) |

Lignin is a major constituent of the cell wall of growing plants with the presence of chemical linkages in all varieties of polysaccharides. For example, in the case of spruce wood, in the majority lignin is linked with the hemicelluloses via covalent linkage (xylan and glucomannan), and a minor portion is associated with the cellulose (Lawoko et al., 2006). Although the concentration of lignin is not distributed in a uniform manner all over the cell and instead of the presence of a high concentration of lignin in the middle lamella, still the lignin is located predominantly in the S2 layer of the secondary wall because of relatively large volumes (Westermark et al., 1988).

There is a requirement of utilizing certain mechanical disintegration of the material to separate lignin from wood or certain other varieties of biomass. Generally, extensive milling of the material is being performed in which the integrity of the structure that is the type of the cell, different layers of the cell, presence of inhomogeneities at the macromolecular level will be eradicated and only a certain amount of lignin is obtained at the end. With such drawbacks, the current knowledge regarding the structure of lignin is based on comprehensive milling of the material of plants following solvent extraction with the help of dioxane followed by purification which will give low to moderate yields of lignin. In all this, there are chances of the presence of minor impurities of carbohydrates in the lignin.

Insufficient information is present regarding the fundamental analysis and characterization of lignins used industrially in the already published data and reports and as a consequence, there are more voids in enumerating a precise understanding about the structure and macromolecular characteristics of the products which are available at an industrial scale. Numerous advancements have been made like the introduction of modern analytical techniques that have significant inputs which help in elucidating the features of other types of lignin like native lignin, change in the structure of lignin structure during the process of kraft pulping, organosolv delignification, and sulfite pulping (Norman, 1969).

From the already reported reports, the content of sulfur in lignosulphonates is around 4–8% (Ralph et al., 2004). Mostly, sulfur exists as sulphonate in lignin, but there are other types also like organic sulfur, sulfite, and sulfate are also present in lignin. Because of the presence of sulphonate in lignosulphonates, they are very water-soluble and insoluble in organic solvents. From the data of Lignotech Borregaard which is a leading producer of lignosulphonates, the degree of sulphonation while considering products at an industrial scale ranges between 0.17 and 0.65 sulphonate groups per phenyl propane unit or around 0.9 to 3.3 sulphonate groups per 1000 g of lignin. The reason behind this range is the de-sugaring of lignosulphonates which were extracted from pulping liquors and by the modification of products like oxidized lignosulphonates which were obtained as co-products during the production of vanillin (Gellerstedt et al., 2006).

The quantity of other functional groups in lignosulphonates like phenolic hydroxyl, aliphatic hydroxyl, and carbonyl groups is dependent on the degree of purity, molecular weight, and the process for producing lignosulphonates (Argyropoulos et al., 2002). The amount of sugar is a significant characteristic while concerning lignosulphonates with industrial importance. They may have some negative impacts also such as the property of being a retardant (Davin and Lewis 2005).

6. Pre-treatment approaches for lignin

For modifying the particle size structure, chemical composition of biomass, pre-treatment methods have grabbed a special place in the case of lignin. It is essential for reducing the recalcitrance of biomass to deconstruction. Pre-treatment helps in destroying the structure of lignin along with the expansion of the accessibility of enzyme to cellulose present in the biomass to have efficient segregation from other compartments precisely hemicellulose and cellulose (Li et al., 2013). Hydrolysis of the carbohydrate in the biomass into monomeric sugars can be achieved rapidly with increased yields of sugars. The major merits of pretreatment methods are (i) the decrease in the particle size of biomass, (ii) rapid analysis of an enzyme to improve the yield of the monosaccharides to avoid the carbohydrate degradation, (iii) less inhibition of the activity of enzymes and the associated energy requirements (Duque et al., 2016). Generally, without pre-treatment methods, the yield is less than 20% but after the implication of pre-treatment methods such as biological, physical, chemical, and physicochemical methods there has been an increase in the yield by 90%. But such pre-treatment methods are energy-consuming for the conversion of biomass into biofuels or during the synthesis of chemicals with high values (Valaskova et al., 2007). The various types of pretreatment methods for lignin exploit various conditions of temperature, pressure, pH range, and solvents.

7. Reductive catalytic fractionation (RCF)-lignin-first biorefinery

The influence of numerous environmental issues and scarcity of resources (Langholtz et al., 2016) has shifted the horizon towards a circular and bio-based economy (Wohlgemuth et al., 2021). Such unavoidable transitions will give rise to the development of alternative technologies intending to suffice the requirements of our society through a sustainable approach (Ragauskas et al., 2006). Concerning such an approach, lignocellulosic biorefineries are key technologies that render renewable chemicals, materials, and bioenergy (Rinaldi et al., 2016). In the past decades, a variety of biorefinery methods have been promised and acknowledged (Schutyser et al., 2018) such as reductive catalytic fractionation (RCF) of lignocellulosic materials (Mika et al., 2018). From the name, redox catalysis has a significant role to play and is the distinguishing feature of reductive catalytic fractionation biorefinery (Sun and Bottari, 2018, Sun and Fridrich, 2018).

The reductive catalytic fractionation is a novel biorefinery method that assimilates the fractionated biomass with depolymerized lignin activated by the redox-active catalyst. In comparison to other obsolete and conventional approaches such as kraft pulping, the reductive catalytic fractionation yields an uncondensed, low molecular weight lignin oil which is comprised of phenolic monomers (Galkin and Samec 2016).

Three ingredients are of utmost importance for operating reductive catalytic fractionation biorefineries (Van den Bosch et al., 2015) are (a) lignocellulosic biomass, (ii) an alcohol/cyclic ether solvent (Song et al., 2013), and (iii) a heterogeneous redox-active catalyst (Yan et al., 2008). Majorly, water is used as a co-solvent in the RCF process (Renders et al., 2016). Furthermore, these ingredients are added into a high-pressure batch reactor which is heated to high temperatures (180–250 °C) for 2–6 h (Galkin et al., 2016). The process of heating to extremely high temperatures will induce solvolytic extraction of lignin from the biomass following partial fragmentation via cleavage of ether bond (Galkin and Samec 2014).

The process of solvolysis creates reactive and unsaturated fragments which are subjected to repolymerization. The redox-active catalyst such as Pd/C (palladium on carbon) reductively stabilizes unstable species and might have a significant effect on the depolymerization process, that is hydrogenolysis of remaining ether bonds (Ferrini and Rinaldi 2014). With time, after the filtration process and evaporation of solvents, the reductive catalytic fractionation yields a stable lignin oil (Parsell et al., 2015) which constitutes phenolic monomers (4-n-propylguaiacol/-syringol, 4-n-propanolguaiacol/-syringol, and 4-n-propenylguaiacol/-syringol) (Sun et al. Sun and Bottari, 2018, Sun and Fridrich, 2018), dimers, and small oligomers depending on the selected catalysts and reaction conditions (Schutyser et al., 2018).

There is immense classical research work regarding RCF using batch autoclaves with all three primary steps taking place in one pot. Since the redox-active catalyst is not involved in the extraction of lignin, there are various opportunities to separate the solvolytic lignin extraction-depolymerization physically from the catalytic hydrogenolysis-stabilization step (Van den Bosch et al., 2017). In the recent past, two research teams have independently performed reductive catalytic fractionation via flow-through setup which comprises an isolated biomass and catalyst bed. Initially, the solvent is sent via biomass bed where the extraction and disassembly of lignin take place (Fig. 3). Secondly, the liquor flows via a catalyst bed which results in additional depolymerization and stabilization of the solubilized fragments of lignin (Anderson et al., 2017). In addition to this, a back-pressure regulator is being mounted at the outlet which provides control over the pressure of the total system (Kumaniaev et al., 2017).

Fig. 3

Fig. 3The two very significant benefits of flow-through reductive catalytic fractionation are (i) generation of a catalyst-free pulp and (b) ensures easy catalyst recuperation, thus, facilitating valorization of pulp and reuse of catalyst (Anderson et al., 2017). The flow-through reductive catalytic fractionation approach is a semi-continuous process and renders better time-resolved data in comparison to the time-averaged data from batch reductive catalytic fractionation. It is very much convenient to monitor the structural differences between the lignin released initially and at the end of the process, and during the deactivation of catalyst (Anderson et al., 2018). Another important benefit is that it ensures the feasibility of altering the reaction conditions like the composition of solvents (Renders and Schutyser, 2016, Renders and Van den Bosch, 2016) and the concentration of additives during the ongoing reaction. This helps in facilitating deeper de-lignification and extraction of lignin at the final stages of the reaction process, but still not been explored so far (Huang and Gonzalez, 2017, Huang and Ouyang, 2017).

There are certain inherent drawbacks of the flow-through RCF approach in comparison to the batch-wise approach such as excessive consumption of solvents. From the literature survey, flow-through reductive catalytic fractionation generally consumes 90 mL gbiomass _1 (Anderson et al., 2017) which is higher than batch-wise processes, which is 4–20 mL gbiomass _1) (Renders et al., 2018). To resolve such an issue, the volumetric rate of flow can be decreased which further decreases the consumption of solvent. Despite numerous promising characteristic features, the flow-through RCF is limited to a 1-g biomass scale (Anderson et al., 2017) whereas on the contrary batch-wise RCF can proceed in a single run with 300 g of biomass (Cao et al., 2018). Hence, there are numerous ongoing joint research projects to intensify the development of reductive catalytic fractionation (RCF) and tackling certain significant challenges associated with the process for sustainable development (Renders et al., 2019).

7.1. Catechyl lignin: A ideal lignin for valorization

Lignin-the biggest source of aromatics comprised of 15–30 wt% of biomass. The conversion of lignin into biofuels and bio-based chemicals renders a significant challenge to decrease the (i) cumulative carbon footprint through diverse communities, (ii) demand for fossil fuels, and (iii) improvement in the economic viability of biorefineries (Rinaldi et al., 2016). Majorly, the conversion approaches are articulated on either reductive pathways or oxidative pathways to cleave ether linkages that are present in the lignin polymer (Wang et al., 2016). This results in the broad range distribution of products (Gao et al., 2014) following limited yields of favorable and desirable monomers (Ma et al., 2015). The steep cost of intricate separations is a major factor (Berstis et al., 2016) owing to the inefficient lignin valorization process (Stone et al., 2018).

Catechyl (C)-lignin-a promising alternative (Chen et al., 2012), has the potential to surpass such limitations and have been discovered recently in the tissues of the seed coat of vanilla orchids (Vanilla planifolia) (Li et al., 2018) and Melocactus obtusipetalus (Li et al., 2020; Wang et al., 2021), Jatropha curcas, Ricinus communis (castor bean) (Tobimatsu et al., 2013) and Aleurites moluccanus (candlenut) (Chen et al., 2013), Cleome hassleriana (Zhuo et al., 2019), castor seed coats (Ricinus communis) (Wang et al., 2020). C-lignin has been biosynthesized in numerous natural plant tissues which co-exist with conventional lignin but have an independent biosynthesis process in nearly 130 species of cactus (Tobimatsu et al., 2013). Presumptively, the high concentration of catechyl-lignin in seed coats renders better strength and impermeability to the structural functions of the tissues (Berstis et al., 2016).

C-lignin-a novel oxoaromatic structure of the polymer is polymerized from a single monomeric unit called caffeyl alcohol which is intensively connected via benzodioxane linkages (Ferrini and Rinaldi 2014). Such type of structural arrangement can be observed in those plant species which constitutes a phenylpropanoid monomer combination of coniferyl alcohol (guaiacyl unit), sinapyl alcohol (syringyl unit), and p-coumaryl (hydroxyphenyl unit) in hardwood and softwood lignins, and hydroxycinnamates, p-coumarate, and ferulate, in herbaceous lignins (Parsell et al., 2015). In the catechyl-lignin, the hydroxyl group on the 5-position of caffeyl alcohol ensures intramolecular ring closure which is generally kinetically favored and further drives the high selectivity toward benzodioxane linkages and restricts the formation of C–C bonds (Galkin and Samec 2016).

Such benzodioxane linkages have offered unique opportunities for depolymerization for generating smaller product distribution by accelerating the percentage of cleavable ether bonds and eradicating a major unwanted condensation pathway (Renders et al., 2019). This modified C-lignin structure has been considered as an alternative and potential product to improve the recovery and downstream lignin usage under biorefinery reaction conditions (Li et al., 2018), and averts the activation of catalysts during the hydrogenolysis process (Stone et al., 2018). In addition, C-lignin has a significant role in the development of sustainable and inexpensive production of various biofuels such as biodiesel and bioethanol. For this reason, the development of certain bio-cellulose feedstocks with high content of C-lignin is a current and important goal of the biotechnology engineering field (O'Leary 2020).

8. Commercially available lignin-based products

LigniMatch which is a joint industrial and academic project addresses the concerns analogous to the environment and the examination of raw materials from an economic point of view which is lignin. There are various products available in the market that have grabbed a lot of attention of researchers regarding the advanced developments associated with the futuristic market of lignin. This project combines the chemical industries and forest industries uniquely. With the aid of LigniMach, various products such as activated carbon, carbon fibers, and phenols (Table 4). have been identified and available at a commercial level (LigniMatch 2009).

Table 4. Three commercial products obtained from lignin and their characteristics.

| Characteristics | Activated carbon | Carbon fibers | Phenols |

|---|---|---|---|

| Lignin source flexibility and availability | Flexible to numerous sources of lignin like kraft pulping, hydrolysis, residues of industries like paper mill, agriculture, etc. |

Kraft-lignin & possibly organosolv-lignin. The pulp & paper industry can provide enough Kraft lignin to supply the current world market of 27,000 tones with carbon fibers from lignin from the Nordic/Baltic region. |

Can be produced from hydrolysis, sulfite & kraft lignin. Enough wood is processed globally to cover the universal market of phenol. |

| Market | The market is ample, covering a broad range of applications. |

Good growth in the carbon fiber market; 12% in average in the last 23 years and expected to increase more. Currently, the production capacity of PAN-fibers does not meet the demand. |

Global market of 10.7 M tones/year. Expected growth is 4.5% per year 2010–2015. Mainly local markets. |

| Property rights | Various patents taken on activated carbon in general in the 80's & early 90's but interest is to account biorefinery concepts & agricultural applications. | Bulk research & patents activity have gained a lot of interest for lignin-based carbon fibers. | No patents have been found till date where lignin is utilized as a source of phenol. |

| Energy and environment | Different methods have different demands for chemicals and energy. The demands of energy for products based on lignin are not much as compared to other processes. |

Carbonization of lignin consumes more energy because of the higher inherent amount of oxygen. With the aid of melt-spinning technology, it is easy to cut down the exploitation of solvents. |

The impact on the environment is dependent on the energy demand for cracking the lignin, as well as catalysts and solvents required during the production process. |

| Costs and competitiveness |

Prices are dependent on the applications. There are numerous alternatives for lignin as a raw material for activated carbon. |

The price of the precursor is significant to keep carbon fibers competitive. It has been assumed that lignin is less expensive as precursor as compared to pitch and PAN that are used in recent days especially if the prices of oil increase and thus will be competitive if reliable quality can be accomplished. |

Processes result in a mixture of phenols with an uncertain market value. Phenol based on pure lignin is costly and not expected to be competitive compared to phenolics based on oil. |

8.1. Activated carbon

This product has various sources of which lignin is one. It has a broad range of applications such as cleaning emissions which are detrimental to the environment or ecosphere (LigniMatch 2009).

8.2. Binders

The research and small-scale applications of lignin are going on when lignin is used as a binder in constructing material, road-making, and pellets for their use in feed industries (LigniMatch 2009).

8.3. Carbon fibers

Recently, such fibers obtained lignin has great potential and have grabbed a lot of attention of researchers to replace those carbon fibers which are based on oil. Such lignin-based carbon fibers are comparatively strong and light concerning their applications in laptops, and aircraft (LigniMatch 2009).

8.4. Phenol

The complexity of the structure of lignin helps in the production of phenolic compounds for its utilization as a base material in a broad category of chemicals (LigniMatch 2009).

8.5. Plastic materials

Lignin has its applications in the production of plastic materials. Such materials have already been implemented such as in electronic industries, and car manufacturing. Polymers made up of lignin are majorly being used in conjugation with materials that are based on the petroleum derivatives like increased biodegradability of plastics (LigniMatch 2009).

8.6. Sorbents

Lignin can be utilized as biosorbents for the purification of water and soil. It is possible to produce medical enterosorbents by hydrolyzing lignin for its applications in the sequestration of bile acids. But such an application has limited market exposure. Ion-exchangers with lignin in it have high sorption capacity in case of heavy metals like copper, and cadmium as well as organic pollutants such as oil products, and pesticides. But this idea is being implemented at a small scale and there is a requirement of chemicals in bulk amount in the case of biosorbents (LigniMatch 2009).

9. Characterization of lignin biomass through one-dimension and two-dimension nuclear magnetic resonance (NMR) spectroscopy

Considering the past few decades, numerous analytical approaches have been developed for characterizing lignin (Pu et al., 2011) to gain an insight into its chemical composition, structural information like the presence of functional groups, monolignol ratio, and inter-unit linkages (Wen et al., 2013). Presently, the exploitation of destructive methods for analyzing the molecular fragmentation of lignin as a characterization technique has been replaced by non-destructive methods (Lu and Ralph 2011). Nuclear magnetic resonance (NMR) spectroscopy has been exploited at a broad scale and considered as one such non-destructive method with context to the characterization of the structure of lignin along with the study of the structural transformation of lignin polymers. Nuclear magnetic resonance (NMR) spectroscopy renders the structural and quantitative analysis of the sub-structural motifs present inside the overall polymer (Guragain et al., 2015).

Advancements in the nuclear magnetic resonance, especially inverse detection techniques and two dimensional (2D) heteronuclear correlation spectroscopy, as well as in the availability of cryogenic nuclear magnetic resonance probes have facilitated the analysis of the structure of lignin in both isolated and whole-cell wall states (in situ) (Kim et al., 2008). Additionally, the experiments with the help of two-dimensional heteronuclear single quantum coherence (2D13C–1H HSQC) by utilizing inverse detection methodology has not only resolved the issue of overlapping of proton signals but also has enhanced the sensitivity of signal to noise ratio by a factor of 31.6 (Wen et al., 2013). Such advancements have decreased the long acquisition times of previously used natural abundance one-dimension carbon detected nuclear magnetic resonance experiments in characterizing the structure of lignin and thus plausible acquisition of 2D13C–1H HSQC spectra of abundant quality for almost all the analysis, from whole cell walls in less than 20 min (Kim and Ralph 2010).

The experiments of 2D13C–1H HSQC NMR have been utilized to evaluate the structure of lignin of various cultivars (Samuel et al., 2010) along with the determination of structural changes during pre-treatments of switchgrasses (Yan et al., 2010). Due to carbon chemical shift at 57–61 ppm and Cγ resonance from β-O-4 ether linkages without a Cα = O group have suggested that there is a significant amount of ether linkage in lignin obtained from switchgrass, that is 0.42 per aromatic ring on an average [38a][37][39e][36c, 36d]. The analysis of the 13C NMR spectroscopy technique of the ball-milled lignin before and after the pre-treatment from dilute acid has suggested that guaiacyl and syringyl units are present and were the major components of switchgrass lignin with p-hydroxyphenyl in a restricted amount. This has also been cross-checked by 2D13C–1H HSQC NMR experiments. Due to pre-treatment, there has been a decrease in the syringyl units by 10% whereas there has been an observation of increased guaiacyl units by 7%, as published by the quantitative 1D 13C NMR investigations. The two-dimensional nuclear magnetic resonance approach has been used intensively to gain knowledge regarding the mechanism of the breakdown of lignin during the pre-treatment method (Pu et al., 2011). A group of researchers (El-Hage et al., 2009) have characterized milled wood lignin (MWL) and ethanol organosolv lignin (EOL) from the species Miscanthus through quantitative 13C NMR and 31P NMR to gain an insight into the mechanism of lignin breakdown during organosolv pre-treatment method. Additionally, the relative abundance of such inter-unit linkages was represented as the quantitative number of every structure per aromatic ring by taking the integral value of the carbon chemical resonances at 102.0–160.0 ppm in the quantitative 1D13C NMR as reference. The carbon signals resonating within the range of 82.5–88.0 ppm consists of ether linkages (β-O-4) as well as other carbon-carbon linkages (β-5 and β- β’) and its integral value were 0.45 per aromatic ring in milled wood lignin (MWL). On the other hand, the carbon signal resonating in the range of 53.0–54.0 ppm consists of carbon-carbon linkages only and its integral value was 0.04 per aromatic ring milled wood lignin (MWL). These aforementioned data have suggested that the milled wood lignin (MWL) lignin consists of β-O-4 structure in bulk amounts, that is 0.41 per aromatic ring, which was decreased by more than 50% in ethanol organosolv lignin (EOL). This indicates that there has been intense cleavage of ether linkages during organosolv pre-treatment (Guragain et al., 2015).

In 31P NMR investigations, both milled wood lignin (MWL) and ethanol organosolv lignin (EOL) samples were phosphitylated with 2-chloro-4,4,5,5-tetramethyl-1,2,3-dioxaphospholane (TMDP) and further analyzed by quantitative 31P NMR, by utilizing cyclohexanol as an internal standard. Using 2-chloro-4,4,5,5-tetramethyl-1,2,3-dioxaphospholane (TMDP), it has been observed that there occurs phosphorylation of hydroxyl groups from aliphatic groups, phenolic groups, and carboxylic acid groups with NMR active 31P nuclei (Pu et al., 2011). From the analysis, the intensity of phenolic carbon resonance (136.0–144.0 ppm) intensity increases from 0.28 per C9 in milled wood lignin (MWL) to 0.50 per C9 in ethanol organosolv lignin (EOL). This indicates that there was a scission of β-O-4 linkages during organosolv pre-treatment. The data of nuclear magnetic resonance have also been exploited to quantify the composition of lignin especially syringyl: guaiacyl: p-hydroxyphenyl ratio in both isolated and in situ forms from lignocellulosic materials. Hence, nuclear magnetic resonance (NMR) profiling has been considered as the best tool for analyzing the detailed structure of lignin bio-energy crops (Samuel et al., 2014).

10. Bio-energy: A consideration of environmental, ecological, and economical aspects

10.1. Net energy balance (NEB)

The concept of net energy balance (NEB) is significant from the viewpoint of choosing a bio-energy platform because a high and positive net energy balance (NEB) is economic and environmentally sustainable. This net energy balance is marked important, particularly when taking into consideration which crops and which process of conversion is worthy enough to claim a substantial biotechnology investment. Although the economic data of production of biodiesel and bio-ethanol based on corn starch is presently competitive with gasoline their net energy balance (NEB) is somewhat less or negative as compared to the favorable net energy balance of (NEB) of lignocellulosic (Hill et al., 2006). A net energy balance of 600 GJ/ha/yr results in the conversion of lignocellulosic biomass into ethanol in an efficient manner. This has resulted in rendering the highest net energy balance of all first- and second-generation platforms (Hill 2007). From all the various bio-energy crops, switchgrass, Miscanthus, and sorghum have the potential to generate the highest net energy balance (Venturi and Venturi 2003).

10.2. Potential benefits from an environmental and ecological point of view

Various platforms of bio-energy platforms have numerous merits and demerits from the context of ecology and agriculture (Tilman et al., 2006). For example, the economical merits associated with the production of ethanol from maize and the production of biodiesel from soybean are usually counter-balanced by the harmful impact of agricultural practices on the environment (Samson et al., 2005). In contrast, perennial feedstocks like switchgrass can provide some help to diminish the issue of soil erosion, enhance the quality of water, and protection of natural diversity (Semere and Slater 2007).

10.3. The change in climate all over the globe and bio-energy choices

Biomass crops and the production of bio-energy to replace fossil fuels have the strength to curb the issue of global warming. For instance, the estimated ability of Miscanthus X giganteus to fix carbon dioxide is around 5.2 to 7.2 t C/ha/yr. This results in a negative carbon balance where there is more fixing of carbon dioxide than emission. In the latest study of maize, switchgrass, soybean, alfalfa, hybrid poplar, and reed canary grass (Phalaris arundinacea), only poplar and switchgrass had a negative carbon balance (approximately 2t C/ha/yr) (Adler et al., 2007). But, concerning the two latest publications, first-generation ethanol platforms have higher carbon dioxide emissions as compared to those fossil fuel emissions (Fargione et al., 2008). Following the already reported data, lignocellulosic ethanol has a positive carbon balance (Searchinger et al., 2008). Such contradictions are due to various methods and models to assess carbon release and fixation. Despite such differences, there is a general agreement that the second-generation ethanol production through lignocellulosic platforms must have a low carbon balance when compared with the first generation platforms (Dias de Oliveira and Rykiel, 2005).

10.4. Economic concerns

Present-day biofuels were hardly profitable before the recent hike in petroleum prices. The production of ethanol from maize was US$0.48 per gasoline energy equivalent liter (EEL) in 2005 and the price of gasoline was US$0.46 per liter (Hill et al., 2006) whereas, with the increase in the prices of crude oil all over the globe, the production of ethanol from maize has become very profitable. Despite such profit margins, traditional crop-based production of biofuel has resulted in direct competition between food and energy. As a result, with the increase in the prices of crude oil, there has been an inflation of the cost of food, feed, and associated products all over the globe. There is an inevitable requirement to shift onto lignocellulosic biomass-based platforms but such platforms are usually not profitable (US$0.70 to US$1.0 per EEL) (Soccol et al., 2005). Also, it has been predicted that there has been a decrease in the cost of production of ethanol from lignocellulosic biomass due to certain processing technologies which result in high yield with lower recalcitrance as compared to the platforms that utilize maize. From the break-even price yield, analysis has shown that switchgrass is comparatively more profitable as compared to conventional crops like sorghum, and maize (Monti et al., 2007).

11. Lignin: A potential source of bioenergy production

11.1. High-lignin feedstocks for the production of biofuels and biochemicals

The cell walls of plants consist of extracellular composites that restrain the internal turgor pressure of plant cells, thus expedite the growth of cells in a particular direction and discover the form and function of the plant. In the majority, the cell wall consists of cellulose, lignin, hemicellulose, and pectins referred to as structural biopolymers along with the presence of glycosylated proteins in abundance. When looking for individual components, the ratio of various components of cell-wall differs from (i) tissue to tissue and (ii) with the developmental phase of the plant (Dale et al., 2010). In the present times, cellulose and lignin have grabbed the attention regarding the production of renewable fuels and products. Though cellulose has gained a lot of attention due to its capacity for biochemical deconstruction through enzymatic hydrolysis (Harris and DeBolt 2010) or thermochemical deconstruction (Jae et al., 2010), lignin is usually regarded as a waste product (Zakzeski et al., 2010) due to issues associated with its structural diversity and heterogeneity, which offers obstacles during deconstruction process (Zakzeski et al., 2010). Despite such challenges, lignin consists of structural units that serve as a source of fuels and high-value chemicals (Weng et al., 2008). Lignin is an amalgamation of three precursor alcohols from the phenylpropanoid pathway (p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol) via a chain of oxidation steps (Boerjan et al., 2003). The process, named lignification alters the biophysical characteristics of the plant cell and their tissue type and is usually known for enhancing the structural integrity and rendering waterproofing property (Mendu et al., 2011).

In recent times, the prime focus of the biofuel community has now started to shift from the production of alcohol to the production of hydrocarbon-based biofuels through the thermochemical deconstruction pathway. Such fuels exhibit the capability to replace gasoline, diesel, and jet fuel, and have the potential to function as drop-in fuels with internal combustion engines (Regalbuto 2009). The molecular layout of bio-oil is dependent on the built-in composition of the biomass and pyrolytic conditions. Principally, the oxidative deconstruction of lignin results in the formation of oxygenates that further can be either deoxygenated for the production of hydrocarbons like hydrodeoxygenation or hydrolysis and fast pyrolysis (Jae et al., 2010) or can be subjected to separation for recovering high-value chemicals like phenols and cresols. Though lignin, based on its low oxygen content, seems to be an encouraging feedstock for the production of biofuel still bulk research requires an hour for the development of effective technologies to convert lignin-derived feedstocks into bioenergy. This study focuses on the identification and examination of feedstocks that exhibit a naturally high amount of lignin via the thermochemical deconstruction process (Mendu et al., 2011).

During the examination of the feedstocks, the group of researchers covered a wide range of tissue types to circumscribe the variation in cell-wall composition (Fig. 3). Concerning the compositions, they illustrated that agricultural byproducts with drupe endocarp from the fruit and nut production industries conformed to the criteria of high feedstock homogeneity concerning the content of lignin (nearly 50% of the cell wall has lignin). With the high heating value of lignin as compared to the cellulose (White 1987), they have reported that biomass of drupe endocarp which is designated as a bioenergy feedstock exhibited the highest net energy density along with fewer costs associated with cleaning boilers and gasifiers (Dodds and Gross 2007) concerning other biomass feedstock. For quantitative analysis of different feedstocks, the protocol was reported by NREL (http://www.nrel.gov/biomass/pdfs/42618.pdf.). For the estimation of calorific values, a bomb calorimeter was used and other techniques like Thermogravimetry analysis (TGA) and gel permeation chromatography (GPC) have been exploited. The compositional analysis of the lignin feedstock was done by the PyroProbe model (Fig. 3).

The data of pyrolysis gas chromatography-mass spectrometry (Py-GC-MS) are compatible with the data of gel permeation chromatography (GPC), thermogravimetry analysis (TGA), and differential thermogravimetry (DTG) analyses which epitomize moderate differences in the deconstruction characteristics of high-lignin endocarp analogous to biomass with low lignin content. The most compelling difference noticed during the process of biomass deconstruction as demonstrated by the differential thermogravimetry (DTG) analysis results. This showed that a high-intensity peak at a molecular weight (MW) of 160 soars in the deconstruction profile of endocarp biomass. The highest alteration of yield in the chemicals obtained from endocarp analogous to switchgrass soars in the form of phenol, 2-methoxyphenol, 2-methylphenol, 2-methoxy-4-methylphenol, and 4-ethyl-2-methoxyphenol. Harmonizing the yield of particular deconstruction products has an economic advantage under conditions when the market demands for such chemicals are amply valuable. Furthermore, tailoring the composition of biomass and deconstruction chemical engineering process renders the strength to improve fuel and chemical synthesis (Haveren et al., 2008). Numerous industries in the market produce bio-oil and other bio-based material through fast pyrolysis such as Avello Bioenergy (Boone, IA, USA), DynaMotive Energy Systems Corp (Vancouver, BC, Canada), and Renewable Oil International LLC (Florence, AL, USA). The strength of compositional analysis and the bioenergy conversion of such high-lignin feedstocks lies in the fact that it acts as a source of bioelectricity, hydrocarbon-based renewable energy, and bio-based chemicals but this domain is still not much exploited. Additionally, it has also been documented that different cell-wall composition has different pyrolytic breakdown products and yields. With an advantageous biotechnological advancement, it will be possible to (i) modify lignin structure in plants with one phenol alcohol instead of three phenol alcohols, (ii) simplify the complex, recalcitrant inter-unit linkages that separate the lignin monomers (Mendu et al., 2011).

11.2. Lignin as co-product of second-generation bioethanol production

With a notion to enhance the economic viability of the production of biofuels from biomass, it is of utmost importance to add value to the lignin being produced as a bio-residue. As well, to meet the goal of replacing 30% of fossil fuel with biofuels by the year 2030, there is an urgency of producing lignin in bulk amounts. The very first important step is the separation of lignin from the constituents of other biomasses to get lignin with high purity. This research work deals with lignin extraction from a bio-residue from second-generation bioethanol production. Here in this work, the biomass is Arundo donax L. (or giant reed) (Fig. 5), which is a non-food plant with a wide range of tolerance of ecological conditions with all types of soils and hence is a significant raw material for industrial applications as a source of fibers alternative to wood, whose availability is decreasing. Extraction methods employed herein utilizes a simple, mild, safe approach and avoids the destruction of fiber content in the bio-residue (Fig. 4). The final goal is to valorize all fractions of the bio-residue, which is an important step for the production of cost-effective biofuel (Cotana et al., 2014).

Fig. 4

Fig. 4