1. Introduction

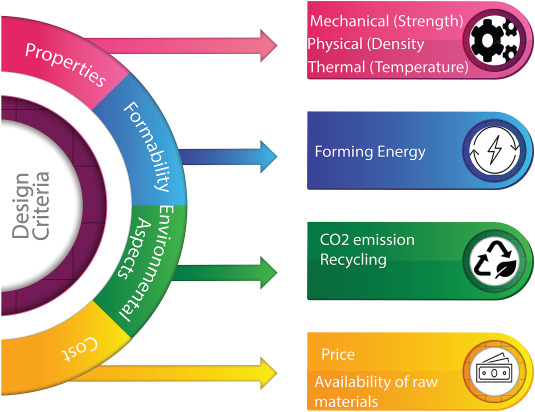

Technological developments across all fields and especially in the material science field is considered as a thriving research frontier in the contemporary development of lightweight materials such as composite materials [1,2]. By 2025, the U.S. automotive industry hopes to achieve a corporate average fuel economy rating of 54.5 miles per gallon (mpg), this is much higher than 2016's requirement of 35.5 mpg [3]. In this regard, lightweight materials such as composite materials hold great promise. Even though they are commercialized after the 2nd world War but composite materials are old as our human civilization [4]. They are formed by two or more different materials for achieving higher physical and mechanical properties in comparison to the individual materials to meet industrial needs and the demand of modern engineering applications [5]. Being the third most abundantly available element in the earth's crust, aluminium metal and its various alloys are widely used for various emerging applications such as automobile and aircraft structures. Particularly in the last two decades aluminium metal and its various alloys diverted researchers towards combining innovative structures and new manufacturing routes to develop metal matrix composites (MMCs) [6,7]. The role of MMC in developing aircraft structures is highly promising due to their higher mechanical properties, low weight, tailor to design for different requirements, ability to accommodate various other novel nanomaterials, and provide strong potential to evade the strength-ductility trade-off [8]. For high fuel efficiency, weight was reduced and superior-strength composite materials were introduced in the aerospace field [9]. Fig. 1 shows some general criteria for the selection of appropriate materials for aircraft applications. Among these criteria for the manufacturing sector, the maximum efficiency and minimum cost of manufacturing routes are considered global competitiveness in product development [10].

Fig. 1. Material selection design criteria for aircraft structural applications.

Fig. 1. Material selection design criteria for aircraft structural applications.Recently, increasing attention has been paid to MMCs due to outstanding mechanical strength, and good wear resistance [11]. Currently, popular matrix materials are aluminium, magnesium, and titanium. But according to reports Aluminium-based MMCs (AMMCs) are accounted for about 69% of mass annually for various industrial uses such as aviation, automobiles, electronic devices, marine industries and space shuttles [12]. AMMC offers a wide range of remarkable physical, and mechanical properties and their combination of properties such as improved ductility, toughness, formability, and electric and thermal conductivities. The tribological properties of AMMC improved by adding nano reinforcements employing hard particles such as carbides (TiC, SiC, B4C), borides (TiB2, AlB2), oxides (Al2O3, MgO, ZrO2, ZrSiO4), nitrides (BN, AlN) and now carbon nanotubes and graphene as well. The nano reinforcement offers high hardness, strength, high-temperature durability, low thermal expansion for improving wear, and at high-temperature mechanical properties.

The overall material and manufacturing process must be optimized for the industrial-scale production process of AMMC. Furthermore, the final properties of composite materials depend upon the manufacturing route adapted for AMMC [13]. Currently, three production techniques are considered for AMMC manufacturing i.e., solid-state technique, liquid-based production and deposition production technique. Indeed, the most effective technique will be considered which will provide the balance between improved thermal and mechanical properties [[14], [15], [16], [17]], i.e., enhancing the load-bearing capability of materials to lower their volume in structural applications, low environmental concerns and minimal fuel and CO2 consumption [18]. Recently various nano reinforcements are explored extensively, particularly their interaction with the MMC matrix and improvements in the integrity of MMC microstructures, and variation of reinforcement, play a vital role in selecting the proper synthesis route for AMMC.

Recently, the focus of the researchers has been shifted towards the AMMC for their various attractive properties and the use of non-metallic particulates for its ease of manufacturing through the conventional casting process for aircraft applications. In this review, some of the recent trends and developments for aluminium 7075 alloy and its MMCs for improving the overall mechanical properties of aircraft are summarized. Moreover, various combinations of hybrid nano-reinforcing materials utilized in AMMC processing were reviewed to analyze mechanical and tribological performance. Fabrication techniques and concentration of nano-reinforcing particulates were also discussed. Lastly, challenges and perspectives for the AMMC are put forward to encourage researchers to explore them further for their inevitable role in aircraft industries.

2. Introduction to aluminium alloys

For more than 80 years, different aluminium alloys proved to be an ideal material for structural aircraft materials. Aluminium alloys have lightweight and good mechanical properties among all metals and are widely used in engineering structures, especially in the aerospace industry [19]. Fig. 2 shows a brief classification of aluminium alloys. Aerospace structures use 80% aluminium by weight. As provided in Table 1 as well, aluminium is always the first choice for many commercially available aircraft. Thus, it carries more weight and offers high corrosion resistance, which ensures the safety of the aircraft and its passengers [20]. Aluminium alloys are prone to corrosion and often required various surface treatments such as plasma electrolytic oxidationprotection, anodic oxidation protection, and surface coatings [21].

Fig. 2. A comprehensive classification of Al alloys (Figure drawn with the help of ref. [26]).

Fig. 2. A comprehensive classification of Al alloys (Figure drawn with the help of ref. [26]).Table 1. Percentage of mass various alloys in different commercially available aircraft [22].

| Mass (%) | Various Commercially Available Aircraft | |||||

|---|---|---|---|---|---|---|

| B747 | B767 | B757 | B777 | B787 | A300B4 | |

| Aluminium | 81 | 80 | 78 | 70 | 20 | 77 |

| Steel | 13 | 14 | 12 | 11 | 10 | 12 |

| Titanium | 4 | 2 | 6 | 7 | 15 | 4 |

| Composite | 1 | 3 | 3 | 11 | 50 | 4 |

| Other | 1 | 1 | 1 | 1 | 5 | 3 |

Engineering components are subjected to different types of loading throughout their service life but fatigue loading is the worst of all. In fatigue, materials fail below the yield point. 7XXX alloys are mostly used because they have the highest mechanical properties among all aluminium alloys [15] A critical problem encountered in the use of the highest strength aluminium alloys (Al–Zn–Mg type) rests with an increased susceptibility to stress corrosion crackingas maximum strength levels are reached by conventional ageing [23]. Owing to the insidious nature of stress-corrosion failure, a compromise is made in the strength level at which the alloy is used, resulting in severe weight penalties, particularly in airframe applications [24,25]. Fig. 3 shows the complete details of all aluminium alloys as potential aircraft materials.

Fig. 3. Applications of various aluminium alloys in aircraft structures (Figure drawn with the help of ref. [27]).

Fig. 3. Applications of various aluminium alloys in aircraft structures (Figure drawn with the help of ref. [27]).Recent advancements in high-strength aluminium alloys such as Zn and Li-based alloys, damage-resistant Al–Cu and Al–Li alloys, have been effective in enhancing fracture toughness, fatigue and resistance against wear and corrosion through optimally controlling heat treatment procedures. The design parameters are also effective for controlling the chemical composition during the heat treatment procedure. The calculation of phase diagram (CALPHAD) is often used in simplifying the alloy design. CALPHAD is used for optimally controlling the various alloying elements for aluminium alloys. Thus, controlling various phases of CALPHAD results in different microstructures and their relevant mechanical properties [28]. One such example of CALPHAD for aluminium alloys is elaborated in Fig. 4.

Fig. 4. Al–Fe–Mg–Si system CALPHAD: (a) quasi-ternary isothermal sectionhaving iron content 0.3 wt% at 550 °C; (b) Vertical segment of the quaternary phase diagram) (adapted from ref. [28] copyright 2020, Elsevier).

Fig. 4. Al–Fe–Mg–Si system CALPHAD: (a) quasi-ternary isothermal sectionhaving iron content 0.3 wt% at 550 °C; (b) Vertical segment of the quaternary phase diagram) (adapted from ref. [28] copyright 2020, Elsevier).An advanced rapid solidification technology (RST) technique allows various combinations of microstructure and mechanical properties. Furthermore, in RST various novel alloying compositions can be achievable through the application of rapid solidification, Thus improving the overall nature of today's alloy systems. Ultrasonic melt processing is also a powerful and highly useful way of affecting the structure and final quality of cast metal [29].

The computational thermodynamics (CT)-based novel approach assisted with machine learning (ML) is now widely used for designing the casting aluminium alloys. This novel approach briefly explains microstructure starting from the exact equilibrium phase diagram calculations and Scheil-Gulliver solidification simulations techniques [30]. This provides a complete database for a reliable thermodynamic and delivers the quantitative relation of “Composition - Process - Microstructure” of the target alloys as depicted in Fig. 5.

Fig. 5. The schematic diagram for the efficient computational alloy design approach by combining CT and ML techniques (adapted from ref. [30] under the creative commons attribution license 4.0).

Fig. 5. The schematic diagram for the efficient computational alloy design approach by combining CT and ML techniques (adapted from ref. [30] under the creative commons attribution license 4.0).Over the last decade, different strengthening mechanisms had been adapted for improving the mechanical properties of various aluminium alloys such as precipitation strengthening, solid solution, work hardening and grain boundary strengthening [31,32].

2.1. Aluminium 7075 alloy

7075 is an aluminium alloy with zinc as the main alloying element. It has high fatigue strength and average machinability, but low weldability and low corrosion resistance compared to other alloys [33] and mainly employed in aerospace and structural applications. Among the numerous commonly used aluminium alloys, 7075 aluminium has the distinction of being the strongest grade aluminium alloy for a variety of industrial applications such as in Ref. [34]. Being lightweight, easy-machinable, and adequate corrosion-resistant metal, it provides strength similar to steel alloys while also being lightweight metal [35]. As with all aluminium alloys, 7075 has a specific gravity of 2.73 (0.098 lb/cubic inch). The 7075 aluminium alloy is used for various components such as fuselage and wing due to its remarkable physical and mechanical properties such as high strength-to-weight ratio and excellent stress corrosion resistance for aircraft applications [36]. Table 2 shows the typical composition of 7075 aluminium alloy.

Table 2. 7075 Aluminium alloy chemical compositions [37].

| Chemical Composition | Al | Zn | Mg | Cu | Fe | Mn | Cr | Si | Ti | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | 89.3 | 5.3 | 2.5 | 1.6 | 0.5 | 0.3 | 0.23 | 0.4 | 0.2 | 0.15 |

Aluminium 7075 alloy has commercial use in various industrial applications such as aerospace, automotive components and marine [38]. In real-time applications, aluminium 7075 alloys are inevitably confronted with many challenges during their processing under conventional manufacturing routes such as surface nitriding, and metal cladding. Thus, various types of heat treatment techniques, cannot be employed on aluminium 7075 effectively [39,40]. Thus there is a strong strive for semi-solid processing of aluminium 7075 alloys.

Aluminium for high-quality aluminium metal matrix (AMMC) composites is fabricated by various routes such as using powder and liquid metallurgy techniques. From all of these manufacturing methods, the stir and squeeze casting methods can produce high-quality AMMCs with desired tribological properties [41].

The T6 heat treatment of aluminium 7075 alloys significantly improves its various mechanical properties due to grain refinement solid solution strengthening, dislocation hardening and precipitation hardening during solution treatment and artificial ageing-based heat treatment techniques. Fatigue cracks initiate at intermetallic particles or neat the surface and caused failure in commercial aluminium 7075 alloys [42]. Different impurities such as iron and silicon produce inclusions in 7000 aluminium alloys and significantly affect fracture toughness and fatigue strength. Furthermore, a sharp decrease in mechanical properties can be observed due to the corrosive environment and fatigue loading specially for the 7000 series aluminium alloys [43]. Thus, due to the formation of corrosion pits on the surface, the crack initiates. One way is to tackle the problem by anodization or surface coatings. Thus, wear resistance, hardness, and corrosion resistance can be enhanced. Conversely, cracks and defects sometimes may trigger due to surface pre-treatment and etching in anodization technique. From all the various surface and heat treatment techniques it is well known that sulfuric acid anodization of aluminium alloy 7075-T73 gives a 60% percent lowers fatigue life [44].

2.2. Properties of aluminium 7075 alloy

Aluminium 7075 is available in several types of tempers such as T6, T651, T73, T7351 and T76. Aluminium 7075 alloys are also considered a logical choice for replacing various other aluminium alloys such as 2014, 2024, and 2017 in many significant applications because of their superior stress corrosion resistance due to T173 and T7351 tempering. Furthermore, the T651 and T6 tempers improve machinability [45]. Fig. 6 shows the various feature of 7075 aluminium alloy.

Fig. 6. (a) Raw microstructure of 7075 aluminium alloy (adapted from ref. [39] under the creative commons attribution license 4.0); (b) Fatigue crack growthrate da/dn versus ΔK plot for 2024-T3 and 7075-T6 alloys (adapted from ref. [46]); (c) The various images of 7075 aluminium alloy rolled plate under a microscope (adapted from ref. [42] copyright 2018 Elsevier B.V); (d) Knoop hardness yield (KHN) loci of as-received aluminium alloy 7075-T651 (adapted from ref. [47] copyright 2021 Elsevier B.V.).

Fig. 6. (a) Raw microstructure of 7075 aluminium alloy (adapted from ref. [39] under the creative commons attribution license 4.0); (b) Fatigue crack growthrate da/dn versus ΔK plot for 2024-T3 and 7075-T6 alloys (adapted from ref. [46]); (c) The various images of 7075 aluminium alloy rolled plate under a microscope (adapted from ref. [42] copyright 2018 Elsevier B.V); (d) Knoop hardness yield (KHN) loci of as-received aluminium alloy 7075-T651 (adapted from ref. [47] copyright 2021 Elsevier B.V.).Fatigue crack initiates microscopically and then propagates. Once the crack is initiated, stress concentration at the crack tip increases with the passage of each fatigue cycle. The fracture toughness of aluminium alloys is not enough to hinder the fatigue crack growth but reducing the value of crack driving force at the crack tip will cause a considerable reduction in the crack growth rate. Different extrinsic toughening mechanisms are applied to protect the crack tip from the full effect of the crack driving force.

Another important property which must be considered is a surface damage phenomenon due to time-variable contact forces at mechanical contacts. Fretting fatigue is characterized by wear, oxidation, high-stress concentrations, and nonproportional loading. Cracks are often triggered by high stresses near the surface [48]. A common palliative treatment available for fretting fatigue is shot peening. During short peening, high compressive residual stresses are introduced near the surface, which retard crack initiation, but also change the microstructure and roughness of the surface. These residual stresses relax with the number of loading cycles. Thus, shot peening improves fatigue life under high-cycle fatigue [49]. In various fields such as aerospace, aviation, shipbuilding, etc., fretting fatigue is an important phenomenon caused by oscillatory motion between two contacting surfaces observed at a micron scale [48]. According to Zhang et al., 7075-T651 alloy properties including fretting and sliding wear are affected by normal load and amplitude than sliding wear [50].

The ultimate goal of today's researchers is to find the exact mechanical response under extremely complex loading for instance Natarajan et al. [51] studied the mechanical properties of S-glass/CFRP composites used for submarine hulls through experimentation and finite element analysis (FEA). An FEA analysis was performed for various parameters of the submarine hull, such as the thickness of the bow, the suitable shape, the stern, and the foil of the submarine. Results demonstrated that FEA-based analysis was in good agreement with experimental and analytical results, and S-glass and carbon fiber (CF) were mechanically stable to withstand the impact and hydrostatic loads. In another study, 3D FEA-based modelling was performed on a specific geometrical model of weft-knitted CFRP to study its interface damage behaviour during tension using the cohesive zone model (CZM). Simulation results demonstrated the highest tensile properties of composites were observed where no interfacial debonding occurred in the weft-knitted model, and the results also aligned with the experimental results [52]. Fretting fatigue should also be considered for further improving the mechanical properties of advanced aluminium alloys and maintaining the structural integrity of aircraft structures.

Das et al. [53] investigated cryorolling (CR) on the HCF and fatigue crack growth rate behaviour of Al 7075 alloy. Results showed that the cryorolled Al 7075 alloys demonstrated excellent mechanical properties. The tensile testing was done according to ASTM Standard E−8/E8M-09. Fatigue crack growth rates have been observed according to ASTM E647-08. Results showed that 430 Mpa, 530 Mpa, 21 J, and 24 Mpa m1/2 for 40CR mechanical results were observed for yield strength and ultimate tensile strength, impact energy and fracture toughness respectively as presented in Fig. 7. Furthermore, the fatigue crack growth (FCGR) resistance mechanism as presented in Fig. 8 showed diffused crack branching mechanism through scanning electron microscope (SEM) images.

Fig. 7. (a) FCGR curve for aluminum 7075 alloy at different stress ratios, (b) Paris plot cross various stress ratios, (c) FCGR curve and (d) comparative Paris plot constants for complete three materials (adapted from ref. [53] copyright 2011 Elsevier B.V.).

Fig. 7. (a) FCGR curve for aluminum 7075 alloy at different stress ratios, (b) Paris plot cross various stress ratios, (c) FCGR curve and (d) comparative Paris plot constants for complete three materials (adapted from ref. [53] copyright 2011 Elsevier B.V.). Fig. 8. SEM images of aluminum 7075 alloys across different R-ratio (adapted from ref. [53] copyright 2011 Elsevier B.V.).

Fig. 8. SEM images of aluminum 7075 alloys across different R-ratio (adapted from ref. [53] copyright 2011 Elsevier B.V.).Zhang et al. [42] studied various mechanical properties of 7075 Al alloy under various aging conditions and optimized fatigue strength. Reported results as presented in Fig. 9 showed the precipitation spacing first decreases and then increases as a result of increasing the aging time. Thus, as a result fatigue strength was optimized due to tensile strength and hardness, first increasing and then decreasing. More importantly at 120 °C for 48 h ageing conditions has the most significant impact on fatigue strength.

Fig. 9. Stress-strain curves (tensile mode) for 7075 aluminium alloys under various ageing time; (b) relation between tensile strength and uniform elongation; (c) The S–N curves of 7075 aluminium alloys under various aging conditions; (d) The relation between fatigue strength and yield strength (adapted from ref. [42] copyright 2018 Elsevier B.V.).

Fig. 9. Stress-strain curves (tensile mode) for 7075 aluminium alloys under various ageing time; (b) relation between tensile strength and uniform elongation; (c) The S–N curves of 7075 aluminium alloys under various aging conditions; (d) The relation between fatigue strength and yield strength (adapted from ref. [42] copyright 2018 Elsevier B.V.).3. Metal matrix composites

Recently, MMCs have gained significant attention across the world for numerous applications as functional and structural materials due to their excellent mechanical properties in comparison to individual materials [54]. MMC is typically a metal or alloy (having ductile characteristics) matrix combined and reinforced with some other metal, non-metallic or organic compounds. There exists a channel in MMC through the matrix to any place in the element in comparison to the two sandwiched substances. The key factor for the improved properties of MMC depends on the bonding of the matrix and other reinforced interfaces.

MMC offers a wide range of diverse properties such as low thermal expansion coefficient, high strength, high stiffness, extreme temperature resistance and excellent tribological properties attractive for high-end applications such as aerospace and aircraft. In this regard, MMCs based on aluminium are widely explored. Aluminium and its various alloys are proven to be an ideal matrix material in MMCs due to its easy fabrication, low density, and good engineering properties [55]. Particularly two prominent heat-treatable aluminium alloys i.e., Aluminium 6061 and Aluminium 7075 series of aluminium alloys are studied mostly [56]. Aluminium 6061 series alloy has high corrosion resistance for construction, automotive and marine sectors whereas Aluminium 7075 demonstrated excellent mechanical properties such as excellent toughness which are promising for aerospace sectors [57]. Thus, AAMC provides intrinsic properties such as creep and fatigue resistance which are regarded as ideal materials for the aerospace and automotive fields [58].

There are various reasons for using composite materials in aircraft industries such as higher specific stiffness, fatigue, corrosion resistance and specific strength (normalized by density) [59]. Nowadays MMC materials are widely used for aircraft applications particularly due to their excellent mechanical properties such as fatigue and impact strength [60]. Various synthetic fibers such as carbon fiber, aramid fiber and glass fibers have been used in MMC. This synthetic fibres-based, MMC apart from their high strength-to-weight ratio further improved its fracture properties [61]. Table 3 discussed MMC particularly related to aircraft and space applications [62].

Table 3. Metal matrix composites in the aircraft industry and space applications.

| Application | Component | Required Property | MMC | Ref. |

|---|---|---|---|---|

| Aircraft | Airframe | High strength and stiffness | B/Al | [[63], [64], [65]] |

| Engine | High temp. strength, stiffness and creep resistance |

Nextel/Al, Cu–Nb, Cu–Nb3Sn |

[[66], [67], [68]] | |

| Space | Space panel | Lower (zero) CIE, higher stiffness, | B/Al | [69] |

| SDI | Higher thermal conductivity with high-temperature strength. | Gr/Al | [70] | |

| Satellites | High strength and low density | Gr/Al, SiCp/Al | [71] |

3.1. Manufacturing of aluminium-based MMC

As MMCs have been developed to meet the demand of materials having high specific strength, and stiffness [[72], [73], [74]]. To date, different methods have been used for the fabrication of MMC. MMCs fabricated mostly through the casting process by the accumulation of reinforcement phase to the matrix typically regarded as liquid state fabrication of MMC [75]. Fabrication of MMC is quite challenging in terms of the uniform dispersion and improved mechanical and hysical properties than the monolithic counterpart. Casting technique both stir and squeeze is widely used for the fabrication of MMC [76]. The stir casting process is widely adopted due to its cheapness and availability for many materials and processing conditions [77].

Stir casting process is simple, inexpensive, mechanical stirring is used for the distribution of reinforcement phase in a molten metal with significant advantages such as up to <30% reinforcement/constituents volume fractions is achievable [[78], [79], [80]]. Morveover, in stir casting, there is an effective control on various process parameters such as strength of mixing, easier control of matrix structure, feasibility wetting, flexibility, relative density, and rate of solidification [[81], [82], [83]]. The mechanical stirring process is well-groomed and easily applied to a wide range of materials [84,85]. For instance, recently highly toughed aluminium 6061 alloy-based MMC with Cu, Zn reinforced particles were fabricated through the stir casting process [86]. Furthermore, many recent investigations proved that stir casting is regarded as the most efficient, economical and easiest fabrication technique for the desired range of properties such as better wettability, lower porosity, and lower shrinkage for the AMMCs for improved hardness, wear resistance and impact energy and excellent productivity for near-net shaped components [87]. Stir casting has the ability to accommodate various additives such as graphite, boron carbide, graphene, carbon nanotubes (CNTs), flyash etc. [[88], [89], [90]]. Another popular technique for the fabrication of AMMC is squeeze casting in which metal solidifies within closed die halves with the combination of gravity die and closed die forging under pressure which offers minimum porosity, minimum shrinkage high metal yield with excellent surface finish [91]. Furthermore, up to 50% reduction in the grain size can be achieved through high-pressure solidification [92]. Apart from stir and squeeze casting-based conventional approaches, numerous techniques such as powder metallurgy, spray atomization and, plasma spraying have been used for the production of AMMC and each one is accompanied by its privileges and drawbacks as highlighted in Table 4.

Table 4. Comparative analysis of various fabrication techniques which are generally employed for Aluminium-based MMC [93].

| Manufacturing Methods | Cost | Advantages | Constrained/Disadvantages |

|---|---|---|---|

| Squeeze casting | Moderate expensive |

|

Perform shape limited up to 2 cm height. |

| Spark plasma sintering | Expensive (electric consumption is involved) | Employed for armour, and nozzle. | Simple symmetrical shapes are prepared only. |

| Spray casting | Expensive | Used in grinding and cutting tools. | Limited shape, large size. |

| Melt infiltration | Cost-effective | High-end applications in space, defence, and industrial due to excellent wear properties at high-temperature. | Limited depth and temperature create blockage in infiltration. |

| Powder metallurgy | Expensive | Used for making valves, pistons, bolts, etc. | Restricted size, the wide range |

| Gas pressure infiltration | Expensive |

|

|

| Stir casting | Moderate expensive |

|

|

| Compocasting | Moderate expensive |

|

High viscosity during the semi-solid route faces porosity and processing difficulties. |

| Friction stir processing | Least expensive | Applicable in the automotive and aerospace industry | Can produce only surface composites |

| Accumulative roll bonding | Expensive | The developed MMC has high corrosion resistance and high strength for structural, and automotive applications |

Requires large load capabilities Low production rate |

| Additive Manufacturing | Expensive | Any complex part with high accuracy can be developed for high-end engineering applications. | Typically employed for small-size parts |

3.2. Role of additives/nanoparticles in MMC

Possible exploration of soft and hard reinforcements in the size of ∼1 μm or even smaller was added in AMMC for certain engineering applications [94,95]. To date, various nano-sized particles are added to strengthen the matrix and improved its various mechanical properties such as a low coefficient of thermal expansion with high mechanical strength, creep, high thermal conductivity, fatigue resistance [[96], [97], [98]]. This is worth mentioning that the role of nano-sized ceramic particles, as reinforcement, is highly promising because there can easily disperse into the AMMC through conventional techniques such as stir and squeeze casting and their small size effectuates improvements in the various mechanical as well as microstructural properties by adding them into liquid metal by stirring before casting [99]. Several particles as summarized in Fig. 10, including silicon carbide (SiC) [100], titanium dioxide (TiO2), alumina (Al2O3), titanium carbide (TiC), tungsten carbide (WC), titanium aluminium carbide (Ti3AlC2), and barium titanate (BaTiO3) are used as reinforcement in MMC [[101], [102], [103]]. For instance, Singh et al. [104] studied Aluminium 7075(T6)-based MMC for three different reinforcements as crumb rubber, silicon carbide, and molybdenum disulfide. Results of tribological studies such as wear loss, frictional force, and coefficient of friction showed that the developed AMMC have the potential to use in lightweight, and wear-resistant at high-temperature for automotive and aerospace applications. In another study, it has been proved that boron carbide (B4C) and Zirconium dioxide (ZrO2) reinforced MMC demonstrated outstanding tribological and mechanical properties [105].

Fig. 10. Classification of various organic and inorganic reinforcement used in MMC (adapted from ref. [110] copyright 2023, American Foundry Society, Springer Nature).

Fig. 10. Classification of various organic and inorganic reinforcement used in MMC (adapted from ref. [110] copyright 2023, American Foundry Society, Springer Nature).Researchers have extensively used nano reinforcement for improving various properties. For instance, graphite as main reinforcement improves the wear resistance of MMC by developing a protective layer between pin and counter face, and the addition of Al2O3 to aluminium improves the corrosion and hardness resistance of AMMC [[106], [107], [108]], the addition of SiC as a secondary reinforcement has a remarkable effect on the wear properties, and adding fly ash improves the mechanical strength [109]. Researchers have extensively used nano reinforcement for improving various properties as comprehensively summarized in Table 5 as well. For instance, it is evident from Table 5 graphite as the main reinforcement improves the wear resistance of MMC by developing a protective layer between the pin and counter face, and the addition of Al2O3 to aluminium improves the corrosion and hardness resistance of AMMC [[106], [107], [108]], the addition of SiC as a secondary reinforcement has a remarkable effect on the wear properties, and adding fly ash improves the mechanical strength [109].

Table 5. Summary of recent works on Aluminum 7075-based AMMC.

| Composition |

Manufacturing Technique |

Mechanical Properties | Outstanding Results | Ref. |

|---|---|---|---|---|

| Aluminium 7075/Mg/Fly ash/Al2O3 particles | Stir-casting process |

|

Aluminium 7075 + 10% Al2O3-+10% fly ash composite demonstrated the highest wear resistance. | [111] |

| Aluminium 7075/B4C particles | Casting by adding K2TiF6flux |

|

B4C particles significantly improved the wear rate for developed MMC. | [33] |

| Aluimiunum 7075/4 wt% TiC | Stir-casting process | – | Electric current has a significant effect on surface roughness and material removal rate of developed MMC. | [112] |

| Aluminium 7075/Mg/Fly ash/Al2O3 particles | Stir-casting process |

|

The developed MMCs with double-stage stirrer have improved properties as compared to single-stage stirrer as a result of wettability and better mixing. | [113] |

| Aluminum 7075/B4C/BN | Stir-casting process |

|

The developed MMC with (Al 99%+B4C 0.4% +BN0.6%) combination demonstrated the highest hardness and lowest wear rate. | [114] |

| Aluminium 7075/Al2O3 particles | Ball milling, and semi-solid stirring method |

|

The tensile strength and hardness of developed MMC were maximum at 1.5 wt% of Al2O3 particles. | [115] |

| Aluminium 7075/Al2O3 particles | Stir-casting process |

|

Extruded Aluminum 7075with 0.4 wt % and 0.8 wt % of Al2O3demonstrated the highest strength and workability. | [116] |

| Aluminium 7075/SiC | Liquid metallurgy |

|

Aluminum 7075-based developed MMC showed remarkable wear resistance under various heat treatment and aging conditions. | [117] |

| Aluminium 7075/Al3Ni nanoparticles | Friction stir processing |

|

Friction stir processing is a promising technique for bulk synthesizing Aluminum alloys with the in-situ formation of Al3Ni nanoparticles improve its various properties. | [118] |

| Aluminum 7075/ZrB2/Fly Ash | Stir-casting process | – | Hardness and ultimate tensile strength were improved by 53.33%, and 23% respectively by adding 5 wt. % ZrB2 and Fly Ash 2 wt.% | [110] |

| Aluminum 7075-T651/TiCp/Al–5Mg–1Zn filler materials | semisolid stirring casting and multi-pass rolling |

|

The tensile strength and hardness of joints were improved by adding TiC particles in comparison to 5183 commercial fillers. | [119] |

| Aluminium 7075/Mica/graphite/E-glass | Stir-casting process | – | Aluminium 7075/3%mica/5%graphite/4%E-glass demonstrated the lowest coefficient of friction value with a maximum reduction of 50.98%. | [120] |

| Aluminium 7075/TiB2 | Stir-casting process |

|

Aluminium 7075/TiB2-peak aging composite with ceramics nanoparticles/interphase/aluminium multi-interfaces demonstrated a higher dynamic recovery rate of dislocation for a higher work hardening rate. | [121] |

| Aluminium 7075/Al2O3/E-glass | Stir-casting process |

|

At 9% wt. Al2O3 and 6% wt. E-glass maximum tensile strength, yield strength, and hardness were achieved. | [122] |

| Aluminum 7075/Si3N4/TaC/Ti | Stir-casting process |

|

Aluminum 7075 reinforced with 0.75 wt%TaC/6 wt%Si3N4, and 1 wt% Ti composites demonstrated the lowest wear rate when the force increased from 20 N to 40 N. | [123] |

| Aluminium 7075/MoO3 | Stir-casting process |

|

The wear resistance of developed MMC was higher at 7.5 wt% of MoO3 | [124] |

| Aluminium 7075/Cr | Stir-casting process |

|

The developed composites with 2 wt.% of Cr demonstrated excellent tribological performance for gears and slideways applications. | [125] |

| Aluminum 7075/graphene | Stir-casting process |

|

Graphene reinforced MMC demonstrated higher hardness number, tensile strength, and compression strength. | [126] |

| Aluminium 7075/Cu | Stir-casting process |

|

Aluminum 7075/Cu -based composite demonstrated higher wear resistance as compared to the aluminium 7075 alloys. | [127] |

| Aluminium 7075/TiB2-graphene | Squeeze casting |

|

The developed MMC (with 0.3% graphene) was 67.8% harder than the aluminium 7075 base alloy. | [128] |