1. Introduction: a technological journey from terrestrial animal production to intensive fish farming

1.1. Modern intensive fish farming

Modern intensive fish aquaculture comprises all life stages of the fish from brood-stock/eggs to fully-grown adults. The hatchery phase is typically conducted in indoor tanks, where one is able to control the environmental conditions and other external factors affecting the fish. While some species are raised in tanks all the way to marketable size, most industrially farmed finfish species are transferred to outdoor ponds or sea-cages for the final ongrowing phase. This is because the volume of water required by a fish depends strongly on its size, and a gradual scaling of the production unit volume as the fish grow is easier to facilitate in the sea or ponds than in indoor tanks. Sea-based fish farming also exposes fish to natural fluctuations in important features of the production environment (e.g. water flow, temperature and light intensity). Although this limits the farmer's ability to control the production conditions, and increases the chance that stressors such as pollutants, pathogens and parasites are introduced into the population, the simplicity and cost-effectiveness of open systems makes this approach more competitive today (Iversen, Andreassen, Hermansen, Larsen, & Terjesen, 2013).

Currently, Atlantic salmon (Salmo salar L.) are the most significant farmed sea-based finfish species with more than 2.3 Mt produced globally in 2014 (FAO, 2016). In Norwegian salmon production, ongrowth is conducted in flexible sea-cages located in sheltered coastal areas, or at locations more exposed to environmental forces (Bjelland et al., 2015, pp. 1–10). As with many other industries, salmon farming has sought to reap the benefits of economies of scale, meaning that both farm size and the size of individual cages has increased with the intent of producing more fish per employee, leading to increased profitability (Hallam, 1991). As a result, production cages at current Norwegian salmon farms often have a circumference of up to 157 m, contain a volume of approximately 40,000 m3, and hold up to 200,000 individual fish. Considering that a typical fish farm consists of 8–16 separate cages, this means that each farming crew (typically 5–10 people in total) may be responsible for several million animals, amounting to a biomass of up to 15,000 t. Sea-based production of salmon is therefore a very large-scale intensive form of seafood production.

Much of the human historical knowledge on animal husbandry has been built on a direct relationship between farmer and animal. However, such relationships are not possible to establish with a population consisting of millions of individual animals living under water, making it almost impossible to evaluate the animals and collect information on the status of the population through direct observation. This challenge will be further amplified by the present trend towards moving aquaculture operations to more environmentally exposed areas, which will render the farms less accessible to farmers (Bjelland et al., 2015, pp. 1–10). Due to these factors, a regime based on direct observation alone may be insufficient to acquire the levels of knowledge, monitoring and control required to tackle the challenges of modern fish farming. Instead, what is required for modern large-scale fish farming are technological tools that enable remote monitoring of large populations of fish in a manner that yields data that can be used to adjust and modify day-to-day operations to optimise the growth and survival of the fish. The idea of applying such principles to commercial fish production may be traced back to the original thoughts and philosophies of Jens Glad Balchen (Balchen, 1979).

1.2. Precision Livestock Farming

Livestock production is the second largest supplier of food for human consumption behind vegetable/cereal agriculture. Although there have been several initiatives concerning automated sensing and detection of farm animal responses (e.g. Van der Stuyft et al., 1991, Maatje et al., 1997), and mathematical modelling of animal behavioural and physiological dynamics (e.g. Bastianelli and Sauvant, 1997, Kristensen and Kristensen, 1998) in the 80's and 90's, the first conceptual framework of Precision Livestock Farming (PLF) was not established until the turn of the millennium by Berckmans (2004). While the general principle of using technology and automation to improve precision in industrial production is directly transferrable from the process and manufacturing industries to PLF, the transition of focus from inert products to live animals introduces the following additional complications that need to be taken into account when developing PLF methods:

-

•

Observation and monitoring is more challenging, as animals at times exhibit complex behaviour that may be difficult to observe and interpret.

-

•

Animals may move and are not always willing or able to cooperate with the farmer, making the implementation of automated actions more difficult.

-

•

In addition to covering the basal requirements for survival, animal needs are also linked with their ability to exhibit certain behaviours, and maintain a certain perceived quality of life, or welfare.

Berckmans (2004) stated three distinct conditions that a system would need to fulfil if it was to achieve sufficient levels of monitoring and control to be considered a PLF system:

-

1)

Animal variables (i.e. parameters related to the behavioural or physiological state of the animal) need to be measured continuously with cost-effective robust sensor technology,

-

2)

a reliable model for predicting (expectation of) how Animal variables will dynamically vary in response to external factors at any moment must be available, and

-

3)

predictions and on-line measurements are integrated in an analysing algorithm for automatic monitoring and/or control.

PLF methods are often defined using a common terminology denoting the different components in a PLF-system (Table 1).

Table 1. Some of the main terms used to define PLF methods and that hence form the foundation of the PFF terminology.

| Term | Explanation |

|---|---|

| Complex, Individual and Time-variant (CIT) system | A complex, individually different and time-variant system. Applies to all living organisms, including animals (Berckmans, 2004, Berckmans, 2013). |

| Bio-response | The biological response of an animal when exposed to external stimuli. |

| Animal variable | Any parameter related to the behavioural or physiological state of the animal, e.g. weight, activity, feed intake (Berckmans, 2004). Typically acquired in the field. |

| Feature variable | Variable that may be calculated based on measured Animal variables and that describes the bio-response of interest (Berckmans, 2013, Norton and Berckmans, 2017). |

| Target variable | Variable that is derived from Feature variables and that relates to the final objective of the PLF method (Norton & Berckmans, 2017). Target variables are used as foundations for making management decisions. |

| Gold standard | Reliable and/or generally accepted method of measuring or observing Target variables (Norton & Berckmans, 2017). Gold standards may be expensive, complex and difficult to assess, but are necessary to verify that a PLF method provides reliable outputs. |

Technological advances over the last decades have enabled the development of several PLF methods and application areas, including the use of modern sensor technologies to monitor animal variables (e.g. Darr and Epperson, 2009, Tebot et al., 2009), using methods from information technology and modelling to synthesise and combine different types of data (e.g. Milner-Gulland et al., 2006, Terrasson et al., 2016), and the application of control theory to increase the level of autonomy (see Johnson et al., 2011 on different autonomy levels) of the production process (Frost et al., 2003). While most of these applications have arisen from research activities, the long-term goal of PLF is to provide industrial methods and tools that contribute to improving animal health and welfare while increasing productivity, yield and environmental sustainability. This is generally achieved through the combination of hardware and intelligent software (Berckmans, 2014). Examples of successful PLF applications in the livestock production industry include the automated monitoring of pig health through cough analysis with microphones (Berckmans, Hemeryck, Berckmans, Vranken, & van Waterschoot, 2015), the utilisation of automated milking robots on cows (John et al., 2016), and the use of computer vision methods to automatically monitor real time positions of animals (Sloth & Frederiksen, 2015).

Aquaculture fish production faces many of the same challenges as modern terrestrial meat production, and some aspects of PLF can therefore be adapted directly to intensive fish farming. However, aquaculture also faces additional challenges that add to the complexity of the farming operations:

-

•

The feed consumed by the fish in fish farms is exclusively provided by the farmer, leading to a strong dependency on farming management.

-

•

Feeding and most other operations are enacted on the entire cage population, as opposed to on individual or small group levels.

-

•

The number of individual animals in fish farms (millions) exceeds what is common in most terrestrial livestock farms.

-

•

The fish live in a complex 3D environment and all farming operations associated with the fish are at least partly conducted in the subsurface environment, which is generally more challenging than terrestrial farming.

-

•

The exposure of the fish to external stressors such as pathogens/diseases (McVicar, 1987), parasites (Grimnes & Jakobsen, 1996), chemical pollutants (e.g. Brodin, Fick, Jonssom, & Klaminder, 2013) and microplastics (Wright, Thompson, & Galloway, 2013) is largely determined by the ambient environmental conditions and outside of human control.

1.3. Scope of this study

We have developed the Precision Fish Farming (PFF) concept that is based on PLF and hence accommodates the features therein, while also addressing the additional challenges of farming animals in water. In this article, we will present the PFF framework by first defining the boundary conditions and possibilities of precision farming in the aquatic environment, then defining the PFF concept in brief terms, and then going through the status of PFF today, within the framework of research and industry. Following this, we will address the potential industrial impacts of PFF exemplified by four specific case studies, before we conclude and recommend future research directions we deem important for the continued development of the PFF concept. We will primarily use examples related to Atlantic salmon farming, because this is a segment of industrial fish farming that has a high technology level, is under rapid development, and hence will be very receptive with respect to PFF-methods. However, we believe that the applications of PFF we suggest will be transferrable to other aquatic farmed species.

2. Adapting precision farming to the aquatic environment: boundary conditions and possibilities

Over the millennia that terrestrial livestock farming has been a part of human culture, the interaction between man and animal has produced a vast body of veterinary, ethological and physiological knowledge on farm animals. Through such knowledge, humans have been able to identify how observable traits and bio-responses exhibited by animals may be linked with management outcomes such as growth (e.g. Tedeschi, Fox, & Guiroy, 2004), health/survival (e.g. Berckmans et al., 2015) and milk production (e.g. John et al., 2016). This process is analogous to the system identification methods used in control engineering to determine relationships between system inputs and system outputs when lacking a complete mechanistic description of key sub-systems (Åström & Eykhoff, 1971). Establishing an understanding of such relationships is a prerequisite for being able to derive the sequence from an observed bio-response, through Animal and Feature variables, to Target variables that lies at the core of the PLF concept. Moreover, a thorough understanding of the system dynamics is also key in identifying possible Gold Standards to validate such methods.

Direct man and animal interaction is more difficult in fish farming than in its terrestrial counterpart, and the population sizes in fish aquaculture make interactions with specific individuals very difficult. Furthermore, intensive cage-based fish farming has a comparatively shorter industrial history (decades) than terrestrial livestock production (millennia). As a result, knowledge about the bioprocesses occurring in industrial fish farming is very limited compared with terrestrial farming; this makes proper system identification a more challenging task. Moreover, it means that the identification of both relationships between bio-responses and Target variables and proper Gold Standards will often be more difficult and likely to be based on a weaker foundation in a fish farming situation.

In addition to influencing the knowledge foundation for deriving PFF methods, the aforementioned factors also complicate the operational aspects of implementing such methods. For instance, it is generally challenging to continuously monitor animals and achieve sufficient information for PFF applications in the aquatic environment. While such information may be obtained using direct observation or low-end technological equipment on land, more advanced technical solutions are required to achieve a similar knowledge basis in fish farms, where one needs to cope with the unforgiving conditions of the subsurface environment at increasingly exposed sites, and the large number of animals at each farm. Moreover, the establishment of Gold Standards may be complicated by the difficulties in directly interacting with individuals. Many Gold Standards used in terrestrial farming require veterinarians or farmers to directly observe and/or interact with the animals, an ability that may be rendered near impossible in commercial fish farms. In spite of all these challenges, the technologies used today by farmers to observe the fish represent good foundations for developing future PFF applications, and often entail already established technical infrastructures for communication and power supply. Furthermore, since farmers are already accustomed to employing technical solutions in their everyday work tasks, the introduction of new technology based upon PFF methods will not represent a completely new concept.

As fish farms increase in size and complexity, the size and designs of fish cagesevolve, and new location types are taken into use (e.g. Bjelland et al., 2015, pp. 1–10), more sophisticated technological solutions will be required to provide sufficient knowledge and information to monitor and/or control the biological production process. Furthermore, a side effect of the increases in scale occurring within the industry is that risks associated with day-to-day operations are also increasing (Kalogerakis et al., 2015). Larger structures sustain larger loads, making handling and manipulation of structural components such as the net or sinker tubes more precarious activities (Lader, Dempster, Fredheim, & Jensen, 2008). In the event of component breakdown during such operations, the forces released in modern fish farms are more likely to cause serious injuries than was the case decades ago. Moreover, with larger populations in each cage, potential negative consequences of suboptimal animal handling such as escapes (Jensen, Dempster, Thorstad, Uglem, & Fredheim, 2009) and impaired welfare (Pettersen et al., 2014) will also increase. Using technology to automate or otherwise increase the security of such operations could thus lead to vast improvements in risk mitigation around commercial fish farms, which might be one of the most important outcomes of using the PFF approach.

In addition, the Norwegian government presently has an arrangement where salmon production companies are awarded new fish production permits (so-called development permits) if they develop new concepts for sustainable production of salmon. How the fish will respond to and grow in new and untested production concepts is largely unknown. Furthermore, many of these concepts include larger fish populations being kept in each production unit (i.e. cages or tanks). Although such concepts also include increasing the volumes of the production units accordingly to achieve comparable stocking densities to those commonly used today, the surface area of the cage facing the upstream current does not scale with the same factor. For example, if the population and correspondingly the production unit volume is upscaled by a factor of five, the upstream facing cage area will scale by a factor of less than three. As a consequence, the water exchange rate does not scale properly with the population (Lader et al., 2008). This may lead to hypoxic conditions in the cage as the oxygen consumption of the fish may then exceed the oxygen replenishment through incoming water. Poor dissolved oxygen conditions reduce the appetite and subsequent growth rates of fish (Remen, Sievers, Torgersen, & Oppedal, 2016). This development emphasises the need for better methods to manage and monitor the populations in commercial fish production systems. We thus argue that the potential industrial impact of PFF may equal or even exceed that of PLF.

3. Precision Fish Farming (PFF)

3.1. Precision Fish Farming and the different elements of the fish farming process

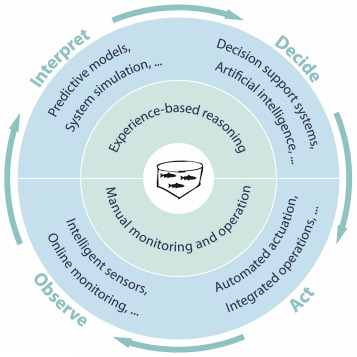

The overarching aims of Precision Fish Farming (PFF) are to: 1) improve accuracy, precision and repeatability in farming operations; 2) facilitate more autonomous and continuous biomass/animal monitoring; 3) provide more reliable decision support and; 4) reduce dependencies on manual labour and subjective assessments, and thus improve staff safety. Through these means, PFF will improve animal health and welfare while increasing the productivity, yield and environmental sustainability in commercial intensive aquaculture. To help in defining PFF, it is useful to envision fish farming as several cyclical operational processes realised in four phases where bio-responses in the cage are observed (Observe phase) and interpreted (Interpret phase), resulting in a foundation for making decisions (Decide phase) on which actions to enforce (Act phase) that in turn elicit a bio-response in the fish (Fig. 1). Similar cyclic concepts have been used to describe processes and products in other manufacturing industries, one of the most notable examples of which is the Plan-Do-Check-Act (PDCA) philosophy (Deming & Edwards, 1982) that has been popular within e.g. the automotive industry (Rother, 2010). This approach also resembles the OODA (Observe, Orient, Decide, Act) cycle, which is a concept for decision making in military strategy (Boyd John, 1987).

Fig. 1. A cyclical representation of PFF where operational processes are considered to consist of four phases: Observe, Interpret, Decide and Act. The inner cycle represents the present state-of-the-art in industry, with manual actions and monitoring, and experience-based interpretation and decision-making. The outer cycle illustrates how the introduction of PFF may influence the different phases of the cycle. Figure credits: Andreas Myskja Lien, SINTEF Ocean.

Fig. 1. A cyclical representation of PFF where operational processes are considered to consist of four phases: Observe, Interpret, Decide and Act. The inner cycle represents the present state-of-the-art in industry, with manual actions and monitoring, and experience-based interpretation and decision-making. The outer cycle illustrates how the introduction of PFF may influence the different phases of the cycle. Figure credits: Andreas Myskja Lien, SINTEF Ocean.Today, most tasks pertaining to the different phases are conducted manually (i.e. close to the centre in Fig. 1). First, the farmer observes the fish via direct visual observation or with data acquisition tools such as cameras, the outcome of which is qualitative or quantitative information on the bio-responses of the fish. The farmer then uses primarily subjective experience to interpret this information, yielding a perception of the current state and condition of the fish. These interpretations are then used as a foundation for making decisions concerning farming operations and management, which are then put into action by manually induced actions on the cage. Such decisions may be made based on the estimated present states or expected future states of the system, representing manual versions of the feedback and feed-forward principles in control engineering respectively.

Methods and tools for fish farming that apply technological solutions and/or automation principles to one, several or all the different phases of farming operations may be considered PFF approaches. The ultimate result of applying PFF to a particular operation will therefore be that the elements in that operation belonging to the different phases of fish farming operations are shifted from an experience-based to a knowledge-based regime (i.e. by moving from the centre towards the outer edge in Fig. 1).

3.2. Status of Precision Fish Farming in present industry and research

Although the PFF concept has not previously been defined, many technological research efforts and equipment innovations for the fish aquaculture industry can be considered tools or components for developing PFF methods, and in a few cases are already PFF methods in their own right. Here, we provide an overview of the present status in this area, covering both industrial applications and research activities. Most relevant methods or concepts included here address a single phase in fish farming operations (Fig. 1), hence a status will be given separately for each phase.

3.2.1. Observe: Animal variables describing bio-responses

The general inability to use direct observation to make representative assessments of individual and population states under water in fish farms means that fish farmers already depend on using technological solutions to monitor their animals. Submerged cameras are the most common tools found on fish farms today, and are used to observe the fish during production, with operators manually, and subjectively, analysing behaviour. Camera systems are useful platforms for automated fish monitoring by applying computer visionalgorithms to the video stream. The possibilities within computer vision techniques are expanding rapidly, both due to the development of enabling hardware such as camera and computer technology, and to the increased application of these technologies within the consumer electronics market. Computer vision methods can quantify several different Animal variables in a fish farm setting, including clustering and movement (e.g. Eguiraun, López-de-Ipiña, & Martinez, 2014), skin status (e.g. Wallat, Luzuriaga, Balaban, & Chapman, 2002), fish size (e.g. Hao, Yu, & Li, 2016), sea-lice infestation levels (e.g. Tillett, Bull, & Lines, 1999) and behavioural changes due to exposure to chemicals (e.g. Eguiraun and Martinez, 2015b, Eguiraun et al., 2016). In addition, computer vision methods could monitor important properties of the physical environment, such as feed pellet quantities (Skøien, Alver, & Alfredsen, 2014), and behavioural expressions observable above the water line such as surface activity (Jovanović, Risojević, Babić, Svendsen, & Stahl, 2016).

While the variation in technologies used to observe live fish in industry is limited, the methodological diversity within research is large, as researchers are constantly looking into new methods for collecting scientific data. In addition to cameras, active hydroacoustic devices are the most common technological tools used to study fish in aquaculture research. The most frequent application of this technology has been the use of echo sounders to obtain echograms describing the vertical fish distribution and schooling density in the cage (Oppedal, Dempster, & Stien, 2011), which are Animal variables that may be used to quantify the bio-response of fish to some treatment (e.g. Bui et al., 2013, Johansson et al., 2006, Oppedal et al., 2007). While conventional echo sounders are limited to producing echograms, more advanced hydroacoustic devices are already in use within other marine industry segments, and could obtain additional Animal variables from caged fish populations. For instance, split-beam sonars can estimate swimming speeds and directions of individual fish within their sonar beam (e.g. Arrhenius et al., 2000, Huse and Ona, 1996, Knudsen et al., 2004), while multibeam sonar systems can produce data on the 3D distribution and movements of the fish (e.g. Melvin, 2016, Tenningen et al., 2016). In addition, sonar based systems may be used to assess individual fish sizes, given that it is possible to establish a relationship between the target strength (TS) of the fish and its mass or length (Knudsen et al., 2004, Soliveres et al., 2017). Passive hydrophones have also been used to provide information on Animal variables related to the behaviour of several fish species including salmonids by recording the sounds emitted or generated by the fish (Kasumyan, 2008, Kasumyan, 2009). Considering that hydroacoustic devices (unlike cameras) are impervious to visibility conditions, this group of technologies could provide a useful foundation for PFF methods designed to acquire behaviour-related Animal variables for farmed fish populations.

Despite the considerable population sizes featured in modern fish farming, indicators of individual fish behaviour may prove equally important in fish farming as population or group level Animal variables. Acoustic fish telemetry is a method for remote sensing where individual fish are equipped with electronic transmitters containing sensors that measure some property in or near the fish, and that transmit raw or post-processed data wirelessly to submerged stationary receiver units using acoustic signals (i.e. sound waves). This technology is widely used for wild fish research (e.g. Finstad et al., 2005, Hedger et al., 2011, Urke et al., 2013), but is also seeing increased usage within aquaculture-related research (e.g. Baras and Lagardère, 1995, Rillahan et al., 2009). Animal variables observed using this technology in a culture setting include individual depth movements (e.g. Føre et al., 2011, Føre et al., 20177), 3D-positions (e.g. Rillahan et al., 2009, Ward et al., 2012), swimming activity levels (e.g. Kolarevic et al., 2016), muscle activity levels (e.g. Cooke, Thorstad, & Hinch, 2004) and respiration rates/feed intake (e.g. Alfredsen, Holand, Solvang-Garten, & Uglem, 2007). The deployment of acoustic telemetry systems requires handling of the fish that often includes surgery, and hence has a certain risk of influencing the states of the fish, and the bio-responses they exhibit. However, at present, acoustic telemetry is the only viable technique for obtaining continuous data series from individual fish in commercial sea-cages, making this technology an attractive candidate for future PFF methods. Furthermore, while other methods for subsurface fish observation (e.g. cameras and sonars) are largely limited to deriving behaviour-based Animal variables, acoustic telemetry may be used to monitor fish physiology (e.g. heart rate, blood composition) since the transmitters units are placed in or on the fish.

Farming operations at sea are subject to natural conditions at the site, as fish kept in sea-cages are exposed to conditions strongly influenced by the ambient environment (e.g. weather, water currents, sea states, temperatures, oxygen saturation, light levels and pollutants). Since many of these factors affect the growth, development and welfare of fish, data on the local ambient environment is important when selecting farming sites for salmon production. Furthermore, farmers increasingly want to monitor such conditions at their site also during production, as this information may be used as a foundation for making decisions concerning farm management, such as avoiding net manipulations when currents are strong, or reducing feeding when temperature decreases. Such data will be useful auxiliary data for deriving PFF methods, as it is often necessary to view an observed Animal variable relative to prevailing environmental conditions to derive desired Feature variables. For instance, temperature and light strongly affect the vertical movements of salmon (Johansson et al., 2006). Evaluating the levels of these factors is critical when seeking Feature variables that are based on depth movements, such as responses to feeding events (Føre et al., 2011).

Table 2 Summarises some of the most common sensors and monitoring methods used to observe salmon in sea-cages today, including both industrially applied systems and solutions primarily used in research. Figure 2 illustrates how a selection of these systems would be applied in a commercial cage.

Table 2. Sensor systems and monitoring methods commonly used to observe Animal variables in aquaculture industry and research, and some properties of these systems.

| Sensor type | Sensor implementation | Animal variables | Information level | Sensing range |

|---|---|---|---|---|

| Sonar | Single beam sonar | Biomass depth distribution within beam | Group | 1 - 200 m |

| Split-beam sonar |

Biomass depth distribution Movement dynamics (position, speed) within beam |

Individual based group | 1 - 200 m | |

| Multibeam sonar |

Biomass depth distribution Movement dynamics (position, speed) within entire cage volume Feed pellet detection |

Group | 1 - 200 m | |

|

Hydroacoustic Telemetry |

Individual fish tags | E.g. depth, position, acceleration and spatial orientation | Individual history | 0 - 1000 m |

| Passive hydroacoustic sensing | Hydrophone | Sound emitted from fish population, general soundscape | Group | 0 - 50 m |

| Camera | Surface camera | Surface activity (jumping/splashing) | Group | 0.5–30 m |

| Feeding camera (submerged) |

Sea-lice count Skin characteristics (scratches, wounds) Behavioural characteristics (e.g. systematic vs. chaotic swimming patterns, normal vs. unexpected behaviour) Species identification |

Individual based group | 0.5–25 m | |

| Stereo camera (submerged) |

Sea-lice count Skin characteristics (scratches, wounds) Behavioural characteristics (e.g. systematic vs. chaotic swimming patterns, normal vs. unexpected behaviour) Species identification Swimming speed and direction Size estimation |

Individual based group | 0.5–25 m | |

| Hyperspectral imager |

Skin spectral characteristics Sea-lice detection and -count |

Individual based group | 0.5–25 m | |

| Multispectral imager |

Detection of spectral signatures Sea-lice count |

Individual based group | 0.5–25 m |

Fig. 2. Illustration of how four systems based on different monitoring principles could be deployed in a commercial cage to observe the fish. While the surface camera (1), underwater stereo video camera (2) and sonar system (3) produce data on the fish within a sub-volume in the cage (delimited by dashed lines for each system), the acoustic telemetry system (4) may collect data on the individual fish carrying acoustic transmitters irrespective of their location in the cage.

Fig. 2. Illustration of how four systems based on different monitoring principles could be deployed in a commercial cage to observe the fish. While the surface camera (1), underwater stereo video camera (2) and sonar system (3) produce data on the fish within a sub-volume in the cage (delimited by dashed lines for each system), the acoustic telemetry system (4) may collect data on the individual fish carrying acoustic transmitters irrespective of their location in the cage.3.2.2. Interpret: Feature variables from animal variables

In the fish farming industry, the interpretation of animal observations is mainly conducted by individual farmers based on personal experience. Although ongoing innovations aspire to automate this process (e.g. systems for remote feeding operations that aggregate and present relevant data from different sources), the existing industrial foundation for automated interpretation of Feature variables is less established than it is for the acquisition of Animal variables. However, this also means that the unreleased potential for developing new PFF methods in this area is considerable.

As production from the cage-based fish farming industry has increased, so has the extent of the research into obtaining a better understanding of the processes occurring in farmed populations. Aggregated knowledge on the different sub-mechanisms and bioprocesses occurring in commercial sea-cages is therefore rapidly expanding. However, before this knowledge can be put to use for decision support on a cage level, it needs to be structured to provide information relevant for the processes occurring in the cage. Mathematical modelling of systems dynamics is a tool commonly used for such inference, structuring and aggregating knowledge by synthesising information from different subsystems into a complete system representation. A mathematical model of a dynamic system can often predict how the system will respond given a specific set of inputs, and may estimate features of the system that are difficult or impossible to measure directly. In aquaculture research, mathematical models exist to estimate fish growth (e.g. Bar et al., 2007, Dumas et al., 2010, Føre et al., 2016, Olsen and Balchen, 1992) and behaviour (Føre, Dempster, Alfredsen, Johansen, & Johansson, 2009). Such models are good candidates as a foundation for PFF-methods aimed at interpretation, as they could predict or estimate properties of the fish based on measured inputs. These inputs will often include various types of auxiliary data (e.g. environmental measurements, feed delivery and feeding schedules) required to drive the model dynamics, but may also include measured Animal variables that the model could then convert into Feature variables more useful for decision support. For instance, a recent study sought to estimate the economic yield of a production operation by combining a model of sea bream growth with temperature as input with simulations of sales plans and strategies (Estruch, Mayer, Roig, & Jover, 2017). Another example of such use of mathematical models could be to use a mathematical model to estimate Feature variables such as the feeding activity of the fish, the distribution of waste material in the water, or vertical fish swimming speeds based on Animal variables such as vertical distribution obtained with an echo sounder as input. Mathematical models representing elements of the environment in production units also exist, covering subjects such as spatial and temporal feed distribution in sea-cages (Alver et al., 2004, Alver et al., 2016). If provided with sufficiently good input data, such models could estimate Feature variables not directly associated with the fish but rather with the production environment.

The use of mathematical models to estimate unobserved states in complex systems has a long history within control engineering, and is realised by including the mathematical model into an observer structure, either based on statistical methods such as Kalman filtering (Brown & Hwang, 1997) or by using non-linear observer methods (Fossen, 2002). Such applications allow the combination of existing knowledge (through mathematical models) with real-time data from sensors to provide better estimates than it is possible to obtain with either sensors or models alone. Estimation techniques are useful for a wide range of industrial applications, including vessel guidance and navigation (e.g. Fossen & Perez, 2009), oil and gas production (e.g. Geir, Mannseth, & Vefring, 2002) and the automotive industry (e.g. Wenzel, Burnham, Blundell, & Williams, 2007), and are well-established methods in all of these fields. Since caged fish production is a predominantly biological process, it is more difficult to measure the different states and processes directly than in more technically-oriented industries. By this reasoning, it is likely that extensive use of estimators based on mathematical models will be necessary components when deriving the PFF methods of the future, as precision farming will require a better foundation for information than is available through present monitoring methods.

3.2.3. Decide: Target variables from feature variables

All important decisions in present day fish aquaculture are made by humans based on the interpretation of observations of the fish and other cage processes based on personal experience, and the use of protocols, legislation and recommendations on farm management. This will probably still be the case in the near future for fish farming operations, as making the “right” decision is a complex task that is difficult to assign to computer-based systems without running a risk of unforeseen and potentially undesirable side effects (e.g. sub-optimal feeding due to limited data on fish responses). However, when fish farming operations are moved to more exposed and remote areas, limited human access will increase the need for autonomy in central tasks such as feeding (Bjelland et al., 2015, pp. 1–10). Limited human presence also means that decision-making processes need to be at least partly automated. Although there exist no systems for automated decision making or decision support that are operative within the aquaculture industry, advances in artificial intelligence and information technology have led to the development of Decision Support Systems (DSS). A DSS is a computer tool that for a given situation or problem combines inputs (e.g. from sensors or mathematical models) and historical user experiences (i.e. from similar situations or problems previously experienced) into compound output values. These output values are used by the DSS as a foundation on which to suggest an appropriate decision, and are in fact Target variables within the PLF/PFF terminology. DSS methods are used in several industries, including oil and gas (e.g. Gundersen, Sørmo, Aamodt, & Skalle, 2012), finance (e.g. Ravisankar, Ravi, Rao, & Bose, 2011) and medicine (e.g. Montani et al., 2003).

An example of research that aspires to go in the direction of DSS for fish farming is found in the proposed concept of using the fish as biological warning systems (BWS) for monitoring seafood safety (Eguiraun, Izagirre, & Martinez, 2015a). Fish would be monitored online using technological methods (e.g. computer vision) to detect atypical behaviour or responses in the fish that imply that the animals are affected by external perturbations, possibly indicating e.g. the presence of noxious substances. Another example of DSS-oriented research in fish farming is given by Føre, Dempster, Alfredsen, and Oppedal (2013) who used a mathematical model to predict how varying the depth of submerged artificial lights could be used to steer the swimming depth of salmon. Combined with online profiling of the temperature gradient at a site, such a model could be used to suggest light placement depths with the intent of optimising the thermal history of the fish, leading to improved conditions for optimising fish growth. Controlling fish swimming depth is also a strategy to prevent sea-lice infestations by selecting the light placement depths such that the fish are steered away from the depth ranges in which the majority of the sea-lice reside (Frenzl et al., 2014). This would require indications of when the densities of copepodites in the water are high, and at which depths (e.g. Oppedal et al., 2017). Such methods could also be combined with automatically submersiblecages or other actions.

3.2.4. Act: manipulating system and eliciting desired bio-responses

Most actions that incite bio-responses at fish farms are manually controlled, and often include the manual operation of mechanical equipment (e.g. winches, cranes, crowding nets and ropes). The task of converting a specific decision into the proper control signals or physical actions that elicit the desired response is assigned to a human operator. An important exception from this is the centralised feeding systems employed at most commercial fish farms. These systems are designed to convert decision level inputs such as cage specific feeding rates and feeding time schedules into the electrical signals (e.g. blower frequency, feed sluice opening rate and feed hose selector) required for the feeding process to achieve the desired system response.

In earlier days, most of the necessary underwater actions at fish farms were conducted by divers. Today it has become common to use Remotely Operated Vehicles (ROVs) for such tasks, greatly reducing the risks of personnel injuries. Although ROVs are most often controlled by human pilots, recent research has demonstrated the possibility of using acoustic positioning methods (Rundtop & Frank, 2016) and computer vision-based systems (Duda, Schwendner, Stahl, & Rundtop, 2015, pp. 1–6) to improve the navigation of ROVs in and around cages, increasing the precision in remote operations. The use of this type of technology could also be extended to Autonomous Underwater Vehicles (AUVs) that move without human interference, and that could in turn be equipped to conduct minor repairs and other underwater tasks autonomously. AUVs have been used for different purposes within several industries, including hydrographic surveys, inspections and prospecting for oil and gas applications, ship hullinspections and military applications (Nicholson & Healey, 2008).

3.2.5. Closed loop Precision Fish Farming applications

At present, there exist no examples of systems that may be branded closed-loop PFF-applications in farm-based fish aquaculture, encompassing the span from observing Animal variables to actuation that elicits a bio-response in the fish. However, as the general level of technology in the world increases, the equipment commercially available to the fish farming industry also becomes more technically advanced and better able to handle more complex tasks. For instance, devices such as biomass frames (e.g. the VAKI Biomass Daily system, Pentair Aquatic Eco-systems Inc.) may be argued to cover both the Observe and Interpret phases in the farming cycle (Fig. 1), as they optically scan the fish, estimate individual volumes based on the scanning data, and then estimate weight distributions based on these numbers. However, there are few examples of solutions that seek also to cover the Decide and Act phases, which often entail human intervention. This aspect is also reflected in the fact that the number and diversity of systems pertaining to each of the different phases as outlined above is higher for Observe and Interpret than for the other two.

However, there are examples of such initiatives within research on live feedproduction, where different cybernetic methods (i.e. mathematical modelling, sensor technology and automated control) have been successfully applied to automatically control feeding, and hence culture growth (Alver et al., 2007, Alver et al., 2010). Although this industrial segment differs greatly from cage-based fish farming in both scale and facilities, both are focused on the husbandry of live aquatic animals, and since such methods are possible to develop for live feed production, similar approaches may apply to farm-based fish production. This potential is even greater for land-based production of fish in onshore tanks, where the ability to control core aspects of the production environment (e.g. temperature, oxygen, flow) is substantially higher than for cage-based production.

3.2.6. Challenges for industrialisation

Many of the technology principles that are potential tools in the realisation of industrial PFF applications have been used industrially and commercially in other market segments, and several have also seen some use within aquaculture. However, for many of these, there exist specific technical challenges related to the basic physics of the subsurface environment, properties pertaining to the selected sensing methods, or limitations of communication protocols when used in a fish farm setting. These challenges need to be overcome before a full step towards commercial exploitation in aquaculture is possible. Potential methods to handle such challenges may range from the implementation of new product features, through adjustment of system settings, to more strategic equipment placement (Table 3).

Table 3. Technology principles that are industrially applied in other segments, and the main challenges of introducing these to industrial aquaculture.

| Technology principle | Present industrial applications | Main challenges in transfer to industrial aquaculture | Suggested remedies |

|---|---|---|---|

| Sonar | Seismic surveys, stock assessment in fisheries | Difficult to capture behavioural details on high density populations | Use higher acoustic frequencies for higher spatial resolution |

| Complex datasets that may be difficult to visualise in relevant manners | Develop visualisation concepts customised to applications (e.g. feeding) | ||

| Acoustic telemetry tags | Fish conservation and ecology studies in relation to hydroelectric dams | Complex and time consuming tag deployment through surgery | Enable more efficient and simple tagging by e.g. miniaturising tag sizes or using other principles such as oral tagging |

| Low bandwidth of acoustic communications channel | Improved communication protocols based on e.g. chirp/sweep signals and TDMA principles | ||

| Difficult to ensure that tagged fish are representative for the population | Increase percentage monitored fish through more efficient tagging methods and higher bandwidth | ||

| Passive acoustics | Terrestrial livestock production | Limited knowledge on relation between sound and Animal variables of salmon | Long term monitoring in parallel with other systems to generate new knowledge |

| Computer vision | Medicine, robotics, manufacturing and mass- production | High turbidity caused by e.g. feed particles or net cleaning particles | Strategic camera placement during feeding/cleaning operations |

| Suboptimal lighting conditions during winter/at night-time | UV lights invisible to fish | ||

| Remote controlled or autonomous vehicles (ROV/AUV) | Oil and gas, shipping, military | Risk of hitting structures/fish while navigating cage volume | Equip vehicle with acoustic/computer vision based navigation means, giving input to adaptive mission planning systems |

| Risk of fish responding to presence of vehicle | Incorporate control system features enabling the vehicle to adapt to fish responses | ||

| Observers (Kalman filtering, nonlinear observers) | Vessel GNC, oil and gas, automotive | Insufficient reliability and quality in sensor data | Using more sensors and higher sampling rates than deemed necessary from a theoretical viewpoint |

| Lack of mechanistic mathematical models of biological dynamics | Use system identification principles to derive input/output relations | ||

| Decision Support Systems (DSS) | Oil and gas, finance, medicine | Insufficient reliability and quality in sensor data | Increase robustness of instruments and communication channels to prolonged submersion in sea water |

| Difficulties obtaining detailed descriptions of user experiences | Introduce routines for systematic registration of metadata during farm operations |

4. Potential industrial applications of Precision Fish Farming

To be of industrial value, a PFF method must positively affect the day-to-day farming situation. PFF methods must therefore be evaluated to test their contributions to improving fish welfare and health, reducing fish losses (e.g. through handling, escapes and disease), improving production efficiency and product quality, and/or reducing environmental impacts of the farming operation, prior to launching innovative actions with the intent of commercialisation. Although it would be more practical to conduct proof of concept studies for PFF methods in controlled laboratory conditions, demonstrating their effects under full scale farming conditions is critical, as culture scale effects modify fish performance (Espmark et al., 2017, Føre et al., 2016). Furthermore, as fish farming operations are primarily conducted outdoors, any piece of equipment or system located at the farming site will be exposed to the elements. PFF methods should thus be tested for durability to prevent equipment malfunction when used on commercial sites.

To illustrate the implementation of PFF methods, we outline four concrete examples of PFF applications that are realistic to implement given present technology readiness levels, and could have a large impact within industrial fish farming. The cases cover important areas in the salmon industry, ranging from biomass monitoring and feeding to parasite management. Moreover, the examples illustrate how PFF principles can be applied to continuous (i.e. throughout the production cycle), regular (i.e. daily) or transient (i.e. occasionally, on demand) time scales.

4.1. Case 1: automated biomass monitoring

Cage population properties such as total biomass, number of fish and fish size distribution in a cage are key inputs to many important decisions in the salmon production process, including the determination of medicinal dosages, assignment of proper feed rations and estimation of total production yield when selling the fish before slaughter. Although systems exist to estimate individual fish sizes and fish size distribution (e.g. biomass frames, stereo visionsystems), these only provide data relevant for their location in the cage, and hence cannot deliver representative data for the entire cage population (Folkedal et al., 2012). This means that decisions where the total biomass, biomass distribution or number of fish in a cage are used as inputs partly need to rely on experience-based estimates provided by farmers rather than on a knowledge-based, objective source.

Due to their importance in central farm management decisions, the ability to predict and quantify such population properties in sea-cages has become a “holy grail” in the salmon farming industry. One way of applying the PFF principles to this challenge is to first identify the relevant Feature variables. Feature variables in this case could be the total biomass in the cage, the total number of fish in the population and the individual size distribution of the population. Although recent studies have demonstrated the potential of using sonar-based solutions to monitor individual fish mass (Soliveres et al., 2017), no existing technological solutions for salmon farming are able to provide data on all these Feature variables directly. It is therefore necessary to develop solutions that derive such data by combining data on different Animal variables, possibly obtained with several different technologies. One possible selection of Animal variables for this purpose could be vertical distribution (sonar) and point measurements of individual size distribution (biomass frames and stereo vision systems). These variables could be combined into a variable estimating the size distribution of the population, by using echograms from the sonar to determine the vertical distribution of biomass in the cage and biomass frames and/or stereo vision systems placed at different depths to observe vertical variations in individual fish size. However, although this scheme would provide new knowledge on population-wide variations in size and vertical variations in biomass properties that are useful properties in their own right, no combination of these two Animal variables can be used to estimate the total number of fish or biomass in the cage directly. One way of achieving such knowledge could be to combine the incoming Animal variable data streams with mathematical models of the behavioural and growth dynamics of salmon (e.g. Føre et al., 2016, Fig. 3) in an estimator structure, such as a Kalman filter. If the model is fed sufficiently detailed data on the external factors tied to the environmental (e.g. temperature levels, sea-states) and management-related (e.g. feed delivery rate) states in the cage that influence fish growth, it can estimate the growth dynamics in the cage. By adjusting the estimated size distribution and vertical distributions based on the monitored Animal variables, the estimator structure will ensure that the population size and dynamics outputs from the estimator adhere to both the historical knowledge included in the model and the real-time data obtained from the sensors. Although this approach is sensitive to both measurement errors and inaccuracies in model equations and parameters, estimates will probably be more reliable than those gained from standalone model simulations.

Fig. 3. Example of comparison between numerical model output (solid line) and experimental data obtained with biomass frame and manual sampling (circles). The grey dashed line marks the onset of PD-disease in the cage. Figure is modified from Føre et al. (2016).

Fig. 3. Example of comparison between numerical model output (solid line) and experimental data obtained with biomass frame and manual sampling (circles). The grey dashed line marks the onset of PD-disease in the cage. Figure is modified from Føre et al. (2016).Since several of the monitoring and simulation tools required in the Observe and Interpret phases for this case study already exist, achieving a closed loop PFF application would primarily require more research into new methods to integrate data from different sources with simulation data. However, as Feature variables describing aspects of the biomass contain information that is relevant for a wide variety of farming applications, it does not make sense to link these to specific Target variables.