1. Introduction

Technological advancements have culminated in the adoption of cost-effective measures to increase production and maximize profits in various sectors [1]. This approach has affected the strategic food sector, which is tasked with meeting the global demand for food. One of the consequences of technological advancements is the high cost of animal feed, which is a critical input for the livestock sector [2]. As a result, there is a growing need to find natural feed ingredients with high protein levels, such as the Azolla plant. The Azolla plant, scientifically known as Azolla microphylla, is a small water spike plant that grows in Indonesian waters. This plant has the potential to provide a protein-rich feed ingredient due to its abundant growth. However, the use of the Azollaplant as an alternative to natural feed ingredients has not been optimized in Indonesia [3]. Therefore, this study aims to evaluate its potential as a natural feed ingredient in the livestock sector.

The fast growth and multiplication rate of the Azolla plant, attributed to its adaptability to different aquatic environments, have made it a potential and strategic alternative to natural feed ingredients for livestock [4]. Its cost-effective high-protein feed significantly accelerates animal growth. However, a significant challenge associated with using Azolla as a raw material for feed is its short shelf life. To overcome this problem, the drying process can be applied, allowing for an increased shelf life and processing into Azolla flour [5]. The drying technology used should be adapted to the final form of the product, depending on the needs of the manufacturer [6]. The rapid development of high technology offers detailed control systems that can maximize the drying process [7]. However, the effectiveness and easy maintenance without incurring significant costs are essential considerations when using high technology in the agricultural product processing sector [8]. Therefore, to optimize the use of the Azolla plant as a natural feed ingredient for livestock, it is crucial to consider the appropriate technology that balances efficiency and cost-effectiveness. This study evaluates the technology processing for alternative feed raw materialsbased on the drying process of the Azolla plant to develop a more sustainable and cost-effective approach to using the plant as an alternative to natural feed ingredients in the livestock sector.

The use of dried Azolla as a natural feed ingredient for livestock presents a promising solution to the challenge of expensive feed costs. The drying process is critical in producing high-quality and storable feed ingredients, and this process can be significantly improved through the use of advanced drying technologies. The utilization of such technologies can result in better product quality and higher selling value. However, the cost-effectiveness of these technologies must be considered to ensure easy maintenance and avoid excessive costs. As the demand for supply needs in the global market continues to increase, there is a pressing need for continuous innovation in drying technology to meet the challenges faced by the agricultural sector. A deployment study is currently underway to evaluate the feasibility and effectiveness of integrating Azolla cultivation into existing livestock production systems [9]. The study aims to assess the practical aspects of Azolla cultivation, including the potential for large-scale production, the nutrient composition of Azolla biomass, and its impact on animal growth and health. The analysis focuses on the effects of different processing technologies on the nutritional value and physical quality of feed, using various alternative feed raw materials as case studies.

By examining the effects of different processing technologies, the study aims to provide valuable insights in optimizing the process. This deployment study involved collaboration between researchers, farmers, and industry stakeholders, focusing on specific regions where Azolla can be effectively cultivated. These areas are characterized by suitable climatic conditions, including warm temperatures and adequate water availability. By establishing Azolla cultivation systems in these areas, this research aims to evaluate the use of Azolla as an alternative feed raw material and assess processing technologies for its potential as a sustainable solution for the feed industry.

2. Methodology

Currently, there are several publications that focus on the content of each Azollaplant and its impact on the growth of farm animals. Some publications highlight the high nutrient levels of the plant [10,11], while others examine its effects on animal growth [12]. However, there is limited information available on the processing techniques of Azolla into dry feed that adapts the high nutrient levels of the plant for use as feed raw materials. To address this gap, this study was conducted to assess the processing technology of Azolla through several stages to determine relevant literature. The study's process involved searching databases such as ScienceDirect, Google Scholar, and SpringerLink for scientific articles using keywords such as monitoring system, drying Azolla, processing Azolla into flour, and using Azolla as ingredients to feed farm animals.

During the process of selecting scientific articles, the intention was to use references from reputable sources. The first stage involved searching for relevant study using predetermined keywords. The second stage assessed the understanding of articles by reading abstracts, methods, and results. Meanwhile, the third stage involved the elimination of publication articles before 2003 to ensure that the scientific articles used had references from the previous 10 years. In this elimination process, 50 articles related to the processing of Azolla into dry were selected to be used as raw materials for livestock feed. This study aims to provide a comprehensive review of the importance of Azolla processing techniques that ensure high nutrient content and extended storage life, leading to reduced feed costs for farmers. Then, the best processing technology is designed and evaluated using CFD simulation.

3. Result and discussion

3.1. Azolla characteristics

Azolla plant contained very complex nutrients, making it a promising alternative to animal feed for breeders [13]. Moreover, with a protein content of 20%–30% [14], Azolla had great potential for further development. Table 1described various literature related to the Azolla plant needed in the livestock sector. The first application was on broiler chicken farming, which had a positive impact on the production of pectoral muscles and weight gain [11]. also reported that the Azolla plant contained 25.62% crude protein and high fiber which were very beneficial in the fattening process of broiler chicken Furthermore, the antioxidants and intestinal digestive enzymes improved the growth performance and immunity in livestock [10].

Table 1. Literature related to the Azolla plant used in the livestock sector.

| Product | Trial Conditions | Parameter | Test Azolla | Result | Reference |

|---|---|---|---|---|---|

| Boiler chickens | Inclusion of DFM diet in Azolla-based diets against performance | 25% | Shows a positive effect on chest muscle production and broiler gizzard weight that can be increased by adding Azolla-based feed. | High crude protein (25.62%) and high fiber content (CF, 19.64%; NDF, 52.76%; ADF, 28.57%). | [11] |

| Shrimp | Evaluate the effects of individual or combined wheat brand replacement with Azolla |

97% Azolla 3% Digestin™ |

Rates of up to 3% have higher growth and better nutrient utilization than control feed. | This result clearly shows that a pinata has a good potency for use in the diet of shrimp | [15] |

| Nile tilapia | Evaluate the results of feeding Bacillus subtilis | Azollafermentation on immunity | Bacillus subtilis fermented Azolla (BSFA) is more effective in improving the growth performance and immunity of tilapia. | Contains antioxidants, intestinal digestive enzymes | [10] |

|

Azolla Microphylla |

Evaluate the cyanobiont and its interaction with the host plant | Microphylla and AzollaCaroliniana | Potential sources of nutraceutical ingredients | Shows that Azollamicrophylla is richer in Vit B12 and Vit B9 compared to Azolla Carolinian. | [16] |

| Azollapinata | This experiment was conducted to explore the nutritional value of Azolla | Protein content | The crude protein content of Azolla is estimated in this study to be 23.49% | Use of fresh Azolla pinnata as the only source of feed for various sizes | [17] |

| Livestock | Determining the composition and nutritional value of two AF in pigs | Nutritional value | Azolla has some nutritional potential, thanks to its high protein content | The use of azole affects the growth of farm animals. | [18] |

| Azollacaroliniana | A scientific explanation of the benefits of Azolla. | Antibacterial antioxidants | Antibacterial and antioxidant | Azolla caroliniana could be used as an antibacterial and as an antioxidant agent in complementary and alternate medicine. | [19] |

Growth retardation and weight loss were observed in all fish sizes fed with fresh Azolla and the mortality rates were found to be 53.3–56.7% [4]. However, Lemna and Azolla were the two aquatic plants with a high protein content of approximately 17% in frozen dried form [20]. [21] discovered that as the level of dry Azolla in the diet increased, the amount of food consumed by animals decreased while the feed conversion ratio increased significantly. Table 2described some literature on the effect of Azolla on the growth, digestibility, and performance of farm animals when the Azolla levels of 10%–25% were included in their diet. In this condition, Azolla administered was dried naturally over a long until its moisture content was reduced.

Table 2. The effect of Azolla on the growth, digestibility, and performance of farm animals.

| Product | Parameter | Azollacondition | Result | Reference |

|---|---|---|---|---|

| Fish | Weight gain | Azolla ration 25% | Giving Azolla to fish feed can reduce the fat content in fish muscles. | [22] |

| Fish | The value of digestibility | Dry Azolla | The highest digestibility value (p < 0.05) at an inclusion rate of 10% Azolla. | [23] |

| Sheep | Weight gain | Dry Azolla | Azolla 10% diet as a best practice for fattening Moghani sheep. | [12] |

| Rabbit | Growth | Azolla Leaf Flour | 10% in the diet of growing rabbits increases production performance and meat quality | [24] |

| Broiler chickens | Growth | Azolla Leaf Flour | The inclusion rate of Azolla food is less than 15% in poultry, 5% in broiler chickens, and less than 25% in recommended fish nutrition. | [25] |

| Livestock, poultry, and fish. | Growth | Fish as promising sources of feed ingredients. | The inclusion rate of Azolla food is less than 15% in poultry, 5% in broiler chickens, and less than 25% in recommended fish nutrition. | [26] |

Table 3 showed that the drying process significantly affected the nutrients obtained from Azolla flour. It was also discovered that all the literature on the use of Azolla flour for feed involved had the drying process [27]. conducted the drying process by washing the plant to remove the mud and putting it in the oven at a temperature of 60 °C or 55 °C [28]. Subsequently, the parameters applied were mixed with other raw materials and the content obtained ranged from 5% to 25% dry Azolla, which significantly reduced feed costs [4].

Table 3. The drying process affected the nutrients obtained from Azolla flour.

| Product | Parameter | Azollacondition | Composition | Reference |

|---|---|---|---|---|

| Broilers | Azolla (Azolla pinnata) is a feed ingredient in the ration of broilers. | Flour | Azolla up to 5% in the ratio of broilers was found to improve performance and can be used in broiler feed at a safe rate. | [21] |

| Commercial Broiler Chickens | Evaluation of dry Azollafeed (Azolla pinnata) and Azolla co-rated with enzymes. | Flour | Higher for all groups fed with dry Azolla | [29] |

| Fish | To evaluate the use of fresh Azolla pinnata as the only source of feed for various sizes. | Flour | Dry Azolla flour can be included up to 25% in tilapia feed in extensive or semi-intensive systems to reduce feed costs. | [4] |

| Tilapia | To evaluate the effect of diet on growth performance, antioxidant capacity, and metabolism | Flour | The inclusion of 20RA and 20-30FD in the ration could be potential feed ingredients in the tilapia ration. | [30] |

| Fish | The results show that Se(IV) is more toxic than Se(VI) | Flour | The protein content in freeze-dried Lemna and Azolla is about 17%. | [20] |

3.2. Azolla drying method

Azolla was one of the spike plants cultivated by farmers as alternative natural feed ingredients. Currently, the only drying process of the plant was sunlight to produce dried Azolla that can be reprocessed into flour for use as a natural feed raw material. During the drying process, temperature variations are used as indicators to ensure that the moisture content is reduced to less than 10%, which was suitable for long-term storage [31]. The temperature variation commonly used in the drying process is between 40 °C and 60 °C. This was because temperatures above 40 °C caused a decrease in the quality of the final product, while temperatures lower than 40 °C require more time. This indicated that temperature variations should be carefully controlled to obtain the appropriate temperature for the drying process [32]. Stated that when the exhaust gas temperature was higher, the dryer efficiency was lower, thereby causing damage to the compounds and protein content in the plant. After the drying process, another indicator that was considered was the moisture content contained in the Azolla plant. Therefore, both the temperature and moisture content should be observed at regular time intervals during the drying process to obtain desired outcomes.

In Indonesia, the potential of the Azolla plant had been developed by farmers using traditional dryers to dry the plant commodities. However, this method degraded the quality of Azolla, causing deviations in ingredient quality. This made it necessary to use a dryer that maintained the quality of dry Azolla and prevented any loss of raw materials. The drying method was adopted to ensure that all products were dried thoroughly to produce high-quality flour. This can be achieved by using a dryer equipped with a control system to maintain the quality of dry Azolla and prevent contamination by environmental influences. The two types of dryers that can be used according to the characteristics of the Azolla plant were the rack and rotary types. The rack type consists of shelves with wire mesh as boundaries between them, while the rotary type uses a rotating cylindrical tube to blow heat through the Azolla during the drying process. Meanwhile, specific parameters should be met such as controlling the drying temperature according to the characteristics of Azolla. The dryer must also be equipped with a real-time control system to ensure that all components of the tool operate optimally according to the specified standards.

3.3. Hybrid-solar cell dryer with automatic control system

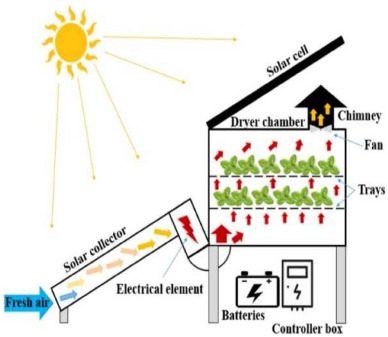

This type of drying method had a monitoring system to measure air temperature, air speed, and relative humidity. The tool was equipped with a solar cell and a drying chamber that contained two aluminum trays with holes and a total volume of 210 cm3. During the drying process, the heat-conducting blades and the solar collector, made with aluminum and a frame slope of 34° absorb sunlight. The electrical element that heated the air in the drying chamber was varied with a fan located in the collector frame and there was an air outlet at the top of the solar drying to direct the air out (see Fig. 1). This drying device was also equipped with a sensor to control the incoming air at a constant speed of 1 m/s and determined the relative humidity during the drying process [33].

Fig. 1. Hybrid-solar cell dryer with automatic system [33].

Fig. 1. Hybrid-solar cell dryer with automatic system [33].3.4. Mixed mode forced convection solar dryer

This study presented the crushing of stevia leaf using the newly developed Solar Blend Forced Convection type dryer (MFSCD) and Open Solar Drying (OSD). The experiments were conducted under an average solar radiation of 567 W/m2, a temperature of about 30 °C, and a drying air flow rate of 0.049 kg/s. The safe moisture content of stevia leaves (end) reached 0.053 (DB.) within 330 and 870 min of drying time in MFSCD and OSD, respectively (see Fig. 2). The overall dryer efficiency and the average excerpta efficiency of MFSCD were 33.5% and 59.1%, respectively [34]. The rigging process provided optimal results by the parameters of the product achieved, namely the aroma and taste of stevia leaves.

Fig. 2. Mixed mode forced convection solar dryer [34].

Fig. 2. Mixed mode forced convection solar dryer [34].3.5. Fluidized bed drier (FBD)

The characteristics and working principle of this single-stage fluidization were aimed at reducing the moisture content from 70% to 3%. In this single-stage FBD, a uniform flow rate and inlet air temperature were used throughout the drying bed. At each position, the total mass of tea was kept constant and a piece of the moisture was evaporated. Subsequently, the mixing and drying of the tea granules were carried out uniformly through a fluidization process. Hot air was used as a carrier of tea grains through a dryer, providing forward motion to the leaves until the dried leaves were released at the end of the discharge (see Fig. 3).

Fig. 3. Fluidized bed drier [35].

Fig. 3. Fluidized bed drier [35].3.6. Shelf-type plant drying technology monitoring system

Table 4 showed that the drying technology applied to plants mostly focused only on temperature in their control systems. Meanwhile, optimal drying required a complex control system to ensure that the product met the established quality standards. Good technology should also be easily operated by users and must not require expensive costs for machine maintenance.

Table 4. A systematic review of the drying system with more on the implementation of the monitoring system used.

| Author(s) and place of experiment | [36] | [37] | [33] |

|---|---|---|---|

| Drying time/rate | The drying process took about 15–25 min, based on the thickness of the leaves, quantity, and types of the tea which were subjected to drying. | 77 h | 30 min |

| Drying temperature | The temperature above the trays were controlled between 50 °C and 100 °C. | the drying temperature was maintained constant at 40 °C | 40 °C, 55 °C, and 70 °C |

| Drying capacity(kg) | Typical dryer capacity fluctuates from about 100 kg/h to 300 kg/h and the average fuel consumption is around 45 kg/h. | about 30 kg of leaves were taken to carry out the tests | 200, 400, and 600 g |

| Test quality of dried product | Typical dryer capacity fluctuates from about 100 kg/h to 300 kg/h | the drying process was conducted until achieving 10% of the humidity of the drying material. As a consequence, the two species have different “expiration dates”. | on the drying trays in sizes 2, 4, and 6 cm. |

| Parameters of energy consumption for drying | the moisture content of the tea leaves declined from around 68% to approximately under 3% and the average fuel consumption is around 45 kg/h. | that biomass density up to 5 kg/m2 is not a limiting factor in the duration of the process. | air temperature, airspeed, and relative humidity |

| Indicator monitoring system | The programmable controller which controls moisture content | the precise monitoring of the evolution of biomass moisture loss and drying rate. |

a constant air velocity of 1 m/s was used for all the experiments. All the tests were performed in three replicates and all the samples were treated with the same drying conditions. |

3.7. Rack type drying monitoring system

In the large-scale industrial sector, dryers used very expensive PLC-based systems in monitoring units, which was not suitable for small-scale systems [36]. To overcome this problem, the use of a monitoring system with a low cost was adopted by adjusting it to the required specifications. Therefore, a microcontroller-based system was found to be an alternative to making a low-cost system. This system processed data using several components and manipulated conditions during the drying process (see Fig. 4). The main function was to digitize the results of sensor capture in the form of digital values from analog sensors using a microcontroller.

Fig. 4. Microcontroller-based monitoring system [36].

Fig. 4. Microcontroller-based monitoring system [36].3.8. Smart system to control aromatic herb

The cabinet-type dryer was made of stainless steel, namely AISI 304, with dimensions of 95 × 60 × 150 cm (see Fig. 5). It was equipped with two doors and a ventilation system to control relative humidity. This drying device had a power of 1250 W and can reach temperatures from +5 °C to 130 °C. The heating was achieved by special air heating with an ascending flow from the evacuation of steam through centrifuges with a flow rate of 40 m3/h. The drying chamber on this device was equipped with automatic heating and ventilation system, ensuring a constant temperature and relative humidity in the drying chamber.