1. Introduction

The increasing need for weight-saving engineering solutions has led to the development of polymer matrix composite materials, now widely applied to aerospace, wind energy generation, sport as well as automotive applications. Polymer composite materials are man-made combinations of two or more different materials, in general reinforcing stiff inorganic or organic fibres and a polymer matrix that produce unique resulting properties, such as an improved stiffness, but also tailored thermal or electrical conductivity, to some extent mimicking many fibrous structures as found in nature. One of the main initial drivers for the development of composites has been the increasing need for materials with high specific stiffness and strength. More recently, the development of composite materials took advantage of their inherent heterogeneity and anisotropy to combine the traditional load-bearing functions of these materials with novel functionalities in the form of embedded elements. The resulting adaptive or “smart” composite materials may integrate actuators and sensors so that they can adapt and react to their service environment; this enables gains in efficiency not only by reducing structural weight, but also by integrating functions directly into the structure, which may act during processing, during part manufacturing and assembly, and during service, either to adapt to the service conditions, or to detect damage and even to effect repair of the structure in service.

An emerging class of such materials is fibre reinforced polymer composites containing thin Shape Memory Alloy (SMA) wires as functional elements [1], [2], [3], [4]. Shape Memory Alloys have been available for 50 years and have found as bulk materials many applications as actuators or dampers, as well as in miniature tooling industry [5], [6]. In comparison to other actuating technologies, SMAs provide the following advantages: high reversible strains (up to 6%) and shape recovery, high damping capacity, large reversible change of mechanical and physical characteristics, and the ability to generate high recovery stresses when they are prevented from recovering their shape. They have recently been available as wires with diameters below 0.2 mm, which may thus be integrated into and bring added functionality to a structural composite material, while not strongly disrupting the initial microstructure and structural properties and compromising the light-weighting benefits of composites. As a result, composite materials with SMA wires could demonstrate functions such as a shape change, a controlled overall thermal expansion, a shift in the part natural vibration frequency upon activation, possible damage reduction and repair … In practice, however, limitations have been encountered as the SMA transformation is in general induced by temperature change or stress (with the exception of magnetic SMA materials), greatly limiting their response time controlled by heat transfer kinetics. In addition, SMA wires integration must be made compatible with the polymer composite, requiring adaptation to the processing route, as well as to the part design to maintain sufficient structural properties, and to limit the weight increase.

The main goal of this article is to provide an overview of the use of SMA wires in structural, fibre reinforced composite materials, from the composite processing stand-point, as well as the resulting properties, spanning from vibration damping, to shape morphing, crack closure and impact damage mitigation. These aspects were also, but partly, reviewed in Refs. [2], [7], [8], [9], [10]. In particular, Lester et al. [8] provided a very extensive review of shape memory alloy composite systems, that also covers metal matrix and ceramic matrix composites, as well as the uses of SMA as a matrix, beyond the introduction of SMA into bulk polymers and polymer composites; the reader is referred to this reference for a more general overview on the response of these systems compared to the modelling methods that have been proposed. Here, we consider only SMAs that are embedded (as thin wires, or in rare cases ribbons or powders) into structural composite materials, and will not cover the literature dealing with the external attachment of SMA rods or wires to composite structures [11], [12], [13]. We also do not consider the use of SMAs as a single material included in a polymer matrix, a field that is now well developed in biomedical applications, including stents and valves [13], [14].

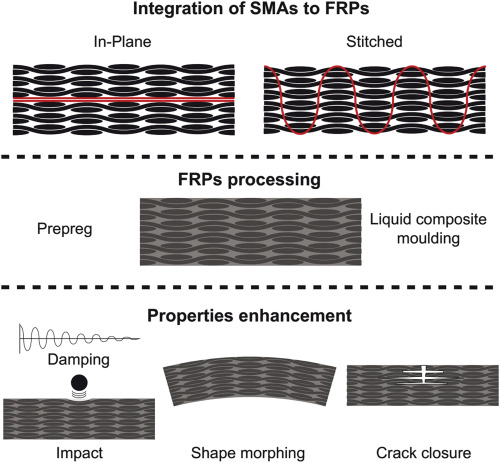

We will first briefly recall the types of SMAs as well as their working principles. We will then review the applications of SMAs into structural composites as found in the literature, and as schematically illustrated in Fig. 1. The method of SMA integration, the choice of polymer and reinforcement material, as well as processing techniques, and the main types of property enhancement and their quantification will be addressed. Finally, we will detail the critical parameters that need to be considered when conceiving a composite with embedded SMA elements: wire positioning methods, interface properties and their change during successive SMA actuation, issues related to thermal effects during cure and during actuation, as well as the optimal positioning of the wire elements for best actuation with minimal impact on weight and other structural properties. Finally, we will review current and potential applications, and the remaining hurdles to address before a wider implementation of these functional materials in industrial applications.

Fig. 1. Schematic concept of SMAs integration and processing in FRPs as well as resulting possible properties enhancement.

Fig. 1. Schematic concept of SMAs integration and processing in FRPs as well as resulting possible properties enhancement.2. Shape memory alloys overview

This class of metallic materials has been discovered in the 20th century, with first observations in 1932 with the expensive and toxic gold-cadmium alloy [15]. In the 1960s [16], nickel-titanium (Ni Ti)-based alloys, which are more affordable and non-toxic, have been established as the main class of Shape Memory Alloys, and attracted interest in a wide range of applications [8], [17], [18], [19]. For an extensive review of the SMA mechanisms, the reader is referred to the numerous books and articles that describe these materials and their mechanisms [1], [2], [6], [8], [17], [19]. We provide here only a brief introduction of the main principles, in particular as needed for applications in composite materials. Most SMAs display three main relevant properties: (i) the shape memory upon heating from a deformed martensitic state, with a possible two-way shape memory effect upon training, (ii) damping in the martensitic state, (iii) superelastic behaviour in the austenitic state.

SMAs are metallic alloys, which undergo a diffusionless, thermoelastic solid-state martensitic transformation of their crystal structure, involving a coordinated shear of atomic layers over distances that are on the order of the atomic layer. As a result, when an SMA, under no load, is cooled down from the cubic austenitic (parent) phase through its transition temperature, monoclinicmartensitic variants form within the microstructure. As shear of the variants takes place in all directions, no macroscopic shape change is observed. The resulting structure is called self-accommodated martensite (SAM). The interfaces between these variants are glissile: when external stress is applied, the most favourably oriented variants grow at the expense of those which are least favourably oriented, thus forming a preferentially-oriented martensite phase (POM), also known as detwinned martensite, as shown in Fig. 2.

Fig. 2. Stress–strain diagram of shape memory alloys and the schematic crystal structures at three typical temperatures. (a) T ≫ Af (b) T > Af and (c) T < Mf(adapted from Ref. [20]). Reproduced with permission from ASCE.

Fig. 2. Stress–strain diagram of shape memory alloys and the schematic crystal structures at three typical temperatures. (a) T ≫ Af (b) T > Af and (c) T < Mf(adapted from Ref. [20]). Reproduced with permission from ASCE.The phase transformation can be analysed based on thermodynamics, as it is driven by a decrease in the Gibbs free energy of the system. Thus, the martensitic phase is present when its Gibbs free energy GM is lower than that of the parent phase GA. As shown in Fig. 3(a), Gibbs free energies GM and GA are in equilibrium at a given temperature T0. The martensitic transformation starts however, below T0, at Ms (martensite start), as undercooling is necessary to initiate nucleation, and finishes at the lower temperature, Mf (martensite finish). While heating, the reverse transformation proceeds starting from As(austenite start) and ending at Af (austenite finish). The resulting martensite fraction versus Temperature plot is shown in Fig. 3(b).

Fig. 3. (a) Gibbs free energy as a function of temperature for austenite and martensite phases. (b) Martensite fraction as a function of temperature, (c) Change in the transformation temperature curves under applied stress, showing the possibility of a stress-induced isothermal transformation from austenite to martensite.

Fig. 3. (a) Gibbs free energy as a function of temperature for austenite and martensite phases. (b) Martensite fraction as a function of temperature, (c) Change in the transformation temperature curves under applied stress, showing the possibility of a stress-induced isothermal transformation from austenite to martensite.2.1. Shape memory effect

If the material is deformed in the martensitic state, creating the POM phase, the stress-strain curve is described as in Fig. 2(c): when the load is released, the material, after some elastic recovery, remains in the deformed state, although this is not a plastic deformation, but the result of the martensitic twins orientation. When reheated above the transformation temperature range, the crystal structure tends to revert back to the original form, and the strain is recovered, provided that there is no irreversible or plastic deformation (as would happen in some steel compositions, which can undergo martensitic transformation but does not exhibit shape memory effect). As a result, when heated, NiTi based materials can exhibit up to 8% recovery strains when free [21]. If the material is constrained, for example if a NiTi wire, that has been strained in the martensitic state, is reheated but fixed at both ends, the material exerts large recovery stresses, up to 700 MPa [1], [10], [21], [22]. In intermediate cases, if a bias force prevents the wire from fully recovering its shape, a mix of strain and recovery stress is obtained. This effect can be exploited in composite materials, either to induce morphing of the part upon temperature change, or to exert a closing force when the material is heated above its transformation temperature and fixed at its extremities in the structure. In some cases, if the material is previously made to deform back and forth between two shapes (this operation is called training), the structure tends to recover its low temperature shape as well without any external bias. This is known as a two-way shape memory effect; however, this is not much exploited in composite applications, as the composite in general is stiff enough to act as the bias force in the cooling down phase. However, as the SMA wires tend to change their behaviour over the first activation cycles, to reach a generally stable stress-strain-temperature behaviour after a rather large number of cycles, it is generally advised to prepare the wires, prior to embedment, even if only one-way SMA is needed.

2.2. Damping of the martensite phase

As the martensite variants are very mobile, their movement and friction between the variant interfaces dissipate a large amount of energy when elastic waves travel into the material. As a result, the intrinsic damping capacity of the martensite phase (in particular in the transformation temperature range) is high; this can be exploited to confer added passive damping to the composite material [6], [19].

2.3. Superelastic effect

A fully austenitic material can also undergo a stress-induced phase change, as illustrated in Fig. 3(c). The transformation thus occurs in isothermal conditions, and reverts back when the stress is released. As a result, a stress-strain curve for a material just above the austenitic phase transformation range is as shown in Fig. 2(b): this behaviour is called superelastic. Since energy is dissipated (under the form of heat) when the material is cycled in the hysteretic stress-strain loop, materials in this state can also act as passive dampers.

2.4. Other effects

SMAs can also be used as temperature sensors, since they also change their electrical conductivity, stiffness and damping characteristics when passing the transformation temperature, which is dictated by the alloy composition. Most of the alloys present a rather large transformation range, which makes the change in properties gradual, but specific alloy compositions with narrow hysteretic ranges are found [23], [24]. The large change in stiffness between the martensitic and austenitic phases (that can change from about 10 to 30 GPa to about 80 GPa, respectively), can also be exploited to produce structures with variable stiffness [25], simply by changing the part temperature. Another interesting sensing capability of the SMAs, not often mentioned, is the almost linear evolution of electrical resistivity with strain at a constant temperature, which could make these materials also useful as strain sensors [26], although this has not been reported for use in SMA composites.

Shape memory alloys are often exploited for their actuation capabilities, which are most striking and stem from their shape memory. The large recovery strains (up to 8%), or large recovery stresses if constrained (up to 800 MPa), led to their commercial application in fastening or clamping devices, and to the development of self-deploying structures [11], [27]. SMA springs have also demonstrated their potential for thermally activated valves, in particular when acting against a steel spring to force their return to the initial position [28]. The two-way shape memory effect could be a solution to make the actuation reversible; however, it is worth noting that high precision in terms of activation magnitude versus the number of cycles is not achieved, as thermal fatigue and drift in the response remain an issue, even though some specific alloy compositions seem to provide better stability [29]. In all cases, accurate prediction of the thermomechanical behaviour of the SMA is needed to design the actuator, taking into account the non-linear and hysteretic behaviour of the alloy, which makes it difficult to control. Another limitation arises from the kinetics of the actuation, which are governed by heat transfer to or from the surroundings. These materials are thus only restricted to very low frequency activation, by opposition to piezo-electric ceramics. A promising competition in terms of frequency is the recent development of Ferromagnetic SMAs. As an example, NiMnGa alloys can achieve magnetically controlled strains up to 10%, with frequencies in the range of 200 Hz or more [30], [31]. Applications as linear motors, valves and pumps are now proposed, although these materials are costly, very sensitive to surface quality and do not provide high recovery forces.

2.5. Comparison with shape memory polymers

SMAs being metallic alloys, their density is in the range of 6.45; as a result, they add weight to the structure when used as actuators, sensors and dampers in composite structures. Shape memory polymers, which are polymers exhibiting shape memory when heated above a transformation temperature (in general the Tg), are much lighter than SMAs. Their reversible transformation is not induced by a phase change, but by conformational entropy of the polymer chains, bringing them back to an equilibrium shape when in the rubbery state. The shape memory effect in polymers has been largely reviewed and investigated for shape morphing, crack closure, as well as damping propertiesimprovements in FRPs [32], [33], [34], [35], [36], [37], [38]. A comparison of the main mechanical and recoverable properties between SMAs and SMPs is provided in Table 1 (two often investigated SMAs compositions are indicated as of interest for the present review). Intrinsic mechanical properties provide an indication of the capacity to recover high vs. low strain as well as stress. Notice that SMPs have very large recoverable strains, but that their stiffness and hence recovery stress is, as expected for polymer based materials, much lower than for metallic SMAs. In addition, they are activated at temperatures close to in-service temperature of many applications, which may also restrict their use. Recovery stress is crucial to act against the bias force exerted by the composite structure. As a result, SMP are mostly used in the direction transverse to the structural fibre reinforcement direction, or in large volume fraction, even as the matrix material itself. For example, Shape Memory Polymer Composites where the SMP forms the full matrix, impregnating carbon fibre reinforcements, have been investigated for making hinges or deployable light structures for space applications, and have demonstrated their effectiveness for shape change if the bias force is not too high [39], with some reservations concerning the potential microbuckling of the reinforcement fibres in the folded state, and the lack of high temperature solutions, which may better survive in a space environment. SMAs, owing to their much higher recoverable stress and temperature ranges, appear suited to use in low volume fractions for shape morphing, crack closure as well as damping properties improvement in FRPs. As an example, they have found use in active stitches to close cracks and improve the mechanical property recovery in self-healing composites [40], [41], [42], [43].

Table 1. Typical properties of SMAs and SMPs found in various literature. Data are indicative.

3. Shape memory alloys in fibre reinforced polymers

The use of SMA wires into FRP structures was initiated in the early 90's by Rogers et al. [46], [47]. By embedding NiTi SMA wires (5, 10 and 15 vol%) into a carbon-epoxy prepreg parallel to the reinforcement layers, they demonstrated that upon heating, the Young's modulus of the structure as well as the yield strength increased by a factor of 4 and 10, respectively. They further showed that the natural frequency of these systems could be tuned by heating the SMAs, which allowed tailoring the vibration properties of the FRPs. Since then, SMAs into composites were investigated by many researchers, including for impact damage resistance and suppression, as reviewed in Refs. [2], [7], [8], [9], [10]. In what follows, studies embedding SMAs into FRPs are detailed to cover the four main areas of properties improvements (see Fig. 1): (i) damping and vibration, where SMAs are integrated in-plane to the composites in the neutral axis, but also as stitches; (ii) impact, where SMAs are also integrated in the neutral axis or as stitches; (iii) crack closure, where SMAs are integrated transverse to the crack, as stitches and (iv) shape morphing, where SMAs are integrated in-plane to the composite, but in the non-neutral axis.

3.1. SMAs in FRPs for damping and vibrational properties improvement

SMAs embedded into composites have been used since many years to improve damping and vibrational properties using a variety of approaches. As mentioned above, SMAs in the martensitic phase have a high intrinsic damping capacity [48], and can thus be introduced as a second phase for passive damping increase without any need to pre-strain the SMA [23], [49], [50], [51]. If this material is heated above the austenitic transformation temperature, the change in Young's modulus of the SMA phase and its decreased intrinsic damping can also contribute to a modification of the vibrational properties, this is often referred to as active modal modification. It is also possible to consider the use of superelastic SMAs, initially pre-strained to reach the stress-strain plateau, if the strain induced by the elastic wave propagation is large enough to dissipate energy through the hysteresis loop (as shown in Fig. 2) [52]. In both cases, a loss factor increase of 100% or more was obtained in carbon-epoxy composite plates, albeit to the penalty of a weight increase, of at least 20% [49]. A more efficient approach is to use the shape memory effect of SMAs to introduce an active damping effect, obtained through a change of temperature above the austenitic transformation temperature, leading to a recovery force. This is particularly striking if the part itself is constrained. Considerable research efforts have been carried out on this topic in the years 2000, in Japan[53], [54], and in Europe in the scope of a European effort to provide a fundamental understanding for the manufacturing and design of SMA FRPs for active vibration control [29], [55], [56], [57], [58], [59], [60], [61]. Balta et al. [59]first produced FRPs made of Kevlar/epoxy prepregs with embedded ternary NiTiCu SMA wires, which were 150 μm in diameter. NiTiCu wires, straight annealed (to provide them with a straight shape upon heating), were selected as they had a transformation temperature close to 50 °C, i.e. above room temperature, but not too high to remain below usual softening temperatures of the polymer matrix. Pre-strained wires (3%) were embedded in the middle plane of the reinforcing fibres, as shown in Fig. 4(b); a frame was designed to maintain the wires and avoid recovery of the wires during processing of the FRPs at 70 °C. The SMA-matrix interfacial shear strength was first assessed and was found optimal for SMA wires having a thin oxide layer on the surface. The recovery force and vibration response of the enhanced composites further showed a narrow hysteresis loop, as illustrated in Fig. 4(a). Recovery force measured on a clamped composite, upon heating, increased with temperature after the transformation temperature, and also increased linearly with the volume fraction of wires; this led to a resonance frequency shift upon actuation at 80 °C of more than 30% above the initial value directly related to the recovery force measured in a clamped-clamped condition, for a composite containing 3 vol% wires. Further characterisation of the vibration response is found in Ref. [61]. This research further led to the processing of an adaptive aircraft aeroelastic profile demonstrator, demonstrating the possible industrial use of adaptive composites [28], [57], [62]. Modelling and material design was adapted to take into account the interaction between the wire and the host materials response upon actuation. Šittner et al. [60], [63] carried out simulations to find optimal parameters in terms of: (i) SMA wires (i.e. Young's Modulus, thermal expansion coefficient, transformation temperatures, hysteresis etc.); (ii) polymer matrix (i.e. Young's modulus and thermal expansion coefficient) and (iii) composite structure (i.e. composite layout, wires volume fraction, SMA pre-strain). Modelling, processing and characterisation of these adaptive structures are also reported in Refs. [29], [55], [56]. Recently, De Matos Junior [64]proposed a semi-analytical model to predict the flutter of a Carbon/Epoxy composite containing embedded SMA wires, providing a tool to assess the effectiveness of vibration reduction, as a function of ply sequence, part aspect ratio, and other geometric parameters, in addition to the SMA properties versus Temperature. Finally, some realistic part concepts have been considered [25], [65], in particular exploiting the fact that the SMA stiffness strongly changes between the martensitic and the austenitic state, thereby easily producing parts with variable stiffness.

Fig. 4. (a) Resonance frequency shift as a function of temperature for clamped kevlar-epoxy composites with 4 prepreg plies but different number of wires (20 wires corresponds to 5% volume fraction wires); (b) Example of Kevlar epoxy composites, with embedded SMA wires. Reproduced with permission [29]. Copyright 2002, The Japan Institute of Metals.

Fig. 4. (a) Resonance frequency shift as a function of temperature for clamped kevlar-epoxy composites with 4 prepreg plies but different number of wires (20 wires corresponds to 5% volume fraction wires); (b) Example of Kevlar epoxy composites, with embedded SMA wires. Reproduced with permission [29]. Copyright 2002, The Japan Institute of Metals.3.2. SMAs in FRPs for impact resistance

Following their capacity to improve damping and vibrational properties into FRPs, SMAs can also supress, or at least decrease the damage area subsequent to an impact event. Two ways to integrate the wires have been studied: (i) in-plane in the FRPs and (ii) through the thickness of the FRP, as stitches.

Paine and Rogers [66] first demonstrated the use of SMA wires (0.4 mm diameter) to improve the FRP response to low velocity impact damage. They integrated NiTi wires into carbon prepregs, parallel to the fibres in the 0° plies that are below the neutral axis of the structure. Overall, the volume fraction of the wires was 2.8%. This strategy allowed a 25% increase in the delaminationresistance upon impact as compared to composites without SMA wires. The wires also allowed stopping the perforation of the structure by the impactor. To further benefit from the SMA wires properties, a pre-strain can be applied to the wires before integrating them into the structure. Birman et al. [67], [68]used a micromechanical model based on the multi-cell method to model pre-strained SMA enhanced FRPs. Their results confirmed the effectiveness of SMAs embedded within the composite layers to improve low velocity impact characteristics, if these are pre-strained and their contraction is prevented during composite manufacturing, thus creating tensile stresses. The improvements can be further tailored by optimizing the wires' distribution throughout the FRP plate. Similar modelling was provided by Roh and Kim [69], [70] and confirmed these conclusions. For further modelling of SMAs embedded in composite structures to improve impact damage characteristics, the interested reader is referred to the following references [71], [72]. Tsoi et al. [73]experimentally investigated the potential of SMAs, pre-strained, into FRPs to improve impact damage properties. They integrated superelastic NiTi and NiTiCu SMA wires (0.15 mm diameter), as well as stainless steel wires for comparison, into glass fibre epoxy prepregs. To allow pre-strained wires to be integrated into the structure, a special frame was designed to maintain the strain during the composite curing process (which was above the transformation temperature of the wires). Pre-strain levels of 0, 1.5 and 3% were investigated for NiTiCu wires. The influence of the position and volume fraction of SMAs was investigated with NiTi wires, which were integrated in between the reinforcing layers, at different positions, and with volume fractions of 0.45, 0.89 and 1.8%, corresponding to 0.5, 1 and 2 wires/mm in the structure, respectively. Overall, results showed that (i) the delaminated area decreased when increasing the SMA pre-strain level; (ii) the SMAs needed to be integrated in between the 0° plies, in the bottom half of the laminate, and especially in the bottom layer to decrease fibre breakage damage; and (iii) increasing the wire density increased the resistance to delamination. From these tests, the authors could create an impact performance map (Fig. 5), comparing the PDA slope (the slope of the damage area versus the incident energy), an indication of the damage resistance of the material (the greater the slope is, the easier the damage accumulation is), with the IEC slope (the slope of the absorbed energy versus the incident energy), a measure of the materials' energy absorption capacity (the greater the slope is, the greater the capacity for internal dampingand impact energy absorption capacity). From this map, reference specimens, without embedded wires, show obviously high slopes, indicating high energy absorption capacity and easy damage accumulation. Steel and NiTiCu wires, have low slopes, representative of better damage accumulation; however these do not have high damping capacity. For improved performance, NiTi wires thus show a good compromise, and the choice of the wire volume fraction depends on the targeted application. The authors further studied the thermomechanical behaviour of a series of NiTi and NiTiCu wires to better understand their capacity to recover stress and strain when varying the temperature [22]. It is important to highlight at this stage that the study of Tsoi et al. [73] is the only one, to the author's knowledge, taking advantage of the SMA pre-strain benefit on the impact characteristic in SMAs enhanced FRP structures. In the remainder of this section, all studies thus not consider pre-straining of the wire before composite manufacturing. Considering the cumbersome processing route needed when integrating pre-strained SMAs in composites (the use of frames to prevent recovery during matrix curing), it is in fact not surprising that many of the studies do not consider such a route.

Fig. 5. Impact performance map [29], [73]. The PDA slope is the slope of the damage area versus incident energy, and the IEC slope is the slope of the absorbed energy versus the incident energy. Where not indicated, SMA wires are NiTi superelastic wires. Reproduced with permission [73]. Copyright 2003, Elsevier.

Fig. 5. Impact performance map [29], [73]. The PDA slope is the slope of the damage area versus incident energy, and the IEC slope is the slope of the absorbed energy versus the incident energy. Where not indicated, SMA wires are NiTi superelastic wires. Reproduced with permission [73]. Copyright 2003, Elsevier.