1. Introduction

With the growing trend of increases in fuel prices over the past decades as well the rising concern regarding global warming, engineering industries are challenged with the task of reducing greenhouse gas emissions and improving the efficiency of their sites.

In this regard, the use of waste heat recovery systems in industrial processes has been key as one of the major areas of research to reduce fuel consumption, lower harmful emissions and improve production efficiency.

Industrial waste heat is the energy that is generated in industrial processes which is not put into any practical use and is wasted or dumped into the environment. Sources of waste heat mostly include heat loss transferred through conduction, convection and radiation from industrial products, equipment and processes and heat discharged from combustion processes [1]. Heat loss can be classified into high temperature, medium temperature and low temperature grades. Waste Heat Recovery (WHR) systems are introduced for each range of waste heat to allow the most optimum efficiency of waste heat recovery to be obtained.

High temperature WHR consists of recovering waste heat at temperatures greater than 400 °C, the medium temperature range is 100–400 °C and the low temperature range is for temperatures less than 100 °C [2]. Usually most of the waste heat in the high temperature range comes from direct combustion processes, in the medium range from the exhaust of combustion units and in the low temperature range from parts, products and the equipment of process units [2].

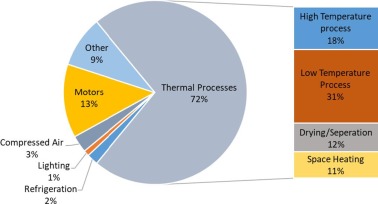

It is estimated that the UK industrial sector consumes as much as 17% of the overall UK economy’s energy consumption and generates about 32% of the UK’s heat-related CO2 emissions. From this value and as can be seen from Fig. 1, 72% of the UK industrial demand is from industrial thermal processes of which 31% is classified as low temperature process heat [3] and almost 20% of that or 40 TWh/yr is estimated to have potential for industrial waste heat recovery [4]. It is found that the most energy consuming industries in the UK are cement, ceramic, iron and steel, refineries, glassmaking, chemicals, paper and pulp and food and drink. These industries together contribute about £50 bn/yr to the UK’s economy [4]. This indicates that improving energy efficiency through waste heat recovery models can help UK businesses to reduce the operating costs of their businesses, improve the energy efficiency of their sites and reduce the UK’s industrial CO2 emissions.

Fig. 1. Energy consumption in the UK manufacturing industry [3].

Fig. 1. Energy consumption in the UK manufacturing industry [3].2. Waste heat recovery systems

Waste heat recovery methods include capturing and transferring the waste heat from a process with a gas or liquid back to the system as an extra energy source [5]. The energy source can be used to create additional heat or to generate electrical and mechanical power [6].

Waste heat can be rejected at any temperature; conventionally, the higher the temperature, the higher the quality of the waste heat and the easier optimisation of the waste heat recovery process. It is therefore important to discover the maximum amount of recoverable heat of the highest potential from a process and to ensure the achievement of the maximum efficiency from a waste heat recovery system [7].

The quantity or the amount of available waste heat can be calculated using the equation shown below.(1)where, Q (J) is the heat content, V is the flowrate of the substance (m3/s), ρ is density of the flue gas (kg/m3), Cp is the specific heat of the substance (J/kg.K) and ΔT is the difference in substance temperature (K) between the final highest temperature in the outlet (Tout) and the initial temperature in the inlet (Tin) of system.

Depending on the type and source of waste heat and in order to justify which waste heat recovery system can be used, it is essential to investigate the amount and grade of heat recoverable from the process.

There are many different heat recovery technologies available which are used for capturing and recovering the waste heat and they mainly consist of energy recovery heat exchangers in the form of a waste heat recovery unit. These units mainly comprise common waste heat recovery systems such as air preheatersincluding recuperators, regenerators, including furnace regenerators and rotary regenerators or heat wheels and run around coil, regenerative and recuperative burners, heat pipe heat exchangers, plate heat exchangers, economisers, waste heat boilers and direct electrical conversion devices. These units all work by the same principle to capture, recover and exchange heat with a potential energy content in a process.

2.1. Regenerative and recuperative burners

Regenerative and recuperative burners optimise energy efficiency by incorporating heat exchanger surfaces to capture and use the waste heat from the hot flue gas from the combustion process [8]. Typically, regenerative devices consist of two burners with separate control valves, which are connected to the furnace and alternately heat the combustion air entering the furnace. The system works by guiding the exhaust gases from the furnace into a case which contains refractory material such as aluminium oxide [9]. The exhaust gas heats up the aluminium oxide media and the heat energy from the exhaust is recovered and stored. When the media is fully heated, the direction of the flue gas is reversed, with the stored heat being transferred to the inlet air entering the burner and the burner with hot media starts firing. Combustion air from the hot media then heats up the cooler media and the process starts again. Through this technique, the regenerative burner can save the fuel needed to heat the air and this improves the efficiency of combustion [10] (see Fig. 2).

Fig. 2. Regenerative burner mechanism [11].

Fig. 2. Regenerative burner mechanism [11].Burners that incorporate recuperative systems are also used commercially. A recuperative burner has heat exchanger surfaces as part of the burner design, which capture energy from the heated gas that passes through the body of the burner [12]. The burner uses the energy of waste gas from the exhaust to preheat the combustion air before it gets mixed with the fuel. The burners consist of an internal heat exchanger with various features such as grooves, counter current flow and fins, which are used to establish thermal contact between the waste exhaust gases and the combustion air coming from the supply pipe [13]. The design works by collecting the both the exhaust gas and waste heat from the body of the burner nozzle, and using them both to transfer heat into the combustion air. This air preheating results in an improved efficiency of combustion and thus more heat from the nozzle.

It should be noted that the burner and the nozzle are inserted into the furnace body and the waste heat is transferred to the burner by convection from the exhaust gases. Osaka Gas [14] demonstrates that for a furnace with a temperature of 1000 °C the air can be preheated to at least 500 °C, indicating a considerable improvement of thermal efficiency (see Fig. 3).

Fig. 3. Recuperative burner structure [14].

Fig. 3. Recuperative burner structure [14].2.2. Economisers

Economisers or finned tube heat exchangers that recover low – medium waste heat are mainly used for heating liquids. The system consists of tubes that is covered by metallic fins to maximise the surface area of heat absorption and the heat transfer rate [15].

The system is located in the duct carrying the exiting exhaust gases and it absorbs the waste heat by letting the hot gases pass through different sections covered by the finned tubes. Liquid is passed through the tubes and it captures heat from the finned tubes. The hot liquid is then fed back to the system, maximising and improving the thermal efficiency [16]. Based on a study conducted by Spirax Sarco [17], it is shown that if an economiser is used for a boiler system, it can increase the efficiency by 1% for every 5 °C reduction of flue gas temperature. This indicates that the fuel consumption of the system can be reduced by 5–10% with a payback period of less than 2 years [18]. Economisers recover the waste heat and improve the efficiency of a system by preheating the fluid in the system such as the feedwater in a steam generator or a boiler, so less energy is required to achieve the boiling temperature. In another study by Maxxtec [19], it is noted that regardless of the design of the system, if the temperature of the flue gas is reduced by 140 °C, the fuel consumption can be reduced by 7%.

It is investigated that several different types of economisers are available for different applications but they have the same functionality [20]. These designs include finned tubes, coiled tubes, non-condensing and condensing economisers. The condensing and non-condensing types are mainly used to improve the efficiency of boiler systems, whereas the other types are commonly used in thermal power plants and large processing units to recover waste heat from the flue gas.

Having mentioned that, Vandagriff [21] investigates, economisers that are used for low-temperature heat recovery namely as deep economisers are also available that are made out of advanced materials such as Teflon, carbon and stainless-steel tubes and can withstand the acidic condensate deposition on the surface of the heat exchanger. Glass-tubed economisers are on the hand used for gas to gas heat recovery and for low to medium temperature applications [22].

2.3. Waste heat boilers

Waste heat boilers consists of several water tubes that are placed in parallel to each other and in the direction of the heat leaving the system. The system is suitable to recover heat from medium – high temperature exhaust gases and is used to generate steam as an output. The steam can then be used for power generation or directed back to the system for energy recovery [23].

For example, as J + G [24] reports, in a coal power plant the heat generated from the combustion process after leaving the combustion chamber has a temperature of up to 1000 °C. The use of a waste heat boiler in this case allows the recovery and utilisation of the heat of the flue gas to vaporise a fluid and produce steam that can be used for energy generation through turbines and generators.

The pressure and the rate of steam production mainly depends on the temperature of the waste heat. If the waste heat is not sufficient for the system to produce the required amount of steam, an auxiliary burner unit or an after burner in the exhaust gases can be added to the system to compensate for that [25].

As Turner [26] reports, waste heat boilers can also be coupled with other waste heat recovery equipment such as afterburners, preheaters and finned-tubed evaporators to improve efficiency by preheating the feed water and produce superheated steam if required (see Fig. 4).

Fig. 4. Schematic of a waste heat boiler incorporating parallel water tubes [26].

Fig. 4. Schematic of a waste heat boiler incorporating parallel water tubes [26].2.4. Air preheaters

Air preheaters are mainly used for exhaust-to-air heat recovery and for low to medium temperature applications. This system is particularly useful where cross contamination in the process must be prevented. Such applications can include gas turbine exhausts and heat recovery from furnaces, ovens, and steam boilers [27].

Air preheating can be based on two different designs, the plate type and the heat pipe type. The plate type consists of parallel plates that are placed perpendicular towards the incoming cold air inlet. Hot exhaust air is fed into the channels between the plates, transferring heat to the plates and creating hot channels, through which the cold air is passed.

The heat pipe type on the other hand consists of a bundle of several sealed pipes placed in parallel to each other in a container. The container is split into two sections accommodating cold and hot air, inlet and outlet. The pipes inside the container accommodate a working fluid which when faced with the hot waste gas at one end of the pipes, evaporates and moves towards the other end of the pipe where cold air is passing [28]. This results in heat being absorbed at the hot section of the pipe, which is transferred to the cold section, heating the cold moving air over the pipes. The working fluid then condenses and moves towards the hot section of the pipe, repeating the cycle [29].

As Nicholson [30] explain, there are mainly three commonly used types of air preheaters which are classified as regenerators, including rotary regenerators, run around coil, and recuperative. These technologies all function with the same principle as air preheaters, however, have different configurations and used for different purposes (see Fig. 5).

Fig. 5. Air preheater layout showing air movement [31].

Fig. 5. Air preheater layout showing air movement [31].2.4.1. Recuperators

Recuperators are a form of heat exchanger units that are usually made out of metallic or ceramic materials, depending on their application, and they are used to recover waste exhaust gases at medium to high temperature [32].

In this technology, the hot exhaust gases are passed through a series of metal tubes or ducts that carry the inlet air from atmosphere. This result in the recuperator preheating the inlet gas which then re-enters the system. The energy that is now available in the system can therefore be described as the energy which does not have to be supplied by the fuel, meaning that a decrease in energy demand and production costs is achieved [33].

Metallic recuperators are used for applications with low – medium temperatures, while heat recovery in high temperature application is better suited to ceramic recuperators. Recuperators can be said to mainly transfer heat to the inlet gas based on convection, radiation or a combination of radiation and convection. A radiation recuperator consists of metallic tubes around the inner shelf where hot exhaust gases pass through. The cold incoming air is then fed to the tubes around the hot shelf and heat is radiated to the wall of the tubes (see Fig. 6).

Fig. 6. Diagram of metallic recuperator [34].

Fig. 6. Diagram of metallic recuperator [34].The tubes transfer the heat to the cold air, which is then delivered to the furnace burners. On the other hand, the convective recuperator exchanges heat by passing hot exhaust gases through relatively small diameter tubes that are placed in a larger shelf. The cold air is passed through the large shelf, picking up heat from the small hot tubes inside the shelf that is heated by the waste gas.

A combination of radiant and convective recuperators provides another possibility which can maximise heat transfer effectiveness. In this technology, hot exhaust gas is fed into a larger shelf and then split into smaller diameter tubes. Cold air is fed into and around the shelf, and this results in a quantitative improvement in heat transfer [35] (see Fig. 7).

Fig. 7. Combined radiation and convective type recuperator [33].

Fig. 7. Combined radiation and convective type recuperator [33].2.4.2. Regenerators

Regenerators transfer heat from the hot gas duct to the cold gas duct through storing the waste heat in a high heat capacity material. The system consists of a chamber which is used as a link between the hot air duct and the cold air duct that takes the heat energy from the hot side, stores and delivers it to the cold side. For instance, regenerative furnaces consist of two brick chambers through which hot and cold air exchange heat. As hot combustion gases pass through the brick chamber, heat from the hot flue gas is absorbed, stored and delivered to the cold airflow when it is passed through the chamber. The flow of the preheated gas is then injected into the flow going to the combustion chamber, decreasing the amount of energy needed to heat the system.

Two chambers are used so that, one is transferring heat to the flow entering the system, the other one is absorbing heat. The direction of inlet flow is changed frequently to allow a constant heat transfer rate to be obtained [36].

Regenerators are suitable for high temperature applications such as glass furnaces and coke ovens and they have been historically used with open-hearth steel furnaces. Regenerators are particularly suitable for applications with dirty exhausts, however, they can be very large in size and have very high capital costs, which is a disadvantage with this technology [37].

2.4.3. Rotary regenerators

Rotary regenerators work in a similar manner to fixed regenerators, however, in this technology, heat is transferred through a porous thermal wheel between the hot and cold flows. In this system, two parallel ducts containing hot and cold flows are placed across a rotary disk or heat wheel which is made out of a high thermal capacity material. The heat wheel takes and stores heat from the flow coming through the hot duct, rotates and delivers it to the flow coming through the cold duct. Rotary regenerators are used for low – medium temperature applications and could potentially offer a very high overall heat transfer efficiency [38] (see Fig. 8).

Fig. 8. Schematic diagram of heat wheel [33].

Fig. 8. Schematic diagram of heat wheel [33].The reason heat wheels are not suitable for high temperature applications is due to the structural stresses and the possibility of large expansion and deformations that can be caused by high temperature differences between the two ducts [39]. Having said that, heat wheels made out of ceramic materials can be used for high temperature applications.

As heat wheels are mainly made out of porous material, cross contamination therefore be cannot prevented. This can be a major disadvantage especially when cross contamination between the two ducts must be prevented. However, this is shown to be advantageous for applications where recovering humidity and moisture from the outlet duct is required [38].

2.4.4. Run around coil (RAC)

This system as can be seen from Fig. 9 and according to Toolan [40], consists of a pair of coiled heat exchangers that are connected to each other by a run around coil that is filled with a fluid such as a water or glycol or a mixture of both [41]. The liquid in the coil takes the waste heat that is captured by the primary recuperator from the exhaust gas of a process and transports it to the secondary recuperator where it would be mixed with the supply air. The possibility of exchanging heat between the two air streams is due to the liquid round coil system, which are connected to each other by a pumped pipework.

Fig. 9. Schematic of run around coil system [42].

Fig. 9. Schematic of run around coil system [42].This unit is used when the sources of heat are too far from each other to use a direct recuperator and when cross contamination between the two flow sources due to moister, corrosive gases, toxic and biological contaminates needs to be prevented. This system is found to have a very low effectiveness when compared to a direct recuperator and needs a pump to operate, which requires additional energy input and maintenance [43]. Having said that and as Carbon Trust [44] discovers, the effectiveness and efficiency of this technology can be improved by using a secondary heat source as shown in Fig. 10.

Fig. 10. Run around coil system compromising a secondary heat source [44].

Fig. 10. Run around coil system compromising a secondary heat source [44].2.5. Plate heat exchanger

Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. A plate heat exchanger is made out of several thin metal plates that are stacked or brazed in parallel to each other and formed into a hollow metallic shell. Each plate usually consists of different pressed patterns that are surrounded with gaskets to control the fluid flow and produce turbulence for better heat transfer [45]. The gaskets are arranged in such a way that allows only one type of fluid to flow through one gap, while the other fluid gets directed through the adjacent gap [46]. As can be seen from Fig. 11, between every two consecutive plates a space or passage has been implemented that makes the hot and cold fluids flow along and through the plane of the plates.

Fig. 11. Schematic of a plate heat exchanger [47].

Fig. 11. Schematic of a plate heat exchanger [47].This way, the hot and cold fluids pass through each section of the heat exchanger passing over the front and back of plates alternatively, exchanging heat and not getting contaminated with each other. The other advantage plate heat exchangers offer in comparison with similar types of heat exchanger such as the conventional shell and tube heat exchangers is the fact the hot and cold fluids are exposed to a larger surface area per unit volume and a larger heat transfer coefficient [48].

It is reported that there are mainly three types of plate heat exchanger, arranged in either single-pass or multi-pass arrangements, as shown in Fig. 12, Fig. 13[49], [50]. The plates of plate heat exchangers can either be gasketed, brazed or be welded together [51], [52]. In a gasket plate heat exchanger, a gasket usually made out of a polymer material is placed between the plates that works as a seal and separator around the edges of the plates [53]. The plates are placed and clamped together in a frame with the use of tightening bolts and two thicker pressure plates on each side.

Fig. 12. Single-pass configuration plate heat exchanger [58].

Fig. 12. Single-pass configuration plate heat exchanger [58]. Fig. 13. Multi-pass configuration plate heat exchanger [58].

Fig. 13. Multi-pass configuration plate heat exchanger [58].The design therefore allows the heat exchanger to be dismantled for cleaning or be optimised to have a bigger or smaller capacity by removing or adding additional plates [54]. The use of gaskets with this design brings the advantage of resistance to thermal fatigue and sudden pressure variation as it gives flexibility to the plate pack. This is ideal for applications that constantly go through thermal cycling by being exposed to variations of temperature [55]. Having said that, the use of gaskets is restricted by the operating temperature and pressure of the cycle which is a disadvantage [56]. Gasket plate heat exchangers are nonetheless proven to give efficient and effective heat transfer with a recovery rate of up to 90% [57].

In a brazed plate heat exchanger, all the plates are brazed together by using copper or Nickel in a vacuum furnace [59]. The design unlike the gasket heat exchanger offers more resistance to higher pressure and temperature ranges and is relatively cheap to maintain [60]. However, as it is brazed, it cannot be dismantled which means issues can be raised when cleaning or modifying the size is required. As the design also has a more rigid construction than the gasket type, it is more susceptible to thermal stress and any sudden or frequent variation in temperature and load can lead to fatigue and the failure of the structure. IITD [61] concludes therefore, that brazed heat exchangers are mainly used for applications where temperature variation is slow and applications where thermal expansion is gradual, such as with thermal oils.

Welded plate heat exchangers are reported to have more flexibility and resistance when it comes to thermal cycling and pressure variations as compared to brazed heat exchangers [55]. This advantage is achieved through the use of laser welding techniques that hold the plate pack together by welded seams [62]. This type of heat exchanger is shown to have higher temperature and pressure operating limits and because of this they are found to be suitable for heavy duty applications [63]. Nonetheless, similar to the brazed heat exchangers, they cannot be dismantled and modified in size.

With the use of a plate heat exchanger in an experiment, Cipollone [64]demonstrated that the performance of an evaporator used for a heat recovery steam generator can be improved when a plate heat exchanger is used as the component to superheat the working fluid of the system.

2.6. Heat pipe systems

As can be seen from Fig. 14, a heat pipe is a device which can transfer heat from one place to another with the help of condensation and vaporisation of a working fluid. A heat pipe consists of a sealed container, a wick structure, and a small amount of working fluid such as water, acetone, methanol, ammonia or sodium that is in equilibrium with its own vapour [65]. A heat pipe can be divided into three different sections: the evaporator section, the adiabatic transport section and the condenser section.

Fig. 14. Schematic of a heat pipe [69].

Fig. 14. Schematic of a heat pipe [69].When heat is applied to one end of the pipe, it is conducted through the pipe wall and wick structure and the working fluid inside the pipe evaporates. As a result, a vapour pressure is generated which drives the vapour through the adiabatic transport section to the other end of the pipe. The vapour then condenses by losing the latent heat of vaporisation through the wick structure and wall of the pipe to the heat sink. The vapour flow then turns into liquid and is absorbed by the wick structure. The capillary pressure that is created by the menisci in the wick structure drives the liquid back to the hot end of the pipe and the cycle repeats [66].

It can be shown that heat pipes have very high effective thermal conductivities. Solid conductors such as aluminium, copper, graphite, and diamond have thermal conductivities ranging from 250 to 1500 W/m K whereas heat pipes have effective thermal conductivities in the range from 5000–200,000 W/m K [67].

Heat pipes are constructed from a range of different materials such as aluminium, copper, titanium, Monel, stainless steel, Inconel and tungsten. The choice of the material used for heat pipes largely depends on the application temperature range and the compatibility of the material with the working fluid [68].

As mentioned earlier, the heat pipe wick structure aids the transport of the working liquid from the condenser back to the evaporator. Various materials and techniques are used to construct the heat pipe wick structure, however as PSC [70] reports, groove, screen/woven and sintered powder metal structures are the most common. It is also reported that heat pipes referred to as thermosyphons are also available; they have no wick structure and work only with the aid of gravity. These heat pipes cannot be used in a horizontal orientation and should be placed vertically. Having mentioned this, heat pipes with a wick structure can operate in both horizontal and vertical orientations and do not have such a limitation.

As shown in Fig. 15, screen mesh structure wicks are usually made out of copper or stainless materials and are expanded against the pipe wall to form the wick structure. Heat pipes made with this structure are capable of transporting the working fluid both horizontally and vertically and also against gravity at a very slight angle from the horizontal [70]. Grooved wick structures on the other hand consist of raised dents that are made perpendicular to the pipe surface by extrusion or threading processes commonly out of copper or aluminium materials. Heat pipes made with this type of structure can operate in gravity aided and horizontal orientations and similar to screen wick structures can transport liquid at a slight angle from horizontal [71]. In contrast, as ATS [72]showed in the conducted experiments, sintered copper powder structures are capable of transporting the working fluid against gravity vertically and also horizontally with not much limitation. This type of wick structure is made usually from copper powder particles that are fused together to form a sintered wick structure.

Fig. 15. Common wick types of a heat pipe [73].

Fig. 15. Common wick types of a heat pipe [73].The type of working fluid used in a heat pipe largely depends on the temperature range of the application for which the heat pipe is being used. For example, as explained by Faghri [65] and ACT [74], for low temperature applications in the temperature range of 200–550 K, ammonia, acetone, “Freon” refrigerants and water are used. Most applications of heat pipes usually fall within this temperature range and water is reported to be the mostly used fluid as it is cheap, has good thermo-physical properties and also is safe to handle [75]. Heat pipes in general have a high thermal conductivity, which results in a minimal temperature drop for transferring heat over long distances, long life that requires no maintenance, as they incorporate passive operation and no moving parts which can wear out and they have lower operation costs when compared to the other types of heat exchangers [76].

2.6.1. Pulsating heat pipes

Pulsating heat pipes or PHPs are passive closed two-phase heat transfer devices that are similar to conventional heat pipes and are capable of transporting heat without the requirement of any additional power input. As shown in Fig. 16, the system consists of a narrow meandering long tube that is filled with a working fluid. The PHP can be in the form of either open-loop or closed-loop configuration and operate by the oscillatory flow of liquid slugs and vapour plugs. As can be seen from Fig. 16, in the closed-loop configuration, both ends of the tube are connected to each other, whereas, for the open-loop configuration, one end of the tube is welded and pinched off, while the other end is open and connected to a charging valve [77], [78]. The main difference between PHPs and heat pipes is the fact that there is no wick structure to deliver the condensate to the condenser and heat transfer is entirely achieved by the oscillatory flow [79]. Holley and Faghri [80] developed a PHP with a sintered copper wick structure and demonstrated that the working fluid is better distributed throughout the pipe which results in more nucleation sites for boiling and as a result the fluctuation in local temperature is reduced.

Fig. 16. Schematic of a pulsating heat pipe [81].

Fig. 16. Schematic of a pulsating heat pipe [81].For instance in an experiment, [82] investigated and proved that with the use of closed-loop oscillating heat pipe, the quantity of using fuel in pottery kilns can be reduced and energy thrift can be achieved. In this experiment, a closed-loop oscillating heat pipe that was made out of copper capillary tube and filled with R123 and water was used as a heat exchanger to recover the waste heat from pottery kilns.

2.7. Heat recovery steam generator (HRSG)

The heat recovery steam generator (HRSG) is a complex system used to recover the waste heat from the exhaust of a power generation plant. It consists of several heat recovery sections such as an evaporator, super heater, economiser and steam drum, which are very large in size. By looking at the configuration of a HRSG in Fig. 17, it can be pointed out that the superheater is placed in the path of the hottest gas upstream of the evaporator and the economiser is placed downstream of the evaporator in coolest gas.

Fig. 17. Heat Recovery Steam Generator (HRSG) [83].

Fig. 17. Heat Recovery Steam Generator (HRSG) [83].Typically, HRSGs comprise a triple pressure system, this being high pressure, reheat or intermediate pressure and low pressure [84]. The system can also recover the waste heat from the exhaust of manufacturing processes to improve overall efficiencies by generating steam that can be used for process heating in the factory or for driving a steam turbine to generate electricity. It is reported that with the use of HRSG for steam production, a system efficiency of as high as 75–85% can be achieved [85].

The system contains an evaporator section and a steam drum for converting water to steam. The steam is then superheated as its temperature is increased beyond the saturation point. As can be seen from Fig. 18, the evaporator is located between the economiser and the superheater with the steam drum on top of it.

Fig. 18. Typical heat recovery steam generator components [86].

Fig. 18. Typical heat recovery steam generator components [86].In the evaporator, the steam for the turbine is generated which is then delivered to the steam drum and the superheater. As shown in Fig. 18, in the steam drum the steam and water mixture is separated from the saturated steam as the feedwater is delivered to the evaporator.

The steam is separated in two steps through a combination of gravity and mechanical work before it gets delivered to the superheater. This heats the steam beyond the saturation temperature, i.e. generating superheated steam. The economiser on the other hand, preheats the feedwater to the evaporator, thus improving the efficiency of steam generation. The steam generated in the process is then sent to a thermodynamic cycle such to generate power and improve the efficiency of the plant.

2.8. Thermodynamic cycles used for waste heat recovery

As Costiuc et al. [87] explain, through the use of thermodynamic cycles, heat recovery from waste sources can be directly conducted to obtain electrical energy and improve energy efficiency of a process. In this regard, Nemati et al.[88] through a comparative thermodynamic analysis of Organic Rankine Cycle and Kalina Cycle suggested that the use of thermodynamic cycles that employ organic working fluids enables a cost effective and promising way of energy recovery from moderate grades of waste heat sources. In this chapter therefore, the usage and functionality of the mentioned thermodynamic cycles for WHR will be reviewed.

2.8.1. Organic Rankine cycle

The Organic Rankine Cycle works on the principle of the Clausius-Rankine cycle, however, the system uses organic substances with low boiling points and high vapour pressures as the working fluid to generate power instead of water or steam [89]. It has been shown that the use of an organic fluid as the working fluid makes the system suitable for utilising low grade waste heat and for power generation using energy sources such as geothermal [90], biomass [91], and solar applications [92].

The Clausius-Rankine Cycle or CRC is introduced as the ideal vapour power cycle and is described as the elementary operating cycle for all power plants that use an operating fluid such as water to generate electricity [93]. A typical Rankine cycle consists of a pump, a condenser, an evaporator and a generator. Fuel is burned in the evaporator and the water as the working fluid is heated to generate superheated steam. This is then directed to the turbine to generate power and then passed through the condenser, losing heat and turning back into its liquid state. The liquid water is then pumped into to the evaporator and the cycle is repeated.

When compared to the CRC, typically an Organic Rankine cycle (ORC) system consists of a heat exchanger which is connected to an evaporator and a preheater in a cycle, and a recuperator that is linked to a condenser [94]. This way, when waste heat travels from the source and passes over the heat exchanger, the heat exchanger will heat the intermediate fluid which then cycles through the evaporator and preheater. The organic fluid is then heated by intermediate fluid causing it to vaporise and becomes superheated vapour.

The vaporised organic fluid then passes with high enthalpy through the turbine and the vapour expands causing the turbine to spin and generate electricity [95]. The vapour then exits the turbine and passes over the recuperator to reduce the temperature and preheat the organic fluid at a later stage.

At the condenser, air or water from a cooling tower or the environment condenses the organic vapour back into a fluid. Once the fluid reaches the pump, the system is pressurised to the required level and the fluid will then pass again to the recuperator where it is reheated and the cycle restarts [96](see Fig. 19).

Fig. 19. Schematic of a Typical Organic Rankine cycle [97].

Fig. 19. Schematic of a Typical Organic Rankine cycle [97].Mamun [98] showed an ORC offers many advantages when compared to conventional steam turbine for waste heat recovery. Stefanou et al. [99]demonstrated that with the use of an ORC along with a waste heat recovery steam generator unit in a steel mill, a net efficiency of almost 22% can be achieved.

The design and performance of an ORC system nonetheless depends on the selection of the working fluid and its specifications in terms of thermodynamics and environmental and safety criteria [100]. This therefore indicates that the selection of the optimum working fluid is an important task when considering the use of ORC for waste heat recovery processes. For instance, Douvartzides and Karmalis [101] considered 37 different working fluid substances and demonstrated that by appropriately selecting the working fluid and the operation for the cycle, the overall efficiency of a plant can be increased by almost 6% and the fuel consumption can be reduced by 13%.

2.8.2. Kalina cycle

Similar to Organic Rankine cycle, the Kalina cycle is a variant of Rankine cycle that uses the working fluid in a closed cycle to generate electricity. This system however, commonly uses a mixture of water and ammonia as the working fluid [102] in a process that usually consists of a recuperator and separator in addition to other components of a Rankine cycle to generate steam and power (see Fig. 20).

Fig. 20. Configuration of a Kalina cycle consisting a Recuperator and Separator [103].

Fig. 20. Configuration of a Kalina cycle consisting a Recuperator and Separator [103].The difference between the Kalina cycle and cycles that use a single fluid to operate is in the fact that the temperature does not remain constant during boiling and this is shown to result in a greater efficiency for the cycle [104]. In a single-fluid cycle, the working fluid is uniformly heated to the evaporating temperature at which a constant supercritical or superheated steam is generated. However, for a binary mixture working fluid such as in the Kalina cycle, the temperature of each fluid is increased separately during evaporation as a result of each fluid having a different boiling point. This will result in a better thermal matching with the evaporator and condenser as the source of the cooling medium does not need to satisfy a particular working fluid in the process [105] (see Fig. 21).

Fig. 21. Comparison of Rankine and Kalina cycles [106].

Fig. 21. Comparison of Rankine and Kalina cycles [106].This can be also clearly illustrated in the T, s diagrams shown below which indicates that for the Kalina cycle, the average hear rejection temperature (Tc) is lower and the average heat addition temperature (Tb) is higher when compared to a Rankine cycle. This and according to Eq. (2) derived for Carnot efficiency (ηCarnot), will result in a higher thermal efficiency [106].(2)

Based on above explanation, Wang [107] by developing a mathematical model from the waste heat recovered through a waste heat boiler demonstrated that the Kalina cycle system shows a better performance when compared to ORC.

On the other hand, Milewski [108] studied the concept of WHR based on the ORC and Kalina cycle in the steel industry and discovered that the Kalina cycle offers a better result when the recovered heat is of medium-high grade nature. In this study, the ORC was a competitor to the Kalina cycle when the recovered heat was below 200 °C.

2.9. Heat pumps

A heat pump is a thermodynamic device which takes and transfers heat from a heat source and to a heat sink using a small amount of energy [109]. Heat pumps collect heat from air, water, or ground and are categorised as air-to-air, water source and geothermal heat pumps. Heat pumps can be used as an efficient alternative to furnaces and air conditioners to cool or heat an environment [110]. Having mention that, Chua [111] explains that heat pump systems can also be used to offer economical and efficient alternative of recovering heat from various sources to improve overall energy efficiency. In this sight and as McMullan [112] describes the heat pump has become an important component in the context of WHR and energy efficient processes.

A heat pump works with the same principle as refrigerators and air-conditioners, however, employs a refrigerant cycle to produce hot air and/or water by extracting heat from a heat source and passing that to an evaporator to heat the refrigerant at low pressure. This is then delivered to a compressor to produce high pressure and temperature gas that can be delivered to a heat exchanger (condenser) [113] (see Fig. 22).

Fig. 22. Heat pump working diagram [114].

Fig. 22. Heat pump working diagram [114].Baradey [115] discusses that heat pump in particular are good for low-temperature WHR, as they give the capability to upgrade waste heat to a higher temperature and quality. This was for instance demonstrated in a study, where, from a heat source of 45–60 °C, the heat pump delivered almost 2.5–11 times more useful energy comparing to other WHR systems used for the equal heat input [116].

Through reclaiming waste heat that is dissipated into the environment and upgrading it by the means of a heat pump, a resulting useful heat can be generated and used directly for the process to reduce the energy intake and improve the overall efficiency of the system (see Fig. 23).

Fig. 23. Heat pump diagram in the context of WHR [117].

Fig. 23. Heat pump diagram in the context of WHR [117].2.10. Direct electrical conversion devices

Systems are also available that produce electricity directly from waste heat and eliminate the need for converting heat to mechanical energy to produce electrical energy. These technologies include the use of thermoelectric, piezoelectric, thermionic, and thermo photo voltaic (TPV) devices for electricity generation [118]. Khalid et al. [119] mentions that these technologies are not widely used in industry, however, a few have undergone prototype testing and have offered promising results. Below the technologies that were mentioned as direct electrical devices are explained.