. Introduction

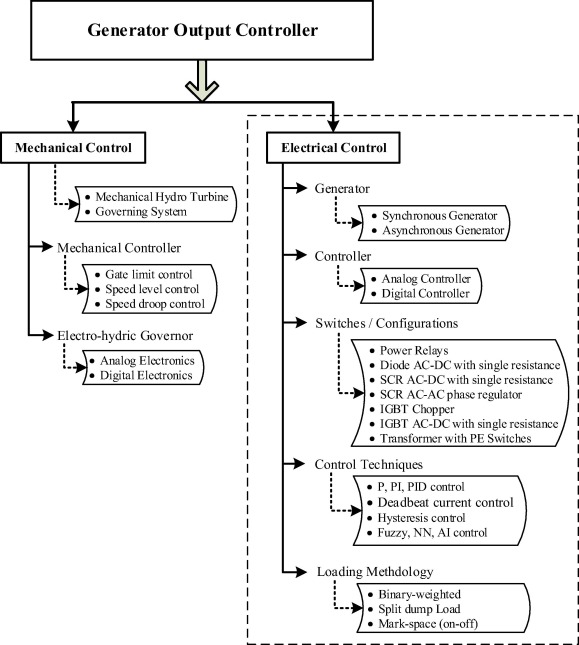

Economic growth and greater energy utilization are essential in raising people’s living standard, as well, rural electrification using renewable and sustainable energy has a significant role in it. World Bank shows much interest in universal electricity access and clean cooking fuels through increasing the renewable energy sources [1]. Hence, the Universe focuses on the development of economically viable renewable energy for rural and remote areas [2], [3], [4], [5], [6], [7]. Among renewable energy sources, hydroelectric energy is a major energy source [8], in which micro hydropower plant (MHP) is the best suitable for rural electrification as it does not require dam and reservoir as of convention hydropower plant [9], [10], [11]. In general, MHP operates in stand-alone and it is built with either self-excited synchronous generator or asynchronous generator for continuously varying load that creates voltage unbalance and frequency fluctuations. These perturbations develop mechanical vibrations and thermal effect, that consequence to generator lifespan deterioration [12]. Therefore, control system on turbine side or generator side must be employed to regulate output voltage and frequency during load variation. As can be seen in Fig. 1, the generator output voltage and frequency can be controlled from turbine side known as mechanical control, or it can be controlled from generator side known as electrical control, or it can be controlled from both sides known as electro-mechanical control. In turbine side control system, generator voltage and frequency is controlled by regulating the speed of turbine, which is governed by controlling the water flows. These water flows are controlled through regulating the inlet valve or opening and closing the valves in multi-pipe system [13]. These hydro turbine speed governing system is carried out using electrical controllers (analog /digital) for improving the system performance. Also, various control techniques adopted to govern the turbine speed such as, gate limit control, speed level control, speed droop control, etc., [13], [14], [15], [16], [17], [18]. However, due to the less dynamic response and high expenses, the mechanical and electromechanical regulators are less preferred in MHP [19], [20], [21], [22].

Fig. 1. Generator Output Controller.

Fig. 1. Generator Output Controller.Similarly, the generator side control system regulates the voltage and frequency by employing dummy resistors during load variation which modifies the amount of power sent to dissipation circuit. The electronic controller with resistive load is also known as electronic load controller (ELC) or dump load controller (DLC). ELC advances over mechanical control system in dynamic response, reduced cost, less complexity, and maintenance [23]. In this regard, a comprehensive review of generator output control in the perspective of controller, control techniques and power electronic configuration is discussed in this paper.

In 1980, Woodward, et.al, introduced power relay based ELC scheme in hydropower plant to regulate the voltage and frequency of generator for providing good isolation between control circuitry and the power lines [24]. Soon after, in 1984, S. Kormilo, et.al replaces power relays with phase control power electronic switches for providing smooth regulation in generation system [25]. These power electronic regulatory switches are connected in between the generator terminals and the dump load to control the generator output voltage and frequency as in [13], [21], [26]. Later on, in 1990, Bonert R, et.al reforms the power electronics circuit configuration to minimize the line distortion in standalone induction generator based ELC system [27]. Eventually, ELC schemes developed with different switches and configuration like TRIAC based regulators in [28], [29], [30], [31], [32], [33], [34], [35], [36], SCR based controlled rectifier in [21], [27], [37], [38], contactors with resistive load [39], and contractors with discreet ballast [40]. Meanwhile, in 1998, Insulated Gate Bipolar Transistor (IGBT) is introduced in ELC for chopping the uncontrolled rectified voltage [41]. Later, IGBT chopper is employed in ELC with various configurations of rectification circuit such as, three phase uncontrolled rectifiers with IGBT chopper [37], [42], [43], [44], [45], [46], [47], [48], [49], single phase uncontrolled rectifier with IGBT chopper [50], [51], 6-pulse diode rectifier with IGBT chopper [52], [53], [54], [55], 24-pulse diode rectifier with IGBT chopper [56]. Also in recent, bidirectional IGBT switches are used for chopping [57], [58], [89] and matrix converter operation [84]. Likewise, in Micro hydro generation system, IGBT switches are employed in different converter configurations such as 2-leg IGBT based voltage source converter [61], [62], 3-leg IGBT based voltage source converter [63], 4-leg IGBT based voltage source converter [64], [65], and 6-leg IGBT based voltage source converter [66].

Initially, Self-Excited Induction Generator (SEIG) is employed in MHG as it is reliable, robust and cost-effective. To regulate the output voltage and frequency of the SCIG based system, numerous controllers and control techniques are used such as analog controller [24], microprocessor based ELC with the current control algorithm [28], microcontroller based fast feedforward control [34], [37], [68], and digital signal processor based ELC [48], [69]. In addition, various control techniques are adopted to enhance the efficiency of SEIG based ELC system like, Proportional controller based ELC [70], [71], PI controller based ELC [36], [41], [43], [44], [58], [59], [72], [73] PID control [74] and harmonics elimination control using p-q control theory [75]. Later, Synchronous Generators (SG) are employed in MHP due to their high efficiency and regulation in energy production, such generator can be implemented using various controller and control strategies like, AIM 65 microcomputer [25], Proportional controller [40], [54], [55], PI controller [45], [76], Fuzzy logic control based battery charging system [77], Micro-controller based ELC [78], PLC based load controller [39], etc. Similarly, asynchronous generators with external excitation (also known as separately excited induction generator) employed in MHP adopting various control techniques such as PI based decoupled voltage and frequency controller [64], [65], [79], [80], [81], [82], PI controller based active and reactive power control [63], [66], deadbeat-current-controller-based active power filter [83], Zig-zag transformer using PI controller [61], [62], [84] integrated electronic load controller using PLL technique [85], [86], [87], automatic generation control technique [88], transformer based ELC [89], IGBT converter based ELC [90], genetic algorithm based dumped load and multivalve control [35], DSP based reactive power control [91], quasi-oppositional grey wolf optimization algorithm based control [60], [92], and other optimization control [93].

Overall, mainly, MHP is employed by self-excited synchronous or asynchronous generator and in modern plants, brushless generators are preferred for hassle free operation [8]. Phase angle control is mainly used with synchronous generators and it is less appropriate for induction generators due to lagging power factor because it increases frequency variation and waveform distortion. To lessen these effects, a binary-weighted controller is adopted in [42], however, binary-weighted controller possesses hindrance due to stepped voltage regulation and complexity in connection. To attain smooth voltage regulation with simple connection, a mark-space (on-off) ratio chopping technique has been adopted in [20], [21], [34], [37], [41], [42], [43], [44], [45], [46], [47], [50], [57], [68], [69], [77], [79], [80], [94], [95], [96], [97], [98], [99], [100], [101], [102]. In addition to smooth voltage regulation, unity power factor is achieved using a single resistance topology [103]. Still, phase unbalance is a problem in this method which leads to waveform distortion and derating of generator. Balancing three phases of generator, all phases are independently controlled using single-phase rectifier with chopper circuit [66]. Likewise, chopping frequency is increased for reducing waveform distortion in [27]. Most of these controllers are designed for under load conditions, but in case of overloaded generator, power factor gets lagged. To compensate this, IGBT based voltage source converter and capacitor is used under various power electronic configuration [48], [61], [62], [63], [64], [65], [72], [73], [83], [85], [86], [87], [88], [89], [90], [91], [94], [99], [104], [105], [106], [107], [108], [109], [110], [111], [112], [113]. In addition to voltage and frequency regulation through dump load, few controllers are designed for utility purpose charging battery, heating water, etc., with harmonic filtration [58], [57], [77], [81], [97]. On the other track, PWM based VSC with various transformer configurations is discussed in [82], [89], [106], [107], [114], [115]. Few schemes without dump load and valve controlstrategy are also being adopted in [116], [117], [118]. Moreover, using unbalanced excitation capacitor the derating of a self-excited three-phase induction generator is studied in [119]. Eventually, the development of ELC is exhibited in Table 1, in the perspective of (i) controllers and control techniques, (ii) machine types and (iii) power electronic typologies.

Table 1. Comprehensive review of electronic load controllers.

| Sl. No | Controller/Control Techniques | Machine | Power Electronics Configuration | Year [Ref. No.] |

|---|---|---|---|---|

| 1. | Analog Controller | SEIG | Power Relays | 1980 [24] |

| 2. | AIM 65 Microcomputer | SG | Thyristors with TRIAC | 1984 [25] |

| 3. | Electronic impedance controller | IG | 3ɸ SCR controlled rectifier with chopper | 1990 [27] |

| 4. | Analog circuit based phase angle control | SESCG | TRIAC based phase angle control |

1991 [28] 2012 [30] |

| 5. | Microprocessor based ELG with the current control algorithm. | SEIG | TRIAC based phase angle control | 1998 [67] |

| 6. | PI controller based ELC and switched capacitor based VAR compensator | SEIG | Uncontrolled rectifier with IGBT based chopper for ELC Thyristor based VAR | 1998 [41] |

| 7. | Microcontroller (MC68332) based fast feed-forward control | SEIG | 3ɸ phase controlled bridge with chopper | 1998 [68] |

| 8. | Double control strategy for voltage and frequency regulation. | IG | 3-leg IGBT based bi-directional VSC, Bidirectional SCR for ELC | 1999 [38] |

| 9. | (Atmega-16) with PI controller based ELC | SEIG | Uncontrolled rectifier with IGBT based chopper for ELC, MOSFET chopper |

1999 [120] 2013 [101] |

| 10. | IGC with under voltage and overvoltage protection | SCIG | TRIAC based regulation system | 2000 [31] |

| 11. | PID controller with dual feedback | Dynamo | TRIAC based regulation system | 2001 [32] |

| 12. | Comparison of back to back thyristor based and IGBT based ELC | SEIG | Uncontrolled rectifier with back to back thyristor based chopper | 2003 [20] |

| 13. | Triple PI controller based ELC | SEIG | IGBT based CC-VSI and IGBT chopper | 2003 [72] |

| 14. | PI controller based power balancing | SEIG | Uncontrolled rectifier with IGBT based chopper | 2004 [43] |

| 15. | Numerical voltage and frequency controller | SEIG | Uncontrolled rectifier with IGBT based chopper | 2005 [46] |

| 16. | PIC 18F252 microcontroller with PI controller | SEIG | Uncontrolled rectifier with IGBT based chopper, TRIAC for capacitor switching |

2006 [37] 2010 [34] |

| 17. | Multi-pipe flow control with reduced dump load. | IG | Thyristor based phase control | 2006 [13] |

| 18. | Design of ELC using PI controller | SEIG | Uncontrolled rectifier with IGBT based chopper | 2006 [44] |

| 19. | Dump load control using PI controller | SG | Uncontrolled rectifier with IGBT based chopper | 2007 [45] |

| 20. | Proportional controller based load control | SEIG | Chopper circuit (Anti-Parallel IGBT) in series with dump load |

2007 [70] 2010 [71] |

| 21. | PID controller based AVR (simulation) | SESA | PSCAD based AVR | 2007 [19] |

| 22. | PI based multi-mode controller | PMSG | TRIAC with analogue controller (CI-tronic™) | 2007 [29] |

| 23. | PI based decoupled voltage and frequency controller | AG | 3ɸ uncontrolled rectifier with IGBT based chopper, 3-leg IGBT based VSI | 2007 [79] |

| 24. | Hybrid excitation system with deadbeat current control strategy | SGIG | IGBT based VSI for active power filter | 2007 [83] |

| 25. | PI controller based voltage and frequency control (simulation) | IAG | 4-leg IGBT based VSC with IGBT chopper. | 2008 [64] |

| 26. | PI controller based active and reactive power control (simulation) | IAG | 3-1ɸ transformer with 6-leg IGBT based current controlled VSI for STATCOM, Uncontrolled rectifier with chopper for ELC | 2008 [66] |

| 27. | Decoupled control (STATCOM and ELC) using PI controller (simulation) | AG | 4-leg IGBT based CC-VSI for STATCOM, 3ɸ diode rectifier with an IGBT based chopper. | 2008 [65] |

| 28. | Simultaneous active and reactive power control of two parallel IG using PI controller (simulation) | IAG | 3-leg IGBT based current controlled VSI with IGBT based chopper. | 2008 [63] |

| 29. | Zig-Zag transformer based ELC using PI controller (simulation) | IAG | 2-leg IGBT based VSC with IGBT chopper. |

2008 [61] 2008 [62] |

| 30. | DSP(TMS320F2812) based IGC with PI controller | SEIG | 1ɸ uncontrolled rectifier with IGBT based chopper | 2008 [50] |

| 31. | Polygon wound autotransformer with 24 pulse bridge rectifier based ELC using PI controller | AG | 2-3ɸ diode rectifier with 2 zero sequence blocking transformer and IGBT based chopper. | 2008 [80] |

| 32. | Integrated electronic load controller using PLL technique (simulation) | IAG | Star-delta transformer, 3-leg IGBT based VSC with IGBT chopper. | 2009 [85] |

| 33. | Integrated ELC with battery energy storage system using PI controllers (simulation) | IAG | Star-hexagon transformer, 3-leg IGBT based VSC with IGBT chopper. | 2009 [81] |

| 34. | Static VAR compensation magnetic energy recovery switch as a shunt controlled capacitor using PLL technique (simulation) | IG | Single phase full-bridge IGBT with a capacitor. |

2009 [86] 2009 [87] |

| 35. | Hybrid control of parallel micro-hydro generators using PI controller (simulation) | SG, IG | Servo motor as governor control and power electronic based dump load controller. | 2010 [121] |

| 36. | Synchronous reference frame theory based IELC (DS-1104 control board) | IAG | Star-hexagon transformer with 3-leg IGBT based VSC with IGBT chopper. | 2010 [104] |

| 37. | TS Fuzzy based multi-mode controller (DS-1104 control board) | PMSG | TRIAC phase controller | 2010 [33] |

| 38. | Variable DC-link voltage using hysteresis controller | SEIG | 3-leg IGBT based voltage source converter | 2010 [105] |

| 39. | T- Connected transformer based ELC with Icosɸ algorithm implementation. | IG | T- connected transformer for reducing triplet harmonics | 2010 [89] |

| 40. | Transient Analysis of SEIG | SEIG | Single phase uncontrolled rectifier with IGBT based chopper for ELC |

2010 [94] 2012 [99] |

| 41. | Star delta transformer with H – bridge VSC based decoupled ELC. (simulation) | IAG | Star delta transformer with IGBT based H –bridge VSC, 3ɸ uncontrolled rectifier with IGBT based chopper | 2010 [114] |

| 42. | Instantaneous reactive power theory-based ELC | IAG | Zig-zag (3-1ɸ isolated transformer), 3-leg IGBT based VSC with IGBT based chopper. | 2011 [106] |

| 43. | Improved 3-leg IGBT based electronic load controller (DS-1104 control board) | IG | 3-leg IGBT based VSC with IGBT chopper. | 2011 [90] |

| 44. | NN based least square (adaline) algorithm for integrated ELC | IAG | Zig-zag (Three single phase isolated transformer), 6-leg IGBT based VSC with IGBT based chopper. |

2011 [107] 2012 [115] |

| 45. | PI based single control structure for voltage and frequency regulation. (DS-1102 and DS-1103 control board) | IG | 3-leg IGBT based VSC and IGBT based chopper. | 2011 [108] |

| 46. | Hybrid topology with smart loading and BESS. (DS-1102 and DS-1103 control board) | SM | 3-1ɸ uncontrolled rectifier with IGBT based chopper, 3-leg IGBT based VSC and 2- IGBT based chopper. | 2011 [95] |

| 47. | Genetic algorithm and PI based dump load and multilevel valve control. | IG | TRIAC as a load phase control switch | 2011 [35] |

| 48. | DSP (TMS320 28335) based reactive power control | IG | 3-leg IGBT based VSC with a capacitor | 2011 [91] |

| 49. | Microcontroller (Atmega-32) with Fuzzy logic based ELC | SEIG | Single phase uncontrolled rectifier with MOSFET based chopper | 2011 [96] |

| 50. | Fuzzy logic control based ELC | SEIG | IGBT based CC-VSI and IGBT chopper for ELC. | 2012 [109] |

| 51. | Battery storage based ELC using PI controller (simulation) | SEIG | Uncontrolled rectifier with IGBT based chopper for ELC, resistance replaced by battery. | 2012 [97] |

| 52. | DSP (TMS320 28335) based Integral resonant single loop voltage control. | PMSM | IGBT based controlled rectifier with 4-leg VSI. | 2012 [110] |

| 53. | Hybrid control of two parallel micro hydro generators and a wind generator. (simulation) | SG, IG | 3-leg IGBT based VSC with capacitor, and 3-leg IGBT based VSC with IGBT based chopper. | 2013 [111] |

| 54. | Hybrid voltage regulation with capacitor bank and STATCOM using PI controller | SEIG | 4-leg IGBT based VSC and star connected capacitor bank. |

2013 [112] 2013 [113] |

| 55. | Harmonic reduction with Multi-pulse ELC using PI controller (simulation) | IAG | Multi-pulse uncontrolled rectifier bridge with the zigzag phase-shifting transformer. | 2013 [82] |

| 56. | Fuzzy logic controlled battery charging system | SG | AC-DC rectifier with DC-DC chopper. | 2013 [77] |

| 57. | Binary weighted ballast load with PI controller |

PMSG SESA |

IGBT switch as a chopper. (Prototype model) Uncontrolled rectifier with IGBT switch (Simulation) |

2013 [42] 2015 [47] |

| 58. | Dump load control using PI controller (simulation) | MHG | Uncontrolled rectifier with IGBT based chopper. | 2013 [100] |

| 59. | Microcontroller (Atmega-32) based ELC | SG | 3 sets of Anti-parallel SCR | 2014 [78] |

| 60. | Self-tuned fuzzy PI controller based ELC | PMSG | Anti-parallel SCR as a phase control switch. | 2014 [21] |

| 61. | Split dump load technique based ELC | SEIG | Bi-directional IGBT for chopping. | 2014 [57] |

| 62. | Atmega-32 based ELC with grid synchronization unit | MHG | Solid State Relays switches between resistors and generator. | 2014 [122] |

| 63. | Atmega-328 based ELC | MHG | MOSFET switch as a chopper. | 2014 [102] |

| 64. | DS-PIC30F6010 based ELC | SEIG | 3-Single phase uncontrolled rectifier with IGBT based chopper. | 2014 [69] |

| 65. | Dynamic ELC for 3ɸ induction motor drive load (DS-1104 control board) | SEIG | IGBT based VSI and uncontrolled rectifier with chopper | 2014 [48] |

| 66. | DSTATCOM-DTC drive based voltage and frequency control using PI controller | SEIG | IGBT based VSI with a capacitor | 2014 [73] |

| 67. | Distributed ELC using PI controller: Excess power to house hold water heaters. (MSP-430 Launch Pad microcontroller) | SEIG | Bi-Directional Insulated Gate Bipolar Transistor Switching method as in [36]. | 2014 [58]2014 [59] |

| 68. | Power quality control of Pico-hydro power plant using star delta and zigzag transformers | SEIG |

6-Pulse Diode rectifier with IGBT chopper 24-Pulse Diode rectifier with IGBT chopper |

2014 [52] 2017 [56] |

| 69. | PI based proportional resonant derivative controller (DSP, TMS320F28335) | SCIG | IGBT chopper connected to the three-phase bus through a non-controlled rectifier. | 2014 [49] |

| 70. | PLC based load controller | SG | 3 Contactors with resistive load | 2015 [39] |

| 71. | Proportional controller (30) | SG | 6-Pulse Diode rectifier with IGBT chopper | 2015 [53] |

| 72. | Harmonic elimination using p-q control theory | SEIG | IGBT based VSC with DC chopper | 2016 [75] |

| 73. | AVR with PI based ballast load frequency regulator. | SG | SCR based AVR and 3-Single phase AC-AC control (TRIAC) based load frequency regulator. | 2016 [76] |

| 74. | Improved Distributed ELC with PI controller. | SEIG | TRIAC based load frequency regulator. | 2016 [36] |

| 75. | Modified ELC with PI controller. | 1ɸ-SEIG | Single phase diode rectifier with IGBT chopper | 2016 [51] |

| 76. | Droop based load control using proportional controller | SG | Contactor with discreet ballast. | 2016 [40] |

| 77. | Steady state analysis of ELC with P, PI, PID controller. | SG | 6-Pulse Diode rectifier with IGBT chopper | 2016 [54], [55] |

In the above table: NN: Neural Network, IG: Induction Generator, SG: Synchronous Generator, AG: Asynchronous Generator, ELC: Electronic load controller; ELG: Electronic Load Governor; AVR: Automatic Voltage Regulator; MHG: Micro Hydropower Generator; IGC: Induction Generator Controller; SEIG: Self Excited Induction Generator; IAG: Isolated Asynchronous Generator; SESA: Self excited synchronous alternator; SESCG: Self Excited Squirrel Cage Generator; PMSG: Permanent Magnet Synchronous Generator

Although existing ELC is utilized for regulating the output voltage and frequency, it creates power wastage. Typical ELC required cooling facility for cooling dump load, especially, during the summer period and tropical regions, which increases system complexity and cost (installation cost and running cost) [85]. Some of these controllers are used for utility purpose [58], [59] whereas, the efficiency and lifetime of the machine is concerned, still an issue. As the capacity of the dump load resembles plant capacity, it requires more cooling system, which affects the generator’s life span. As per the survey of CIGRE [54], a major source of breakdown in hydroelectric generator is due to electrical, mechanical, and thermal stresses. Understanding these stresses are important to increase efficiency and lifespan of the generator. The lifetime of a generator depends upon environmental condition and operating stresses (electrical, mechanical and thermal). Variation of dump load with respect to the main load creates electrical and mechanical stresses, as well as, thermal stress in generator are created due to unbalance loading, continuous loading, bearing fault, etc. In existing ELC with typical dump load, afore discussed stresses are accountable. Considering this problem in existing ELC, 20 percent of dump load is reduced in the proposed strategy by increasing the reference frequency. Performance of generator and domestic appliances under reduced dump load have been experimentally investigated in this paper. Moreover, lifespan of the generator under existing and proposed strategy is estimated with their thermal effects. In addition, protection of system from load disturbances and sensor fault is embedded in the controller. Overall the paper includes; design and operation of electronic load controller with experimental arrangement and testing in Section 2, investigation of generator and domestic loads with 20 percent voltage and frequency variation in Section 3, lifetime estimation of hydroelectric generator with existing and proposed strategy is deduced in Section 4, sensor fault detection and isolation technique is implementation in Section 5, Section 6 discusses the realization of proposed strategy with result and discussions in Section 7 and concluded in Section 8.

2. Design and operation of electronic load controller

In this section, the design of an electronic load controller with hardware setup and functioning procedures is discussed.

2.1. Design of ELC

Electronic controller functions as a frequency regulator on a generator by diverting surplus electrical power to ballast resistive load [8], as in Eq. (1). As frequency is the main control variable, difference between measured frequency and desired reference frequency is considered as the error signal given in Eq. (2).(1)(2)

where, PG is power generated; PD is dump load power; PM is main load power; F is output frequency; Fr is reference frequency; Δf is error signal.

Error signal through PI controller decides the firing angle, which determines the amount of power dissipation. Switches are fired at such firing angle to dissipated surplus power, equation (3).(3)

where, Kp is proportional gain and Ki are integral gain of PI Controller.

Power rating of ballast resistive load is equal to or be slightly greater than rated capacity of plant. Per phase resistance value and power consumption of dump load are calculated using Eqs. (4), (5),(4)(5)

where, R is dump load resistance value; VS is generator phase voltage (rms value); K is dump load multiplication factor and normally considered around 1.2; α is firing angle; PD is dump load power.

2.2. Experimental arrangement

Experimental arrangement (Fig. 2a) consists of a 3 kVA synchronous generator (S.G) driven by 3.5 kW prime mover (DC motor drive), rating of both machines is given in Table 4. As well, the enforcement of dump load controller mainly consists of sensing unit, control unit and switching unit (Fig. 2b). Frequency of output voltage is sensed and compared with reference value to control firing angle of switches.

-

i.

Sensing Unit: The sensing circuit consists of potential transformer (VDE 0570) for measuring and providing voltage signals to zero-crossing detector circuit (ZCD). ZCD is circuited using LM741 IC for developing square wave proportional to the voltage signals. ZCD’s output is fed to phase locked loopbased frequency multiplier circuit (CD4046 & 74LS294) for higher resolution during F to V conversation. The circuit locks the rising and falling edge of input square wave signal with the falling edge of output signal for increasing frequency of output (approximately 10 times). As the phase locked loop is driven by positive signal transitions, output of ZCD block is locked with falling edge. Finally, the multiplied frequency signal is converted into a voltage signal using LM2907 IC and fed to comparator where the processed signals are compared with the reference value for getting error signal.

-

ii.

Control Circuit: error signal is amplified by PI controller and reduces the steady-state error (kp = 1.13 & Ki = 0.512), the controller gain values are obtained by trial and error tuning method. Initially, the proportional gain is tuned until the constant rate output by setting the integral term to zero. Once the obtained response is fast enough, the integral gain is tuned to reduce the steady-state error. PI controller’s output is compared with high frequency carrier wave for providing pulses to switches through driver circuits. The high frequency is generated using SG3524 IC. The non-inverting amplifier based driver circuit with opto-isolator is used to provide isolation between the signals and power circuits.

-

iii.

Switching Unit: Three-single phase rectifier (GBPC3506) with IGBT chopper(STGW40N120KD) and ACNW3190-1335 IC based opto-isolated gate driver circuit for engaging resistive load depend up on controller signal. In addition, output quantities of generator are measured and analyzed using three phase power quality analyzers (PQA – FLUKE 435) is used and input quantities of the generator (torque and speed) are measured using spring dial arrangement and tachogenerator respectively. Moreover, the surface temperature of generator under various operating conditions are measured and analyzed using a thermal analyzer (FLUKE Ti-32) and smart view software respectively.