1. Introduction

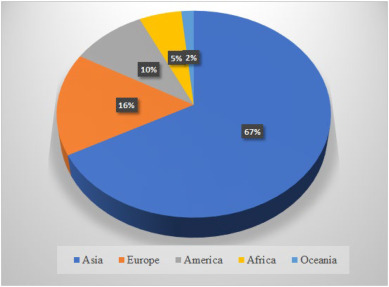

The Aquaculture and fisheries sector's contribution to the global gross domestic product (GDP) varies mostly from 1 to 10 percent. The strengthened demand and higher prices of seafood forecasted the value of global seafood exports in 2019 to USD 164.5 billion (Food and Agriculture Organization (FAO), 2019). The seafood processing industry plays a major role in preserving the large fishery production and also provides consumers a good variety of processed seafood products. The region-wise distribution of seafood industries in the world is given in Fig. 1. Of the total seafood production in the world, only 45% is consumed in the form of fresh fish and the remaining 55% is processed and consumed as frozen fish (29%), canned fish (14%), and cured fish (12%) (Pedro and Nunes, 2007). The fisheries sector heavily relies on external sources of power for aquaculture, fishing, post-harvest and product distribution operations. Among them, a sizeable amount of energy has been used in the harvest and post-harvest sectors including fish transportation and processing (FAO, 2014). The fuel usage in post-harvest operations is mainly linked with ice supply, refrigeration and air conditioning, drying, and smoking processes (Parker and Tyedmers, 2015).

Fig. 1

Fig. 1Fig. 2 shows the energy and water flow in a typical seafood processing plant. A seafood plant requires a large quantity of electrical energy. In that, maximum energy is used for equipment like electric motors i.e. compressors for the freezer, cold storage and ice-making machine, and lighting that needs magnetic ballasts and air conditioning (The United Nations Environment Programme (UNEP), 1999). An especially huge amount of energy is utilized for various fish processing activities including chilling, freezing, cleaning, packing, and sorting (Gephart et al., 2017). Bord Iascaigh Mhara (BIM) (2017) reported that 15% of global energy consumption is related to refrigeration and air conditioning operations. Energy consumption in seafood processing mainly depends upon the age and size of the plant, degree of automation, intensity and type of processing operations, plant management practices, plant layout and organization, equipment efficiency, and range of products manufactured (United Nations Environment Programme (UNEP), 1999). Anantheswaran et al. (2014) presented potential energy-saving options for the meat processing industry such as lighting, load management, boiler maintenance, and recovering waste heat from refrigeration systems, etc.

Fig. 2

Fig. 2The seafood processing industry also employs a high volume of water to maintain proper storage and hygiene conditions to avoid product spoilage. The major areas of water usage include seafood cleaning, washing, cooking, freezing and thawing, preparation of brine, and cleaning of equipment and floor, and storage and transport (Henriksson et al., 2018). It has been reported by the Export Inspection Council (EIC) of India that a minimum of 10 L of water is necessary to process 1 kg of fish (EIC, 2005).

Both energy and water are finite sources in the earth, that too, in a rapidly changing modern world, both are going to be placed under extreme stress, especially in the seafood sector. On one side, the production of fuel and generation of power depends on water availability, and on the other side pumping and supply of water needs energy (King et al., 2008). Very recently, attention has been paid to the quantum of energy essential for freshwater pumping and supply (Vora et al., 2017) and wastewater treatment in the fisheries sector (IEA, 2016). As a consequence, in the energy-water nexus, additional energy is required for drawing fresh water and further processing of wastewater which results in increased greenhouse gas (GHG) emissions and incurring additional costs to the plant. The alternatives could be water reuse and minimization of waste generation for saving both energy and water. Thus, more proactive fundamental changes are required in the seafood processing sector for long-term gains.

Nevertheless, reports suggest that the energy and water utilized in fish processing industries does not match with the actual requirements. The imbalance is due to the inefficient energy and water management practices followed by the processing industries (The Marine Products Exports Development Authority (MPEDA), 2017). The wastage of energy and water in monetary terms is huge and has a significant impact on productivity and profit. In the seafood supply chain, only the activities after seafood have been harvested and brought to the processing unit were considered in the review manuscript.

Most of the studies published address either the energy or water consumption pattern in a particular processing line in the seafood industry. However, no study comprehensively focused on the importance of energy, water, and their nexus in seafood processing industries. Hence, the review work was formulated to address the importance of energy and water use optimization, and evaluate the current management practices and suggest optimization strategies in the seafood industry.

2. Research methodology

To carry out the study on the optimization of energy and water consumption in the seafood industry, various research questions were formulated and analyzed.

-

i)

What is the significance of energy and water optimization in the seafood industry?

-

ii)

What is the existing trend of energy and water usage pattern in the seafood industry?

-

iii)

What are the current management practices involved in energy and water use in the seafood industry?

-

iv)

What are the possibilities for improvement and optimization strategies?

-

v)

Seafood - energy-water nexus and its environmental impact

The relevant review and research articles were collected and sorted under the above-mentioned topics using different databases such as ScienceDirect, Scopus, Web of Science, FAO, and Bureau of Energy Efficiency (BEE) online library. For exploring the maximum information related to the formulated questions, various keywords directly related to the main research topic such as energy and water optimization in the seafood industry, automation process in energy and water usage, wastewater treatment, greenhouse gas emission from fish processing sector were used. After avoiding duplication of contents, finally, 88 topic-focused articles were selected, critically evaluated, and discussed in this review article.

3. Analysis of energy and water use management practices of the seafood industry

In the descriptive analysis, the collected papers were analyzed, categorized, and presented as factors involved in energy and water consumption and its importance, existing management practices, and nexus between energy and water in the seafood processing industries.

3.1. Energy consumption and its significance in seafood processing industries

Seafood, a highly perishable commodity, warrants continuous and uninterrupted power supply to ensure the safety and quality of the product in the plant (Gokoglu and Yerlikaya, 2015). Energy consumption in the seafood plants largely depends on the age and size of the plant, degree of automation, intensity, and type of processing operations, management practices involved, plant layout and organization, the efficiency of the equipment, and variety of products manufactured (United Nations Environment Programme (UNEP), 1999). A huge amount of energy is utilized for processes like chilling, freezing, cleaning, packing, and sorting activities (BIM, 2017). The rising energy costs have shown a negative impact on the overall return for seafood processors. To maintain a competitive position in the global seafood trade, cost-reduction measures are to be adopted by the seafood processors by improving the energy efficiency of the plant (Fisheries and Aquaculture, 2007). According to Tomczak-Wandzel et al. (2015), 80% of electricity consumption is a function of production and the remaining 20% is constant and it is independent of production. In another evaluation performed by Asakereh et al. (2010) related to energy consumption in the canned fish production industry in Iran, initial cooking and sterilization of products contributed to the major part of input energy amounts to 21,202.6 MJ/tonne of fish. The distribution of various connected loads in a seafood processing plant in Kochi-cluster is shown in Fig. 3. The major equipment in a typical seafood plant are compressors, freezers, cooling towers, condensers, ice-making units, and motors.

Fig. 3

Fig. 3The average operating time of the whole refrigeration unit in a typical seafood industry is 10–16 h per day. According to Bureau of Energy Efficiency (BEE) (2015), in the total connected load, 73% of power demand is required by compressor units only. Also, the type of freezers employed has a critical role in the energy consumption pattern of the seafood processing industries. In addition, the freezing load completely depends upon the product size, shape, and customer demand.

According to Bureau of Energy Efficiency (BEE) (2015), the major reasons for poor energy use efficiency in seafood industries are due to the processor's interest in the improvement of growth, rate of production, quality of the finished products rather than efficiency, and energy management practices. The lack of trust given by government agencies on energy-efficient and low carbon footprint products and technologies are also reasons for low energy use efficiency in the industries. The minor reasons are that the fear of production disturbance and quality issues, constraints in especially skilled labor, and the absence of nearby specialist cooperatives that can bolster the activities of industries.

Emission of GHG is directly contributed at different levels of fishing operations like harvesting and transportation, processing, and storage of raw material and processed products (Food and Agriculture Organization, 2008). Besides the harvesting of fish is the major contributor to GHG, processing and storage of fish and fisheries products also contribute significantly towards GHG emission (European Commission, 2011). Although there is no accurate estimate about the amount of GHG emission at different stages of the seafood industry, its occurrence at various stages of processing is not negligible. It has been reported that processing and packaging contribute only 10% of total GHG emissions. However, the leakage in refrigeration systems, usage of emission-intensive materials in processing results in a higher rate of GHG emissions (Seafish, 2014). According to literature, greenhouse gas emission per tonne of fish caught was 1.13 tonnes in India (Boopendranath and Hameed, 2013) and 1.7 tonnes globally (Tyedmers et al., 2005). The global fuel use intensity in the fisheries sector, for 2011, is estimated to be 489 L/tonne of fish which accounts for total carbon dioxide emissions of 179 million tonnes CO2 equivalent (Parker et al., 2018).

The energy consumption in the seafood industry depends on the type of installation, equipment, and processes. It has been reported that the heating process alone requires about 29% of the total energy consumption whereas cooling and refrigeration consume 16% in the fish canning industry (Terehovics et al., 2018). It has also been reported that power consumption for refrigeration at the seafood industry level is about 380 kWh per ton of product.

UNEP report (United Nations Environment Programme (UNEP), 1999) indicated that heat processes such as cooking of canned fish and fish meal and oil production required maximum energy whereas filleting of fish consumed lesser energy. In a typical processing industry, the energy required for the filleting of fish was about 65–87 kWh, canning about 150–190 kWh, and fish meal about 32 kWh per ton fresh fish intake.

3.2. Water consumption and its significance in seafood processing industries

According to BIM (2017), the fish processing stage consumes the highest amount of water (42%) followed by cleaning (38%) operations in the seafood industry (BIM, 2017). Water used for other on-site services such as washroom sinks, toilets, canteen sinks come under other uses (Fig. 4). According to the cleaner production assessment in fish processing, the amount of fresh water used per tonne of fish is 5–11 m3, 15 m3, and 0.5 m3 for filleting, canning, and fish meal, respectively (United Nations Environment Programme (UNEP), 1999). Similarly, the Clean in Place (CIP) and other systems in seafood industries engross significant water consumption and consequently produce a large quantity of wastewater (BIM, 2017). All stages of fish processing operations require water starting from transportation, cleaning, production, and packaging. The different sources of wastewater production in seafood industries are depicted in Fig. 5.

Fig. 4

Fig. 4 Fig. 5

Fig. 5The water consumption in each stage can be classified into four levels such as initial stage, primary process, secondary process, and final stage as shown in Fig. 6. Thawing, washing, peeling, glazing are the major water-consuming processes in the seafood processing sector. Water consumption from these activities was 79.15 % of total water consumption. Wastewater is generated from the thawing of raw materials, washing activities, cutting and butchering of raw materials.

Fig. 6

Fig. 63.2.1. Water consumption in shrimp processing

Major factors that decide the rate of water consumption in the seafood industry are the type of product that is to be processed and the unit operations involved in it. In shrimp processing, to improve peeling efficiency, the raw shrimps are stored in ice for 2 days and peeled after the thawing process (Fig. 7). During this process, there is the continuous use of water for washing out the inert material. Also, during the thawing process, a significant amount of water is released through the floor drain as wastewater. The meat is either PUD (peeled un-deveined) or PD (peeled and deveined) based on consumer demand and sorted according to required counts. The used water which contains the waste is drained through the floor drains. In the next stage, the quality of the peeled shrimp is analyzed visually as per set standards. The product is again cleaned with water using a washer machine followed by an impurity checking process is performed. Hence, a large amount of wastewater is generated in processing of shrimp. The sorted and graded shrimps were frozen based on the market requirement i.e. individually or as a block. The frozen item is further packed appropriately and stored in the freezers at −18 °C until export (Thomas, 2016).

Fig. 7

Fig. 73.2.2. Water usage in fish filleting process

Generally, the fish is cleaned in large wash tanks. After removing the skin, it is filleted and washed again as depicted in the process flowchart (Fig. 8) and the resultant water contains a large amount of waste. Subsequently, it is allowed to settle for removing the solid waste and water separately (Thomas, 2016). After inspection, the fillets are packed and moved to the freezer and stored at −18 °C (Thomas, 2016). The soluble, colloidal and particulate form of contaminants in the wastewater from a seafood processing industry is very high (Tay et al., 2006). Consequently, the chemical oxygen demand (COD) and biological oxygen demand (BOD) of this wastewater generated during each stage of the fish filleting process are very high. The common contaminants present in the wastewater of the seafood industry are fats, oil, grease, suspended solids, and nutrients like nitrogen and phosphate. Also, the degree of contamination largely depends on the processes carried out. The processes like washing, filleting, and fishmeal processing produce lightly, mildly, and heavily contaminated wastewater respectively (Tay et al., 2006).

Fig. 8

Fig. 83.3. Current practices of energy management in the seafood processing sector

Due to the energy and water intensiveness of the seafood processing sector, many initiatives were taken up in the past, across the world, to study the energy and water use pattern of seafood processing units. Energy optimization in the seafood industry essentially involves reducing the amount of energy, either it is electrical energy or conventional energy sources like petroleum, natural gas, coal and oil consumed by industry during the period between procurement of raw material to delivery of the final processed product (Tang et al., 2014). Optimizing the energy consumption can substantially contribute to the reduction in operating costs during the processing of seafood materials (Boopendranth and Hameed, 2013). Moreover, the utilization of large quantities of energy can lead to poor processing efficiency and increased emission of effluents to the environment, which harms the products’ carbon footprint count (The Renewable Energy and Energy Efficiency Programme (REEEP), 2005). Some of these studies are discussed in this section.

The Bureau of Energy Efficiency (BEE) conducted an energy use and technology audit in the Kochi seafood processing cluster, in thirty units covering all types and sizes of industries. The prime energy source of the cluster is electricity and no other thermal energy sources apart from diesel, which is used to run a diesel generator as a backup power source. Average energy consumption of 26,90,733 kWh was observed for the total units in the cluster with the specific energy consumption ranging between 375.10 kW and 841.5 kW/tonne of production. They proposed few energy-saving measures like proper maintenance of condenser coils, replacing thermocol insulations of cold storage doors with polyurethane foam (PUF) or glass wool insulation, proper insulation of damaged areas, replacing reciprocating compressors with screw compressors with variable frequency drive (VFD), etc. In the case of screw compressors, the specific energy consumption is about 0.82–1 kW/TR which is a good alternative for conventional reciprocating compressors (Bureau of Energy Efficiency (BEE), 2015).

The use of a programmable logic controller (PLC) control system in the refrigeration plant for automatic operations has been reported. The PLC will control the automatic loading and unloading of the compressor based on the load. The system can be coded based on the requirement of the functioning of equipment and machine. An energy-saving of 5% can be obtained through the automation of equipment in the processing line (BIM, 2017).

Indzere et al. (2020) analyzed energy efficiency in the thawing process of the fish processing industry. They reported that the air blast method of thawing is one of the best energy-saving techniques and suggested replacing the current boiler house with a cogeneration plant for additional energy savings.

The general recommendation by Tomczak-Wandzel et al. (2015) for increased energy efficiency includes increasing the cooling efficiency, reducing the heat loss, heat recovery facilities, and use of renewable energy resources. The Energy and Resources Institute (TERI, 2017) conducted a detailed analysis of different seafood processing industries in Veraval, Gujarat. They reported that the installation of a desuperheater between compressor and condenser can recover the waste heat and it can be used for hot water production for cleaning purposes. The centrifugal pumps used in ice-making can be replaced by horizontal multistage mono-block pumps which results in 30–50% energy saving. They also reported that the replacement of a flat V-belt with cogged V-belt can save 3–5% of energy. The results also revealed that a 0.1 bar pressure difference between evaporator and condenser results in additional 7% power consumption. Hence by installing two calibrated pressure gauges it is possible to make necessary modifications in the refrigeration system whenever the pressure goes beyond 0.2 bar (TERI, 2017).

Dincer (2002) reported that the energy can be stored using thermal storage systems for use at a later time. The chilled water or ice prepared during the off-peak hours can be stored in an insulated vessel and it can be used for air conditioning purposes during the peak period. One way is to run the refrigeration framework at a steady rate, utilizing the thermal storage system as a support that stores cooling energy when demand is not as much as production, and discharging the cooling energy when demand surpasses production. This is one of the best energy-saving methods currently implemented by small and large-scale firms. Apart from this, some firms introduced a thermal energy storage system in which the chiller employed for ice making is utilized during the night for thermal energy storage and ethylene glycol or other auxiliary refrigerant is utilized during daytime. Accordingly, the industry could save electricity costs by employing a differential energy management plan for peak and off-peak periods.

UNEP report (United Nations Environment Programme (UNEP), 1999) suggested some of the key housekeeping procedures to reduce energy usage in the seafood industries. An installation of switch On-off program by installing sensors to turn off lights and equipment when not in use; improving insulation aspects on heating and cooling process; use of efficient equipment; effective equipment maintenance, eliminating steam leaks; capturing of waste energy and heat to use elsewhere in the process, etc.

3.4. Current practices of water management in the seafood processing sector

As a part of sterilization and cleaning, the seafood processing industries consume high volumes of water. The wastewater from the processing lines contains high amounts of fish waste which produces heavy organic effluent (Gassert et al., 2013). The installation of water treatment units in the thawing and gutting stages in the plant reduces water usage by up to 70%. The fish oil in the wastewater was removed using an oil separator which results in value addition. According to a detailed audit of energy and water use in the seafood processing industry in Vietnam conducted by Dan et al. (2003), reported that the installation of pressurized hoses and suitable sized capacitor banks could save 70% of the water used for cleaning purposes and 10% savings in the electricity bill, respectively. In the seafood industry, water management techniques and wastewater reuse practices must be promoted and recognized, as industrial wastewater recycling is a suitable option (Guimarães et al., 2018).

Alkaya and Demirer (2016) revealed that the wastewater generated during the anchovy thawing process can be recycled using a closed-circuit water recirculation system and it can be further used for the gutting process. It has been reported that the anchovy gutting and thawing process decreased specific water consumption by 77% and 65% respectively, with a total water saving of 45%. Bugallo et al. (2012) employed the methodology of combined material and energy flow analysis (MEFA) and best available techniques (BAT) in the mussel processing plant. They reported that the water consumption and management of wastewater and solid water streams are disturbing factors in the seafood process plants. The results of the energy and water audit conducted by Bezama et al. (2012) in frozen fish processing companies in Chile indicated that the adoption of cleaner production techniques has reduced water and energy consumption by 28% and 24.5%, respectively.

Thrane et al. (2009) comprehensively analyzed the data of water usage and COD emissions of the Danish fish processing industry and reported that gut removal using a vacuum system, boiling using a microwave, and usage of gas for de-skinning can significantly reduce water consumption in mackerel processing lines. Also, the reuse of the brine used for pickling and adoption of advanced wastewater treatment processes like heat centrifugation, nano-filtration, and reverse osmosis would result in lesser water consumption and decreased COD emissions. Similarly, in the canned tuna processing industry in Thailand, fitting of pressure nozzles for spray cooling, the use of hot water (60 °C) as a replacement for cold water and its supply at a reduced rate for can washing could reduce water consumption by 66%, 55% and 14%, respectively (Uttamangkabovorn et al., 2005).

Souza et al. (2018) reported water management practices for the processing of Atlantic Salmon and dolphins. The authors employed water flow meters and electrical devices to control the water usage in the cleaning process and reused relatively clean wastewater for minor requirements in the warehouse. Also, they reported that the filleting process of Dolphin and Atlantic Salmon resulted in a high amount of solid waste generation. They suggested reusing the solid waste for the fish-meal preparation and expansion of plants for possible production of fish by-products which could increase income and produce less waste and environmental impact.

Kurniasih et al. (2018) reported that water consumption can be reduced by adopting a waste minimization process as shown in Fig. 9. The wastewater in the thawing process was recycled and reused in situ because it contains less value of BOD and COD. The recycling of water from floor washing was carried out separately as it contains a high rate of BOD and COD. The waste was segregated into two parts mainly solid and liquid. The liquid waste was reused after carrying out the wastewater treatment. The decrease in waste triggered a reduction in water use by 89.76 m3 for a week. They also reported that about 30% of savings in water were achieved for washing procedures.

Fig. 9

Fig. 9Tomczak-Wandzel et al. (2015) had suggested that quick separation of waste products from used water in process plants demand lesser effort for treatment. The normal approach to treat wastewater includes physical treatment, biological treatment, chemical treatment, and sludge treatment. In physical treatment, screening, sedimentation, and skimming operations are utilized to expel the solids. These unit operations reduced the total suspended solids up to 85% and BOD5 and COD in wastewater up to 65% (Tay et al., 2006). Biological treatment includes the utilization of microorganisms to isolate dissolved supplements from a release. Organic and nitrogenous mixes in the release can fill in as supplements for quick microbial development under oxygen-consuming, anaerobic or facultative conditions (Grady et al., 2011). Similarly, aerobic treatment is a characteristic oxidation process that can evacuate 98% of organic waste (Van Lier et al., 2020).

Sludge from the wastewater of seafood processing units has a higher level of impurities. However, due to its moderate volume, these waste streams contribute only 3–27% of overall outflows of the industry. The sludge generated from wastewater is currently disposed after providing treatment like thickening or dewatering or anaerobic or aerobic digestion or composting (Tuan and Sillanpää, 2010). Ching and Redzwan (2017) reported that liquid fertilizer can be obtained from treated wastewater from seafood processing firms.

Gómez-Sanabria et al. (2020) have undertaken a study on sustainable wastewater management in Indonesia's fish processing industry focusing on governance issues. They offered a unique perspective by integrating work on qualitative governance and quantitative modeling research to achieve wastewater treatment goals. While providing reform measures, they also highlighted the challenges of obtaining various aspects of governance and the absence of important cost data as the limitation of their approach.

3.5. Seafood -energy-water nexus and environmental impact

The interconnection and drivers between food, water, energy, and GHG emissions are vital in the climate change perspective and increasing GHG emissions. In future, GHG emissions associated with energy used for seafood processing are likely to be another factor that will add to the complexities of processing plant management. Minimizing GHG emissions must be considered jointly with water management practices to achieve the dual objective of maximizing water productivity and minimizing carbon emissions. Hamidov and Helming (2020) stated that the interconnectedness of the three sectors of water, energy, and food to improve cross-sectoral coordination in support of sustainable development, the nexus has become an important concept in resource management. D'Odorico et al. (2018) highlighted the increasing role of seafood consumption in the food-water nexus and observed that fishmeal and fish oil in aquafeeds should be replaced with crop-based constituents to improve water sustainability of the fisheries sector. Gephart et al. (2017) introduced a concept of the ‘seafood gap’ in the global food-water nexus on the issues of freshwater use in seafood production chains and corresponding GHG emissions. A study on the efficient usage of water and energy resources in the seafood supply chain was carried out in China. They reported that processing and packaging operations combinedly consumed about 2.92 × 108 kWh of energy and 4.23 × 107 m3 of water and corresponding environmental impact was released in the entire supply chain (Liu et al., 2020). The availability of seafood comes with many challenges that demand the attention of society to ensure security along the supply chain especially the post-harvest operations in the seafood production and thus reduce the waste generation and GHG emissions (Avadí et al., 2014).

4. Discussion

4.1. Energy optimization methodologies

The suitable methodology has to save energy and reduce wastage and consequently reduce the operating cost of the plants. Most of these actions require only good management practices such as effective policy and planning, and optimum supply chain management (Amulya et al., 2018). The different management practices involved in energy use optimization of the seafood industry are comprehensively discussed in this section.

4.1.1. Automation of existing process line and workflow optimization

Energy wastage in the seafood industry can be greatly reduced by precisely controlling the working of all equipment in the process line. Merely controlling the timely switching on and off of equipment can save a lot of energy, which is practically impossible in manual operation (BIM, 2017). The latest technology for the improvement of energy efficiency that has been extensively applied in the seafood industry is process or heat integration. This methodology focuses on workflow optimization in the processing line thus savings in the heating and energy cost can be achieved. This methodology has great potential in the seafood processing sector. The use of equipment during the peak tariff period (electricity usage during 6:00 p.m. to 6:00 a.m.) also results in higher energy costs. Hence, the activities that can be completed during the daytime can be scheduled accordingly such as running of flake and tubular ice machine. Thus, workflow optimization is an important part of the energy optimization process. The literature suggests that almost a 10–40% reduction in energy consumption can be obtained by automation of equipment in the seafood processing industries (Amulya et al., 2018). In another study by BIM (2017) reported that energy-saving of 5% can be attained through automation of equipment in the processing line of the seafood industry.

4.1.2. Sensitize the labor about energy conservation

The manpower attitude and behavior have a major impact on the total energy consumption of processing plants. Awareness among the laborers regarding energy wastage that can occur due to mere negligence or ignorance has to be imparted (BIM, 2017). Instructions can be given regarding reducing energy wastage, for example, the chill room doors should be closed immediately after loading or unloading to prevent the heat transfer from a cold room to ambient, thus rise in temperature of the cold room can be avoided.

4.1.3. Equipment maintenance, replacement, and upgradation

Existing equipment should be monitored for their efficient working through periodic repair and maintenance. Regular servicing and replacement of worn-out parts should be periodically carried out. This can improve the processing efficiency of the equipment and that in turn of the whole plant (Brush et al., 2011). The energy cost in the pumping of water can be accounted for up to 90% of the total cost of a pump. Just by monitoring wear and tear, impeller damage, bearing, blockages, inadequate suction, and improper pump clearance, about 2–7% of energy savings can be achieved. Other low-cost methods are proper lubrication, alignment of pump/motor, and monitoring of pressure, flow, current, power, and temperature. In large industries, the installation of control systems for automatic shutdown of pumps when there is no demand of load can be envisaged. Installation of multiple pumps in parallel manner for the variable load can save up to 10–50% of electricity consumption for the highly variable load (Rosenberg et al., 1999). If reciprocating and centrifugal-type compressors are replaced by a screw compressor, higher processing efficiency can be obtained. This is a relatively capital-intensive method but a high reduction in energy consumption can be obtained. It is not possible to replace all the existing conventional equipment with new technologies due to large investments and an extended payback period. But the least efficient equipment can be replaced periodically if the operation and maintenance cost is very high. The appropriately sized motors based on load can save up to 1.2% of total motor electricity consumption (Rosenberg et al., 1999). The installation of adjustable speed drives on motors will also save a considerable amount of energy to the tune of 40% (Cascade Energy Engineering (CEE), 2007). This is one of the most applicable methods to reduce the motor electricity load for small and large-scale fish processing sectors.

4.1.4. Energy auditing and budgeting

The effective reduction in energy consumption can be achieved through periodic energy auditing of the seafood industry. Energy audits can give an idea about the extent of energy utilized for various purposes in the industry and accordingly energy conservation measures can be executed (Fisheries and Aquaculture, 2007). Auditing of energy consumption should be carried out in all seafood industrial firms periodically. By proper energy auditing, it is possible to find out the weak zone of the firm and further actions can be taken up to rectify the defect (Chiaroni et al., 2017).

4.1.5. Use of renewable energy and green industry concept

The implementation of renewable energy in the seafood sector in a sustainable manner can stimulate new economic opportunities and bridge the energy deficit along the seafood supply chain. Switching to renewable energy sources from conventional sources is of great advantage not only to the industry but also to the environment. Nowadays, the green industry is a trending concept which emphasizes those activities and measures which help curb environmental depletion, swapping renewable energy is one of the potential alternatives (FAO, 2014). BIM (2017) reported that solar PV systems and wind turbines can be a realistic and attractive option for energy generation for seafood processors in some areas. Since seafood industries deal with the most perishable products, an uninterrupted power supply is to be ensured for the operations. Hence, the plant cannot rely upon only electricity or the renewable energy sources. Hence, a hybrid system can be established to have a continuous electricity supply. Solar photovoltaic panels can be installed for the generation of electricity which can meet minor requirements such as the lighting in the main processing hall, storage space, washrooms, and air conditioning load of processing hall and corridors (Backlund et al., 2012). Widodo et al. (2018) carried out a techno-economic analysis of solar photovoltaic power plant for small-scale fish processing in Kota Langsa and reported that hybrid mode of power supply with solar energy has a lower payback period for the plant.

Solar thermal technology can be considered as a potential alternative to traditional heating operations involved in the seafood industry as part of energy-saving measures. Quijera et al. (2013) connected a water-based solar thermal collector to the heat pump and the boiler in a series arrangement and supplied heat energy for all the middle-level heating processing operations in a tuna fish tinning process. Besides, the solar thermal system can directly supply heat to low heat requiring operations. Kumaresan et al. (2012) investigated the performance of a solar parabolic collector integrated with a thermal energy storage system and reported that the stored thermal energy can be utilized for the processes requiring medium-level heat energy in the food processing industries. The authors suggest that two options for the integration of renewable energy in the seafood industry. As a direct energy-saving measure, the solar photovoltaic panels can be installed in the plant to generate electricity and it can be combined with conventional sources as hybrid power. Secondly, solar thermal technology can be used in heat processing operations, thus indirectly saving the energy used in the heat processing operations of the seafood industry.

4.1.6. Energy generation from food waste

Very recently, seafood waste has been considered to be having huge potential for the preparation of various value-added products like chitin and chitosan from shrimp shell waste. Waste to energy generation can be considered as a viable option since this approach not only provides energy to the plant but also lessens the burden of the waste disposal problem. The seafood waste can be converted into fertilizer and aqua or poultry feed by anaerobic digestion or fermentation and as biogas/producer gas using gasification and pyrolysis process (Nikmaram and Rosentrater, 2019).

4.1.7. Refrigeration system management

Refrigeration units are a key part of the seafood processing industry. Some low-cost energy efficient methods for proper maintenance of refrigeration units were reported by Galitsky et al. (2005a). The methods are ensuring proper closing of cold storage, leakage detection, ensuring proper temperature in cold storage (every 1 °C increase in temperature results in 1–3% increased energy demand), proper defrosting of the cold storage door, proper lubrication of compressor, ensuring the correct amount of refrigerant charge because the low and high charge will increase energy consumption by 20%, frequent contaminant checking of refrigerant, having least bends in pipes, and fittings for interconnecting pipes, installing thermal energy storage system for cooling, segregation of different cooling requirements, free cooling of outside air for air conditioning of building which can reduce the movement of hot air infiltration to the refrigeration chamber, installation of a cooling tower in which the air in contact with warm water evaporates water to some extent.

In the compressors, increasing suction pressure and temperature of the low stage compressor can reduce the energy consumption, and in the case of two-stage compressor systems saves 8% of energy demand (Iowa State University (ISU), 2005). In the condenser, the use of hard water for water-cooled and evaporative condensers should be avoided. Automatic purging of condensers can be used to remove non-condensable gases (Centre for Analysis and Dissemination of Demonstrated Energy Technologies (CADDET), 1996). In large-scale plants, condenser temperature and pressure should be fixed at a minimal level using the computer controls based on ambient wet bulb temperature for reducing the energy consumption during refrigeration (ISU, 2005). Each degree Celsius reduction in condensing temperature saves compressor energy by 2–3%. Studies reported that the use of axial fans instead of centrifugal fans in air-cooled or evaporative condensers reduced the fan load by up to 50% (ISU, 2005). Defrosting of the evaporator should be done only if there is an increase in pressure drop in evaporating coil and water defrosting is found to be more efficient provided that water should not be frozen in the evaporator coil (ISU, 2005). The duct leakage inspection should be carried out periodically in all firms and that would reduce the energy consumption of HVAC (Heating, Ventilation & Air-Conditioning) up to 30% (Galitsky et al., 2005b).

The authors propose the following management practices in the refrigeration system to save energy and reduce the cost of processing seafood. It was observed that in seafood industries, running compressor units alone require 75% of the total connected load. Hence, the conventional reciprocating compressors can be replaced by energy-efficient screw compressors. The compressor operation should be monitored continuously and may appropriately be switched on or off based on the load requirement. Appropriate care may also be taken on the type of freezer and product being handled which is responsible for fluctuating energy consumption patterns on daily basis. Mostly, irregularly shaped products may be frozen on blast freezers, blocks and packages especially fish fillets may be processed in plate freezers for effective energy utilization.

4.1.8. Modeling energy use

Mathematical modeling and simulation techniques can be used to understand the energy use pattern in the seafood processing plant. Several mathematical and computational intelligent-based systems have been applied to model and optimize the energy flows of the food supply chain (Nikkhah and Van Haute, 2020). Mathematical (multiple linear regressions, data envelopment analysis) and computational intelligent-based (artificial neural networks, adaptive neuro-fuzzy inference systems, genetic algorithm) approaches are widely used for modeling and optimization of the energy flow in the food supply chain. Frontier technologies like Artificial Intelligence (AI), Internet of Things (IoT) and Machine Learning (ML) systems can effectively be used for prediction and optimization of energy use in processing plants. Subramanian et al. (2018) suggested three application areas of energy modeling that is optimal design and operation of flexible processes using demand and price forecasts, sustainability analysis and process design using hybrid methods, and accounting for the feedback effects of breakthrough technologies.

4.2. Water optimization methodologies

Water consumption in seafood industries is substantially high due to the water-intensive activities involved in the process line (Tomczak-Wandzel et al., 2015). Besides this fact, the irresponsible handling of water by the industries aggravates huge water loss due to both over-utilization of freshwater resources and improper disposal of wastewater thus generated (Safe Drinking Water Foundation (SDWF), 2017).

4.2.1. Automation of equipment and process-line

Automation of water circulatory system is mainly aimed to have an improved process water control. The reduction of water consumption in the seafood processing line is possible by automating the equipment which cannot be easily overlooked. The conventional taps in the waterline may be replaced with self-closing ones like solenoid one-way valves. The solenoid valves in the water supply system can be operated automatically employing a controller through an Internet of Things (IoT) system to help track and allocate water. It has been reported that cut-off valves, flow diversion valves, and water flow meters were dependable accessories that could be used to reduce water usage in the seafood processing industries (BIM, 2017). OSU (2016) reported that improved design of equipment utilizing superior materials of construction, improved design concepts, and materials handling may be much more efficient in water-saving than existing equipment. Seferlis (2008) reported that automation of existing equipment in the process line could increase the water and energy use efficiency in the food industry. Souza et al. (2018) reported water management practices for the processing of Atlantic Salmon and dolphins. The authors employed water flow meters and electrical devices to control the water usage in the cleaning process and reused relatively clean wastewater for minor requirements in the warehouse. It is observed that the industrial automatic control systems presented in the section provide an important insight into the development of integrated control and decision support systems for the effective usage of water in the seafood industries.

4.2.2. Monitoring water use pattern and water quality

The continuous monitoring of real-time water use in the industry could provide a lot of insights into the water optimization framework strategies. The appropriate sensors and flow meters may be installed at specific points in the process line. These arrangements can be particularly helpful in detecting any leaks by observing the sensor readings during the water usage (United Nations Environment Programme (UNEP), 1999). Although this installations can incur some initial expenses to the industry, the savings both in terms of money and resources are exceptionally high. Many researchers have successfully developed systems for online water use and quality monitoring based on different algorithms. Partalas et al. (2008) employed algorithms for ensembles of regression models to predict water quality. Similarly, a hybrid approach of support vector regression with genetic algorithm optimization was investigated for water quality forecasting in aquaculture ponds by Liu et al. (2013). An online water monitoring system based on ZigBee and GPRS to detect several chemicals in the water (Wang et al., 2011) can be applied in the seafood industry and appropriate waste treatment options may be executed before its reuse. Yu et al. (2016) used a hybrid intelligent method for predicting dissolved oxygen content in crab culture. Thus, these water quality prediction techniques may appropriately be followed to treat and reuse the water.

4.2.3. Recirculation and recycling

While considering the mandatory safety standards established for the seafood industry, it is a prerequisite to adopt the most suitable technology to recycle and reuse the water in the process lines. The reusability of water can be improved by taking into consideration of different water streams from the various operations which may aid the water reuse option and improve wastewater treatment efficiency (Guimarães et al., 2018). Using the automated design methodologies minimum water supplies can be targeted for the various seafood industry operations. It has been reported that a recycling unit in thawing equipment can reduce water consumption by 60% (Fish Processing, 1996). Nevertheless, opportunities for possible recirculation of water may be explored to reduce water consumption in the seafood industries as reported by Danielson and Spuhler (2018) at the office and household, and Theobald (2017) for water optimization strategies in food processing industries. The recycled water can be used for employee washrooms, ETP operations, and direct groundwater recharging purposes.

4.2.4. Updating or modifying conventional systems

Minor changes may be incorporated into the existing system to utilize the available resources effectively. For example, a trigger action based shut-off devices or nozzles can be fitted onto the water hose, the addition of timers or pedals to ensure metered discharge of water, adjusting the flow to the minimum required level to maintain performance (OSU, 2016). This can be relatively cheap in investment but can tremendously improve the cleaning potential of water since it is pressurized during application. Almost a 40% reduction in water usage can be attained by employing the pressurized application method (Fish Processing, 1996).

4.2.5. Waste minimization in the seafood industry

The first step to implement waste minimization is to segregate waste generated from the different production processes. It aims to separate waste streams according to the type of component, and further concentrate to facilitate and reduce the volume and the cost of waste treatment. Tomczak-Wandzel et al. (2015) had reported that quick separation of waste products from used water in the process plant ensures lesser effort for treatment. Solid waste can be easily minimized by recovery and recycling into value-added products, while liquid waste and other wastewater can be reused appropriately in the same processing line. Large amounts of waste and by-products are generated in the seafood processing plants like skin, flesh and bones. Some of the byproducts contain functional bioactive compounds and have elevated protein and amino acid levels. About 20–80% of waste generated can be utilized for the preparation of fish silage, fish sauce, and fishmeal (Ghaly et al., 2013). Other fish and fishery products waste can be used for the preparation of various value-added products like proteins, amino acids, oil, minerals, bioactive peptides, enzymes, and collagen. Thus, efficient utilization of wastes and by-products would decrease the waste generation and correspondingly energy and water required for wastewater treatment can be decreased (Tomczak-Wandzel et al., 2015). Kurniasih et al. (2018) reported that minimization of waste generated in the seafood industry can save 27.2% of clean water that is to be used for the production process in a week. As a result of waste minimization approaches, the reuse and recycling of liquid waste can generate the economic potential of 51% of the freshwater used in the production process.