1. Introduction

There is no well drilled today without the use of drilling fluids. These fluids may vary in composition but their functions remain largely the same. Apart from transporting cuttings from the bottom of the well to the surface, keeping the drill bits and drillstring cool, holding cuttings in suspension when mud circulation ceases and preventing formation fluids from prematurely gaining access into the wellbore; drilling fluids also are designed to reduce filtrate loss to the formation, form thin filter cakes that plaster the walls of the borehole to ensure minimal fluid loss to the formation and promote the stability of the drilled well. However, it should be noted that when a permeable formation is exposed to drilling mud during mud circulation, the liquid components of the mud would find its way into the formation while the solid components of the mud would build a thin cake of mud solids on the wellbore walls. This initial filtration is referred to as spurt loss (Kumar, 2010). After a mud cake is formed, the loss of filtrate from then on is referred to as continuous fluid loss and is detrimental to drilling operations (Azar and Samuel, 2007). During overbalanced drilling operations, there are two mechanisms notable for the filter cake build up process. They are the static and dynamic filtrationmechanisms (Bageri et al., 2013). According to Annis and Smith (1996), filtration of a dynamic nature essentially takes place while mud circulation is in progress whereas static filtration takes place when the mud circulation ceases. A clear line of distinction exists between both filtration types. First, mud flow essentially reduces the cake thickness due to erosion effects of the flow whereas mud cake thickness grows in static filtration conditions. There is a general consensus among researchers that filtration of a static nature enhances the growth of the cake while dynamic filtration helps in retarding the growth of the cake (Dewan and Chenevert, 2001). Enumerating the importance of a thin filter cake, Baroid Industrial Drilling Products (2017) opined that the ability of mud to form a thin mud cake, with low permeability values is an attractive property since it has a lot to do with the usability and functionality of the drilled wellbore. On the reverse side, when rotation is stopped and left non-rotating for long periods in the wellbore, with a thick filter cake in the well, one may likely be facing a plethora of problems which may include but are not limited to: differential pressure sticking, lost circulation, logging problems, high torque and high drag issues, problems in installing casings downhole and faulty cementing jobs (Annis and Smith, 1996). Having noted these, therefore, a description of the quality of the filter cake is important since a mud engineer reports them, and records it on the mud report along with filtrate volume and cake thickness (Schlumberger, 2017a, Schlumberger, 2017b, Schlumberger, 2017c). In times past, engineers formulating drilling muds have been making use of polyanionic cellulose (PAC) and carboxymethyl cellulose (CMC) as well as various polymers as filter loss control additives (Caenn and Chillingar, 1996). However, polymers as Igwe and Kinate (2015) put it, are stable at circulating temperatures, but can decompose to form residues when subjected to static reservoir temperatures for long periods of time. Over time, there has been a shift from using commercial polymers to using agro-wastes containing cellulose as filtration loss control agents in drilling fluids. Dagwa et al. (2012) puts it that the use of agro-wastes is attractive due to the numerous advantages it offers especially in the aspects of cost effectiveness and reducing environmental hazards. Reeling out the benefits of cellulosic wastes, Malik et al. (2017) opined that materials containing high cellulose contents are cost effective and their use is widespread. As a result of this, many scholarly papers have been published in both local and international journals that address the subject of using cellulosic agro wastes in oilfield applications. Most of these publications give qualitative and quantitative studies of what has been done in assessing how useful these wastes containing celluloses are in drilling fluids as fluid loss control agents. However, due to the elaborate nature of the studies that have been presented by diverse researchers, there is need to assess all the studies and the research findings in one piece so as to isolate what has been achieved and identify possible areas of interest where more studies should be directed. To achieve this, this paper made a chronicle of the available studies on the use of agro-wastes containing cellulose for use as filter loss control agents in drilling muds. The various research findings as presented by diverse authors are highlighted and the future research needs on the subject are presented. However, there is a limit to what can be accomplished in just an article, hence, considering the list of all cellulosic materials that could possibly be used as filter loss control agents in drilling muds in one review paper would in itself not be wrong but it is deemed that their inclusion in this work would overcharge and widen its scope. Therefore, the cellulosic agro waste materials reviewed in this work were narrowed down to the ones that are readily available in Nigeria namely: rice husk, saw dust, groundnut (peanut) husk, coconut shell, kernel nut shell, cassava, millet, wheat, newspaper, wood, potato, grass (bamboo, elephant grass) etc. Table 1 shows the selected cellulosic materials and their availability.

Table 1. Statistical data for cellulosic material production in Nigeria.

| Material/source of cellulose | Nigeria's Production | Units of measure | Source | Region of Nigeria where they are grown |

|---|---|---|---|---|

| Cotton | 235 | (1000 480 lb. Bales) | USDA (2017b) | Northern and South western region |

| Millet | 4800 | (1000 MT) | USDA (2017c) | Northern Nigeria |

| Corn | 6900 | (1000 MT) | USDA (2017a) | Niger, Kaduna, Taraba, Plateau, Adamawa |

| Rice | 4400 | (1000 MT) | IRRI (2017) | Enugu, Cross River, Ebonyi, Benue, Borno, Kaduna, Kano, Niger and Taraba |

| Cassava | 47,406,770 | Tonnes | Obudulu (2017) | South East and South South regions (Wikipedia, 2017) |

| Palm Oil | 970 | (1000 MT) | USDA (2017e) | South East and South South regions |

| Groundnut | 3000 | (1000 MT) | USDA (2017d) | Northern Nigeria (Ajeigbe et al., 2014) |

| Coconut | 267,520a | Tonnes | Fact fish (2016) | South East and South South regions |

| Potato | 1,200,000b | Tonnes | Potatopro (2013) | Plateau, Kaduna, Kano, Katsina and Bornu state |

| Bamboo | Abundant | – | – | South West, South East region (Ogunwusi and Onwualu, 2011) |

| Elephant grass | 20,800c | kg DM/ha per year | FAO (2011) | Southern Nigeria |

| Wheat | 60 | (1000 MT) | USDA (2017f) | Northern Nigeria |

| Newspaper | Abundant | – | – | All parts of Nigeria |

| Wood | Abundant | – | – | South West and South South regions |

- a

-

Data as at 2014.

- b

-

Data as at 2013.

- c

-

Data as at 2011.

It must be said that for all the cellulosic materials chosen for this study for use as filter loss agents are essentially not competing with humans as food but are from the by-products of the crops and/or plants of their origin. Hence, a wide variety of cellulosic agro-waste materials are available for use as filter loss control additives. Typical examples are fibres, roots, husks etc. From Table 2, the crop/plant where the cellulose is obtained is shown while the part of the crop/plant considered a waste is highlighted as well as the cellulose and hemicelluloses content in percentages are shown. From the table, it is seen that cotton stalk has the highest cellulose content while palm kernel nut shell has the least cellulose content.

Table 2. Cellulose and hemicellulose composition of selected cellulosic materials.

| Crop/plant/source from which cellulose is obtained | Part of plant or crop used for cellulose extraction | Cellulose content (%) | Hemicellulose content (%) | Source |

|---|---|---|---|---|

| Cotton | Cotton seed hull | 48.7 | 18.5 | Wartelle and Marshall (2006) |

| Cotton stalk | 62 | 18 | Yanik et al. (2007) | |

| Millet | Millet husk | 44.9 | 36.2 | Raveendran et al. (1995) |

| Cassava | Cassava peels (dry) | 37.9 | 37 | Aripin et al. (2013) |

| Corn | Corn cob | 38.4 | 40.7 | Feng et al. (2006) |

| Corn stalk | 49 | 37.9 | Kristensen, 1996, Raveendran et al., 1995 and Yanik et al. (2007) | |

| Rice | Rice husk | 43.8 | 31.6 | Kristensen, 1996, Nakbanpote et al., 2000 and Raveendran et al. (1995) |

| Rice straw | 28–36 | – | Rowell (1990) | |

| Oil Palm | palm fruit fibre | 44.29 | 12 | Chiejina and Osibe (2015) |

| Oil pam mesocarp fibre | 60 | – | Satyanarayana et al. (1981) | |

| Palm kernel nut shell | 6.92 | 26.16 | Okoroigwe et al. (2014) | |

| Groundnut | Groundnut shell | 42.2 | 22.1 | Raveendran et al. (1995) |

| Coconut | Coconut husk | 40 | 0.2 | Reddy and Yang (2005) |

| Coconut shell | 14 | 32 | Cagnon et al., 2009, Hasanah et al., 2012 | |

| Grass | Bamboo | 43.9 | 26.5 | Abbasi and Abbasi, 2010, Scurlock et al., 2000 |

| Elephant grass | 31.5 | 34.3 | Abbasi and Abbasi (2010) | |

| Wheat | Wheat Straw | 32 | 33 | Chen et al. (2008) |

| Barley | Barley straw | 48.6 | 29.7 | Abbasi and Abbasi, 2010, Naik et al., 2010, Sander, 1997, Tamaki and Mazza, 2010 |

| Newspaper | Newspaper | 40.0–55.0 | 25.0–40.0 | Chandra et al. (2012) |

| Wood | Gmelina wood saw dust | 27.14 | 13.50 | Chiejina and Osibe (2015) |

| Mahogany wood saw dust | 51.71 | 13.00 | Chiejina and Osibe (2015) |

2. History of using agrowastes in the oil and gas industry

The potential of agro wastes to be transformed into a portfolio of usable products is undeniable as their usage is found diverse fields such as civil engineering, building construction, wood work etc. The oil and gas industry is not left out. Most technical applications of agro wastes have been in the area of lost circulation prevention. Their usage as lost circulation materials (LCM) dates back to the history of drilling fluids and by extension the drilling industry (Almagro et al., 2014, Bruton et al., 2001). However, Almagro et al. (2014) further added that the early LCMs were more of wastes from manufacturing processesand they were chosen because they were inexpensive and readily found near the drill sites. However, it is necessary to define what lost circulation is. Lost circulation is defined as a condition in which the path of the drilling mud and/or cement slurry is short circuited; thereby leading the mud to be lost to one or more unintended zones in the formations instead of returning up the annulus (Nelson, 1990). By extension, lost circulation materials (LCMs) are essentially additives of small or fine particle size that can effectively control the loss of drilling fluid into thief zones. Almost every conceivable material has been used (either in the laboratory or in the field) as a lost circulation material (Culver, 2007, Krause, 1991). In attempting to evaluate materials in the laboratory, an effort is made to simulate field conditions but this does not really capture all the dynamics that would be experienced in the field. Thus, in order to ascertain the true value of any product or additive to drilling muds, the performance of such an additive or product in the field is the only reliable yardstick. Hence this section discusses the pros and cons of specific agro wastes that are used as LCMs and most importantly the field applications of these agro wastes as LCMs. This is summarized in Table 3. In the table, four agro waste materials namely – walnut hulls, saw dust, a blend of agro wastes and cotton seed hulls are highlighted. From the table, it is observed that walnut hulls are effective as LCMs due to their ability to resist degradation, though one drawback in their use is that they may wear out the rubber parts of mud pumps, however, in the field, it is well reported to be a good lost circulation material. On the other hand, saw dust though cheap and non-reactive is not suitable for use in oil based muds and may not be effective if used alone in the field as a lost circulation material. Finally, a blend of the agro wastes is reported to be useful in multiple ways. They are reported to perform better in preventing lost circulation in the field than when the individual agro wastes are used.

Table 3. Overview of agrowastes used as LCMs, their pros and cons and field applications.

| Agrowaste | Pros | Cons | Field application |

|---|---|---|---|

| Walnut hulls | Due to their high compressive strength, they are most resistant to breakdown and degradation prevents the bit balling problem (GEO Drilling Fluids Inc., 2010a). They reduce torque and drag of drill pipe and drill collars, increase rotary speed and drilling rates (Scott and Lummus, 1955). | Drilling experience has shown that using coarse walnut hulls causes valve sticking and accelerated wear and tear of rubber parts in mud pumps (Scott and Lummus, 1955) | Scott et al. (2012) reports that 40lbm/bbl of walnut were added to an 8.8 lbm/gal mud to drill a depleted zone with 4000 psi overbalance. It was observed that over a 5 day period of drilling and circulating, only 4% of the size was degraded showing that walnuts are highly resistant to degradation; Scott and Lummus (1955) report that when 75bbl of mud containing 50lb/bbl of ground walnut shells was squeezed into a loss zone in a wildcat well drilled in Duval County area of Texas, the loss of circulation was cured |

| Saw dust | Saw dust is an inexpensive and non- reactive LCM. It is composed of various particle sizes which are useful in plugging a wide range of pore and fracture sizes (GEO Drilling Fluids Inc., 2010b) | Saw dust proves to be uneconomical in oil based muds due to its absorbent property (Adams and Eustes, 2011); Degrades at high temperatures (Kandarpa and Vetter, 1980). | As reported by Gorter et al. (1982), saw dust was used as part of a gel caustic mud system to cure lost circulation that occurred while drilling the 17.5 inches hole in a well named Wallaby-1 in Australia. A total of 820 kg of saw dust was expended as part of the mud system |

| Blends of agrowastes used as LCMs | Useable in multiple applications, reduce permeability and spurt losses (Luzardo et al., 2015) yields better performance in preventing losses (Almagro et al., 2014, Kumar and Savari, 2011, Nayberg and Petty, 1986, Whitfill, 2008, van Oort et al., 2009). | Not available | As reported by Cremeans and Cremeans (2003), the blend of cottonseed hulls, sawdust, cross linked polymer and corn starch was added to a mud system and used for drilling. The fluid was circulated for about 90 min. The fluid was effective in stopping the loss of circulation. |

| Cotton seed hulls | Not available | Degrades at high temperatures (Kandarpa and Vetter, 1980). | Kinchen et al. (2001) reported of a field in the Indian Basin field, Eddy County, New Mexico experiencing lost circulation due to the vuggy and fractured nature of the formation. Circulation was re-established when pills comprised of cotton seed hulls and other materials were pumped into the formation. |

2.1. A review of lost circulation and lost circulation materials

In order to fight lost circulation, the oil and gas industry has over time relied on three types of agents. These include: (1) bridging, (2) gelling, and (3) cementing agents. Of the three types, the one used almost always depends on the stage in the life of the well. Bridging agents can be classified as fibrous, flake, granular, or blended (Ali et al., 1991). This classification is in sync with other works. For instance, conventional lost circulation materials (LCM's) have been classified based on their appearance as fibrous, flaky, and granular or a blend of all three (Canson, 1985). However an updated classification has been made by Alsaba et al. (2014) wherein they reclassified LCMs into the following categories: granular, flaky, fibrous, LCM's mixture, acid soluble, high fluid loss LCM squeezes (HFLS), swellable/hydratable LCM's, and nanoparticles. A summary showing the specific examples of LCMs, their mechanism of preventing lost circulation, their advantages and disadvantages and their application scenarios are summarized in Table 4.

Table 4. Review of the types of lost circulation materials.

| Types of lcm | Examples | Mechanism of preventing lost circulation | Advantages | Disadvantages | APPLICATION SCENARIOS |

|---|---|---|---|---|---|

| Fibrous LCMs | Saw dust, Shredded paper, Cellulose, Nylon and Mineral fibres (Alsaba et al., 2014) | Forms a mat-like bridge on the wall of the wellbore thus providing a filtration medium for smaller particles to deposit and form a cake (Howard and Scott, 1951, Nayberg and Petty, 1986) | Low cost, non-reactive in nature (GEO Drilling Fluids Inc., 2010a, GEO Drilling Fluids Inc., 2010b); non-abrasive; increases mechanical strength of formations (Luzardo et al., 2015); Less rigid in nature, easy to be pumped into large openings and useful for wellbore strengthening (Adams and Eustes, 2011) | Degrades at high temperatures; May not be applied to OBMs since most of them are absorbents (Adams and Eustes, 2011); swelling and shrinking of fibres can occur in the presence of moisture (Luzardo et al., 2015); they may plug off the ports of coiled tubing nozzles (Nayberg and Linafelter, 1984) | Applicable to porous and highly permeable formations |

| Flaky (Lamellar) LCMs | Cotton seed hulls, Corn cobs, Cellophane, Mica, Vermiculite, Flaked CaCO3(Alsaba et al., 2014) | Forms a mat like structure on the wall of the hole (Howard and Scott, 1951, Nayberg and Petty, 1986) | Not available | Cementing equipment at surface and downhole may be plugged hence not normally used in cement; may contain chemicals that extend thickening time of cement (Adams and Eustes, 2011) | Applicable to highly porous formations (Luzardo et al., 2015) |

| Granular LCMs | Nutshells, Graphite, sized, CaCO3, Perlite, Glisonite, Coarse bentonite (Alsaba et al., 2014) | Forms a seal at the wellbore wall or within the fracture (Howard and Scott, 1951, Nayberg and Petty, 1986) | Useful for wellbore strengthening because of their rigidity and resistance to crushing (Mansour et al., 2017) | Not available |

Applicable to fractured or highly permeable formations (Schlumberger, 2017) |

| Nanoparticles | Calcium Carbonate, Silica, Iron Hydroxide (Contreras et al., 2014) | Not available | Effective in plugging pore throats, controls spurt and fluid loss thus reducing formation damage, can reduce friction and wear and improve fluid rheology (Luzardo et al., 2015) | Nanoparticles can be expensive (Luzardo et al., 2015) | Not available |

| High fluid loss LCM squeeze | Cement-bentonite, Cement, Cement-gilsonite, Diesel- bentonite-cement (Economides et al., 1998). | They form a plug that seals the loss zone (Alsaba et al., 2014) | Provides a permanent solution for the loss circulation problem, Effective against complete and severe losses (Luzardo et al., 2015) | Cannot be applied to producing zones, An irreversible process, mixing, pumping and setting times leads to delay in the drilling process (Luzardo et al., 2015) | Used in curing complete losses in fractured or highly permeable formations (Alsaba et al., 2014); Applied to non-producing zones (Luzardo et al., 2015) |

| Mixture of LCMs | Blends of fibrous, flaky and granular LCMs | Penetrates fractures and voids and seals them (Luzardo et al., 2015) | Useable in multiple applications, reduce permeability and spurt losses (Luzardo et al., 2015) yields better performance in preventing losses (Almagro et al., 2014, Kumar and Savari, 2011, Nayberg and Petty, 1986, Whitfill, 2008, van Oort et al., 2009). | Possibility of removing granular materials at the solids control unit; the density and viscosity of the mud may be altered depending on the particle size; particle size selection may be difficult (Luzardo et al., 2015) | Applicable to highly permeable zones, fractures and vugular formations (Luzardo et al., 2015) |

| Acid/Water Soluble | CaCO3, Mineral fibres, Sized salts | Not available | Can be used for different types of formation, They are non-damaging to reservoir sections, ability to build up firm and acid soluble filter cake (Luzardo et al., 2015) | Acidizing practices for its removal can lead to formation damage, Requires much higher solids loading to achieve optimum seepage loss control (Luzardo et al., 2015) | Used to cure lost circulation in reservoir sections (Luzardo et al., 2015) |

| Hydratable LCM combination | Blends of LCMs with reactive materials such as polymers (Alsaba et al., 2014) | They form a plug that seals the loss zone (Alsaba et al., 2014) | No risk of bit nozzles plugging, can cover a wide range of fracture widths (Luzardo et al., 2015) | Requires special placement techniques in order to get to the right location (Alsaba et al., 2014, Luzardo et al., 2015) | Not available |

From Table 3, Table 4, it is observed that differences in texture, thermal stability, compressive strength, cost and their effect on the payzone are factors that influence how and where the LCMs are deployed. In addition, it is observed that sandstone formations which are naturally porous and permeable require LCMs that form a mat-like bridge on the wall of the borehole to combat lost circulation e.g. fibrous and flaky LCMs. However, in fractured and highly permeable formations, LCMs that can plug, seal and limit the growth of the fractures are used. Examples include high fluid loss LCM squeeze, mixture of LCMs etc.

3. Studies into the use of cellulosic agro-wastes as filter loss control agents in drilling muds

In recent history, the use of cellulosic agro waste materials has taken a widespread dimension leading to considerable attention by researchers. The increased attention is attributed to the tripartite advantages they offer namely: their low cost, bio-renewability and availability (Belgacem and Gandini, 2008). Various authors at different times have carried out studies on using different materials containing cellulose as filter loss control additive in drilling muds. Researches into the use of agro-waste materials as filtration control agents in drilling muds date back over six decades. The growing body of evidence from work in this field indicates that there has been some back and forth oscillations on the use of various agro-waste materials as drilling fluid loss control agents. For instance, Rogers (1963) reports that as pre-gelatinized starches took the centre stage in the early 1940's, the use of cooked starch ended. This indicates that starches were used as fluid loss additives prior to that time. Emerging thereafter were the works of researchers such as Lummus and Ryals, 1971, Morris, 1962 and Nestle (1952) where they evaluated cellulosic materials such as peanut shells, ground peach seeds and tree bark (Douglas fir) respectively as possible filtration control agents. In recent times, the use of polymers is common. The trend later reversed with the re-emergence of cellulosic materials in the 1990's as seen in Table 5. During this time, starches from different plants such as cassava, corn, millet, potato etc. were tested for their suitability (Ademiluyi et al., 2011, Amanullah and Yu, 2004, Nyeche et al., 2015, Ukachukwu et al., 2010). However, having the benefit of hindsight from the works of early researchers puts the subject into broader perspective and illuminates the road ahead. A summary of recent researches in this area, the cellulosic material used by the authors, the property of the material they studied as well as their major findings has been highlighted in Table 5.

Table 5. Summary of previous researches into the use of agro-waste materials as fluid loss agents in drilling fluids.

| Author(s), year | Material used | Property of material studied | Major findings |

|---|---|---|---|

| Akaranta and Osuji (1997) | Orange mesocarp | Filter loss | It is possible to produce carboxymethylated products from orange mesocarp cellulose comparable to a commercial grade CMC in imparting desirable basic properties in drilling muds |

| Ismail and Idris (1997) | Sago and tapioca starches | Filter loss | The presence of sago and tapioca starch in drilling mud could reduce fluid loss by 90%. When compared with PAC and tapioca, sago experienced lower fluid loss. Large amounts of sago and tapioca was needed to produce same viscosity as PAC |

| Bazarnova et al. (2001) | Carboxymethylated Aspen wood (Saw dust) | Rheology, fluid loss and pH | Carboxymethylated aspen wood reduced the filtration index, gel strength, and yield point of bentonite clay composites without changing their elastic and relative viscosities. This allows use of such composites for preparing drilling fluids |

| Amanullah and Yu (2004) | Corn based starch | Filter loss | The corn based starch developed had better filter loss control characteristics. |

| Iscan and Kok (2007) | Walnut shells | Rheology and filter loss | The pulverized walnut shell of 6 mm was effective in reducing filter loss |

| Ukachukwu et al. (2010) | Millet starch | Rheology and filter loss | The millet starch holds good promise as a filter loss control material and was stable at high temperatures |

| Hamida et al. (2010) | Waxy hull-less barley (WHB) | Filtration loss | WHB displayed good filter loss characteristics. |

| Ademiluyi et al. (2011) | Cassava starch | Filter loss and viscosity | Cassava starch can be used as filter loss control additive |

| Adebayo et al. (2012) | Saw dust | Filter loss and cake thickness | Sawdust gives good viscosity and gel values though kaolin should be added to improve cake thickness |

| Adebayo and Chinonyere (2012) | Saw dust | Filter loss and density | Large sizes of sawdust particles controlled filter loss better than smaller sized particles though the cakes obtained with large particle sizes are unstable |

| Olatunde et al. (2012) | Gum Arabic | Filter loss, gel, rheology | Gum Arabic can be used as filter loss additive. |

| Chike–Onyegbula et al. (2012) | Guinea corn starch | Filter loss | Guinea corn starch is a viable alternative to conventional filter loss control additives |

| Azizi et al. (2013) | Agarwood waste | Filter loss | Agarwood waste has the potential to be used as filter loss additive |

| Egun and Abah (2013) | Cassava starch | Filter loss | Cassava starch can be used as filter loss control additive |

| Samavati et al. (2014) | Acid modified Fufu starch | Filter loss, rheology | Acid modified fufu starch showed great potential as a filter loss control material |

| Okon et al. (2014) | Rice husk | Filter loss and filter cake thickness | The rice husk reduced filter loss to an extent comparable to PAC and CMC |

| Dagde and Nmegbu (2014) | Groundnut husk | Filter loss | At high concentrations in a drilling mud, peanut husk can compete favourably with PAC as filter loss additive |

| Nmegbu and Bari-Agara (2014) | Corn cob cellulose | Filter loss, pH, mud density, rheology | The corn cob cellulose reduced filter loss to an extent comparable to PAC |

| Anawe Paul et al. (2014) | Rice husk and Saw dust | Filter loss, pH viscosity, density | For rice husk to be used as filter loss agent in OBMs, modifications should be made for a desirable mud cake thickness to be achieved. |

| Ghazali et al. (2015) | Corn starch | Filter loss | Increased concentration of corn starch reduces filter loss, hence can be used as filter loss control additives |

| Nyeche et al. (2015) | Potato starch | Filter loss | A combination of potato starch and PAC in a near equal proportion is suitable for the improvement of filter loss control properties of mud for economic reasons. |

| Dias et al. (2015) | Corn starch | Filter loss | The results showed that the formulations developed from starch can be used as alternatives to the conventional product |

| Hossain and Wajheeuddin (2016) | Grass | Rheology and filter loss | Smaller sized grass particles are suitable for good filter loss control |

| Samavati and Abdullah (2016) | Ubi kayu starch | Filter loss | Ubi kayu displayed an adequate fluid loss (under 2 ml at drilling temperature of 250 °F for light, average and heavy mud weights with the values of 1.4, 0.8 and 0.4 ml, respectively. At 275 °F only average weight mud samples exposed an acceptable fluid loss volume (0.4 ml). This starch failed as a filter loss control agent when subjected to a temperature of 300 °F (with volume ranging from 60 to 250 ml) |

| Chinwuba et al. (2016) | Pleurotus tuber-regium (King tuber Mushroom) | Fluid loss and cake thickness | The Pleurotus tuber regium performed poorly as a filter loss control agent. It is not available and is thermally unstable. |

| Salamachi et al. (2016) | Psyllium husk | Rheology and filter loss | The psyllium husk was found to have adequate rheological properties comparable with 5% by weight of bentonite. The laboratory findings further indicate that psyllium husk has the potential to be used as a viscosity and filter loss control agent in WBMs |

| Zoveidavianpoor and Samsuri (2016) | Cassava starch | Filter loss, cake thickness and mud rheology | Nano sized tapioca starch is effective in filter loss control in WBM controlling loss by more than 60%, while keeping thickness of the filter cake reduced by a little more than 80%. |

| Harry et al. (2016) | Cassava starch | XRD of starch, viscosity and fluid loss control | Cassava starch can be used as filter loss control additive |

| Amanullah et al. (2016) | Date seed powder | Filter loss | Date seed powder can be used as a filter loss control additive in clay free water and salt water based muds |

| Salawudeen et al. (2016) | Defattened achi (B. eurycoma), coconut fibre and corn starch fibre | Filter loss | The combination of achi, coconut fibre and corn starch fibre performed well as a filter loss reducing agent in drilling mud. To achieve this result, a low fibre content of 0.25 g of the two fibres is required while a high concentration of 1.25 g is required on the part of the achi. |

| Saengdee and Terakulsatit (2017) | Sugar cane bagasse ash | Filter loss | Sugarcane bagasse ash reduced filtrate loss and produced thin and consistent cakes; however, the cake thickness and filter loss volumes increased with increasing temperature |

| Seteyeobot et al. (2017) | Rice husk and plantain peelings | Rheology and filter loss | In substantial amounts, a mixture of rice husk and plantain peelings can be used as a rheology and filtration control additive in drilling muds |

| Onuh et al. (2017) | Coconut shell and corn cobs | Filter loss | In comparison, corn cobs prevents filter loss better than coconut shell, however when both are combined, their performance as fluid loss control agents increases than when used singly |

| Igwilo et al. (2017) | Annona muricataand Carica papaya | Filter loss | Annona muricata and Carica papaya can be used as fluid loss control additives for WBMs, however, in comparison, Annona muricataperformed better than Carica papaya in controlling fluid loss |

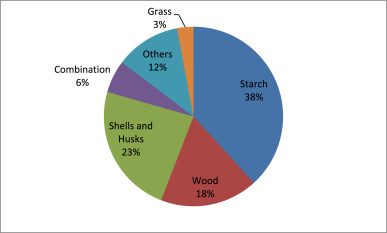

Taking a closer look at Table 5, it is observed that most researchers studied the starch extracts from different plants, but some new introductions such as grass, orange mesocarp, psyllium husk, sugarcane bagasse ash, Annona muricata and Carica papaya are observed. The trials of these new materials as possible fluid loss control materials with positive outcomes show that the research frontiers keep being pushed. To have a better understanding of the trend of studies in this area with the materials being used as a focal point, a pie chart showing the leaning of the researchers on the basis of the material they tested as possible fluid loss control material is shown in Fig. 1. From the figure, it is observed that starch was the most studied material accounting for 38% of the researches while shells and husks follow with 23%. The least was grass with 3% where only one researcher made trials which he found successful.

Fig. 1. Percentage leaning of studies on different groups of agro-waste materials.

Fig. 1. Percentage leaning of studies on different groups of agro-waste materials.Starch was the most studied material probably because of its gelling characteristics; though it has a major drawback which is degradation. However, since the sources of these starches do not compete with food such as in the case of potato peels, cassava peels etc., then studies on their use as possible fluid loss control agents is not misplaced. On the other hand, the most probable reason wood did not receive much research attention may be that it has a number of applications and the sawdust generated from wood operations may not be readily available because they are used for a variety of other purposes. Such purposes as the USDA (1969) put it include: (1) absorbents; (2) abrasives; (3) fibres; (4) insulators. Following the extensive narrative on using starch as a fluid loss control material, it is imperative to ascertain the starch content (if any) of cellulosic agro-wastes. Table 6 chronicles this. From the table, it is seen that beyond corn that has the highest starch content, the dry peels of cassava and potato contain a reasonable quantity of starch that could be extracted for use as fluid loss control materials.

Table 6. Starch composition of selected agro-waste materials.

| Sample | Starch (%) | Source |

|---|---|---|

| Rice husk | 11.2 | Scaglione and Gellman (1986) |

| Barley hull | 8.4 | Scaglione and Gellman (1986) |

| Dry wood from grimes apple trees | 6.75 | Pallardy (2008) |

| Dry wood from sugar maple twig | 1.1–6.4 | Isselhardt (2011) |

| Dry wood of Birch | 7.6 ± 1.2 | Kaakinen et al. (2004) |

| Corn | 61 | AMG Engineering (2013) |

| Sweet potato (pomoea batatas L) | 20.78 ± 0.02 | Eleazu and Ironua (2013) |

| Potato peels (dry mass) | 52.14 | Arapoglou et al. (2010) |

| Peanut red skins | 0.74 | Scaglione and Gellman (1986) |

| Cassava root peels (dry mass) | 44.9–59.6 | Gómez et al. (1983) |

Analysing further the information obtained from Table 5, the experimental leaning of the researchers is isolated. This is shown in Fig. 2. From the figure, the study areas are highlighted. Of these study areas, two areas namely: filter loss and rheology of muds formulated with agro wastes received considerable research attention while the other areas such as: filter cake characteristics, microscopic structure analysis of the filter cake and economic analysis of muds formulated with agro wastes received little or no research attention.

Fig. 2. Percentage leaning of researchers on fluid loss control research.

Fig. 2. Percentage leaning of researchers on fluid loss control research.These last three areas are important in filter loss studies. First, the filter cake characteristics are not just limited to its thickness. It also extends to parameters such as cake porosity, permeability, slickness, texture etc. Some of these characteristics such as texture although, almost always subjective in its determination may take notations such as hard, tough, firm, soft or rubbery as the case may be. However, according to the American Petroleum Institute (2003), these descriptions may convey useful information about the cake quality. In the field, the selection of drilling muds that would cause minimal damage to a formation is dependent on the characterization of the muds filter cake (Blkoor and Fattah, 2013). However, the gap in the literature observed in this area can most likely be attributed to the subjectivity surrounding these descriptions.

Second, the microscopic structure and texture of mud cakes containing cellulosic agro waste materials is an important area in filter cake analysis in that it provides an insight into the effects of the different drilling fluid additives present in the cake. Beyond this, it gives the mud engineer the latitude to determine quantitatively the chemical compositions of the filter cake. This information would ultimately arm the mud engineer to know what could be done to the filter loss additive to enable it perform effectively and know the recipe that would effectively remove the cake when processes such as cementing is to be done (Bageri et al., 2013). To carry this out, tools such as x-ray diffraction, computerized tomography, scanning electron microscopy, and x-ray fluorescence are useful (Bageri et al., 2013). Although microscopic studies of the structure and texture of mud cakes with polymers as the fluid loss control material abound in literature (Chenevert and Huycke, 1991, Elkatatny et al., 2011, Nasir-El-Din et al., 2007, Overveldt et al., 2012, Plank and Gossen, 1991; little or no studies exist as regards when agro wastes containing cellulose are used as filter loss control additives.

Third, in choosing an alternative material to be used in place of a certain drilling fluid additive, beyond assessing its chemical and physical properties, the economics of using that alternative material is imperative. In the present context, most researchers as found in the literature focused only on the physical and chemical properties of the agro wastes leaving out their economic analysis. This creates a lacuna to be filled.

4. Discussion of the results of experimental researches on the use of agro-wastes as fluid loss agents

4.1. API filter loss experiments

Table 7 presents a summary of the experimental research endeavours by different authors and the quantitative results they obtained on the API filter loss when they used agro-waste materials as fluid loss control agents. The table highlights the mud type, the agro-waste, the temperature and pressure conditions under which they carried out their study of fluid loss, the particle size of the agro-waste material they used, the amount or concentration of the agro-waste material used and more importantly the fluid loss volumes obtained in each case. A look at the table shows that about 85% of the researchers focused on studying how agro-waste materials can reduce filter loss in water based muds. The most likely reason for the huge number of researches on water based muds (WBMs) is because water-based muds are the cheapest drilling fluids to formulate and the most commonly used (Yunita et al., 2015). In addition, one common approach by most of the researchers observed from Table 7 is that most of them graduated the concentration of the agro-waste material they used; most probably to know the optimal amount of agro-waste that would reduce filter loss in drilling mud. Hence, we find graduations of agro-waste concentrations in multiples of 5 g as in the cases of Adebayo and Chinonyere, 2012, Anawe Paul et al., 2014, Hamida et al., 2010 and Okon et al. (2014) etc. However, there are other cases where lower units such as 0.25 ppb, 1 g and graduations in multiples of 2 g are recorded as in the works of Hossain and Wajheeuddin, 2016, Nyeche et al., 2015, Dagde and Nmegbu, 2014 and Egun and Abah (2013) respectively. On a technical note, the following highlights are isolated.

Table 7. Summary of experimental results on filtration loss of various agro waste materials.