1. Introduction

The decarbonization of the society has drawn interest from the scholarly community in addition to being a widely acknowledged necessity on political agendas around the world. Burning fossil fuel is the primary cause of climate change and eliminating this remains crucial to any plan to create a society that is completely carbon neutral (Lund et al., 2022). Currently, the world burns around 1000 barrels of fossil fuel every second. The uncontrolled use of fossil fuel contributes significantly to global warming by releasing greenhouse gases into the atmosphere. Millions of people will die worldwide if the global temperature rises by more than 2°C and around one million species will go extinct entirely (Khandaker et al., 2022). Londoo-Pulgarin et al. (2021)established that the conflict between environmental concerns and the demand for economic growth will intensify during the next three decades. This tension is expected to deteriorate more in favor of economic expansion and rising energy demand. The need to reduce dependence on imports will require both industrialized nations and emerging markets to invest money to encourage increased consumption efficiency and the promotion of alternative and environmentally clean energy sources. Given the intricacy of the problems, it is necessary to use all resources efficiently and sustainably (D'adamo et al., 2021).

Governments and stakeholders have paid close attention to bioenergy in recent years due to its potential to support a variety of economic, social, and environmental goals and promote sustainable development. The use of bioenergy has been widely considered one of the key measures for reducing climate change, providing energy security, bolstering the agricultural sector, and promoting rural development (Kaoma et al., 2021). In 2017, bioenergy accounted for more than 70% of the green energy used in the EU, and production between 2000 and 2020 increased significantly. With 596 TW-hours, bioelectricity was the third largest source of electricity in 2017 behind wind and hydroelectricity (TWh) (Alsaleh et al., 2021). Currently, 10% of the world's primary energy supply comes from bioenergy. Bioenergy has the potential to provide anywhere from 10% to more than 60% of the world's primary energy supply. The production of bioenergy is expected to increase from its current level of 56 EJ to 145 EJ by the year 2060 as a result of modern bioenergy usages taking on a more significant role than traditional biomass use (Duarah et al., 2022; Næss et al., 2021). Many industrial sectors that use energy compete for the same sustainable biomass resources since it serves as a direct replacement for various fossil fuels. Even at maximum sustainable bioenergy production levels, cross-sectoral competition is fierce both within the energy system and in the larger context (Lund et al., 2022). The capacity of bioenergy to harvest significant volumes of biomass will decide its future development (Rather et al., 2022). In light of this, a variety of bioenergy resources are frequently suggested for large-scale energy cultivation, including crops, algae, and lignocellulosic biomass. Continued biomass business will be important for the development of bioenergy in the future. Generally, plants and biologically derived agricultural, residential, commercial and industrial waste can be used to make biofuels. The starting materials for the generation of biofuels are vegetable oil waste, municipal trash, plant materials, manure, and food waste (Sarkar et al., 2021; Simsek and Uslu, 2020a).

Pocha et al. (2022) explored the use of underutilized lignocellulosic biomass wastes for the production of biofuel and as a source of sustainable alternative fuel. The biomass wastes examined include pineapple fruit peel, dried carrot pulp, watermelon rind waste, banana peel, and several others. The physicochemical properties of the fuel produced using these wastes were compared with those of their fossil fuel counterparts, and they conform to the standard. The work reviewed the biological processes for producing biofuels from agricultural waste while emphasizing evolving technological processes to improve fuel yield.

CNSL, which is a waste obtained from cashew nuts, can be used to produce biodiesel. The biodiesel obtained can be used solely to run a diesel engine or in combination with other fuel. This fuel performs well when used in dieselengines and it is a sustainable option that should be considered in the race to clean combustion and environment. It has the potential to offset the carbon footprint of the cashew industry and make processes involving the use of diesel engines clean. The major drawback to this fuel lies in the fact that it produces high NOx emissions and BSFC.

1.1. Cashew Tree

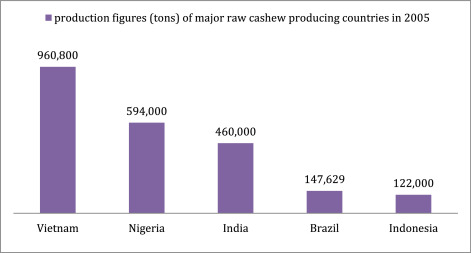

The cashew tree (Anacardium occidentale) is indigenous to many countries. The Amazon basin, Tanzania, Brazil, Malawi, Senegal, Thailand, Sri Lanka, India, Angola, Kenya, Mozambique, Nigeria, and Indonesia are the top cashew producing countries (Yuliana et al., 2012). According to the Food and Agriculture Organization, about 4.1 million tons of cashew nuts were produced worldwide in 2016, mainly in Africa and Asia. In the world, approximately 5.7 million hectares are used for cashew plantations (Paula et al., 2020). In contrast to the data in Fig. 1, the largest cashew producer and exporter worldwide currently is India (Pushparaj and Ramabalan, 2013). Missionaries from Portugal brought it to India in the year 1400 (Das et al., 2003). The benefits offered by the kernel, apple, nut and wood produced by cashew trees are the main reason it is cultivated in most countries.

Fig. 1. The major raw cashew producing countries with their production figures in 2005 (Pushparaj and Ramabalan, 2013).

Fig. 1. The major raw cashew producing countries with their production figures in 2005 (Pushparaj and Ramabalan, 2013).Cashew nut shells are extremely hard (Jeyavishnu et al., 2021). In most cases, it comprises 10.8% water and 2.6% ash., with a moisture content of 6.47% on average (Jeyavishnu et al., 2021). Cashew nut shells are often discarded as waste, adding to already existing environmental concerns in various countries (Abrego et al., 2018; Kala et al., 2019). It contains a viscous oil with a dark brown color known as cashew nut shell liquid (CNSL), which is always found in the pericarp of cashew fruit (Kala et al., 2019). The waste from the cashew fruit has also been suggested as a source of high fructose or as a feedstock for animal feed enriched with protein (Yuliana et al., 2012). Furthermore, CNSL is always obtained as a secondary product of industrial cashew nuts (Lomonaco et al., 2017). It makes up approximately 30-35% of the overall weight of the shell and is the utmost integral component (Nyirenda et al., 2021). CNSL is inexpensive, readily available, non-toxic, and biodegradable (Kala et al., 2019).

The cashew apple, which is an overdeveloped pedicel, serves as food. It is used in the production of several beverages and meals. It can also be used to make juice, jelly, jam, wine, and syrup. In an aqueous two-phase system, cashew tree gum has been proposed as a polymeric material substitute for fractionated dextran (Yuliana et al., 2012). The bark and leaves of the cashew tree have been used in traditional treatments for malaria and toothaches (Yuliana et al., 2012). Due to its widespread acceptability and demand, the nut is regarded to be increasingly significant on the global market. Cashew nut is the main commercial product obtained from cashew plantations. It generates foreign exchange revenues for countries that produce it for commercial reasons (Ike et al., 2021). Cashew nut export revenue in Nigeria is projected to be approximately 7 to 8% of export revenue that is not from oil, with a proposed annual export value of $25 to $35 million US dollars (Ike et al., 2021). Cashew nut is popular as snack and also used in Asian cuisines, particularly Thai and Chinese (Lomonaco et al., 2017). Most CNSL derivatives are exported at negligible prices, with an average price of USD 250 / tons, despite the fact that CNSL has a wide range of applications. Instead, its use has been restricted to industries with low added value (Uliassi et al., 2021).

1.2. Cashew Nut Shell Liquid

As discussed in the previous sections, CNSL and its components have been used in numerous studies as feedstock for the development of environmentally friendly products because they are classified as a natural and renewable raw resource (Maia et al., 2015; Zombe et al., 2022). CNSL phenolic lipid mixtures are an ideal starting point from a chemical point of view for a variety of chemical reactions that make use of their aromatic rings, polar functional groups, and double bonds on the side chains. Insecticides, germicides, antioxidants, thermal insulators, friction materials, plasticizers, surfactants, paints, resins and varnishes have all been produced using them (Uliassi et al., 2021; Paula et al., 2020). CNSL is also used as a core material for the creation of polyols and polyurethanes, as well as a bioadditive to help reduce the environmental effect of crude oil fuels (Jeyavishnu et al., 2021). It can be used as a natural substitute for commercially available mineral oils and synthetic oils in the industry (Bhaumik et al., 2019). The current surge in the prices of petrochemical feedstocks, conjoined with concerns about environmental issuesand the continued reduction of natural fossil reserves, position CNSL as a sustainable option for providing renewable energy (Fig. 2). Its benefits outnumber those of other renewable bioresources such as biomass and grain oils (Ike et al., 2021; Nyirenda et al., 2021). Since CNSL is non-edible, it does not lead to an imposition of strain on the food supply system, and because it is made from waste, it does not contend for landmass for cultivation. Due to the fact that it is made up of phenolic components, the environmental effects of disposing a large amount of CNSL may be problematic (Kala et al., 2019; Liu et al., 2022; Lubi and Thachil, 2000). Therefore, the use of CNSL to produce other good resources is a way to contribute positively to the environment.

Fig. 2. Schematic diagram of the value chain of CNSL.

Fig. 2. Schematic diagram of the value chain of CNSL.In addition to the aforementioned usage of CNSL, it also serves as a primary component in biodiesel production. Biofuel is a broad phrase that refers to any biomass-related product that is used as a source of energy, and biodiesel falls under biofuel (Shilpa et al., 2014). In numerous countries, biodiesel has been used solely or in combination with diesel in compression ignition engines (Costa et al., 2019). It is described as a mixture of short-chain alcohols, such as methanol or ethanol, and long-chain fatty acid alkyl esters produced during the transesterification or esterification of vegetable or animal fats and oils(Costa et al., 2019; Simsek and Uslu, 2020b). It is a renewable, noncarcinogenic fuel that is free of sulfur, and also lowers the release of toxic gases (Costa et al., 2019). In terms of availability, pollution, and cost, biodiesel is said to be in a position of advantage over conventional diesel (Adekanbi et al., 2021; Shilpa et al., 2014). Some of the benefits include reduced CO emissions, better cetane rating, biodegradability, and non-toxicity (Simsek et al., 2021a; Shilpa et al., 2014). The total global production of biodiesel has been steadily increasing year by year, reaching more than 45 million tons in 2019 (Toldra-reig et al., 2020). In 2019, 91 plants in the United States produced more than 5.6 million tons of biodiesel. Almost 80% of brand-new diesel vehicles are set up for B20 use, which combines diesel and 20% biodiesel (Toldra-reig et al., 2020). The need for bioenergy is expected to account for 30% of all fuel used worldwide for road transportation by 2050 (Toldra-Reig et al., 2020). Furthermore, the worldwide biodiesel market is expected to increase at a rate of 14.5% by 2024 (Jung et al., 2021). Biodiesel can be made from both plant and animal biomass. Common biomasses used for biodiesel production include edible oils, non-edible oils, cooking oils, and algae (Abdul Hakim Shaah et al., 2021; Fadhil and Saeed, 2016; Altikriti et al., 2015; Simsek et al., 2022a, b, c). There are about 350 oil-producing crops in existence and they can be classified as edible or non-edible (Abdul Hakim Shaah et al., 2021). Due to the debate on the scarcity of food that may arise from biodiesel production using edible crops, non-edible feedstocks are now prioritized for biodiesel production. Furthermore, the feedstock used as raw material for the production of biodiesel represents up to 80% of the total cost (Toldra-reig et al., 2019). All of these reasons make CNSL a good fit for the production of biodiesel. As reported in past research, the calorific value of CNSL can be as low as 34,531.50 kJ/kg and as high as 41780 kJ/kg (Coulibaly et al., 2022; Thanigaivelan et al., 2022; Taiwo 2015).

The goal of this study is to find out more about the current state and developments of the use of CNSL in biodiesel production as well as the performance of the fuel and its blends in diesel engines. It contributes to the literature by providing an overview of the current problems associated with CNSLBD and the areas future research needs to focus on to improve the fuel. It also suggests ways to improve the efficacy of this fuel. This research seeks to investigate the efficacy of different techniques that have been explored by researchers to improve the performance of CNSLBD. This work hypothesizes that employing technologies that involve engine modifications and altering the composition of CNSLBD with additives and other chemicals such as nanoparticles makes the fuel work maximally. It further seeks to investigate the modern technologies have not been explored in improving the performance of biodiesel produced from CNSL.

1.3. Extraction of cashew nut liquid

Extraction procedures can be performed in both hot and cold mediums, with the former involving heating and the latter taking place at room temperature (Ike et al., 2021). The techniques commonly employed in obtaining CNSL from cashew nut shell involve three basic procedures, which are Mechanical Extraction, Thermal Extraction and Solvent Extraction. Depending on the extraction method used, CNSL is divided into two categories: technical CNSL (tCNSL), which is produced by industrially burning the nuts at high temperatures and contains cardanol (60-65%), cardol (15-20%), polymeric material (10%) and trace amounts of methylcardol; natural CNSL (iCNSL), which is extracted using solvents and its main components are anacardic acid (62.9%, cardol (23.98%), and cardanol (Chatterjee et al., 2017; Leite et al., 2015). An estimate of 3.3 kg of cashew nut shell is needed to make 1 kg of CNSL and approximately 20% of the nutshell oil is found in raw cashew nut (Kumar et al., 2018). Other approaches, such as pyrolysis, the use of supercritical carbon dioxide, supercritical water, and ultrasonication, can be used to obtain CNSL from the nut (Ike et al., 2021). Electrosynthesis is also a powerful tool that can be used to manufacture high-value products from CNSL. It uses electricity instead of stoichiometric amounts of chemical components and no high temperature or pressure is required (Medeiros et al., 2020). However, it is important to separate CNSL from the pericarp without using harsh chemicals or high temperatures because doing so could allow CNSL to be employed in medicinal and specialty polymer compositions (Smith Jr. et al., 2003). Fig. 3summarizes the different extraction processes. Since there are different methods to recover CNSL from cashew nuts, optimal extraction condition varies with respect to the technique used. Aina et al. (2018) reported that at 10 minutes of pressing time and a moisture content of 14.01 to 16.99%, the best amount of CNSL was extracted, the best extraction efficiency was achieved, and the best percentage of oil was recovered in a CNSL expeller. Abrego et al. (2018)reported that the best yield for the extraction of CNSL using the pyrolysis method occurs at 500°C.

Fig. 3. Process of Extracting CNSL from cashew nuts.

Fig. 3. Process of Extracting CNSL from cashew nuts.1.4. Biodiesel Used in Diesel Engine

The sources of feedstock used for biofuel production are divided into four categories. They are the first-generation biofuel, second-generation biofuel, third-generation biofuel, and fourth-generation biofuel. First-generation biofuels come from edible oils, second-generation biofuels come from non-edible oil sources, and third-generation biofuels come from microalgae biomass (Ravanipour et al., 2021). Biodiesel has lower oxidative stability than petroleum-based diesel. This has prompted researchers to explore antioxidant-active chemicals for the biofuel industry (dos Santos et al., 2015). CNSL also serves as an antioxidant, which is useful for improving the performance of other biodiesel (Bastos and Tubino, 2016). The direct use of CNSL components as antioxidants or as raw materials for the synthesis of novel compounds with enhanced antioxidant action stands it out (Maia et al., 2015). They help biodiesel stay stable over time. The oxidation process is divided into numerous parts and is dependent on several variables. It can occur through a variety of methods, including hydrolytic processes, enzymatic action, photooxidation, and autooxidation (Bastos and Tubino, 2016). The addition of thiophosphate ester additives increases unsaturation at the long side-chain substituents, which increases the antioxidant activity of CNSL and the creation of thermally stable films (Ike et al., 2021). This optimizes their performance when blended with biodiesel.

Rios et al. (2012) examined the effects of three antioxidants on the thermo-oxidative stability of soybean biodiesel. It includes 2,6-di-t-butyl-4-methylphenol, a synthetic antioxidant, hydrogenated cardanol and alkyl hydrogenated cardanol, which were obtained from CNSL. The oxidative stability of the biofuel with and without antioxidants was examined using thermogravimetric analysis and Metrohm 743 Rancimat in accordance with the EN 14112 method. The antioxidants were added at concentrations of 200, 300, and 400 ppm. The results demonstrated that each antioxidant had a positive impact on the thermooxidative stability of the soybean biodiesel. Using the Rancimat method, the results demonstrated that antioxidants increased the biodiesel stability by at least 71%. An electrolytic process was employed in extracting CNSL from cashew nut and it was also used as an antioxidant for soy biodiesel by dos Santos et al. (2015). The biodiesel performed optimally and also gave better results.

Kumar et al. (2018) reviewed the research status of the use of CNSL as biodiesel. The review provides detailed information on cashew crop cultivation, oil extraction methods, and fuel modification techniques conjoined with the combustion behavior and emission characteristics of CNSL in a compression ignition engine. It was observed that neat CNSL performs poorly in a compression ignition engine when compared to diesel. Preheating, blending, using fuel additives, and enriching air oxygen intake can be used to improve the fuel. The study indicated that a maximum of 40% substitution of CNSL is possible without deteriorating the performance of the engine.

Olugasa et al. (2022) assessed the performance and emission attributes of an orange peel biodiesel blended with CNSL. The effectiveness of CNSL in lowering NOX emission while enhancing the performance of the biodiesel was examined. A 70:30 blend of orange peel biodiesel and CNSL was used (B70). From the experimental findings, the combination of orange peel biodiesel with CNSL resulted in a modest reduction in NOX emission. B70 produces 150 ppm of NOX, while pure orange peel biodiesel and diesel produce 159 ppm and 193 ppm of NOX, respectively. The hydrocarbon emission of B70 was 22.3% lower than that of diesel and 8% lower than that of B100, which is pure orange peel biodiesel. B70 performs better than B100 and diesel in terms of CO and CO2 emissions. In addition, the brake thermal efficiency (BTE) is higher for B70 under all loads.

Joy et al. (2019) evaluated the effect of cetane improvers on the performance and emission profile of compression ignition engines. Dimethylether was employed to optimize the performance of pure CNSLBD in diesel engines. As a result of the oxygen content of the fuel, all emissions were lowered. Performance parameters such as BSFC and BTE were within considerable limits. This attests to the potential of CNSLBD as an environmentally friendly fuel.

Hasan et al. (2019) explored the ability of CNSL and liquid extract from roselle seeds to improve biodiesel storage stability. The feedstocks used in this work, which were CNSL and crude extract from roselle seeds, are wastes. Beyond being used as a primary raw material for biodiesel production, this shows that waste has other usages in the biofuel industry.

1.5. Review Methodology

Several studies have worked on the concept of biodiesel production from non-edible substances and the use of CNSL as a feedstock for biodiesel production as well as antioxidants for improving biodiesels. For example, Lomonaco et al. (2017) discussed the benefits of the conversion of CNSL, which is an agrowaste, to a sustainable petrochemical resource, as well as the challenges related to its production and use as a fuel. William et al. (2020)provided an extensive overview of the usage of glycerol-modified CNSL as a pour-point depressant and flow improvers in waxy crude oils. Bastos and Tubino (2016) provided a detailed report on the use of CNSL as an antioxidant in biodiesel.

However, there is no adequate study reporting the state of research on the production of CNSLBD, its performance in diesel engines, and its potential as a source of bioenergy. This research seeks to address this dearth by providing a detailed overview of the current state of the usage of CNSL in biodiesel production. It gives report of different original research that has used CNSLBD in compression ignition engines and the results of their research.

Collection of papers was sorted and divided into two. The first category was an array of original research articles discussing the performance of CNSLBD and its blend in compression ignition engines, while the second group is a group of articles that gives a thorough discussion of cashew nut shell liquid and its use in biodiesel synthesis.

The remaining portion of this work is divided into two sections. Section 2 gives a detailed discussion on cashew nut shell liquid, its use as biodiesel, and the performance of biodiesel produced from the feedstock in a compression ignition engine. Section 3 gives a summary of the whole work and it also defines what the focus of future research on CNSLBD should be.

2. Discussion

2.1. Prospects of using CNSL as a fuel in the energy industry and as a resource for driving sustainability

Energy has always been crucial to the advancement of a nation. It is seen as a gauge of social and economic progress. In addition to GDP and per capita income, per capita energy consumption is seen as an indicator of a country's growth and development level (Simsek et al., 2022d). Increasing the effectiveness of energy systems and improving energy management is now more prioritized than energy production, as most widely used energy technologies are fossil based (Adekanbi, 2021). The global emphasis has shifted to increased productivity, increased efficiency, and lower manufacturing costs (Chauhan et al., 2016). To meet the future global energy demand, it is essential to not only deploy new energy technologies, but also maximize available energy resources. Our society is now confronted with the need to end its dependence on fossil fuels because there are acknowledged concerns about environmental and human health issues caused by their excessive use. These concerns include atmospheric pollution, respiratory disorders, and climate change activities, which are caused by the release of greenhouse gases (GHG) (Angulo-Mosquera et al., 2021; Simsek et al., 2021b, c). The emission of greenhouse gases from various industries, including the production of energy, is a significant barrier to sustainable growth. Even clean energy sources, such as hydroelectricity, have some emissions. It is well known that the production of electricity using fossil fuel contributes significantly to global GHG emissionsand results in higher emissions than those produced using renewable energy sources (Khan et al., 2022). Using clean energy sources makes it possible for us to safeguard the environment from dangerous chemicals and poisonous pollutants, keeping everyone's health (Abbina and Anilkumar, 2017).

An option to ensure energy security and alleviate the environmental problems associated with the use of fossil fuels in developing nations is to use biomass for energy generation (Kaoma and Gheewala, 2021; Sawadogo et al., 2018). Biomass is widely distributed throughout the most populous regions, where there is greater energy consumption, with the exception of the poles and some desert regions. Biomass is available virtually everywhere on the planet. However, current biomass production, which can be used as a source of energy, is primarily generated away from areas of consumption (Nunes et al., 2021). Organic wastes are also classified as biomass. Large quantities of wastes, residues and sewage resulting from the widest range of anthropogenic activities are often produced in urban areas (Battista et al., 2022). This can be maximized by converting them into fuels. Waste management is expensive and complex. For low-, middle-, and high-income countries, respectively, waste management consumes around 19%, 11%, and 4% of total yearly municipal budgets. In poor nations, municipalities spend 20% to 50% of their budgets on trash management and disposal. (Khan et al., 2022). Hence, using waste as fuel can help reduce some of the expenses that governments of different countries and individuals incur on waste disposal. Agriculture, which is largely responsible for the socioeconomic conditions in developing nations, has recently expanded to meet the demand for food as a result of population growth. As a result, a lot of agricultural waste is produced, including animal dung, crop remnants, animal carcasses, and leftover agricultural chemicals (Angulo-Mosquera et al., 2021). For example, Ghana is estimated to produce 10.33 Mt of crop leftovers annually, while Brazil produces 298 Mt, while China produces 500 to 800 Mt of agricultural waste annually, 500 Mt in India, 65 Mt in Turkey, and 76.7 Mt in Mexico (Angulo-Mosquera et al., 2021). Valorising CNSL, by using it as a feedstock for biodiesel production, is a way to put commonly generated agricultural waste to good use. There is always a significant amount of CNSL waste produced by shelling cashew nuts. The management of this waste is still difficult today. In spite of their potential for energy, CNSL are often disposed at waste collection sites, especially in developing countries. Fuel briquettes can be produced from cashew nut shells using the densification method, according to Chungcharoen et al. (2020). The fuel briquettes obtained from cashew nut shells has the potential to cook with a manageable level of GHG emissions. Generally, cashew has historically been grown primarily in developing countries, where it serves as both a vital source of income for most growers and processors worldwide and as an agricultural product that considerably boosts national GDP and export exchanges (Dendena and Corsi, 2014).

Since biomass requires 100 times more employees per unit of energy produced than fossil fuels, it may also help ease the effects of unemployment. Using biomass as a fuel source for power generation has the potential to increase social welfare in rural regions, boost the economy, and protect the environment. (Giwa et al., 2017). In addition, compared to highly capital-intensive and mechanized fossil fuel technology, enterprises based on renewable resourcesare frequently more labor-intensive, which aids in the creation of new job markets. The cost of operation and maintenance for manufacturing facilities that use renewable energy sources is also extremely low. Fig. 4 provides a representation of the amount of energy generated through biofuels in different regions. Additionally, farmers and rural communities immediately benefit from the use of agricultural renewable raw materials in emerging technology (Abbina and Anilkumar, 2017). Sustainability as a point of discussion has generally gained more traction, and most companies are incorporating this fully into their operations. In addition, many supply chain focal points are working to include sustainability in their corporate objectives. Agrifood supply chains are responsible for at least 19% and up to 31% of global greenhouse gas emissions and 50% of eutrophication (Agyemang et al., 2018). Maximizing waste produced by the agricultural industry is a way to offset the emission footprint of agro-food supply chains. In addition, the construction of new waste to energy plants also leads to more job openings. It promotes sustainable development and provides a more effective waste management system. However, countries with sophisticated economies like Italy, Germany, Finland, France, and Japan are where these options are mostly used. Most of the world's most polluted cities are located in underdeveloped nations, where garbage is frequently left untreated and causes air pollution (Khan et al., 2022). Blair et al. (2021)assessed the connections between the supply chains for bioenergy and related biomass and the UN Sustainable Development Goals (SDGs). In this study, it was established that maximizing bioresources and valorizing waste for bioenergy production can directly and indirectly contribute to the achievement of some SDGs. These include SDGs 8 (Decent Work and Economic Growth), 9 (Industry, Innovation, and Infrastructure), 12 (Responsible Production and Consumption), 7 (Affordable and Clean Energy), 2 (Zero Hunger), 6 (Clean Water and Sanitation), 15 (Life on Land), 1 (No Poverty), 4 (Quality Education), 5 (Gender Inequality) and 10 (Reduced Inequalities).

Fig. 4. Amount of energy generated by different regions between 1990 to 2020 (Duarah et al., 2022).

Fig. 4. Amount of energy generated by different regions between 1990 to 2020 (Duarah et al., 2022).Various federation laws on the development of renewable energy and policy issues related to the development of bioenergy in developing countries must be improved (Giwa et al., 2017). Governments should promote renewable efforts by reducing subsidies for technology based on fossil fuels and increasing incentives for the renewable energy sector (Abbina and Anilkumar, 2017). Every new government infrastructure installed in different countries should also be clean and companies should be encouraged to start greening their operations by transitioning to clean energy. All of these initiatives would aid the effectiveness of clean fuels. Farmers have an impact on the evolution of the bioenergy sector as both producers of biomass and users of energy. Local farmers, who are important stakeholders in the establishment stage of market supply chains, must participate in and accept the development of modern bioenergy systems in rural regions (Xu et al., 2022). To increase the use of CNSL as a fuel, the supply chain of this feedstock should be optimized. Cashew processing factories should be encouraged to use their wastes as substrates for biodiesel production, and an effective waste collection technique should be deployed in this industry.

2.2. Components of Cashew Nut Shell Liquid

Cardanol (decarboxylated anacardic acid), a meta-substituted n-long chain (C15) unsaturated alkylphenol, cardol, and methyl-cardol are the primary compositions of CNSL (Kumar et al., 2018). In simple terms, the components of CNSL are cardol, methylcardol, anacardic acid, and cardanol (Scaldaferri and Pasa, 2019; Ghosh and Karak, 2020). The concentration of these compounds varies depending on the extraction process used to obtain CNSL (Ike et al., 2021). For example, due to the decarboxylation of the anacardic acid constituent during the thermal extraction process, which regularly results in cardanol or 2-pentadeca-diethylphenol, commercial grade CNSL may contain little or no anacardic acid; this process may also result in polymerization, which represents 20 to 25% of the polymeric substances in the oil (Ike et al., 2021). These CNSL components are made up of four constituents with varying degrees of unsaturation in the C15 alkyl side-chain unsaturation, namely saturated, monoene, diene, and triene. Fig. 5 shows the diagrammatic representation of the constituents, while Fig. 6 presents the composition of each constituent.

Fig. 5. Diagrammatic representation of the components of CNSL.

Fig. 5. Diagrammatic representation of the components of CNSL. Fig. 6. Schematic diagram showing the components of CNSL.

Fig. 6. Schematic diagram showing the components of CNSL.2.3. Biodiesel Synthesis using Cashew Nut Shell Liquid

The most widely used technique for the synthesis of biodiesel from non-edible oil, such as cashew nut shell liquid as well as animal fats, is transesterification(Abdul Hakim Shaah et al., 2021). In the transesterification reaction, reactants—oil triglycerides and alcohol—are reacted in the presence of a catalyst (Fig. 7) (José et al., 2020; Sundaramahalingam et al., 2021). This reaction leads to the formation of fatty acid methyl esters and glycerol (Fig. 8) (Senthil Kumar and Thirumalini, 2020). The catalysts commonly used are either acidic or alkaline (Rezania et al., 2019). In industrial biodiesel manufacturing facilities, transesterification by alkaline catalysis is the predominant method. Ali and Fadhil, (2013) used alkali-catalyzed transesterification to produce biodiesel from spent fish frying oil. Al-Tikrity et al. (2016) used this same technique to produce Cyprinus carpio fish oil. However, the fact that this process could lead to soap production makes raw materials such as animal fat that contain moisture and free fatty acids problematic for alkaline transesterification (Tolda-reig et al., 2020). Homogeneous catalysts, such as NaOH and KOH, are typically recommended for industrial biodiesel production, but their removal is relatively difficult and occasionally polluting, adding additional costs to the finished product (Santos et al., 2019). Non-edibles typically have high viscosity, free fatty acids (FFAs), and moisture content. When making biodiesel from non-edible oil, transesterification is an effective way commonly used to reduce moisture, FFAs, and viscosity in order to obtain a better yield (Abdul Hakim Shaah et al., 2021). Methanol and ethanol are the alcohols that are the most used in the transesterification process for biodiesel generation (Abdul Hakim Shaah et al., 2021). This methodology also works for the production of CNSLBD. CNSLs with higher acidity and viscosity can also be prone to giving reduced biodiesel output and are more likely to create soap (Vedharaj et al., 2014). With better reusable catalysts and increased transesterification efficiency, some current research on biodiesel manufacturing aims to maximize yield and reduce expenses (Tolda-reig et al., 2020).

Fig. 7. The Diagrammatic Representation of the production of CNSLBD.

Fig. 7. The Diagrammatic Representation of the production of CNSLBD.