1. Introduction

The thermoelectric effect entailing the conversion of thermal energy to electrical energy is useful for the generation of renewable energy from waste heat. The effect is also the basis of thermocouples for temperature measurement.

The thermoelectric effect is exhibited by thermoelectric materials, which are effective due to the combination of high thermoelectric power, low electrical resistivity and low thermal conductivity. The achievement of this combination of properties is challenging, because the properties are not independent of one another. For the case of electrons dominating the mechanism of electrical and thermal conduction, the electrical conductivity and thermal conductivity are directly proportional to one another, in accordance with the Wiedemann–Franz Law. Moreover, the electrical conductivity and thermoelectric power are inversely related, because the electrical conductivity increases with the carrier concentration, whereas the thermoelectric power decreases with the carrier concentration. The efficiency of the energy conversion is described by the dimensionless thermoelectric figure of merit ZT, where Z is the thermoelectric figure of merit and T is the average temperature in K in the range of temperature.

The most established thermoelectric materials are inorganic materials, such as PbTe, Bi2Te3 and SnSe. These materials are expensive and suffer from low processability, brittleness and toxicity. This situation calls for the investigation of polymers as thermoelectric materials. Polymers tend to be low cost, low in thermal conductivity, high in processability and ductility, and low in density (lightweight).

Compared to the traditional inorganic thermoelectric materials, polymer-based thermoelectric materials (including polymers and polymer-matrix composites) are disadvantageously low in ZT, electrical conductivity and thermoelectric power, though they are advantageously low in the thermal conductivity. Therefore, the emphasis of research on polymer-based thermoelectric materials is on increasing the electrical conductivity and thermoelectric power.

This paper reviews polymer-based thermoelectric materials, including nonstructural and structural materials. Nonstructural thermoelectric materials are used for wearable, flexible or stretchable electronics. Structural thermoelectric materials are used for structures, such as airframes and satellites. Nonstructural thermoelectric materials are mainly in the form of polymers and polymer-matrix composites with discontinuous fillers. In contrast, structural thermoelectric materials are structural composites involving continuous fibers as the reinforcement.

2. Nonstructural thermoelectric materials

Due to the requirement of low electrical resistivity, conventional polymers are not effective as thermoelectric materials, unless other constituents are used with them, thus forming a polymer-matrix composite. On the other hand, if the polymer is a conductive polymer, other constituents may not be necessary. Examples of conductive polymers are polyaniline (PANI), polypyrrole (PPY), polyacetylene (PA) polythiophene (PT), poly(3,4-ethylenedioxythiophene) (PEDOT) and poly(phenylene vinylenes) (PPV).

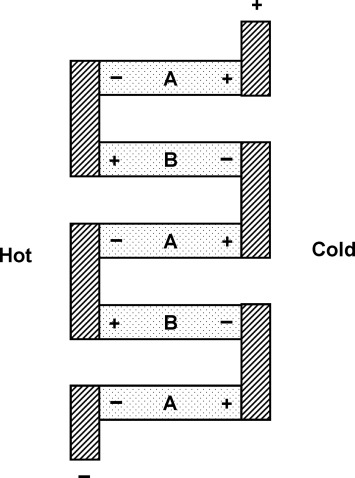

A thermoelectric energy generator needs both n-type and p-type thermoelectric materials (i.e., materials with opposite signs of the thermoelectric power) arranged as illustrated in Fig. 1. The series connection of the alternating n-type and p-type elements results in a relatively large electrical output, in spite of the small output of an individual element.

Fig. 1. A thermoelectric energy generator consisting of conductors A and B (dotted regions) that are alternating and electrically connected in series. The shaded regions are conductors that electrically connect A and B. The temperature to the left of the device is different from that to the right of the device.

Fig. 1. A thermoelectric energy generator consisting of conductors A and B (dotted regions) that are alternating and electrically connected in series. The shaded regions are conductors that electrically connect A and B. The temperature to the left of the device is different from that to the right of the device.In case of conductive polymers, the n-type and p-type behaviors are obtained by appropriate doping of the polymers [1]. Doping to form n-type conductive polymers is relatively difficult and the stability of the resulting doped polymer is typically inadequate [2], [3], [4], [5], [6]. Therefore, the requirement of having both n-type and p-type thermoelectric polymers, as needed in a thermoelectric generator, is challenging. Moreover, the ZT values of conductive polymers are typically low, such as 0.00008, as exhibited by a composite with conductive polymer poly(3-butylthiophene) (P3BT) and polystyrene [7]. However, a ZTvalue of 0.44 has been reported for a polymer-polymer composite with a PEDOT matrix and PEDOT nanowires [8].

Because of the limitations of conductive polymers, the combined use of polymers and other constituents is a commonly used approach. A particularly common constituent used in thermoelectric polymer-matrix composites is carbon nanotubes (CNTs), which are attractive for their electrical conductivityand amenability for being doped. For example, CNT can be doped by nitrogen [9], [10] or treated with polyethyleneimine (PEI) to become n-type [11]. Due to the conductivity of the CNTs, the polymer does not have to be conductive. As the CNT content increases, the electrical conductivity increases greatly, while the thermal conductivity is increased only slightly [12]. By using a CNT forest (with aligned CNTs), the thermoelectric power is much increased [13]. A conductive polymer (amino-terminated poly(3-hexylthiophene-2,5-diyl) (P3HT)) may be grafted on the surface of the CNTs [14]. The grafting provides higher thermoelectric power than a mixture of the two constituents [14]. A related nanoscale architecture involves CNT nanosheets sandwiched by PPY nanowires [15]. Yet another nanoscale architecture involves polymer cores, each of which is covered by CNT/polyurethane networks [16]. The coating of CNT with small organic molecules can also enhance the thermoelectric behavior [17].

Graphene may be used in place of CNT [18]. A nanoscale architecture involves graphene nanolayers sandwiched by PPY nanowires [19]. Graphene can also be doped n-type with nitrogen. A latex-matrix composite containing CNT exhibits ZT 0.0015 [20].

An issue in the use of CNT or graphene relates to the dispersion in the polymer. Solvents are used for this purpose, though they cause environmental issues in the manufacturing process. To alleviate this problem, an organic-inorganic composite matrix (such as hydrophilic pyridinium salt polymer) may be used [21].

Another class of nonstructural thermoelectric polymer-matrix composites are those that contain discontinuous inorganic fillers, such as SnSe0.8S0.2 [22], SnS nanobelt [23], BiTe-SbTe [24], TiO2 [25], silver [26], tellurium nanowires [27], [28], etc. Optionally these fillers are used along with CNTs in order to improve the electrical conductivity. In particular, the incorporation of TiO2 nanoparticlesto a PANI-matrix CNT composite increases the thermoelectric power, due to the lower carrier density and the consequent higher thermoelectric power [25]. The incorporation of silver helps to increase the electrical conductivity [26]. A composite with poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) as the matrix and CNT and silver as fillers exhibits ZT 0.0076, which is still low [26]. A composite with poly(methyl methacrylate) (PMMA) as the matrix and tellurium nanowires as the filler exhibits ZT 0.0028 [27]. However, a composite with a PEDOT matrix and tellurium nanowires as the filler exhibits ZT 0.39 [28].

The large variation in ZT among the various thermoelectric materials is due to the sensitivity of ZT to the composition as well as the method of preparation of the composite [29]. The method of preparation affects the distribution of the constituents, in addition to affecting the interfaces in the resulting composite material.

3. Structural thermoelectric materials

The most advanced polymer-matrix structural composites are those involving continuous fibers, such as carbon fibers, which is attractive for their combination of low density, high strength and high modulus of elasticity [30]. The high modulus allows carbon fibers to be highly effective as a reinforcement. Short fibers are considerably less effective than the continuous fibers, due to the imperfect bonding between fibers and the matrix. A high volume fraction of the fibers is crucial for attaining high strength and modulus in the composite. Due to the high degree of alignment of the continuous fibers, the continuous fiber volume fraction can be high (e.g., 60%). In contrast, the degree of alignment of discontinuous fibers, nanofibers and nanotubes is much lower, thus limiting the volume fraction. In case of nanofibers and nanotubes, the small diameter of the nanofibers and nanotubes causes the area of the interface between the nanofibers/nanotubes and the polymer matrix to be very large. As a consequence of the large interface area, the mechanical weakness at the interface becomes a more severe problem than the case of fibers that are not in the nanoscale.

3.1. Through-thickness thermoelectric behavior of a continuous carbon fiber polymer-matrix composite

In spite of their electrical conductivity, carbon fibers are not good thermoelectric materials, due to their high thermal conductivity and low thermoelectric power. In a continuous carbon fiber polymer-matrix composite, the behavior in the fiber direction (which is in the plane of the composite laminate) is dominated by the fibers, whereas the behavior in the through-thickness direction is dominated by the polymer matrix. Therefore, an approach for enhancing the thermoelectric behavior of a carbon fiber polymer-matrix composite involves tailoring the through-thickness behavior through the use of interlaminar fillers. A combination of fillers are used, with tellurium particles (a well-known thermoelectric material) used in the amount of 13 vol.% for increasing the thermoelectric power, bismuth telluride particles (a well-known thermoelectric material that is more expensive than tellurium) used in the amount of 2 vol.% for increasing the electrical conductivity and decreasing the thermal conductivity, and carbon black (which is conductive and conformable, due to its being in the form of porous aggregates of nanoparticles) used in the amount of 2 vol.% for increasing the electrical conductivity. Thus, the through-thickness thermoelectric power is increased from 8 to 163 μV/K, the through-thickness electrical resistivity is decreased from 0.17 to 0.02 Ω cm, the through-thickness thermal conductivity is decreased from 1.31 to 0.51 W/m.K, and ZT at 70 °C is increased from 9 × 10−6 to 9 × 10−2 (increased by 4 orders of magnitude) [31], [32], [33]. In spite of the large increase in ZT, the ZT value remains too low to be practical for thermoelectric power generation. The low value is partly due to the temperature being not high (as limited by the temperature ability of the polymer matrix) and the consequent low value of T in ZT.

A thermoelectric energy generator needs both n-type and p-type thermoelectric materials (Fig. 1). Carbon fiber polymer-matrix composites with opposite signs of the thermoelectric power have been obtained by using thermoelectric particles of opposite signs (namely tellurium and bismuth telluride) positioned in the interlaminar interface of the two composites [31]. As illustrated in Fig. 2, the composites with opposite signs can be electrical connected so as to expose their interface, which is the thermocouple junction for temperature sensing [33]. In Fig. 2, the through-thickness thermoelectric behavior is exploited.

Fig. 2. A thermocouple junction formed by electrically connecting two composites (A and B) with opposite signs of the thermoelectric power. The copper foil is the thermocouple junction [30].

Fig. 2. A thermocouple junction formed by electrically connecting two composites (A and B) with opposite signs of the thermoelectric power. The copper foil is the thermocouple junction [30].3.2. Longitudinal thermoelectric behavior of a continuous carbon fiber polymer-matrix composite

Another configuration of a thermocouple is in the form of a continuous carbon fiber polymer-matrix composite makes use of the thermoelectric effect in the fiber (longitudinal) direction. The thermocouple involves two dissimilar materials, which are carbon fiber laminae with fibers that are p-type for one lamina and n-type for the other lamina [34]. The two laminae form an interlaminar interface (Fig. 3), as ordinarily made in the absence of any interlaminar filler. The p-type and n-type fibers are obtained by the intercalation of the carbon fibers with acceptor and donor intercalates, respectively. The interlaminar interface between these dissimilar laminae is the thermocouple junction [34]. For the fibers to be intercalated, they need to be relatively graphitic.

Fig. 3. An optical microscope image of the cross-sectional view of a part of a continuous carbon fiber epoxy-matrix composite. Only an interlaminar interface and its two adjacent laminae are shown. The fibers in the top lamina are in the plane of the image; those in the bottom lamina are perpendicular to the plane of the image.

Fig. 3. An optical microscope image of the cross-sectional view of a part of a continuous carbon fiber epoxy-matrix composite. Only an interlaminar interface and its two adjacent laminae are shown. The fibers in the top lamina are in the plane of the image; those in the bottom lamina are perpendicular to the plane of the image.An advantage of using the interlaminar interface as the thermocouple junction is that two laminae with fiber in different directions (e.g., perpendicular to one another) gives a two-dimensional array of thermocouple junctions (Fig. 4). The array allows spatially resolved temperature sensing [34], [35]. Because light causes heating, the set-up can be used for light sensing too.

Fig. 4. A two-dimensional array of thermocouple junctions for spatially resolved temperature sensing. It is in the form of an array of interlaminar interfaces, as obtained by using two fiber laminae with orthogonal fiber directions. The intersection (overlap) of a fiber group of one lamina and a fiber group of the other lamina gives a thermocouple in the array. The fibers within a group are electrically shorted together at each of their two ends. The orthogonal fiber groups serve as an x–y grid of electrical interconnections for measuring the voltage from a chosen thermocouple in the array.

Fig. 4. A two-dimensional array of thermocouple junctions for spatially resolved temperature sensing. It is in the form of an array of interlaminar interfaces, as obtained by using two fiber laminae with orthogonal fiber directions. The intersection (overlap) of a fiber group of one lamina and a fiber group of the other lamina gives a thermocouple in the array. The fibers within a group are electrically shorted together at each of their two ends. The orthogonal fiber groups serve as an x–y grid of electrical interconnections for measuring the voltage from a chosen thermocouple in the array.4. Conclusions

This paper provides a review of thermoelectric polymer-matrix composites. In contrast to previous reviews [29], [36], [37], [38], [39], [40], [41], [42], [43], [44], [45], [46], [47], [48], [49], [50], which address only nonstructural materials, this paper addresses both nonstructural and structural materials. The structural materials addressed are continuous fiber polymer-matrix composites; the nonstructural materials addressed are discontinuously reinforced polymer-matrix composites and polymer-polymer composites. The composition, structure and thermoelectric behavior of these composites are addressed.

In contrast to conventional structural composites, a thermoelectric structural composite makes use of the reinforcing continuous fibers to contribute to the electrical conductivity of the composite. The directionality of the continuous fibers allows tailoring of the thermoelectric behavior in various directions, particularly the through-thickness direction and the fiber direction. The use of laminae with dissimilar fibers (with opposite signs of the thermoelectric power) that are in different directions provides an array of unmodified and ordinarily made interlaminar interfaces, which serve as an array of thermocouple junctions that are based on the fiber-dominated thermoelectric behavior in the fiber direction of each lamina. By modification through positioning fillers at the interlaminar interface, the filler-dominated through-thickness thermoelectric behavior can be tailored, thereby resulting in an increase of ZT in the through-thickness direction to 0.09, i.e., an increase by four orders of magnitude. By using dissimilar fillers at the interlaminar interface, dissimilar composites that exhibit opposite signs of the thermoelectric power are obtained [31], [32], [33].

Nonstructural thermoelectric composites include those containing inorganic particles or nanofibers (such as tellurium nanowires and CNTs) and those in the form on polymer-polymer composites. The polymers include conductive and nonconductive polymers. They exhibit a large range of ZT values, depending on the composition, structure and method of preparation. The highest ZT of 0.44 is exhibited by a polymer-polymer composite in the form of conductive polymerPEDOT containing PEDOT nanowires [8]. A high ZT of 0.39 is exhibited by a PEDOT-matrix composite containing tellurium nanowires [28]. However, for most of the composites reported, the ZT value is low, ranging from 10−6 to 10−1.

Conflict of interest

There is no conflict of interest.