1. Introduction

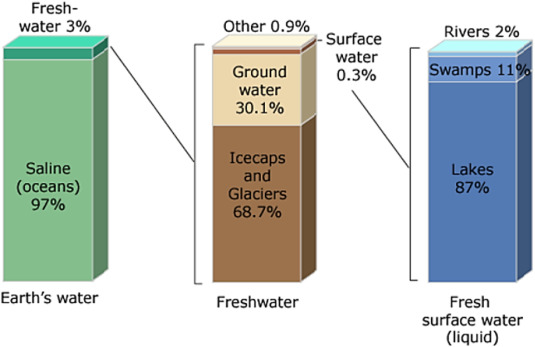

Water scarcity is a major global issue that provides considerable hurdles to long-term development. With rising population growth, urbanization, and the effects of climate change, freshwater supplies are becoming scarce in many parts of the world. As a result, there is growing concern about the effects of water shortage on human health, agriculture, industry, and the environment, making it an urgent topic for research and action [1,2]. Nevertheless, up to 97% of the planet's water is oceanic saline with a salinity of up to 30,000 parts per million of total dissolved solids (ppm TDS). Only three percent of the world's water is fresh [3]. The vast majority of the world's supply of potable water originates either from underground aquifers, such as wells, or from the surface of the earth, in the form of rivers, lakes, and reservoirs. Fig. 1 depicts the distribution of water across the earth's surface. The water that falls to Earth as rain or snow from the sky is the purest water on the planet [4]

Fig. 1. Distribution of earth's water [3].

Fig. 1. Distribution of earth's water [3].According to statistics, more than 750 million people suffer from the problem of drinking water. It is expected to experience a water shortage of about 60% in 2025 due to the rising global population [5]. Consequently, by 2050, it is expected that more than half of the global consumption of fresh water will be [6]. Since rivers, lakes, and aquifers are the only natural resources for drinking water on which the existence of the population in severely arid regions depends, the demand for fresh water has increased with the rapid pace of industrialization, especially after the world population has increased dramatically [7,8].

The only possible way to technologically and economically deal with the problem of water shortage is to desalinate the inexhaustible sources of water in the seas and oceans that can properly provide all human needs [9,10]. The desalination of saline water from its natural sources is one of the important alternatives that are in place all over the world. In recent years, substantial advancements have been made in desalination technology, and the global number of desalination facilities has rapidly expanded. According to the report of the International Desalination Association (IDA) for the year 2016, more than 120 countries in the world use desalination techniques to provide fresh water. The number of units in the world reaches more than 4000 units and produces about 30 million cubic meters per day [11,12]. The economic comparison is one of the criteria that separates the different options for consumer access to fresh water, and therefore, it may be more efficient to desalinate salt water than transport fresh water to areas of need far from natural sources [13,14].

Solar distillation has been proposed as a promising and long-term way of creating consumable potable water. In tropical and subtropical regions where potable water is scarce, sun distillation of brackish water has been utilized for a number of years. In various regions of the world, severe seasonal water shortages are becoming increasingly frequent. Moreover, desalination process is the most user-friendly and environmentally beneficial alternative technique [15]. This process can be powered by a variety of heat sources, including sunlight. Solar radiation has no fuel costs, but it requires greater area (for its capture) and typically more expensive equipment to achieve high temperatures.

A solar distiller is a simple device that uses solar radiation to purify or distill contaminated water [16]. It is suitable for use in households and businesses. It can be modest or substantial. It is meant to provide an average of 12 to 3 gallons of drinking water per day for a single home, or considerably larger quantities for a whole neighborhood or village. The lack of fresh water is partially alleviated in many parts of the world by creating greenhouse-like glass building and enclosing shallow saltwater basins within them. These solar energy distillation plants are low-tech and relatively cheap. They work well in places where only small plants are needed [17].

In their most basic form, solar stills are basins partially filled with saline water and topped with a transparent cover (see Fig. 2). The basins are thermally insulated on all sides, with the exception of the transparent top surface. The operation of solar stills is fundamentally based on a distillation process. Through a sloped transparent glass, solar energy enters the gadget and heats a basin of salted water [18]. The basin is predominantly black in order to absorb energy more effectively. On the colder glass panels, the hot water evaporates and then condenses. The condensed droplets are collected and used as potable water as they trickle down the panels [19].

Fig. 2. Schematic view of the CSS [19].

Fig. 2. Schematic view of the CSS [19].Researchers have investigated diverse techniques to improve the efficacy of solar distillation systems, including alterations to the distiller's configuration and the integration of supplementary components to elevate the water temperature [[20], [21], [22], [23], [24]]. Several methodologies involve the utilization of either a steady stream of water or a sporadic flow of cooling water onto the cover in order to reduce the temperature of the glass lid [25,26]. The impact of wind velocity on surface temperature has been observed, whereby heightened air movement has been found to elevate condensation and evaporation rates, consequently leading to increased production rates [27].

The studies have developed various solar stills incorporating solar collectors, condensers, low-pressure operation, heat recycling, heat storage, color multi-stage/multi-effect designs, and hybrid solar still/PV systems with the aim of enhancing productivity [28]. The utilization of phase change materials (PCM) possessing high latent heat capacities has been explored as a potential approach to enhance energy absorption and storage for the purpose of augmenting production, as indicated by sources [29]. Previous research has investigated the utilization of graded solar stills and single-basin simple solar distillers that incorporate phase change materials (PCM) for energy storage and enable continued distillation after sunset by utilizing stored energy. The findings indicate that a temperature differential between the water and the cooler's glass cover is advantageous [30].

Furthermore, the investigation of the sustainability dimensions of pyramid solar stills has been the subject of scholarly inquiry. Many studies [[31], [32], [33], [34]] conducted a thorough examination of sustainable water purificationtechniques, which encompassed pyramid solar stills. The authors emphasized the potential of these methods to offer safe drinking water in regions that are geographically isolated and have restricted access to clean water. The individuals engaged in a discourse encompassing diverse dimensions, including energy efficiency, environmental impact, and cost-effectiveness. Ultimately, they arrived at the consensus that pyramid solar stills exhibit potential as viable instruments for achieving sustainable water purification [35].

2. Classification of solar distillers

Solar stills can be classified into two types: single-effect and multiple-effect, which can be further categorized as either active or passive based on the heat source used for water evaporation. In passive solar stills, clean water is produced solely through solar radiation, while active solar stills use additional thermal energy from a solar collector to generate potable water. The authors' research is significant because it highlights the benefits of implementing active techniques and increasing the number of steps in solar stills to enhance the rate of evaporation and condensation, compared to traditional solar stills. The schematic representation of various solar still configurations are represented in Fig. 3 [34,36]. In order to increase the daily output of solar stills, various additional systems such as thermal solar collectors, heat exchangers, solar ponds, and hybrid PV/T systems have been incorporated in numerous studies [37]. Cooling the condensing surface has been attempted by several researchers, with methods such as running water over it to increase the temperature difference between the condensing surface and evaporated water [38]. And decreasing glass cover temperature by a layer of continuously flowing water [25], or using an intermittent flow of cooling water on the lid [33]. Wind velocity is also a factor that affects the temperature of the surface, as increased air movement leads to increased convective heat transmission from the cover to the atmosphere, which in turn increases the evaporation and condensation rates and output of the system [39].

Fig. 3. Designs of single effect passive and active solar stills [34,36].

Fig. 3. Designs of single effect passive and active solar stills [34,36].During the past ten years, a large number of studies have been widely discussed in the literature of single-effect solar still designs of varying types. Fan solar stills [40], spherical and pyramidal solar stills [41], wick solar stills [42], solar chimney and condensers [43], rotating wick solar stills [44], rotating disc solar stills [45], and solar stills with revolving drums [46]were among these designs.

Researchers have investigated the use of phase change materials (PCMs) for energy storage in solar stills. They studied the performance of a graded solar still and a simple solar distiller with a single basin, where a PCM was used as an intermediary for energy storage. The results showed that the distillation productivity was enhanced by continuing the distillation process after sunset, thanks to the energy stored in the PCM. The larger temperature difference between the water and the glass cover, which was at a lower ambient temperature, facilitated this enhancement. The employment of a simple solar distiller with a PCM storage medium however, is still uncommon [47,48].

3. Parameters affecting solar still productivity

The quantity of water that is produced by a solar still in a single day is typically used to evaluate its performance. This evaluation is affected by three primary factors: the operational parameters, the design parameters, and the meteorological parameters, as shown in Fig. 4 [49]. The solar radiation, outside temperature, relative humidity, wind speed, dust, and cloud cover are examples of meteorological parameters that are outside of our influence. However, the operational parameters, such as the color of the water, the water flow, the surfactant additives, the salinity and contaminant levels, system maintenance, water feeding, the position of the solar still, and other variables, can be adjusted to increase efficiency. In a similar fashion, design parameters such as the number of basins and slopes, the various types of still designs, and the inclination of the cover, thermal energy storage, basin absorption rates, reflectors and mirrors, a sun tracking system, insulation thickness, additive materials, and the depth of the water in the basin can all be altered to improve performance [50]. Solar stills can achieve better performance by optimizing both design and operational parameters, although uncontrollable factors such as solar radiation, temperature, humidity, wind speed, dust and cloud cover, remain constant [51].

Fig. 4. Governing parameters of a solar still [49].

Fig. 4. Governing parameters of a solar still [49].4. Pyramid type solar still

While evaporation and condensation rates are directly proportional to the surface area of the solar still, the pyramid solar still outperforms the basin solar still due to its larger condensation surface area [[52], [53], [54]]. The top cover of these distillers has the form of a pyramid in this design. The structure is referred to as the pyramid distiller because of this fact. It is more productive than traditional stills because it has a larger evaporation surface relative to the amount of basin space it requires [55].

Pyramid-shaped solar stills have been the subject of many studies aimed at improving their performance. Researchers have experimented with various modifications, such as adding components to increase the water's temperature [56], using cooling air to lower the temperature of the glass cover [57], and utilizing wind velocity to enhance heat transmission. Solar stills have also been developed with solar collectors [58], condensers [4], low pressure systems, heat recycling, heat storage, and hybrid PV systems to improve productivity [59]. However, these stills are not yet commercially viable due to their limited production. Researchers have also investigated the use of phase change materials with high latent heat capacity to absorb energy and enhance distillation productivity [60]. A recent study involved constructing a passive solar still in the shape of a pyramid with a rough-textured surface and a wicked concave still design, along with reflectors, to increase the evaporation and solar radiation absorption areas [61]. Additionally, it is worth noting that the triangular and square pyramid shapes are the exclusive options for covers and basins in this type of solar still [62]. Pyramid solar stills have many benefits, but the main one is that the side wall doesn't shade the water surface as much as in conventional solar still. [63], Furthermore, pyramid-shaped solar stills have a higher productivity because the condensing area is larger than the area of a conventional single slope type [64,65].

The problem statement of this study is to address the lack of comprehensive and up-to-date information on the latest techniques being used in the field of pyramid solar distillers. The study aims to provide a detailed review of recent advancements in pyramid solar distillation techniques, including new technologies, methods, and best practices.

Previous studies on pyramid solar distillation have mainly concentrated on specific techniques or particular aspects of the technology. However, the aim of this study is to provide a comprehensive and up-to-date overview of recent advancements in the field. Through a review of the latest techniques and innovations in pyramid solar distillation, this study sheds light on the efforts of researchers to enhance the efficiency of solar distillation systems. It covers the advancements made in this field up to the year 2023.

This research is a significant contribution to the field of solar energy utilization for water desalination and purification. By comprehensively reviewing recent techniques and innovations in pyramid solar distillers up to 2023, this study aims to enhance the efficiency and productivity of solar distillation systems, making them more practical and accessible for use in various regions worldwide. The originality of this work lies in its focus on providing a broad overview of the latest advancements in the field, rather than focusing on specific techniques or aspects of pyramid solar distillation. Furthermore, this review offers valuable insights for further advancements in pyramid solar distillers, highlighting their potential impact on addressing water scarcity and improving water quality in underserved communities. This paper can serve as a guide for researchers in choosing the optimal technique to achieve the best-optimized productivity from a pyramid solar still. In summary, this research is a crucial step towards developing more efficient and effective methods for harnessing solar energy for water desalination and purification, which could have a significant positive impact on improving access to clean water in many parts of the world.

5. Techniques used to improve the performance of pyramid type solar still

The availability of clean and safe drinking water is a critical global issue, especially in regions with limited access to freshwater sources. Pyramid type solar stills, as a simple and low-cost technology, offer a viable solution to address this challenge by utilizing solar energy to convert saltwater or contaminated water into freshwater through distillation. However, the efficiency and productivity of pyramid type solar stills can be further improved through the implementation of various techniques. These techniques, which include advancements in materials, condenser design, absorber performance, and storage systems, play a crucial role in enhancing the overall performance of pyramid type solar stills. The importance of these techniques lies in their potential to increase freshwater output, reduce heat losses, and enhance solar energy absorption, making pyramid type solar stills more efficient and effective in providing a sustainable source of clean water for communities facing water scarcity. This article will delve into the techniques used to improve the performance of pyramid type solar stills, highlighting their significance in addressing the global water crisis and improving access to safe drinking water in underserved area.

5.1. Glass cover inclination

The inclination of the solar glass has a significant impact on the efficiency of solar stills. A number of different variables, including the angle and orientation of the cover, as well as the latitude, affects this inclination. The amount of solar radiation that is received is directly proportional to the rate of evaporation, and it is anticipated that surfaces that are tilted with respect to the latitude angle will receive an average amount of solar radiation each year [37]. To optimize performance, the inclination angle is adjusted in relation to the sun's azimuth angle and solar intensity. In a study by Kabeel et al. [66], the impact of the condensing surface angle on productivity was investigated using three identical square pyramid distillers with varying glass cover angles of (1) 30.47°, (2) 40°, and (3) 50°, as shown in Fig. 5. The findings of the research revealed that as the angle of the glass cover in pyramid solar stills surpasses the latitude angle, there is a gradual reduction in the yield.

Fig. 5. Layout of square pyramid solar stills with varying angles of top glass cover [66].

Fig. 5. Layout of square pyramid solar stills with varying angles of top glass cover [66].5.2. Glass cover cooling

In a study conducted by Nagarajan et al. [57], a theoretical assessment was carried out to investigate the potential increase in the production of fresh water using a triangular pyramid-shaped solar still. This was achieved by blowing air across the entire surface of the glass, starting from the top and moving downwards. Fig. 6 demonstrates this process. According to the findings of the study, the volume of fresh water that was generated significantly increased, reaching approximately 10.1 kg/m2 at the highest air velocity (U = 40 m/s), and reaching up to 20 kg when the basin was used as a confinement. However, the actual production of fresh water is contingent upon the average speed of the surrounding wind. According to the findings, there was a rise in production proportional to a rise in velocity from 0.5 to 4 m per second. This represented a 104% increase.

Fig. 6. A diagram of a triangular pyramid solar still featuring cover cooling [57].

Fig. 6. A diagram of a triangular pyramid solar still featuring cover cooling [57].Mahian and Kianifar [67] conducted an experimental investigation to examine the effect of wind speed and Reynolds number on the efficiency of a single-basin square pyramid solar still with a basin area of 0.90 m2, utilizing natural and forced convection in Mashhad, Iran. The study revealed that the daily output of distilled water increased with the rise in both Reynolds number and wind speed. The mathematical model demonstrated that at a Reynolds number of 35,000, the daily production of freshwater could increase by up to 56%. The findings suggested that the use of a low-cost fan with minimal power could be a viable and cost-effective approach to enhance the evaporation rate and, consequently, the production of freshwater (Fig. 7).

Fig. 7. View of modified distiller with forced convective heat transfer [67].

Fig. 7. View of modified distiller with forced convective heat transfer [67].Taamneh and Taamneh [68] investigated the impact of forced and free convection on the performance of a square pyramid distiller under the climate conditions of Tafila, Jordan. They conducted an experiment using a solar still equipped with a pyramid-shaped glass cover and a basin area of 0.95 m2. The results indicated that forced convection systems are more efficient and cost-effective than free-convection systems, leading to an increase in evaporation rates and approximately 25% more fresh water.

In a separate study, Kabeel and Mohamed [69] analyzed the effectiveness of a pyramid-type distiller with a graphite absorber plate and a cooled glass cover at Tanta University in Egypt. Under the same climate conditions, the modified system produced between 9 and 9.19 l/m2/day, while the standard pyramid-shaped still produced between 4.37 and 4.43 l/m2/day. Compared to a conventional pyramid-shaped still, the modified pyramid-shaped still improved daily production by between 105.9% and 107.7%. Additionally, using graphite to cool the glass cover increased the daily efficiency of the proposed pyramid distiller by 97.2%–98.9% compared to a normal pyramid-shaped still. The use of graphite and the cooling of the glass cover also reduced the price of the distilled water generated by the pyramid distiller by 13.6%.

5.3. Thermal storage materials

Modi and Kuldeep [70] conducted a study to investigate the impact of thermal storage material (TSM), forced condensation, and evaporation on the productivity of a square pyramid distiller. Two experiments were carried out with water depths of 2 cm and 3 cm, with and without thermal storage (using black granite). The results showed that the still with forced evaporation at a water depth of 30 mm had a 33.24% higher daily yield than the still with forced condensation. When combined with thermal storage, the system achieved a 61.48% higher daily production of 2253.6 ml/m2 and an efficiency of 27.04% (61.53% higher). Sathyamurthy et al. [71] investigated the impact of water mass on the performance of triangular pyramid solar stills with and without a latent heat thermal energy storage system (LHTESS). According to their conclusions, lowering the amount of water mass resulted in an increase in the production of fresh water, and LHTESS resulted in a 35% increase in production. Additionally, Ravishankar et al. [72] investigated the productivity of pyramid-shaped solar stills using paraffin wax phase change materials under dry and arid conditions in Chennai, India. They found that the proposed techniques increased fresh water productivity by up to 20%.

5.4. Basin absorber modification

5.4.1. Basin absorber with nanomaterials

According to Owen and Well [73], Solar still basins reflect around 11% of the incoming solar radiation, rather than absorbing it. Shanmugapriya et al. [74], analyzed the thermophysical properties of an acrylic pyramid solar still with and without Zn2+ substituted Cr2O3 nanoparticles. Pure and Zn2+ doped Cr2O3nanoparticles were synthesized with different dopant concentrations and used with black absorber paint to enhance heat transfer. The solar still achieved a maximum average daily yield of 3.628 l/day and an efficiency of 23.48% under various test conditions. The output of the solar still containing 7.5 mol% Zn2+doped Cr2O3 nanomaterial was found to be higher due to the greater absorption of solar energy compared to other methods. In addition, Kabeel et al. [75], carried out an experiment to evaluate the efficiency of a novel pyramid basin-type solar still. This still featured an absorber plate covered with TiO2nanoparticles that had been doped with black paint. The experiment was carried out at varying water depths. When compared to an absorption plate that did not contain nanomaterials, the water temperature was 1.5° Celsius higher after the addition of TiO2 nanoparticles to the black paint. The accumulated yield of the solar absorber plate with a coating of 6.6 kg/m2 and without a coating of 6.2 kg/m2 was measured when the water level was 1 cm. In comparison to the conventional basin-type pyramid solar still, the TiO2 nano black paint coated pyramid solar still produced a distillate output that was 6.1% higher (Fig. 8).

Fig. 8. Schematic representation of both the traditional and enhanced absorber plates of pyramidal solar stills [75].

Fig. 8. Schematic representation of both the traditional and enhanced absorber plates of pyramidal solar stills [75].Response surface methodology (RSM) software was used by Farouk et al. [53] to make a mathematical model that could predict how well a pyramid solar distiller (PSD) would work in different weather conditions and with different types and amounts of nanoparticles. The study aimed to investigate the impact of different nanomaterials added to the water basin on the performance of the PSD. The study determined that titanium oxide (TiO2), aluminum oxide (Al2O3), and copper oxide (Cu2O) were the three distinct nanomaterials utilized. The optimal RSM parameter values were also anticipated. The ideal conditions for obtaining maximum PSD production were found to be 19.5% Cu2O concentrations, 720 w/m2 solar intensity, 38.6 °C ambient temperature, and 0.5 m/s wind speed. The average daily output gain for Cu2O -PSD, Al2O3-PSD, and TiO2-PSD was found to be 57%, 46%, and 36%, respectively, above PSD, with an average daily output of 6150, 5720, and 5300 ml/m2/day at a nano-concentration of 0.3%, compared to traditional PSD which produced 3900 ml/m2/day.

5.4.2. Basin absorber with wick materials

Saravanan and Murugan [76] examined the performance of a square pyramid solar still (SPSS) in the presence of wick materials experimentally. The test was carried out at Aditya Engineering College in Kakinada, India. Many wick materials, such as polyester, terry cotton, jute cloth, and woolen fabric, were inserted vertically in the water basin, as illustrated in Fig. 9. The studies conducted investigated the performance of various basin water depths (2, 3, 4, 5, and 6 cm) on the distiller's productivity. The results indicated that a basin water depth of 2 cm produced the highest yield compared to the other depths tested. Furthermore, the trial findings demonstrated that employing woolen textiles over jute, terry cotton, and polyester increased SPSS output by 9.4%, 20.9%, and 33.1%, respectively. On the other hand, Prakash et al. [77] design and analyze a novel pyramid distiller using corrugated wick material within the basin to augment system productivity in the climate of Coimbatore, Tamilnadu, India. The efficiency of the still has been found by conducting experiments and measuring various temperature elements of the still, solar radiation intensity and ambient temperature. The findings demonstrated that the distillate production is greater by 17.68% when compared to the conventional non-wick still. In addition, the researchers showed that the daily yield for produced stills was 4.82 L, and their efficiency was 50.25%.

Fig. 9. A schematic representation of a modified still with a vertical wick [76].

Fig. 9. A schematic representation of a modified still with a vertical wick [76].