1. Introduction

In the recent era of development, energy consumption increases many folds. This increased dependency on energy created many adverse impacts on our environment. Further fossil fuels are also limited in nature. This can be mitigated by intensifying the use of renewable energy such as small hydropower, geothermal, solar, wind, biomass, etc in the energy sector and with the wise use of the energy we are consuming i.e., by increasing the efficiency of the system. This is possible when the waste heat from the system will be reduced with the help of various waste heat recovery (WHR) systems and processes.

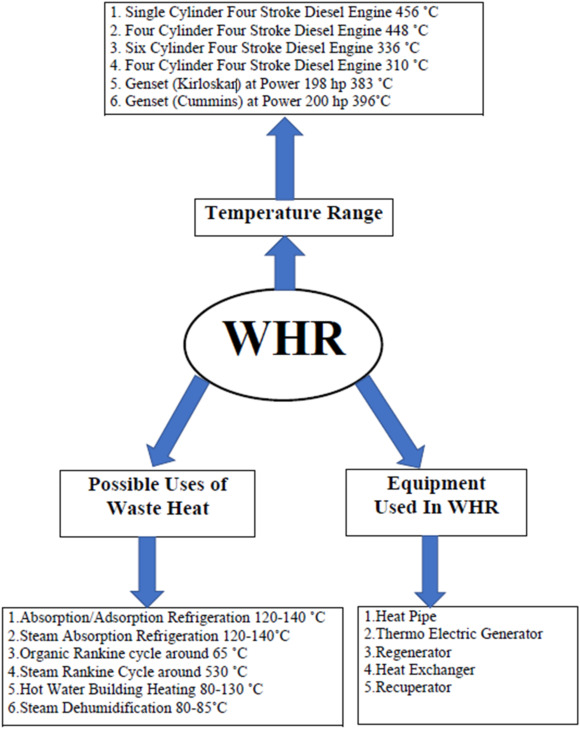

Generally, 30–40% of the total energy is used by the transportation sector in any industrial country. Out of the total energy released by the combustion of the fuel in any IC engine, only about 30% is used by the vehicle. The rest of the energy is frittered away into the atmosphere by the coolant system, Engine block, and exhaust of the engine. Among the stated waste heat sources, engine exhaust dissipates 40% of energy into the atmosphere (Yu and Chau, 2009). Similarly, a considerable amount of waste heat is present in different industries such as Cement and lime, Glass, etc. There are many ways to recover this waste heat. This paper will focus on different WHR systems like organic Rankine cycle (ORC) and thermoelectric generators with special attention to the organic Rankine cycle. Several Researchers review the various features of ORC (Armstead and Miers, 2014; Hatami et al., 2014; Jadhao and Thombare, 2013; Imran et al., 2018; Chintalaa et al., 2018). Recovery of the waste heat will improve the efficiency of the systems which in turn will save a considerable amount of energy throughout the world. It will also decrease global warming (Wanga et al., 2011a). The various aspects of WHR are given by schematic representation in Fig. 1.

Fig. 1

Fig. 11.1. Original contribution of this work

While reviewing the literature available on WHR, it is found that numerous works in the literature concentrate on any one aspect of the WHR and ORC. It may be the review of different configurations used in ORC, selection of working fluid in ORC, or any particular WHR technology. This work provides a comprehensive state-of-the-art review of various aspects of WHR technologies such as ORC, thermoelectric generators, etc. with a special focus on ORC. Considerable key focus areas of this work are as follows.

Discussion on performance and research challenges regarding the different architectures of ORC and selection of working fluid. Investigation on various experimental and parametric optimization studies on ORC. Identification of technical challenges associated with the application of Phase change material (PCM) in WHR. The utilization of WHR in adsorption cooling and hybrid vehicles is also examined. Besides these Indian scenarios on WHR is briefly discussed. Different knowledge gaps between present status and future studies have been also been identified.

Therefore, a compiled review of all relevant aspects related to WHR is a unique feature of this work. This state-of-the-art review is written to provide the comprehensive information at one place for the researchers working in this domain. Novelty lies in the attempt to review this area of WHR. This compilation could be a framework for future research and studies and would also help to bridge the knowledge gap between the present status and the future scope.

2. Organic Rankine cycle

ORC offers enormous possibilities to recover the heat from residual high and low-temperature heat resources. An overview of ORC is represented in Table 1 showing different applications and Manufacturers (https://orc-world-map.org).

Table 1. Overview of ORC installations.

| Share (%) of total installed capacity | ||

|---|---|---|

| Important WHR applications | Diesel Engine/Gas Turbine | 66.8 |

| Cement and lime | 8.3 | |

| Primary or fabricated metals | 7.2 | |

| Waste to energy | 5.8 | |

| Glass | 5 | |

| Different Power Plants | Geothermal | 76.5 |

| Biomass | 10.7 | |

| Heat recovery (Engine and Gas turbine) | 8.5 | |

| Leading Manufacturers | ORMAT | 65.7 |

| Turboden | 12.6 | |

| Exergy | 9.8 | |

The operation of ORC is similar to the conventional steam Rankine cycle (SRC), the only difference is that the organic working fluid is used in ORC and water used in SRC. A lower boiling point and higher vapor pressure compared to the water enable the ORC to operate at a lower temperature. Higher molecular masses of the working fluid in ORCs lead to compact designs. Further, it results in higher turbine efficiencies which can be up to the order of 80–85%, and higher mass flow rates (Chintalaa et al., 2018). A simple Rankine cycle mainly consists of four types of equipment namely condenser, pump, evaporator, and turbine. Working fluid is pumped into the evaporator where it gets heated by the waste heat to generate superheated steam. Steam is then passed to the turbine where it expands and produces the work and then it passes through the condenser where it loses the heat and its phase change takes place into liquid. The working fluid is again pumped into the evaporator and in this manner, the cycle repeats itself. A typical layout of ORC is given in Fig. 2.

Fig. 2

Fig. 2Waste heat available at low temperatures in the exhaust of the engine can be recovered by ORC. ORC is advantageous in many aspects in comparison to the various heat engine cycles. The weight and volume of the WHR system based on ORC are less and the utilization of waste energy is more. It gives high waste energy utilization and downsizes the system volume and weight which is an important feature for WHR in vehicles. Furthermore, the cost of ORC is less in comparison to the other WHR sources (Wanga et al., 2011a). According to the exhaust gas temperature when the temperature of a gas is above 650 °C it is termed as high-temperature exhaust gas, for 230 °C and 650 °C termed as medium temperature and below 230 °C it is termed as low-temperature exhaust gases Jaber et al. (2016). So, looking at the importance of the ORC as the WHR system many researchers have reviewed the various characteristics of ORC (Lecompte et al., 2015; Mahmoudi et al., 2018; Sprouse and Depcik, 2013; L Nadaf and B Gangavati, 2014; Wanga et al., 2011b). Mondejar et al. (2018) stated the maritime applications of Rankine cycles. A techno-economic survey of ORC systems was presented by Quoilin et al. (QuoilinMartijnVanDenBroek and PierreDewallef, 2013). Shi et al. (Shia et al., 2018) reviewed the modified ORC in WHR systems. Dolz et al. (2012) described a method to analyse different possibilities to use waste energies in a Diesel engine. Srinivasan et al. (2010) used ORC and examined the exhaust WHR potential of an IC engine. The specific emissions (NOx and CO2) was quantified. Further over a wide range of engine load and injection timing, the improvements in fuel conversion efficiency (FCE) with ORC turbocompounding and exhaust gas recirculation (EGR) was studied. The Pinch-point analysis was also performed by the authors in the case of the ORC evaporator. Their study reveals that higher PPTD results in more exergy destruction irrespective of various engine operating conditions in the evaporator. Serrano et al. (2012) investigated a two-stage turbocharged diesel engine that used the Rankine cycle WHR system. So, the several salient features of the ORC make it an attractive and efficient solution for WHR which can improve the overall efficiency of the system.

2.1. Recent trends in ORC

2.1.1. Different working fluids used in ORC

Working fluid is an important factor upon which the actual performance of an ORC-based WHR system depends. Several techno-economic aspects are related to the selection of working fluids in the ORC-based WHR systems. Working fluid is a medium that undergoes different thermodynamic processes during a cycle such as vaporization, expansion, and condensation. Generally, the working fluids are classified in the three groups termed as dry, wet, and isentropic. The slope (dT/ds) of the saturated vapor line on the temperature-entropy (T–s) diagram decides the category. The positive slope shows dry working fluid, negative for wet and infinite slope represents the isentropic working fluid as shown in Fig. 3. Dry or isentropic fluids are preferred in ORC systems because after isentropic expansion they reached a superheated state (Armstead and Miers, 2014). which means there is no chance of the presence of droplets after expansion.

Fig. 3

Fig. 3Li et al. (Dian-xunZHANG and WANG, 2015) mentioned about three types of working fluids. The first kind is the pure substances of a halogenated hydrocarbon containing chlorine ions, such as HFC-134a. The second kind is natural refrigerants like NH3 (R717) and hydrocarbons such as propane-butane and isobutane (R600a). The third kind is a mixture consisting of HFC or HCFC substances. The authors suggested that flammability, thermal and chemical stability, toxicity, thermal conductivity, liquidity, and price are the factors that should be considered while selecting the working fluid. Many researchers worked on the selection of working fluids for the ORC. A thermodynamic model was built by Wang et al. (Wanga et al., 2011a) with the help of MATLAB and REFPROP to analyse the different working fluids. Based on chemical and physical properties, nine pure organic working fluids were selected. It was concluded that from the environmental impact and safety point of view R245fa and R245ca are suitable although R123, R11, R113, and R141b performed better thermodynamically. It was suggested that future investigations can be conducted for engine fuel consumption and weight evaluation. Liu et al. (2018) used the Alkanes as working fluid in ORC to utilize multigrade (EGR, engine coolant, and exhaust gas) waste heats of diesel engine and found cyclic alkanes more advantageous than linear alkanes in terms of exergy losses, thermal efficiency, and net power output although cyclic alkanes showed weak performance in extracting heat from engine coolant. Mago et al. (2008) analysed regenerative ORC and used dry organic fluids such as R123, R245ca, isobutane, and R113 having their boiling points ranges from 12 °C to 48 °C. Further, it was mentioned that the second law analysis showed an increase in irreversibility if the dry working fluids are superheated. This fact emphasized that organic fluids should be operated at the saturation condition so that the irreversibility can be reduced. The authors further concluded that working fluid having a higher boiling point has better thermal efficiency.

Wang et al. (2017a) analysed the ORC using HFE7100, HFE7000 and HFE7500 as working fluids under constant external conditions. A computer program was developed to compare parametrically the first and second law efficiencies, power output, turbine size factor with an increase in turbine entry temperature. Their analysis showed that HFE7000 had the maximum thermodynamic efficiencies and power output whereas the lowest turbine size factor. Javanshir et al. (2017) designed a regenerative ORC using dry working fluids. The authors performed a large number of parametric calculations for fourteen dry working fluids and proposed an optimal solution to select the working fluid(s). The authors concluded that R113, iso-Butane, and Butane performed better in terms of specific net-work output. In their work Ma et al., 2016 (Ma et al., 2016) found that thermal efficiency depends on the choice of the working fluid whereas the WHR efficiency depends on the heat source properties. Several pieces of research have been carried out on Zeotropic mixtures. The properties of the zeotropic mixtures depend upon their components and the proportion of each component. Temperature glide is an important property that is exhibited by the Zeotropic mixtures and it helps for reducing the irreversibility instigated by temperature difference during the heat transfer process. Tian et al., 2017 (Tian et al., 2017). conducted the thermo-economic analysis of various zeotropic mixtures. In these binary zeotropic mixtures, one component was R123 and others were various siloxanes like D4, MDM, and MD2M. Their study concluded that as per thermodynamic performance D4/R123 (0.3/0.7) is the best option whereas as per economic performance MD2M/R123 (0.35/0.65) is the best choice. An overview of different studies carried out on working fluid is presented in Table 2.

Table 2. Some studies related to different working fluids used in ORC.

| Authors/Year | Working fluid studied/used | outcomes |

|---|---|---|

| Wang et al., 2011 (Wanga et al., 2011a) | R11, R141b, R113 and R123, R245fa, R245ca | R245fa, R245ca were suitable from an environmental impact and safety point of view. |

| Li et al., 2015 (Dian-xunZHANG and WANG, 2015) | R245fa | R245fa found better for ORC. |

| Liu et al., 2018 (Liu et al., 2018) | Alkanes | In terms of exergy losses, thermal efficiency, and power output, cyclic alkanes performed better. |

| Mago et al., 2008 (Mago et al., 2008) | R113, R245ca, R123, and isobutane | No need to superheat the dry organic fluids. |

| Wang et al.2017 (Wang et al., 2017a) | HFE7000, HFE7100 and HFE7500. | HFE7000 has the maximum thermodynamic efficiencies and power output. |

| Javanshir et al., 2017 (Javanshir et al., 2017) |

Fourteen Dry working Fluids R113, R114, Butane, Isobutane, etc. |

Specific net-work output was higher in the case of R113, iso-Butane, and Butane. |

| Ma et al., 2016 (Ma et al., 2016) | R 123, R245fa, R141b | R141b achieved the highest efficiency (21.82%) |

| Tian et al., 2017 (Tian et al., 2017) | Siloxanes-based zeotropic mixtures. | Economically MD2M/R123 performed better whereas D4/R123 was thermodynamically better. |

| Wang et al., 2017 (Wang et al., 2017b) |

Following four pairs used R245fa/R134a, water/ethanol, R1233zd/R1234yf and toluene/R143a. |

R1233zd/R1234yf found most suitable. |

| Shu et al., 2016 (Shu et al., 2016) | Toluene, D4, Decane, and Cyclohexane were selected in the HT-Loop while in LT-Loop R41, R125, R143a, and R218 were selected. | R143a and toluene showed the highest exergy efficiency (39.1%), thermal efficiency (9.9%), and net power output (33.9 kW). |

| G. Yu et al., 2016 (Yu et al., 2016) |

Toluene, R143a |

Toluene, R143a performed better techno-economically. |

| Shu et al., 2013 (Shu et al., 2013) | R245fa R1234yf, R125, R143a, R134a, R218, R124, R600 and R600a. | Sub–trans-DORC based on R143a performed better. |

| Zhang et al., 2013 (Zhang et al., 2013) | R245fa, R134a | For HT Loop R245 fa and for LT Loop R 134a selected as working fluid. |

| Yang et al., 2014 (Yang et al., 2014) | R245fa | For both loops, HT and LT R245fa were selected as working fluid. |

| Yang et al., 2016 (Yang et al., 2016) | R245fa | Concluded that to reduce the system complexity in both loops R245fa is used. |

| Fu et al. (Fu et al., 2015) | R245fa | For the experimental study, R245fa was chosen. |

| Pei et al. (PeiJing et al., 2011) | R123 | – |

| Zhou et al. (Zhoua et al., 2013) | R123 | – |

| Peris et al. (Peris et al., 2015) | R245fa | – |

| Miao et al. (Zheng et al., 2015) | R123 | The mass flow rate of the R123 was the independent parameter to control the ORC system. |

| Kosmadakis et al. (George and ManolakosGeorge, 2015) | R-404a, R-407c, R-410a, R-32, R-125, R-143a. | R-404a was selected. Although it was having the third-highest efficiency among alternatives but due to the lowest high cycle pressure. |

| Pu et al. (Pu et al., 2016) | R245fa HFE7100 | For the same pressure drop, R245fa has a larger electric power output than HFE7100. |

| Yang et al. (Yang et al., Huang) | R245fa | – |

| Desideri et al. (Desideri et al., 2014) | Solkatherm | – |

In the above table, we can see that many Chlorofluorocarbons (CFC) and Hydrofluorocarbons (HCFC) refrigerants have been used, but due to several environmental considerations, these will be phased out according to Montreal protocol.

Further from the survey of available scientific literature, it can be summarised that the selection of working fluid depends upon different factors such as thermal stability, environmental impacts, non-corrosiveness, appropriate critical temperature and pressure, Thermal Efficiency, work output, and Economy, etc. But keeping in mind environmental impacts and safety levels, R245fa and R245ca are suitable working fluids for engine WHR applications. However, these Hydrofluorocarbons possess Global warming potential and Hydrocarbons like R600a are inflammable. Some of the eco-friendly refrigerants and their properties are summarised in Table 3.

Table 3. Properties of some Eco-friendly working fluids.

| Eco-friendly working fluids | Boiling point Temperature (K) | Critical point Temperature (K) | ODP | GWP |

|---|---|---|---|---|

| Propane (R290) | 231 | 370 | 0 | 20 |

| Isobutane (R600a) | 261.3 | 408 | 0 | 4 |

| R134 a | 247.08 | 374.21 | 0 | 1430 |

| R245fa | 288.05 | 427.2 | 0 | 1030 |

| R1233zd | 291.47 | 438.75 | 0 | 5 |

| R1234yf | 243.7 | 367.85 | 0 | 4 |

| R143a | 225.91 | 345.86 | 0 | 4427 |

R1233zd and R1234yf forms new category of eco-friendly refrigerants which is called Hydrofluoroolefins (HFOs). From the above table it can be appreciated that R1233zd and R1234yf are environmentally friendly refrigerants. These are the promising alternative refrigerant with outstanding eco-friendliness and energy efficiency. Owing to the growing importance of HFOs several researchers conducted the experimental and numerical study to measure the various physical and chemical properties such as surface tension, thermal conductivity, density, diffusion coefficients, solubilities and viscosity of different HFOs (Miyara et al., 2018; Kondou et al., 2015; Romeo et al., 2017; Alam et al., 2018; He et al., 2018).

As the condensation process possess the great importance for the refrigerants so various studies had been conducted to understand the condensation and boiling processes (Nagata et al., 2016; Raabe, 2015; Righetti et al., 2018; Liu et al., 2019a; Longo et al., 2019). Wang et al. (TaoWang and MaogangHe, 2020) used the molecular dynamics simulation method to study homogeneous condensation process along with density and heat capacity. Study revealed that R1233zd(E) has faster condensation rate among HFOs.

Due to their noteworthy property of being eco-friendly, they have applications in various fields. Many researchers investigated the performance of HFOs in the application of hybrid compression absorption systems in which waste heat or solar heat used to drive the absorption cycle (Liu et al., 2019b; Salhi et al., 2018; Sujatha and Venkatarathnam, 2018; Wu et al., 2017, 2018). Zühlsdorf et al. (2018) used the mixtures of 50% Propylene/50% Butane and 50% R1234yf/50% R1233zd(E) in the booster heat pump. An improvement in the thermodynamic performance of the overall heat supply system was reported. The usage of HFOs in ORC systems is rising in order to reduce environmental impacts. As a result of this, many researchers have examined the use of HFOs in the ORC system (Eyerer et al., 2019; Molés et al., 2015; MolésJoaquínNavarro-Esbrí and PerisAdriánMota-BabiloniCarlosMateu-Royo, 2017; Yang and Yeh, 2016; Eyerer et al., 2017; Eyerer et al., 2016; Heberle and SchifflechnerDieterBrüggemann, 2016; Schifflechner et al., 2021). Yang et al. (Yang and Yeh, 2016) conducted the optimization study for different working fluid with low environmental impact and found that R1234yf showed the best energy performance as shown in Fig. 4.

Fig. 4

Fig. 4Further R1234yf and R1233zd are dry working fluid and thus superheating is normally not required. In general, R1234yf and R1233zd is used as a pair to extract waste heat available at different temperatures. R1234yf is used to recover the waste heat at low temperature whereas 1233zd is used to recover the waste heat at high temperature. Wang et al. (2017b) examined the regenerative dual loop ORC system to extract the waste heat from IC engine available at different temperatures. R1234yf was used in the low temperature loop (LT loop) and R1233zd in the high temperature loop (HT loop). Fig. 5 represents the temperature and entropy diagram of the system. In the figure, saturation liquid and vapor lines of R1233zd and R1234yf are represented by the red and blue domes, respectively. The magenta lines indicate the regenerative supercritical HT loop (HT1–HT6) that uses R1233zd as the working fluid, while the green lines represent the regenerative subcritical LT loop (LT1–LT8) that uses R1234yf as the working fluid.

Fig. 5

Fig. 5In this study four pairs of different working fluids were used and from environmental friendliness and thermodynamic performance point of view, pair of R1234yf and R1233zd found most suitable. Although HFOs are eco-friendly and non-inflammable but still more studies needed to know any kind of ill effect of HFOs on the living organisms.

Further zeotropic mixtures are good alternatives because they reduce the irreversibility of the system. Hydrofluoroethers are also being taken into consideration in different studies. But more thermo-economic studies are needed to establish better criteria for the selection of working fluid.

2.1.2. Different configurations

2.1.2.1. Regenerative ORC

A regenerator is an internal heat exchanger (IHE) that is used to preheat the working fluid before entering into the vapor generator. A simple ORC with a regenerator is shown in Fig. 6. Under certain conditions, the performance of the ORC can be improved by the use of a regenerator. Few kinds of research show that the use of regenerators improves thermal efficiency but there is no increase in system output.

Fig. 6

Fig. 6Flow and heat transfer analysis of a regenerator ORC was performed by Ge et al. (Zhong et al., 2015). The schematic arrangement of different equipment is given in Fig. 6 and different thermodynamic state points are shown on the T-s diagram in Fig. 7. Their study reveals two characteristic temperatures. The authors denoted these temperatures as Tw1(1) and Tw1(2). The condition established that if the inlet temperature of flue gas (Tw1) is in between or equal to these characteristic temperatures then the regenerator should be employed.

Fig. 7

Fig. 7Wang et al. (2017b) proposed a regenerative supercritical-subcritical dual-loop ORC system studying the effect of a regenerative heat exchanger. The authors gave a threshold value of turbine inlet temperature above which regeneration is beneficial. The authors concluded that any increment in the turbine inlet temperature results in an improvement in thermal efficiency. Mago et al. (2008) compare the regenerative ORC with the basic ORC and found the regenerative ORC superior in terms of first and second law efficiencies whereas on other hand it showed lower irreversibility. Also, for the same power production, regenerative ORC used less waste heat. A study shows that the flow resistance of regenerators generally not considered can increase the turbine exit pressure, decreasing the expansion ratio of the turbine.

2.1.2.2. CO2 transcritical cycles

Generally, organic working fluids have low thermal decomposition temperature which poses a great problem to extract waste heat directly from the high-temperature exhaust gases. Conventionally to deal with this issue in ORC WHR systems, a thermal oil circuit is used or dual loop ORC is employed. But the introduction of the thermal oil circuit makes the system bulky and results in extra energy and exergy losses. Whereas dual loop ORC increases the complexity and cost of the system. So, space limitation in vehicles makes it difficult to incorporate the above provisions, and miniaturization purposes are defeated. This problem can be overcome by using the CO2 transcritical power cycle (CTPC) because of the high thermal decomposition temperature of Carbon dioxide. From the above discussion, it is clear that CTPC is capable of extracting heat from the exhaust gases which are at high temperature thus use of an intermediate heat transfer loop can be avoided in ORC applications. In addition to this carbon dioxide allows the use of microchannel-based compact heat exchangers (Shu et al., 2017). Also, organic working fluids such as R123, R245fa, etc. cause environmental problems. At constant temperature, any heat exchange process increases the irreversibility and in the conventional ORC systems, heat exchange takes place at a constant temperature. Whereas carbon dioxide has a better thermal match without pinch limitation in the heat transfer process. Therefore, CTPC offers many advantages which makes it a very good option for WHR systems (Li et al., 2018). Many researchers reviewed the various aspects of CO2 based critical cycles (Karimi, Dutta, Kaushik, Bansal, Haque; Ahn et al., 2015; Chen et al., 2010). Y. Ahn et al. (2015) presented the review on supercritical CO2 cycle and discussed the research challenges associated with it. Chen et al. (2010) presented the selection criteria for the working fluids for ORC and supercritical Rankine cycle. Manente and Costa (Manente and costa, 2020) designed a unique supercritical CO2 cycle configuration that included dual expansion and dual recuperation. Chen et al. (2006) presented a comparative study between CTPC and ORC with R123 as working fluid for WHR applications. Configuration of CTPC is given in Fig. 8. It is found that CTPC performed better with no pinch limitation in the heat exchanger and this finding is attributed to the better temperature glide matching between heat source and working fluid. As it is evident in Fig. 9 that heating and cooling process taking place at temperature glide rather at constant temperature.

Fig. 8

Fig. 8 Fig. 9

Fig. 9Shu et al., 2017 (Shu et al., 2017) designed the CTPC system, suitable for high-temperature heat sources. The authors chose two different engine operating conditions. The authors reported that the average fuel consumption was reduced by 2.84%. Li et al., 2018 (Li et al., 2018) dynamically tested the CTPC system with and without a recuperator. Their study helps to understand the dynamic behaviour of the CTPC system. Their study reveals that the CTPC system does not vary much with the alterations in heat sources on the other hand easily changeable according to the adjustments which make it a very good option for WHR in the truck engine.

2.1.2.3. Cascade ORC

In any engine, generally, 70% of the total energy production is dissipated in the environment through the exhaust gas (EG), charge air (CA), coolant system, and exhaust gas recirculation. These heat sources are variable both in quantity and quality. So, these multi-grade characteristics and diversity of waste heat sources prove to be problematic while recovering the waste heat. Therefore, generally, the cascade-Organic Rankine Cycle (C-ORC) is utilised to recover the multigrade heat efficiently. Generally, the C-ORC consists of two loops. The first loop is the high-temperature loop (HT loop) mend for extracting heat from high-temperature sources such as exhaust gas recirculation and exhaust gas. The second loop is the low-temperature loop (LT loop) which is used to extract heat from low-temperature sources like coolant and charged air. Shu et al., 2016 (Shu et al., 2016) studied the 243-kW diesel engine. A novel WHR system was proposed based on the transcritical C-ORC to recover the multigrade waste heat from the engine in a cascaded pattern by the use of waste heat present in the EGR, exhaust gas, jacket water, and charge air. He et al. (2011) presented a combined thermodynamic cycle in which the ORC and the Kalina cycle together was used. ORC was used to extract heat of exhaust gas and lubricant whereas the waste heat of cooling water was extracted with the help of the Kalina cycle. The authors reported that the proposed combined cycle recovered more heat than the traditional cycle configuration. Ma et al. (2016) investigated the single loop ORC system whose layout is given in Fig. 10. In which the jacket water heat was used in the preheater and exhaust gas heat in the evaporator. The authors reported the WHR efficiency of 10.28% and an increment of the Internal combustion Engine efficiency of 14.23%.

Fig. 10

Fig. 10Yu et al. (2016) constructed and experimentally investigated a novel cascaded WHR system. The steam Rankine cycle was used in the HT loop and an ORC was used in the LT loop. The authors compared the three different configurations and found that the combined configuration of the Diesel engine with RC/ORC performed better. In another work, Yu et al. (2015) proposed a novel transcritical C-ORC. The techno-economic analysis was performed. The authors focused on four techno-economic indexes i.e., component-to-system cost ratio (CSCR), electricity production cost (EPC), depreciated payback period (DPP), and savings-to-investment ratio (SIR). Their results indicated that toluene and R143a gave the lowest EPC and the highest SIR.

2.1.2.4. Single loop and double loop ORC

Generally, a single ORC system is not capable of extracting the heat efficiently when there are several heat sources associated with WHR systems such as charged air, exhaust, and coolant, etc. This happens because the heat available in these sources is at different temperatures. Both the quality and quantity of heat are different in these sources. To overcome this challenge, two different loops are used. One is an HT loop which extracts the heat from high-temperature sources and the other is an LT loop which extracts heat from low-temperature sources or uses the residual heat of the HT loop or it may use to recover the heat both from low-temperature source as well as residual heat of high-temperature source at the same time. A layout of the dual-loop organic Rankine cycle (DORC) is presented in Fig. 11, proposed by Shu et al., 2013) (Shu et al., 2013). In the proposed system HT loop recovered the heat from the exhaust whereas the LT loop recovered the heat from the coolant then it takes the residual heat of the HT loop after that it extracts the remaining heat of the exhaust. Authors adopted two different modes, subcritical–subcritical (sub-sub) DORC and subcritical–transcritical (sub–trans) DORC, and used different working fluids in both the cycles.

Fig. 11

Fig. 11A unique layout of a single loop ORC system was proposed by Kim et al. (Young et al., 2016). which is presented in Fig. 12. The proposed system utilised heat both from low temperatures and high-temperature sources. Exhaust gas was the high-temperature source whereas the low-temperature source was engine coolant. In their proposed configuration low temperature and high temperature, recuperators were used to preheat the working fluid.

Fig. 12

Fig. 12Tian et al. (2017) proposed a different configuration of the DORC system as represented in Fig. 13 in which an internal heat exchanger (IHE) was used in the HT loop. This IHE was placed in between the turbine and condenser. In this IHE, the working fluid coming out from the turbine interacts with the working fluid going into the evaporator and transfers the heat. The authors also analysed the situation when IHE was equipped in the LT cycle and concluded that it enhanced thermal efficiency.

Fig. 13

Fig. 13Zhang et al. (2013) used the DORC system to exploit the waste heat energy of a Diesel engine as demonstrated in Fig. 14a. In the HT loop, working fluid extract the heat in the evaporator 1which is given by exhaust gases. In the LT loop working fluid gets heated in the intercooler after that it passes through the preheater where it absorbs the residual heat of the HT loop. After that working fluid absorbs the heat given by the coolant in the evaporator 2. Different state points of the HT loop and LT loop are shown in Fig. 14b. The system achieved a significant reduction in the brake specific fuel consumption (bsfc) and the relative output power was improved.

Fig. 14a

Fig. 14a Fig. 14b

Fig. 14bYang et al. (2014) presented a different configuration of the DORC system as per the layout given in Fig. 15a This system would capable to recapture the multigrade heat of a six-cylinder Diesel engine. In this system, the authors used a recuperator in the HT loop to preheat the working fluid. Different state points on the T-S plot presented in Fig. 15b. The proposed system achieved an increment of 13% in thermal efficiency.

Fig. 15a

Fig. 15a Fig. 15b

Fig. 15bAfter the above work in 2014 Yang et al. (2016) 2016 used the DORC system in a gas engine to extract the multigrade waste heat. A different layout of DORC was proposed by Wang et al. (2017b), which is demonstrated in Fig. 16. The authors used the two regenerators both in high-temperature ORC circuits and in low-temperature ORC circuits. In both the loops, regenerators were used to transfer heat from the superheated working fluid which is coming out from the turbines after expansion to the subcooled working fluid coming out from the pump. HT loop used R1233zd working fluid, operated in the supercritical range whereas the LT loop used R1234yf operated in the subcritical range.

Fig. 16

Fig. 16A summary of various studies related to the various cycle architectures is presented in Table 4.

Table 4. Summarised Studies with different configurations.

| Authors/Year | Different Configurations | Working Fluids | Performance/Efficiency | Highlights |

|---|---|---|---|---|

| Ge et al., 2015 (Zhong et al., 2015) | Regenerative ORC | R123, R245fa | Output 556 kW | Proposed a simplified optimal design method. |

| Shu et al., 2017 (Shu et al., 2017) | CTPC | CO2 | – | The average fuel consumption was reduced by 2.84%. |

| Li et al., 2018 (Li et al., 2018) | CTPC | CO2 | Turbine Isentropic Efficiency 57%. | CTPC was least affected by narrow fluctuations of heat sources. |

| Shu et al., 2016 (Shu et al., 2016) |

Transcritical C-ORC |

HT Loop used Toluene, LT Loop R143 a | Thermal efficiency 9.9%, net power output 33.9 kW | Toluene and R143a were suitable combinations for the HT and LT Loop. |

| Yu et al., 2016 (Yu et al., 2016) | Cascaded dual-loop RC/ORC used | Water, R123 | Mechanical Power of 15.0 kW could be obtained by this test bench. | WHR increases with the increased engine load, |

| G. Yu et al., 2016 (Yu et al., 2015) |

Transcritical C- ORC |

Toluene, R143a |

– | Expanders and heat exchangers would be the critical component for optimizing the system cost. |

| Shu et al., 2013 (Shu et al., 2013) | Subcritical and transcritical DORC |

R125, R134a, R245fa, R143a, R218, R124, R600a R600, and R1234yf |

Net power output 39.91 kW, Exergy efficiency 48.42% | Sub–trans-DORC system with R143a gave the best net output power and exergy efficiency. |

| Zhang et al., 2013 (Zhang et al., 2013) | DORC | R245fa, R134a | – | Relative power output improved by 2%. |

| Yang et al., 2014 (Yang et al., 2014) | DORC | R245fa | WHR efficiency was 5.4% | BSFC was reduced by a maximum of 4%. |

| Yang et al., 2016 (Yang et al., 2016) | DORC | R245fa | The thermal efficiency was found to be 8.79%–10.17%. | The heat transfer area of the heat exchangers was mainly influenced by operating parameters and engine operating conditions. |

2.2. Experimental studies on ORC

With the continuous improvement in ORC technology, many experimental and parametric studies have been conducted in recent years. Chang et al. (Changa et al., 2015) used a scroll type expander in an ORC system with HFC-245fa as a working fluid. The authors reported that when the cycle was operated under fixed superheating conditions, the maximum cycle efficiency, expander efficiency, and power output of the expander are 9.44%, 73.1%, and 2.3 kW respectively. The authors concluded when the expander is operated in various superheating conditions, the expander and cycle efficiency simultaneously increases with the increase of superheating. Authors also concluded that expander efficiency, as well as cycle efficiency, increases with the superheating but this also increases the irreversibility in the evaporator. A 250 kW ORC cycle system was constructed by Fu et al. (2015). Under design conditions, their system achieved the net power output of 243 kW while system thermal efficiency and isentropic efficiency were reported 9.5% and 63.7% respectively.

Pei et al. (PeiJing et al., 2011) studied an ORC system and gave a novel idea to reduce the cavitation in the pump. The bypass provided in the conduit between the pump and the tank solved the cavitation problem. Zhou et al. (Zhoua et al., 2013) constructed an ORC system to extract the heat from flue gases. In this system, the R123 was used along with scroll expander. Peris et al. (2015) developed a model based on various data on ORC performance in the laboratory and industry. This model was used to calculate electrical production. The authors reported the net electrical efficiency and isentropic effectiveness of the expander, 10.94%. and 64.89% respectively with a payback period of 4.63 years.

Miao et al. (Zheng et al., 2015) tested and analysed the operation characteristics and performance of an ORC prototype with R123 as the working fluid with the scroll expander. Heat source temperatures were kept between 140 °C and 160 °C. The ORC system was controlled by the mass flow rate of working fluid and external load. Shaft powers of 2.35 kW and 3.25 kW were reported at 140 °C and 160 °C source temperature respectively. Kosmadakis et al. (George and ManolakosGeorge, 2015) conducted an experimental investigation on an ORC. A system was designed to operate under supercritical conditions. A converted scroll expander was used in the ORC engine. ORC engine was tested at 95 °C. The authors achieved about 6% thermal efficiency. Pu et al. (2016) constructed the compact ORC system for extracting waste heat from a low-temperature heat source and studied the influence of main parameters on the system performance. Yang et al. (Yang et al. Huang) also performed the experimental study on a 3 kW ORC system and investigated the effect of pressure drop and condenser temperature on system performance. Desideri et al. (2014) performed the experimental study on a 10 kW ORC for the WHR. Song et al. (2015) used the recuperator in an ORC system which was used to preheat the working fluid before going into the evaporator. When the ORC unit is employed in any IC engine to extract the waste heat energy, its increased weight and back pressure due to this, affect the engine performance. Battista et al. (Di Battista et al., 2015) experimentally investigated these effects and found that increased weight required an additional power equal to 1% of fuel consumption. Aly (1988) employed an ORC and used R12 in a diesel engine to recapture waste heat available in the cooling water and exhaust gas. The author reported that the cycle power output can supplement the base engine power by about 16% of its output power.

To understand the system's behaviour and inertia, steady and transient experiments were done in three engine operating points by Torregrosa et al. (2016). Simple control system based on adaptive PIDs was used to taken account the dynamic impacts of an ORC, namely high inertia effects of boiler and condenser and low inertia effects of condenser pump and volumetric expander. In order to understand the dynamic performance of a microscale ORC system under various load conditions, Liu et al. (2019c) conducted the experimental research. It is reported in the study that small disturbances by the load changes can be balanced by the systems but in the case of large disturbances system was not able to restore to a stable state. Wei et al. (2008) formulated the dynamic model for an ORC and validated with the experimental data to know the behaviour of the system during transient conditions. In a novel design of an ORC, Yun et al. (2015) used the multiple expanders in parallel. experimentally investigated an ORC. Performance of the system was tested in different operating modes and in dynamic tests. Jung et al. (2015) performed an experimental and model study of an ORC. In the study dynamic behaviour of the system was focused and zeotropic mixture of R245fa and R365mfc was examined. Generally, the ORC operates under highly transient conditions because due to load variation temperature of heat sources are liable to change frequently. These conditions required better control mechanism. Peralez et al. (2017) in his study showed that effective superheat control is a key factor for controlling an ORC system for engine WHR. Cai et al. (2020) studied the dynamic characteristics of an ORC having zeotropic mixture (R134a/R245fa) as the working fluid. It is found in the study that response speed of ORC system with increases with mass fraction of R134a. The system response speed with the disturbance of fluid mass flowrate was faster as compare to the exhaust temperature. In another study Cai et al. (2021) established the dynamic model for a calibrated ORC which was applied to the subcritical and transcritical system. Pei et al. (2011) constructed and dynamically tested an ORC with R123 having the working fluid. ORC efficiency was found 6.8% with temperature difference of about 70 °C between the hot and the cold sides. Galindo et al. (2017) modelled an ORC and calibrated it with an experimental setup of an ORC which used the swash-plate expander. An experimental study was performed on ORC by Bai et al. (2020) to know the characteristics of the ORC under varying mass flow rate of the working fluid and cooling source. The study revealed that when the mass flow rate of the working fluid is increased by 0.01 kg/s, evaporation pressure increases by 26.10 kPa. Further mass flow rate of cooling source affects the operating parameters. Therefore, study concluded that the simultaneous regulation of both the mass flow rate of the cooling source and the mass flow rate of the working fluid would be better control strategy for an ORC control system.

After the survey of available literature on various experimental studies related to ORC, some important parameters which are having a key role in ORC based WHR systems, are summarised and represented in Table 5.

Table 5. Some Experimental studies related to ORC.

| Authors | Working Fluid | Expander type | Heat Source Temperature (°C) | Expander Efficiency (%) | System Efficiency (%) |

|---|---|---|---|---|---|

| Chang et al. (Changa et al., 2015) | HFC-245fa | Converted Scroll type | 95.6 | 73.1 | 9.4 |

| Fu et al. (Fu et al., 2015) | R245fa | Turbine | 133.9 | 63.7 | 9.5 |

| Pei et al. (PeiJing et al., 2011) | R123 | Impulse Reaction Turbine | 100 | 65 | 6.8 |

| Zhou et al. (Zhoua et al., 2013) | R123 | Scroll Expander | 90–220 | 57 | 8.5 |

| Peris et al. (Peris et al., 2015) | R245fa | Volumetric | 170 | 64.89 | 10.94 |

| Miao et al. (Zheng et al., 2015) | R123 | Scroll Expander | 140–160 | – | Thermal Efficiency 6.39 |

| Kosmadakis et al. (George and ManolakosGeorge, 2015) | R-404a | Converted Hermetic scroll expander | 95 | – | Thermal Efficiency 6 |

| Pu et al. (Pu et al., 2016) | R245fa HFE7100 | Single stage axial turbine expander | <100 | 59.7 | 4.01 |

| Yang et al. (Yang et al. Huang) | R245fa | Converted open-drive scroll type | 100 | 70.40 | Thermal Efficiency 6.39, System Efficiency 3.93 |

| Desideri et al. (Desideri et al., 2014) | Solkatherm | Modified single-screw expander | 27.5–108 | 64.78 | 9.8 |

| Song et al. (Song et al., 2015) | R416A | – | 105 | 0.8 | Thermal Efficiency 12.5 at 3.5 MPa Evaporator pressure, Electric Efficiency 6. |

After reviewing the various experimental studies, it is concluded that ORC is a prominent technology for WHR. But only a few works in the literature show the actual performance of ORC systems and there is a lack of techno-economic studies. Therefore, it is suggested that more investigations be done to know the effect of increased weight due to the ORC unit, back pressure, etc. on the whole system. In most of the experimental studies the steady-state conditions are considered so there is the need to investigate and understand the dynamic nature of the system. This will further help in developing better control systems for the system. Generally, the researcher used the scroll expander and very few used axial flow turbines. Further R123 and R245 fa were the working fluids that were mostly used.

2.3. Parametric optimization/simulations on ORC

There are many parameters involved in an ORC system such as evaporator pressure, condenser pressure, expander isentropic efficiency and condenser temperature, etc. These are the different parameters upon which the performance of the system depends. The number of parameters increase as the complexity of the architecture of the system increases. Many researchers performed parametric optimization and simulations to improve the performance of the ORC. Generally, in parametric analysis objective functions are formed to maximize net power output and minimize heat transfer area. Roy et al. (2010) used the ORC to utilize the waste heat available in the flue gas at the exit of the ID fan of a power plant. The optimization study on ORC using different working fluids was conducted and found that R123 gave the best results. Tian et al. (2012) techno-economically analysed an ORC system for WHR. The authors screened and recommended a suitable working fluid for the ORC. The authors took expansion ratio, thermal efficiency, electricity production cost (EPC), and the net power output per unit mass flow rate of the hot exhaust (Pnet) as the different screening criteria. Their results showed that R141b gave maximum Pnet and lowest EPC. Xi et al. (2013) conducted an optimization study on three different configurations. Vapor from the turbine was taken out and was used in the feed-water heater to preheat the working fluid before the evaporator and termed as single-stage regenerative ORC (SRORC). In another configuration, two feed-water heaters were used and termed as double stage regenerative ORC (DRORC). The authors compared the performance of these two cycles with the basic ORC (BORC) and found that DRORC exhibits better thermodynamic performance. Wang et al. (2014) and J. Song, C.-w. Gu (Song and Gu, 2015) studied the DORC for the WHR and conducted the parametric analysis to optimised the various parameters. Wang et al. (2013a) examined the effects of various parameters on the net power output and surface area of the heat recovery vapor generator (HRVG) and the condenser. M.-H. Yang, R.-H. Yeh (Yang and Yeh, 2015) conducted thermo-economic optimization with the use of a numerical method for the ORC-based WHR system and reported that the system with R245fa achieved an improvement of 6% in thermal efficiency. Yang et al. (2015a) used the Genetic algorithm (GA) as an optimization tool in their study. Imran et al. (2015) used the Non-dominated Sorting Genetic Algorithm-II (NSGA-II) as an optimization tool in which the minimum cost of the evaporator and minimum pressure drop was taken as objective functions whereas a constant amount of heat transfer was put as a restriction. Tian et al. (2014) developed a semi-dynamic model for an ORC application and conducted a parametric analysis to screen the working fluid among water, R134a, and R245fa, and found R245fa most suitable. Yang et al. (2015b) used the GA and studied the effect of condensation temperature, superheat degree, and evaporation pressure on the system performance. The authors chose the net power output per unit heat transfer area (POPA) and exergy destruction rate (EDR) as objective functions and found a maximum POPA of 0.74 kW/m2. Wang et al. (Wang et al., 1040) built the dynamic mathematical model of an ORC as a WHR system by Simulink. Different ORC parameters were analysed under various engine operating conditions. Their results showed that the dynamic response of condensing pressure was not varied much under different working conditions whereas the dynamic response of the evaporating pressure, working fluid enthalpy at the end of heating, and superheat degree changed a lot. An optimization model was built by Zhang et al. (2016) aimed to maximize the net power output of a bottoming ORC and investigating the unsteady parameters by using the Monte Carlo simulation.

Hountalas et al. (2007) performed a study on the Diesel engine to recover the waste heat to improve the brake specific fuel consumption. The authors used three different strategies to recover waste heat. Rankine Bottoming Cycles, electrical turbocompounding, and mechanical turbocompounding was used. The author used an engine simulation model and concluded that both mechanical and electrical turbocompounding increased the expansion ratio and exhaust gas temperature whereas the Rankine cycle did not affect the exhaust gas temperature and on the other hand provided the good bsfc reduction at both low and high engine loads. In another work, the authors developed the simulation model of the Rankine cycle which was used as a WHR system of a 2-stroke Diesel engine (Hountalas et al., 2012). A new approach was presented by Stobart (2015) in thermal management for vehicle propulsion. The author showed by the availability analysis that effective thermal efficiencies of 25–30 percent are feasible. The author concluded that high pressure resulted in reduced heat transfer which further reduced work output.

A review presented on parametric analysis shows that proper selection of working fluid, various operating parameters, and control strategies affect the performance of the ORC. Further, it is found that operating conditions of the ORC are variable and dynamic due to the factors like sink temperature and waste heat source. Because sink temperature depends upon the ambient temperature which is variable whereas the supply of waste heat is variable due to part load condition in an internal combustion engine and due to transient conditions in other waste energy resources.

3. Application of phase change material (PCM) in WHR

The main forms of thermal energy storage systems are Sensible Thermal Energy Storage (STES) and latent thermal energy storage (LTES). Generally, the waste heat is of fluctuating in nature. This reduces the efficiency of WHR systems. Due to this limitation, WHR is designed for one single operating point which forces them to operate at off-design conditions. This problem of intermittency in the availability of waste heat energy could be significantly reduced by employing thermal energy storage systems. A wide variety of PCMs are used in the LTES systems. Li et al. (2021) discussed the application of various medium-high temperature PCMs in industrial WHR applications. Magro et al. (Dal Magro et al., 2017) retrofitted the PCM based technology in the ORC-WHR system and reported the reduction in the thermal power fluctuation of a waste heat source which resulted in an increase in average thermal efficiency from 15.5% to 16.4%. Yu et al. (2019) employed the double LTES system in ORC-WHR system and LiNO3–KCl–NaNO3 is used as PCM. Their results showed a reduction in the fluctuation of engine exhaust heat and an increase in total output work.

The use of sensible heat storage increases the volume and weight of the system. On the other hand, PCM can store more energy in a small volume. There are various sources of waste heat energy in IC engines such as coolant, exhaust, and charged air, etc. This energy can be absorbed by the energy storage system and later on, it can be used in different applications such as to heat the passenger compartment and to warm the engine quickly while starting up. When an engine is cold started it uses more fuel and also produces more emissions. This problem can be overcome if the waste heat can be stored and then it is used to warm up the engine. Shon et al. (2014) used the waste heat of the coolant in an IC engine and stored this as latent heat in the fin tube heat exchanger and the PCM and then used its released heat to shorten the warm-up period. It was demonstrated with experiment that if 1300 kJ of heat which is stored in the 4.2 kg of xylitol is transferred during warm-up to the 5.5 L coolant in a 2L IC engine then there will be an increase of 56 °C temperature of the coolant. It further demonstrated that after installing the improved heat exchanger in an actual engine, warm-up time was shortened by 33.7%. Further results showed that coolant flow rate affects the absorption efficiency of a heat exchanger more strongly than the temperature of the coolant. and to increase the heat absorption efficiency there is a need to improve the convective heat transfer inside the tube. Similarly, Pandiyarajan et al. (2011) experimented on a PCM-based heat recovery system. The layout diagram of the system is presented in Fig. 17. A finned shell and tube heat exchanger was used along with the thermal storage system. The authors designed and fabricated the combined sensible and latent hat storage system for storing thermal energy. The system was filled with the phase change material inside the metallic cylindrical capsules and arranging them in a storage tank as per the layout given in Fig. 18. The performance of the engine was evaluated first with the heat exchanger and then without it and found that 10–15% of fuel power was stored in the combined heat storage system. Future studies could be concentrated on the use of multiple PCMs which will lead to a cascaded latent heat storage system.

Fig. 17

Fig. 17 Fig. 18

Fig. 18