1. Introduction

Eco-innovation, concerning novel endeavours that promote environmental, green, and sustainability-oriented solutions, is a concept of a significant importance to manufacturing firms, due to innovation prospects of environmental benefits. Manufacturing firms are used here to mean businesses involved in the production of new products (or finished goods) from raw materials and/or assembled components, e.g., Volkswagen the automobile manufacturer, Caterpillar the construction equipment manufacturer, Sony the electronics manufacturer, and Pfizer the pharmaceuticals manufacturer. Past research and practice tended to primarily focus on pollution control and waste reduction activities or on environmental initiatives for public goods and within the service sector. However, research on eco-innovation strategies transcends environmentally motivated innovations and encompasses products, processes, business model, marketing, and organisational innovations with environmental benefits (Arundel and Kemp, 2009; Geng et al., 2021). For instance, researchers note the importance of eco-innovation oriented towards practices such as resource efficiency (Levidow et al., 2016; Malinauskienė et al., 2018; Thurner and Roud, 2016) and cleaner production (Arundel and Kemp, 2009; Spirko et al., 2016). Eco-innovation strategy in this context means a set of actions and commitments by manufacturing firms for realising innovation that targets and boosts sustainable development. Therefore, the challenge for manufacturing remains to analyse eco-innovation strategies for an inclusive view of environmental, green, and sustainability-oriented solutions – as opposed to atomistic, piecemeal proposals. Significantly, literature is ambiguous on the nature of research topics and practical targets related to eco-innovation strategy in manufacturing. Furthermore, an analysis of the domain suggests the absence of a systematic literature review that analyses existing research and practice on eco-innovation strategy in manufacturing. This paucity serves as the focus for this article.

The aim of this article is to review the eco-innovation literature involving manufacturing firms based on a systematic approach and to offer a comprehensive insight on strategic considerations from manufacturing research and practice on eco-innovation. The review examines research clusters, methodologies, and theories for eco-innovation studies within literature. Using insights on research topics as challenges and practical targets as strategies for manufacturing eco-innovation from the review, the article sets an agenda for future eco-innovation research involving manufacturing firms.

This review is unique and needed because studies of eco-innovation in manufacturing firms consistently link environmental benefits with improvement in overall eco-efficiency (Afshari et al., 2020). This article complements previous eco-innovation reviews on manufacturing small and medium enterprises (SMEs) and digital transformation (Karakaya et al., 2014; Pacheco et al., 2018; Savastano et al., 2019) by focusing specifically on themes for eco-innovation strategies in manufacturing firms. Recent studies note that managers often lack a full understanding of what effective strategies and mechanisms could facilitate eco-innovation in manufacturing firms for delivering eco-innovative and sustainable solutions optimally (Salim et al., 2019). Driven by trends towards global knowledge economies, research also argues that eco-innovation strategies are crucial for the creation of wealth, new jobs, and achieving sustainability goals (Kemp and Andersen, 2004). Such trends also note potential boosts in firm competitiveness in areas of resource efficiency with lower production costs, reduced environmental costs of pollution control and waste management, and improved corporate image and stakeholder relations.

For manufacturing firms, eco-innovation plays a key role in moving towards sustainable production and evolving eco-innovation initiatives from traditional pollution control to cleaner production (Hojnik et al., 2018). Such transition opens up new business opportunities and allows manufacturing firms to grow through launching new products, entering new markets, deriving economic benefits, and influencing firm performance strategically (Metechko and Sorokin, 2018). In order to achieve such strategic objectives, manufacturers need to identify the most effective organisational mechanisms to improve the social and economic effectiveness of adopted measures for eco-innovation (Zarnic et al., 2012). Here, the suggestion is that insights on the nature of cost-efficiency for eco-innovation directs the manufacturing sector towards more environmentally sustainable growth paths. Additionally, at a macro level, there are clear indications of cost-efficiency for different environmental policy options. For instance, studies of GDP per capita analysing the cost-efficiency of environmental policies show that green R&D subsidies represent the most cost-efficient (increase in GDP from 0.03 in 2020 to 0.17% in 2030) with potential revenues from green R&D subsidy forecast to increase (0.31% of GDP in 2020 to 0.56% of GDP in 2030) (Li et al., 2018). This prospect implies that manufacturing firms should engage and implement eco-innovations strategically for improvements in economic performance. Such strategic considerations motivate contemporary eco-innovation studies, on the one hand, to explore drivers (e.g., environmental regulation and policies) for adopting eco-innovation in the manufacturing (Dewangan et al., 2017) and China (Feng and Chen, 2018a). On the other hand, there are studies emphasising the strategic barriers (e.g., financing) facing the adoption and diffusion of eco-innovation in countries such as Sweden (Alderin et al., 2016), Korea (Yi et al., 2020) the United Kingdom and the Netherlands (Simms et al., 2020). Such ambiguities stress the need for comprehensive insights on strategic considerations for eco-innovation to enhance and align organisational level strategies with wider national and regional initiatives promoting socio-economic prosperity and sustainable development.

The remainder of this review proceeds as follows. Section 2 introduces the review methodology, while Section 3 presents the review findings regarding topics and targets of manufacturing eco-innovation. Section 4 proposes theoretical foundations and discusses potential directions for future eco-innovation research.

2. Eco-innovation for manufacturing: a background

2.1. Defining manufacturing eco-innovation

Generally, innovation as a concept is neutral in terms of the type of change endeavour and focus. Innovation broadly involves the development and implementation of new ideas for products, processes, behaviour, and policies, see for instance, (Barragan et al., 2012; Bernauer et al., 2006; Cheng et al., 2013). In contrast, defining eco-innovation is very challenging even though literature provides several characterisations of the concept as illustrated by Table 1. Nonetheless, most definitions offer perspectives that emphasise the effects of innovation on the environment (e.g. (Carrillo-Hermosilla et al., 2010; Kemp and Pearson, 2007; Oltra and saint Jean, 2009),). However, in practice, bodies such as (European Commission, Europe INNOVA, OECD, and Eco-innovation Observatory) define eco-innovation based on the intentions of the moderniser, i.e., an individual, organisation, or country, in terms of what motivates or drives such moderniser to adopt eco-innovation. Further complexity in defining eco-innovation stems from regular comparison of eco-innovation with other related concepts such as sustainable innovation, green innovation, and environmental innovation. Yet, researchers note that sustainable innovation implements economical, ecological, and social aspects, whereas the remaining related concepts mainly stress economic and ecological aspects, even though studies tend to use these concepts interchangeably (Laperche and Picard, 2013). However, there are suggestions that adopting eco-innovation requires more societal and policy guidance, as the innovation process generates reflective changes in society and adapts business practices, consumption behaviours toward sustainability (Díaz-García et al., 2015).

Table 1. Systematic review protocol.

| Review element | Description | Focus in the review |

|---|---|---|

| Purpose | Aim of the review | The aim of this systematic literature review is to review and assess the status of eco-innovation in manufacturing and to define research gaps for future studies. |

| Search strategy | Course of action to conduct the search process | The search strategy was a manual search of Scopus indexed peer-reviewed articles using specified keywords |

| Search strings | Keywords used to conduct the search |

“eco innovation” OR “sustainable innovation” OR “green innovation” OR “environmental innovation”, “eco-innovative strategies”, “environmentally friendly innovation” OR “green technology innovation” OR “low-carbon innovation” AND manufacturing OR engineering OR industrial |

| Databases | Online database, publisher or professional network for scientists and research | The study uses Scopus |

| Screening and inclusion criteria | Terms for selecting and including publications | The screening and inclusion criteria for the review are: eco-innovation studies and research on manufacturing, engineering and industrial in ‘empirical’ and ‘theoretical peer-reviewed journal articles |

| Exclusion criteria | Terms for excluding publications | Exclusion criteria for the review are: duplicates, conference proceeding papers, and articles using the term “manufacturing”, “engineering” and “industrial” in unrelated topics |

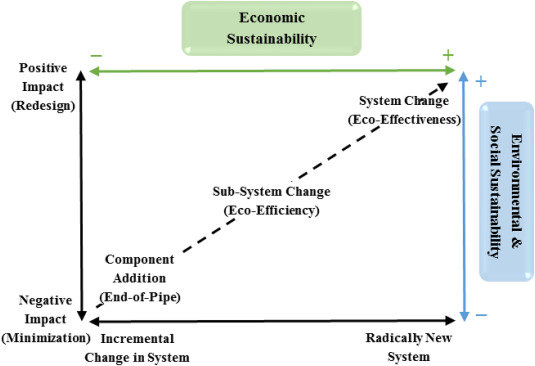

Fundamentally, putting emphasis on innovation towards ecologically specified sustainability targets is what makes eco-innovation a unique concept. Furthermore, from a technical viewpoint as shown in Fig. 1, trends suggest that as industry moves on from end-of-pipe solutions to more integrated technologies and product innovation, environmental motivation entangle with innovation (Schiederig et al., 2012). Thus, this review considers the three sustainability pillars for economical, ecological, and social considerations to capture a comprehensive eco-innovation perspective, ensuring eco-innovation for manufacturing focuses on the effect on the environment of implementing eco-innovation strategy in manufacturing, and the motivation it has over manufacturers, researchers, and policy makers.

Fig. 1

Fig. 1Eco-innovation strategy in manufacturing that supports the concerns in this definition contends with continuous trade-offs between economic growth and environmental protection. Economic effects of eco-innovation i.e., in relation to growth and employment, are not straightforward and are likely to vary, depending on the type of innovation and the context in which it is used. For instance, even though some studies find mediating influences of eco-innovation between motivation and organisation performance (Sun et al., 2007), there remains a contradiction between economic growth and ecological environmental protection (Song et al., 2020). Studies also argue that pure cost strategies are no longer viable in the current aggressive global competition, rather the ability to innovate and develop new market opportunities seems to be more significant (Andersen, 2008, 2010; Fernández-Mesa et al., 2020; Kemp and Andersen, 2004). With recognition that competition on knowledge is central in the knowledge economy, the rising importance of competition on values is less recognised and the idea of presentational innovation increasingly acts as a third form of innovation (along with technological and organisational innovation) with implications for eco-innovation (Pacheco et al., 2017). Presentational innovation as described by (Rennings, 2000) relates to the rising role of branding, image, and design for competitiveness, in which the identity a product gives, the story associated to the product. This story is as important as its function to consumer groups with interests on knowledge about a product – as opposed to the knowledge on pricing. Consequently, manufacturers need to move beyond reactive strategies for eco-innovation based on regulatory effects, from institutions to more proactive strategies attuned to management systems, organisational structures, or competencies to appreciate or utilise potential benefits from their environmental investments.

2.2. Manufacturing strategy and eco-innovation

Previous manufacturing studies indicate that rapid industrialisation with customisation potentials, leads to high rates in terms of investment but unfortunately also generates high resource consumption and contamination processes that create higher pollution and energy deficiency (Brook et al., 1992). Thus, there have been several manufacturing strategies with proposed solutions to natural resource scarcity and technologies motivated by the dynamics of economic systems and sustainable manufacturing practices, as shown by Fig. 2. Beginning with pollution control initiatives during the 1970s motivated by debate surrounding the scarcity of productive natural resources, current strategies for the 21st century now consider industrial ecology in a “system of systems” that ties several closed-loop production systems with interdependent and harmonious circular flow of resources (Hodson, 2010). Evolution in strategy occurs because studies note that earlier expositions e.g. (Solow, 1991), highlight sustainability as a socio-technical attribute of a development strategy, concerned more with a ‘feasible’ rather than a ‘desirable’ society. However, recent research (Dangelico et al., 2017; Durugbo et al., 2019; Sharpe and Agarwal, 2014) propose emphasis on sustainability as a dynamic and evolving concept, in need of updates to strategies and variables due to socio-technological changes in industry and society.

Fig. 2

Fig. 2Generally, manufacturing strategies tend to depend on evaluations of market potentials and risks. This focus is because manufacturing firms are part of larger networks and national systems of innovation that demand environmental considerations for production and the wider economies of nations and regions (Hirscher et al., 2018; Marra et al., 2017). Therefore, sustainability requires action, involvement, and renewal of roles by actors (e.g., governments, consumers, researchers, etc.) within these networks and systems (Sperling and Arler, 2020). Organisationally, such transitions demand proactivity in managerial practices and corporate strategies that promote eco-innovation for manufacturers (Tang et al., 2020) such as the social manufacturing concept introduced by (Kemp and Andersen, 2004; Zhang et al., 2019) that prompts different levels of user participation in the production process (e.g., Do-It-Yourself (DIY) and Do-It-Together (DIT) design strategies). Institutionally, sustainability transitions benefit from a set of institutional guidelines and principles for driving and guaranteeing eco-innovation for manufacturing firms remains a priority (Andersen, 2010; Arranz et al., 2020; Huiling and Dan, 2020).

Overall, the subject of eco-innovation remains a rich and untapped field of research. Researchers such as (Torgerson and Hall, 2012) identify general areas for future research such as measuring the greenness of national systems of innovation, multi-dimensional studies of eco-innovation research, and analysing complex feedback mechanisms and interrelations for sustainability. There are also calls (Puente et al., 2015) for more regional studies of developing countries on institutional and financial supports, with spotlight on manufacturing firms from different parts of the world. However, the general nature of eco-innovation strategies in manufacturing remains complex and unclear. For a start, research indicates that eco-innovation strategy in manufacturing increases the need for external skills (Sharpe and Agarwal, 2014) and requires the incorporation of open innovation strategies (also known as industrial symbiosis strategies) (Karimi and Nabavi Chashmi, 2019) and sustainable product-services systems (Erkoyuncu et al., 2019; Zhang et al., 2020) that foster partnerships. The argument being that for eco-innovation strategies to achieve sustainable development, manufacturing firms cannot innovate in isolation, particularly given the diversity of active firm activities and the specificity of scientific and technical knowledge on the environment. Hence, partnership is a way to create and capture collective creativity. Partnership also supports new services beyond a firm's core skills by offering complementary capability needs and harnessing customers' proximity. Different findings also suggest these skills lead to broader typologies for sustainable business models (Wagner et al., 2011) and green entrepreneurship models (Alhyasat et al., 2018) that should include strategic business practices and network linkages with the overall corporate strategy (Denyer and Tranfield, 2009; Kitchenham, 2004; Savastano et al., 2019). In view of ambiguities on eco-innovation strategies in manufacturing, there is a need for reviews to offer clarity on cogent strategies to inform research and practice. This need is the motivation for this review that focuses on analysing eco-innovation literature involving manufacturing firms.

3. Methodology

This research applies the systematic review methodology (Torgerson and Hall, 2012) that seeks to identify available research studies methodically with respect to a given theme. With focus on well-defined stages, a systematic review lessens the possibility of researcher bias and aids in methodical analysis of scientific fields and studies (Denyer and Tranfield, 2009; Kitchenham, 2004; Torgerson and Hall, 2012). The following subsections details the stages of the review, as summarised in Fig. 3.

Fig. 3

Fig. 33.1. Planning

The planning stage involves developing a well-focused research question followed by a review protocol (Denyer and Tranfield, 2009; Kitchenham, 2004; Savastano et al., 2019). Guided by the motivation and focus of this article, this review attempts to break new grounds for eco-innovation in manufacturing through analysing research topics and practical targets related to eco-innovation strategy and confronts the following research questions:

-

RQ1. What are the research topics within eco-innovation literature involving manufacturing firms?

-

RQ2. How can manufacturing firms formulate practical targets for eco-innovation strategies to enhance their sustainability?

These research questions guide the search strategy and review protocol in accordance with the systematic review methodology. Informed by the research questions, the review protocol, as summarised by Table 1, details focus for collecting, screening for quality, and synthesising findings. The search and screening for review articles entails using one main inclusion criteria, i.e., conceptual and empirical peer-reviewed journal articles in English language with specific focus on eco-innovation in manufacturing. Accordingly, the review excludes conference proceeding papers, systematic reviews, theses, reports, book chapters, and papers with unrelated topics.

3.2. Conducting

With the establishment of the review protocol, the review progressed with a literature search process using search strings to sift through article titles, abstracts, and keywords. The string set used to limit and capture publications were “eco innovation”, “sustainable innovation”, “green innovation”, “environmental innovation”, “eco-innovative strategies”, “environmentally friendly innovation”, “green technology innovation”, “low-carbon innovation”, “manufacturing”, “engineering”, and “industrial”. The search strategy proceeded electronically and involved using the search strings on the titles of Scopus English language indexed peer-reviewed articles. This search returned 172 English articles. As part of this stage, articles were downloaded from digital libraries and repositories of Elsevier (www.elsevier.com), Multidisciplinary Digital Publishing Institute (MDPI) (www.mdpi.com), Taylor and Francis (www.routledge.com), Wiley (www.wiley.com), Springer (www.springer.com), Emerald (www.emerald.com/), Inderscience (www.inderscience.com) and so on.

After testing for eligibility and cross-referencing, the screening process identified 134 unique journal articles, as summarised in Table 2, which formed the basis for the review. The majority of the articles were from the Journal of Cleaner Production, followed by Sustainability, Business Strategy and The Environment, International Journal of Environmental Research and Public Health, and Resources, Conservations & Recycling. ‘Other Publications’ that account for review articles in Table 2 include Climate Policy, The European Journal of Social Science Research, International Journal of Sustainable Development & World Ecology, International Journal of Innovation Management, International Journal of Sustainable Engineering, and International Journal of Operations and Production Management. Omitted journal articles from the original set focused on research areas such as academic-industrial cooperation for engineering education and approaches to sustainable innovation teaching within a new engineering postgraduate program. The accumulated body of literature, which includes journal articles published from 2006 to 2020, served as the focus for the extensive review and the trend captured by Fig. 4 shows yearly increase in the number of published articles.

Table 2. Peer-reviewed journal sources of review articles.

| Journal Name | Number of articles |

|---|---|

| Journal of Cleaner Production | 28 |

| Sustainability | 12 |

| Business Strategy and The Environment | 8 |

| International Journal of Environmental Research and Public Health | 6 |

| Industrial Ecology | 4 |

| International Journal of Production Economics | 2 |

| Climate Policy | 2 |

| Chemical Engineering Transactions | 2 |

| International Journal of Sustainable Engineering | 2 |

| Ekologi | 2 |

| Corporate Social Responsibility and Environmental Management | 2 |

| Energy Economics | 2 |

| Sustainable Development | 2 |

| Technological Forecasting and Social Change | 2 |

| International Journal of Business Innovation and Research | 2 |

| Journal of Human Sport and Exercise | 2 |

| Other Publications | 54 |

| Total | 134 |

Fig. 4

Fig. 43.3. Reporting

The next stage in the review involved reporting the findings based on analysing successfully screened articles in line with the review protocol. In accordance with the systematic review approach, a content and thematic analysis (Denyer and Tranfield, 2009; Kitchenham, 2004; Savastano et al., 2019) was carried out to identify, classify, and outline themes (research topics as challenges and practical targets as strategies) and to describe and compare main findings from the accumulated journal articles. The themes were identified to capture important patterns across and within the 134 journal articles. The process of analysis in this study followed an adapted version of Braun and Clarke’s (2006) 6-phase guide. First, the analysis involved familiarisation with the 134 journal articles, making notes of initial ideas for codes and themes. This step involved reading articles thoroughly and subsequently evaluating the body of literature in line with the research questions. Next, the analysis incorporated Webster and Watson’s (2002) “concept matrix” to record emerging themes. This method of analysis provides structure and helps to clarify the concepts from a review. Initially, comparative analyses of research data, methodologies, theories, and contributions preceded the clustering of topics and targets for eco-innovation strategy in manufacturing. Discussions then took place between the authors to finalise themes in line with suggestions by Braun and Clarke (2006) that researcher judgment is necessary to determine the nature of themes for reporting.

In terms of methodology, the review shows a distribution of 6% (8 articles out of 134) and 94% (126 articles out of 134) between conceptual and empirical studies, respectively. Empirical studies, as illustrated in Fig. 5, contain mathematical (e.g. statistical and econometric) models with 47% (63 out of 134), questionnaire surveys with 22% (29 out of 134), qualitative case interviews with 9% (12 out of 134), multi-methods with 8% (11 out of 134), and other methods such as TRIZ methodology, mental models, and action research with 8% (11 out of 134). Studies involving mathematical models apply quantitative framings such as game theory, evolutionary game model, non-linear models, projection pursuit model, SBM-DEA model, spatial lag model, system generalized method of moments (SYS-GMM) model, comparative analysis, fuzzy sets, analytic hierarchy process, and clustering algorithms. Underpinning the conceptual and empirical studies are widely used management theories, as shown in Table 3. The table describes the main construct of each theory and gives instances of the use of these theories in the reviewed studies.

Fig. 5

Fig. 5Table 3. Theories in eco-innovation studies involving manufacturing firms.

| Theory | Definition | Examples of eco-innovation studies in industry |

|---|---|---|

| Theory of knowledge based firms | Knowledge is the most strategically significant resource of a firm. |

|

| Absorptive capacity theory | Firm's ability to assimilate new knowledge for improving organisational learning. | |

| Ecological modernization theory | A school of thoughts argues that the economy benefits from moves towards environmentalism. |

|

| Theory of Planned Behaviour | Attitudes, norms, and perceived behavioural controls, together shape an individual's intentions that influences its behaviours. |

|

| Theory of interpersonal behaviour (TIB) | Intentions are immediate antecedents of behaviour, but habits mediate behaviour. |

|

| Niche theory | Argues that the niche of species is determined by the habitat, in which it lives and accompanying behavioural adaptations. |

|

| Institutional Theory | Attends to the more resilient aspects of social structure and considers the processes by which structures become authoritative guidelines for social behaviour. |

|

| Social Network Theory | The role of social relationships in transmitting information, channelling personal or media influence, and enabling attitudinal or behavioural change. |

|

| Resource Based View (RBV) Theory | A managerial framework used to determine strategic resources a firm could exploit to achieve sustainable competitive advantage. |

|

| Group Consensus Theory (GCT) | A social theory holds that social change should take place within the social institutions provided by it. |

|

| Resource Dependence Theory | The study of how the external resources of organizations affect the behaviour of the organisation. |

|

| Stakeholder Theory | A view of capitalism that stresses the interconnected relationships and value creation between a firm and its stakeholders. |

|

| Organisational Learning Theory | Posits on organisation learning as a process that focuses on knowledge creation and use used within organizations through interactions. |

|

| Industrial Symbiosis Theory | The part of industrial ecology that engages separate industries in a collective approach to competitive advantage. |

|

| Social Capital Theory | Entities consist of some aspect of social structure and facilitate certain actions for individuals within structure. |

|

| Dynamic capabilities theory | Firm's ability to integrate internal and external competences to address rapidly changing environments. |

|

During the reporting stage, themes emerged based on clustering concepts from articles and reviewing the themes to ensure coverage of research foci in the reviewed articles. Focused on the purpose of this review, the themes centre on research topics as challenges and practical targets as strategy. Using thematic analysis as part of the systematic review methodology enables deep and thorough understanding on data gathered. This review plans to contribute to knowledge through providing directions for future research based on analysing targets and topics of eco-innovation strategy in manufacturing.

4. Findings

The next section presents the research findings on eco-innovation topics and targets in manufacturing research and practice.

4.1. Topics for eco-innovation in manufacturing research

The analysis of the literature by this review suggests five main clusters on topics for manufacturing research involving eco-innovation: (i) eco-design and engineering, (ii) firm characteristics and performance, (iii) decision-making behaviour and options, (iv) industrial trends and indicators, and (v) energy intensity and efficiency. Fig. 6 and Table 4 captures these clusters and the next subsection details findings on these clusters from the literature.

Fig. 6

Fig. 6Table 4. Topics for eco-innovation in manufacturing research.

| Topics | Overview | Concepts from previous studies |

|---|---|---|

| Eco-design and engineering | Emphasis on advanced methods of productions and processing to achieve environmental sustainability. |

Eco-design definition (Chang and Deegan, 2008) Ecological problems motivate eco-friendly technologies (Lucchetti and Arcese, 2014; Galia et al., 2015; Bossle et al., 2016; Sullivan and Gouldson, 2017; Bag, 2018; Sanni, 2018; Malinauskienė et al., 2018; Livotov et al., 2019; Chang et al., 2019; Savastano et al., 2019; Afshari et al., 2020) Tools and techniques used for eco-designs (Choudhary et al., 2009; Gajdzik and Burchart-Korol et al., 2011; Wasmer et al., 2011; Ferrer et al., 2012; Negny et al., 2012; Köhler et al., 2013; Solli, 2013; Laperche and Picard, 2013; Lema & Lema, 2016; Kong et al., 2016; Spirko et al., 2016; Hou et al., 2017; Rogge & Schleich, 2018; Freire, 2018; Gupta and Barua, 2018; Correa et al., 2019; Faludi and Gilbert, 2019; Mitchell et al., 2020; Shahsavar et al., 2020; Palčič and Prester, 2020; Peng et al., 2020) TRIZ laws (Barragan et al., 2012; Hede et al., 2015; Mocan et al., 2016; Livotov et al., 2019; Malhotra et al., 2019) Air shock concept for solving technical engineering problems (Chakroun et al., 2014) 3D IC packing technology (Tu, 2011) Sailplane Fuselage Integrated Design Application (SFIDA) (Campana et al., 2017) Robotic systems (Mocan et al., 2016) Green biased technical change (Zhang et al., 2020) |

| Firm characteristics and performance | Emphasis on delivering outcomes with high efficiency, competitiveness and growth and shedding light on the common characteristics among firms' that eco-innovate. |

Measuring green innovation efficiency(Hwang et al., 2008; Oltra and Saint Jean, 2009; Bartlett and Trifilova, 2010; Yangjun and Chuanxu, 2016; Chen et al., 2016; Piccinno et al., 2016, 2018; Marzucchi and Montresor, 2017; Feng et al., 2018; Du et al., 2019; Malhotra et al., 2019; Wang et al., 2017; Pigosso et al., 2018; Laurent et al., 2019; Yi et al., 2020; Sun et al., 2020) EcoWater project for measuring eco-innovation efficiency at meso-level (Levidow et al., 2016) Green innovation performance and innovation ambidextrous (He et al., 2019) Fuzzy MICMAC analysis for defining overall manufacturing competitiveness (Dewangan et al., 2017) Contradiction between economic growth and ecological environmental protection (Hashmi & Alam, 2019; Sun et al., 2020) Ecological and economic performance (Scarpellini et al., 2016; Sharpe and Agarwal, 2014; Yurdakul and Kazan, 2020; Awan and Sroufe, 2020) Mediating effect of eco-innovation on organisation performance (Cheng et al., 2014; Alhyasat et al., 2018; Hojnik et al., 2018; Angsukanjanakul and Vasuvanich, 2019; Handayani et al., 2017; Kerdpitak et al., 2019; Fernández-Mesa et al., 2020) A win-win situation of ecological environment and employment stability (Bernauer et al., 2006; Woo et al., 2014; Shan and Wang, 2019) Environmental and economic performance improvements (Hellström, 2007; Doran and Ryan, 2012; Tessitore et al., 2013; Buchart-Korol et al., 2014; Ganapathy et al., 2014; Rubashkina et al., 2015; Dangelico et al., 2017; Ghisetti et al., 2017; Jin et al., 2017; Luqmani et al., 2017; Golini and Gualandris, 2018; Feng and Chen, 2018; Fernando et al., 2019; Li et al., 2018; Liu and Gong, 2018; Zhang et al., 2019; Aravossis et la., 2019; Salim et al., 2019; Arranz et al., 2020; Sellitto et al., 2020) Common characteristics of manufacturing firms that eco-innovate (Dangelico and Pujari, 2010; Chertow and Ehrenfeld, 2012; Segarra-Oña et al., 2014, 2016; Díaz-García et al., 2015; Keshminder and Chandran, 2017; Ociepa-Kubicka and Pachura, 2017) |

| Decision making behaviour and options | Emphasis on strategies and managerial practices for promoting green innovation for manufacturers |

Decision-making behaviour of manufacturing firms' eco-innovation (Scholz, 2006; Raisch and Birkinshaw, 2008; Guoyou et al., 2013; Rodrik, 2014; Thurner and Roud, 2016; Segarra-Oña et al., 2016; Pacheco et al., 2017; Tseng and Bui, 2017; Li and Liu, 2018; Gramkow and Anger-Kraavi, 2018; Jové-Llopis and Segarra-Blasco, 2018; Lu and Jiao, 2018; Murray, 2018; Roud and Thurner, 2018; Thomas et al., 2018; Hao et al., 2019; Prieto-Sandoval et al., 2019; Yu et al., 2019; Nguyen et al., 2020; Song et al., 2020; Tang et al., 2020; Xu et al., 2020; Xu and Zhai, 2020) Strategies that may favour eco-innovation implementation in SMEs (Lombardi and Laybourn, 2012; Klewitz and Hansen, 2014; Puente et al., 2015; Mitchell et al., 2015, 2020; Metechko and Sorokin, 2018; Prieto-Sandoval et al., 2019; Boutillier, 2019; Karimi and Chashmi, 2019) Green manufacturing practices are significantly related ecological conscious behaviour of consumers (Huiling and Dan, 2020; Waheed et al., 2020) |

| Industrial trends & indicators | Emphasis on trends in manufacturing that prioritise cleaner production and sustainability. |

Thematic areas of eco-innovation index (Loučanová & Nosáľová, 2020) Eco-innovation indicators from the perspective of niche theory (Peng et al., 2020) Eco-innovation trends in manufacturing (Feng and Chen, 2018; Geels et al., 2018) Cleaner production (Ishak et al., 2016) Usage of critical materials (Köhler et al., 2013) Necessity of training design engineers with new skills (Levidow et al., 2016; Malinauskienė et al., 2018; Thurner and Roud, 2016) No clear sign of eco-innovation impacts on economic advantages or production efficiency (Tessitore et al., 2013; Correa et al., 2019; Simms et al., 2020) Social manufacturing (Hirscher et al., 2018) Participatory design strategies (Wagner and Llerena°, 2011; Simboli et al., 2014; Sellitto et al., 2015; Metechko and Sorokin, 2018; Shahzad et al., 2020; Waheed et al., 2020) |

| Energy intensity and efficiency | Emphasis on energy use and intensity with respect to different orientation. |

Reducing energy intensity leading to energy efficiency (Porter & van der Linde, 1995; Wurlood and Noailly, 2018; Skeete, 2019) Energy intensity is not explained by a shift to cleaner production rather by the efficient use of energy and ecological improvements (Mulder and de Groot, 2012) Quantified impacts of green innovation on energy intensity (Carrillo-Hermosilla et al., 2010) |

4.1.1. Eco-design and engineering

Eco-design and engineering challenges is a research cluster that investigates advanced methods for productions and processing to achieve environmental sustainability. Eco-design characterises an advanced method for product and process design to achieve sustainability that meets both customer demand and environmental sustainability (Chang and Deegan, 2008). Here, economic growth and ecological problems motivate manufacturing firms to apply eco-friendly technologies during design (Livotov et al., 2019) and to design policies that promote eco-innovation by harnessing knowledge on current industrial practices and activities. Tools and techniques for eco-designs research include the popular TRIZ (Teoriya Resheniya Izobretatelskikh Zadatch) principles (Livotov et al., 2019; Malhotra et al., 2019; Mocan et al., 2016) and Life Cycle Management (LCM) approaches (Mitchell et al., 2020) and renewable power generation technologies (Rogge and Schleich, 2018) to measure environmental impacts of products, services, and activities. Examples of LCM approaches include Life Cycle Planning (LCP), Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) to evaluate environmental costs for the life of a product or through-life service. Eco-engineering includes eco-design and wider considerations for advanced manufacturing technologies that contribute to both firm's performance and eco-innovation. Examples of technologies with eco-engineering focus include the air shock concept for solving technical engineering problems (Chakroun et al., 2014), 3D IC packing technology (Tu, 2011), Sailplane Fuselage Integrated Design Application (SFIDA) (Campana et al., 2017), robotic systems (Mocan et al., 2016), and green biased technical change (Zhang et al., 2020).

4.1.2. Firm characteristics and performance

Firm characteristics and performance challenges is the next research cluster with goals of delivering high efficiency outcomes concerning competitiveness and growth, and for shedding light on common characteristics among firms that eco-innovate. For instance, eco-innovation in the chemical industry tends to involve process technology and organisational eco-innovations with most of the focus on adoption rather than creation. In general, the implementation levels of eco-innovation and Traditional Environmental Management (TEM) practices, as well as environmental and economic performance improvements, remain different between eco-innovation planners and adopters (Keshminder and Chandran, 2017; Segarra-Oña et al., 2016). Studies also present clear evidence of a positive correlation between industrial green development and the overall green growth of industrial organizations (Feng and Chen, 2018a).

In terms of performance, studies tend to present regional cases for potential eco-efficiency improvement along value chains. For instance, a study considers improvements for eco-innovation efficiency within large manufacturing firms through analysing water-service value chain at meso-level as part of the EcoWater project (Levidow et al., 2016). Related studies also use green innovation efficiency as a measure of the overall innovation of industrial enterprises using regression modelling (Yi et al., 2020), data envelopment analysis (Du et al., 2019), and TRIZ (Malhotra et al., 2019). On the other hand, studies regarding green performance within Chinese manufacturing industry (Wang et al., 2017) find that manufacturing eco-efficiency is higher than average innovation efficiency at both national and provincial level. Such insights motivate studies of eco-innovation efficiency linking eco-innovation performance and innovation ambidexterity (i.e., the firm's management ability to innovate based on exploration and exploitation) (He et al., 2019). There is also research using interpretive structural modelling and Fuzzy MICMAC analysis on manufacturing firms across India (Dewangan et al., 2017) to show that prioritising eco-innovation enablers increases the overall manufacturing competitiveness. However, there are contradicting studies showing no clear sign that a higher rank in eco-innovation could directly determine economic advantages or benefits for production efficiency – suggesting a contradiction between economic growth and ecological environmental protection (Hashmi and Alam, 2019; Sun et al., 2020). Thus, the link between eco-innovation and ecological performance remains complex and unclear (Scarpellini et al., 2016; Sharpe and Agarwal, 2014). For, instance eco-innovation appears to have a direct impact on pollution prevention, resource saving and recycling, and at the same time, indirect impact on cost reduction and thus the overall economic performance (Yurdakul and Kazan, 2020). In contrast, some studies find mediating effects of eco-innovation on organisation performance among manufacturing firms (Aeknarajindawat and Jermsittiparsert, 2019; Awan and Sroufe, 2020; Handayani et al., 2017; Kerdpitak et al., 2019). Other studies find direct influence of environmental performance on employment, in a win-win situation of ecological environment and employment stability achieved particularly among dirty industries such coal mining and petroleum extraction (Shan and Wang, 2019).

4.1.3. Decision-making behaviour and options

Decision-making behaviour and options challenges represent a research cluster seeking to propose decisions criteria and strategic choices for promoting green innovation in manufacturing. Focusing on strategic choices of manufacturing firms, some researchers argue for mental models to explain decision-making behaviours (Li and Liu, 2018) while other authors stress the need for strategically working in clusters particularly noting the inner workings of the largest clusters involving highly innovative firms in energy-intense industries (Thurner and Roud, 2016). Such behaviour remains critical due to imperatives for undertaking eco-innovation practices at strategic levels in enterprises because manufacturing eco-innovation practices eventually positively impacts consumers with ecological conscious behaviour (Huiling and Dan, 2020; Waheed et al., 2020).

There are also studies positing on decision cycles to inform eco-innovation strategies such as the take-make-distribute-use-recover cycle identified as favourable for eco-innovation implementations in SMEs (Prieto-Sandoval et al., 2019). Thus, eco-innovation could serve as the focus for incrementally or radically transformational processes that embrace using sustainable materials, making sustainable products, distributing products local markets, using green marketing strategies (e.g., integration with other stakeholders to share materials and potential by-products), and recovering waste and energy from production processes.

4.1.4. Industrial trends and indicators

The research cluster involving industrial trends and indicator challenges aims to analyse trends of transition to a mode of manufacturing that prioritises cleaner production and sustainability along with eco-innovation indicators. An important focus of research in this theme is the Eco-innovation index by the European Commission, which proposes sixteen indicators from eight different data sources that measure how well individual European Union (EU) member states perform along different dimensions of eco-innovation. The index identifies five thematic areas of eco-innovation inputs, eco-innovation activities, eco-innovation outputs, resource efficiency and socio-economic outcomes (Loučanová and Nosáľová, 2020).

Another area of concern for this theme is the analysis of manufacturing eco-innovation trends using proposed indicators. For instance, a study shows declining trends for eco-innovation growth in manufacturing between 2008 and 2011, attributed to the global economic crisis (Feng and Chen, 2018a). The study also highlights eco-innovation-driven development strategies by governments to redress this situation by strengthening green development policies. Using niche theory, another study offers indicators for eco-innovation with implications for saving resource, reducing environmental pollution, saving energy, and reducing emissions proposals (Peng et al., 2020). Other studies such as Geels et al. (2018) analyse challenges of socio-technical transitions research according to four main heading, i.e., emergence, diffusion, impact, and more synthetic cross-cutting issues.

Notably, in recent years, trends show transition in the production process to cleaner production modes for manufacturing (Ishak et al., 2016), for using critical materials (Köhler et al., 2013), and for resource efficiency with lower energy costs (Levidow et al., 2016; Malinauskienė et al., 2018; Thurner and Roud, 2016). However, some studies suggest limited links between higher eco-innovation and economic advantages in marketplaces or benefits for overall production efficiency (Tessitore et al., 2013), e.g., in recycling of plastics (Correa et al., 2019). For some researchers, there is a unique problem of eco-innovation perception by manufacturers and consumers, with suggestions to incorporate social manufacturing (Hirscher et al., 2018) and participatory design strategies such as DIY, DIT and through production clusters (Metechko and Sorokin, 2018).

4.1.5. Energy intensity & efficiency

Energy intensity and efficiency challenges is a research cluster that predispositions and arrangements for energy use. This theme seeks to shed light on energy use and consumption patterns along with design revisions required for reducing negative impacts on environment. Importantly, the quest to reduce energy intensity in manufacturing endures as a core objective of climate policies, and bodies like the International Energy Agency suggest that reducing energy intensity also contributes to the competitiveness of manufacturing firms, leading to energy efficiency “win-win” scenarios for policymakers and manufacturers (Porter and van der Linde, 1995; Skeete, 2019).

Energy intensity at the aggregate level remains unexplained by a shift to cleaner production in the overall economy (i.e., composition effect), rather explanations tend to originate from the efficient use of energy and ecological improvements within manufacturing industries (Mulder and de Groot, 2012; Voigt et al., 2014). In this regard, quantifying the impact of eco-innovation on energy intensity of manufacturing industries involves analysing patent statistics and input substitution involving the use of more labour, capital, or environmental innovations and innovative energy-efficient production techniques (Carrillo-Hermosilla et al., 2010).

4.2. Targets for eco-innovation in manufacturing practice

With insights from research topics, a range of determinants, i.e., drivers and barriers, for eco-innovation emerge from the manufacturing literature, as summarised by Table 5. The drivers or stimuli for eco-innovation include government funding and subsidies (Jové-Llopis and Segarra-Blasco, 2018; Li et al., 2018; Yi et al., 2020); R&D (Hou et al., 2017); leadership skills (Bag, 2018); and firm's internal factors such as firm size, performance, and training (Galia et al., 2015; Li et al., 2018). In contrast, the barriers of eco-innovation adoption identified in the literature (Ghisetti et al., 2017; Simms et al., 2020) include financial barriers, lack of consumers' demand, cost-consciousness, and absence of pressures to eco-innovate by key social actors such as consumers, policy makers and NGOs. There are also phenomena with neutral influences on eco-innovation like economy's openness (Yi et al., 2020). These determinants relate to internal factors (e.g., firm's internal factors, innovative organisational strategies, and enterprise scale), external factors (e.g., government funding, environmental regulation, and policies), and bilateral factors (e.g., easy access to formal sources of knowledge), i.e., factors with combined internal and external influences.

Table 5. Determinants of eco-innovation in manufacturing.

| Determinant | Examples | Sources |

|---|---|---|

| Driver or stimuli | Government funding and subsidies | (Jové-Llopis and Segarra-Blasco, 2018; Li et al., 2018; Yi et al., 2020) |

| R&D | (Hou et al., 2017; Li et al., 2018) | |

| Environmental regulation and policies | (Chang et al., 2019; (Feng and Chen, 2018a); Gupta and Barua, 2018; Jin et al., 2017; Jové-Llopis and Segarra-Blasco, 2018; Li et al., 2018; Roud and Thurner, 2018; Sanni, 2018; Tang et al., 2020; Wagner et al., 2011) | |

| Effectiveness of new product development team, and leadership skills | Bag, (2018) | |

| Firm's internal factors (e.g., firm size, performance, training, cooperation, market maturity and openness) | (Galia et al., 2015; Li et al., 2018) | |

| Joint tax-subsidy mechanism | Chang et al., (2019) | |

| Innovative organisational strategies | Sanni, (2018) | |

| Easy access to formal sources of knowledge | (Sanni, 2018; Yu et al., 2019) | |

| Anticipated regulation and self-regulation | Yu et al., (2019) | |

| Ease access to loans from financial institutions | Gupta and Barua, (2018) | |

| Market demand | (Jové-Llopis and Segarra-Blasco, 2018; Wagner et al., 2011) | |

| Resources efficiency | (Gupta and Barua, 2018; Roud and Thurner, 2018) | |

| Green manufacturing capabilities | Gupta and Barua, (2018) | |

| State ownership | Roud and Thurner, (2018) | |

| Barrier or inhibitor | Financial barriers | Ghisetti et al., (2017) |

| Impact of technology on products' characteristics, lack of consumers' demand, cost-consciousness, and absence of pressures to eco-innovate by key social actors | Simms et al., (2020) | |

| Enterprise scale, and industrial structure | Yi et al., (2020) |

Grounded on these determinants, the analysis of the existing studies by this review suggests eight main targets as strategies for eco-innovation in manufacturing practice, as shown by Fig. 7 and Table 6. These targets are: (i) industrial clusters and collaborations strategy, (ii) eco-engineering standards and skills strategy, (iii) green knowledge sharing and sourcing strategy, (iv) energy pricing and costing strategy, (v) innovation incentives and investments strategy, (vi) environmental regulations and protection strategy, (vii) energy structures and systems strategy, (viii) competitive and creative design strategy.