1. Introduction

The construction industry is faced with many challenges that have hindered its growth and led to extremely low productivity levels when compared with other industries such as manufacturing [1]. As a matter of fact, the construction industry is one of the least digitized industries in the world and most stakeholders acknowledge the age-long culture of resistance to change [2]. The lack of digitisation and overly manual nature of the industry makes the management of projects more complex and unnecessarily tedious [3,4]. The absence of adequate digital expertise and technology adoption within the construction industry has also been linked to cost inefficiencies, project delays, poor quality performance, uninformed decision-making and poor performance in terms of productivity, health and safety [5]. In recent years, it has become apparent that the construction industry must embrace digitisation and rapidly improve technological capacity especially with challenges of existing labour shortages, COVID-19 pandemic and the need to provide sustainable infrastructures [[6], [140], [141], [142]].

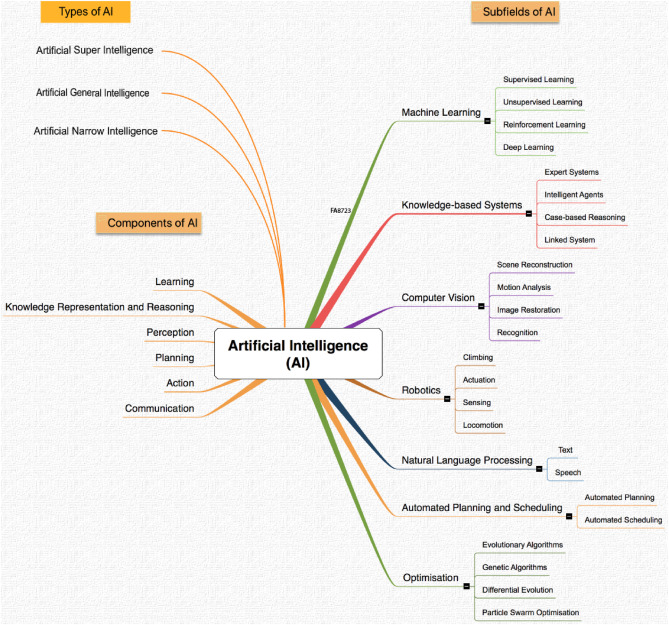

A foremost digital technology, Artificial intelligence (AI), has helped to achieve significant contributions to the improvement of business operations, service processes and industry productivity in recent years [1]. The adoption of AI techniques has helped to enhance automated and provide better competitive advantages as compared to conventional approaches [7]. The subfields of AI such as machine learning, natural language processing, robotics, computer vision, optimisation, automated planning and scheduling [8], have been applied to tackle complex problems and support decision-making for real-world problems. For instance, in the manufacturing industry, the advent of the fourth industrial revolution, commonly known as Industry 4.0 is geared towards automation, data-driven technologies and the application of advanced AI techniques [9]. It is evident that this revolution has led to significant process improvements, cost-efficiency, reduced production times, improved safety and helped to achieve firms’ sustainability goals [7,10,11]. However, the construction industry is yet to reap any significant benefit from AI despite its existing challenges.

In the past few decades, researchers have published articles on the application of AI and its subfields to tackle construction-specific challenges. For instance, machine learning has been used for health and safety monitoring, cost estimation, supply chain and logistics process improvements, risk prediction amongst others [[12], [13], [14], [15]]. Robotics has been applied in site monitoring and performance evaluation, offsite assembly, and the management of construction materials, plant and equipment [16]; Kumar et al., 2016; [17,18]. Knowledge-based systems have also been applied for tender evaluation, conflict resolution, risk and waste management, sustainability assessments, etc. (Myllyviita et al., 2017; Zhao et al., 2016; [19,20]. Despite this, construction remains one of the least digitized industries in the world and continues to struggle with the beneficial adoption of AI and other digital technologies. Some studies have attributed the lack of AI adoption to various challenges such as cultural barriers, high initial costs of deploying AI-based solutions, trust, security, talent shortages, computing power and internet connectivity. However, it is clear that there exists a lot of grey areas in the research trend of AI applications, future opportunities and barriers to adoption in the construction industry.

For the purpose of addressing the identified gap, it is important to answer the following research questions: (1) what are the areas of AI application in the construction industry (2) what are the future opportunities for AI application in the construction industry (3) what are the challenges to adoption of AI in the construction industry. It is therefore paramount to critically investigate the applications of AI in construction to understand the trends, opportunities, and barriers. The specific objectives of this study are to:

-

1.

Critically review the existing applications of AI and its subfields in the construction industry,

-

2.

Identify the opportunities for increased applications of AI in the construction industry and,

-

3.

Identify challenges affecting the adoption of AI in the construction industry

This study is an important contribution to knowledge that addresses the lack of information about AI in construction. This study first provides background knowledge on AI, its types, components and subfields and then discusses existing implementations in the construction industry.

2. Research methodology

An extant review of literature was conducted to identify the existing applications of artificial intelligence in the construction industry. Database queries were run on SCOPUS database and validated by data in other databases such as Institute of Electrical and Electronics Engineers (IEEE), Association for Computing Machinery (ACM) and Science Direct for dates ranging from 1960 to 2020 (six decades). Since modern AI research can be traced to the 1950s [21], the chosen dates were influenced by the desire to understand the trends in the adoption of AI over the decades in the construction industry as well as to identify the research gaps, opportunities and challenges. The databases (SCOPUS, IEEE, ACM, Science Direct) were selected for data identification because they host a collection of high impact publications especially in construction, engineering and computer science. SCOPUS is the largest citation database of research literature and quality web sources, and holds information about publications in IEEE, ACM and Science Direct. Hence, SCOPUS was chosen as the main data source while the others were used for full article download and data validation.

It was observed that most of the studies focused on using specific AI techniques in achieving stated goals, hence, the need to focus our search on specific AI techniques. The search was performed using twenty-nine (29) free-text keywords of the subfields and the construction industry: “Robotics” OR “Computer vision”, OR “Machine learning” OR “Expert System” OR “Knowledge-based Systems” OR “Optimisation” OR “Natural Language Processing” OR “Artificial Intelligence” OR “K-Means Clustering” OR “Hierarchical Clustering” OR “Fuzzy Clustering” OR “Model-based Clustering” OR “Linear Discriminant Analysis” OR “Monte Carlo” OR “Deep Belief” OR “Deep Boltzmann” OR “Deep Learning” OR “Convolutional Neural Network” OR “Stacked Autoencoders” OR “Recurrent Neural Network” OR “Deep Neural Network” OR “Speech processing” OR “Evolutionary computing” OR “Evolutionary Algorithms” OR “Swarm Intelligence” OR “Discrete Optimisation” OR “Convex Optimisation” OR “Automated Planning” OR “Automated Scheduling” AND “Construction Industry”, etc using advanced search to achieve the focus of the study.

The search was limited to articles in English. For keyword searches that produced over 100 articles, conference papers were excluded on the rationale that this is an established domain used regularly in construction. As a result, the majority of the conference journal publications are already written as journal articles. This was particularly useful in the domain of optimisation and knowledge-based systems, whose searches produced over 500 papers each. Afterwards, for subfields that have further classifications containing meaningful information such as machine learning, knowledge-based systems and optimisation, further searches were conducted using the same method.

After assessing the 1800 publications, 1272 were finally considered relevant and included for further investigations. The main inclusion criteria were the description or evaluation of an AI subfield and its techniques delivering a practical application in the construction industry. This was based on the abstract or title or the full-text article whenever the title or abstract are unclear. For each article, the following data were extracted: (i) application area in construction (ii) methodology/techniques used (iii) findings.

3. Overview of artificial intelligence and its subfields

The idea of developing machines exhibiting intelligence like humans traced back to several fields, which include philosophy, fiction, imagination, computer science, electronics and engineering inventions [22]. Alan Turing's test for intelligence [23] was a turning point in the field of AI as the test exceeds the traditional theological positions and mathematical conclusions about the possibility of intelligent machines. Sixty years later, intelligent machines are outperforming humans in so many domains such as learning [24] by leveraging rapid advances in other technologies such as big data and computer processing power [25]. The definition of AI as given by Ref. [26]; states that “AI is the study of how to make machines do things, which at the moment, people do better” captures the concept of AI perfectly. Fig. 1 shows an overview of the types, components and subfields of AI.

Fig. 1

Fig. 1There are three types of AI namely; Artificial Narrow Intelligence (ANI), Artificial General Intelligence (AGI), and Artificial Super Intelligence (ASI) [27]. ANI, Sometimes referred to as weak AI [27], it is a form of AI where machines exhibit intelligence in a particular domain such as chess playing, sales prediction, movie suggestions, language translation and weather forecasts [28]. AGI, sometimes referred to as strong AI, is concerned with making machines operate at the same level as humans [28]. According to Pennachin (2007), it refers to making machines that can solve a range of complex problems in different domains, control itself autonomously, with its own thoughts, worries, feelings, strengths, weaknesses and disposition. This remains a major goal of AI, but it has proved difficult to achieve and elusive. Artificial super intelligence (ASI) is concerned with building machines that exceed human capabilities across several domains [27].

The major components of AI, as shown in Fig. 1, are: (1) learning; (2)knowledge representation; (3) perception; (4) planning; (5) action, and; (6) communication [29]. Some studies have also classified some of these components as tasks that can be carried out by AI as compared to human senses.

To understand the current state of AI in the construction industry, it is pertinent to identify the major subfields of AI as shown in Fig. 1 above. Generally, the advances of AI application in industry has birthed various well known subfields of AI including: (a) machine learning (b) computer vision (c) natural language processing (e) knowledge-based systems (f) optimisation (g) robotics (h) automated planning and scheduling. An insight into each of these subfields is presented below.

3.1. A. Machine learning

Machine Learning is concerned with the design and use of computer programs to learn from experience or past data for the purpose of modeling, control or prediction using statistical techniques without being explicitly programmed. The Machine Learning methods include: (A) Supervised Machine Learning: this is concerned with the study of how machines make decisions based on what they have learnt from labelled datasets i.e. input and desired output pairings. It is categorised into classification and regression [30]; (B) Unsupervised Machine Learning: this is concerned with making machines learn essential structure in unlabelled datasets. It is categorised into clustering and dimension reduction techniques [31] and; (C) Reinforcement Learning (RL): this is defined as “learning of a mapping from situations to actions so as to maximize a scalar reward or reinforcement signal” [32]. It is a computational approach involving learning from the outcome of interactions with the environment; and, (D) Deep Learning: this is the current state-of-the-art in machine learning which has proven to give more accurate predictions than conventional machine learning techniques [[33], [34], [35]].

3.2. Computer vision

Computer vision is a multidisciplinary field concerned with artificial simulation of the human visual system. To achieve the ultimate goal of making machines mimic human intelligence, computer vision seeks to enable high level understanding of digital and multidimensional images by capturing images via appropriate devices; processing them using state-of-the-art algorithms, and analysing images to facilitate decision making.

3.3. Automated planning and scheduling

Planning is a subfield of AI concerned with enabling intelligent systems to achieve desired goals or objectives by carefully selecting and sequencing actions based on their expected outcomes [36]. Scheduling involves the selection of plans and allocation of time and resources necessary to achieve the desired goals based on the total available resources [37]. Planning and scheduling techniques are being adopted to provide solutions to complex applications that better fit the problem constraints and user needs [38]. Planning, due to complexity, cost, and time-consumption is used in situations where its benefits outweigh the cost [36]. Common heuristics and algorithms used for planning and scheduling include search techniques, optimisation techniques and genetic algorithms.

3.4. Robotics

Robots are highly automated devices that carry out physical activities in the real world. Robotics is an interdisciplinary engineering activity that involves the design, manufacture, operation and maintenance of robots and other computer actions to mimic physical human actions. Robots are for highly specialised tasks, taking shapes most suitable for their use and not necessarily the humanoid shape, and they interact with the environment using sensors and actuators [18]. [39] explained that the majority of the learning problems in robotics are reinforcement machine learning problems.

3.5. Knowledge-based systems

Knowledge-based Systems (KBS) is a branch of AI that is concerned with machine decision-making based on existing knowledge. Essentially, a KBS consists of a knowledge base, an inference engine and a user interface to interact with. The knowledge base is created from the storage of domain expert knowledge, past cases or experiences or other relevant sources. Its main advantage is the increased productivity and efficiency of easy access and interactions with large requisite domain knowledge. KBS makes inferences and arrive at conclusions that are heuristic, flexible and transparent, and provide the logic behind the advice given when necessary. KBS are classified into (A) Expert Systems: the knowledge base consists of task-specific knowledge from an expert in a particular domain to imitate decision-making in humans to solve specific problems [40]; (B) Case-based Reasoning (CBR) Systems: the knowledge base of CBR systems is composed of past experiences or old cases which are used to explain, interpret, or critique new situations [40]. For effectiveness in some domains, CBR systems must use expert knowledge to select the appropriate cases similar to the new project (Juell & Paulson, P., 2003); (C) Intelligent Tutoring Systems: these systems use AI techniques to provide tutors with what they teach, who they teach and how they teach it [41]; and, (D) DBMS with intelligent user interfaces and linked systems: are database systems with intelligent user interfaces driven by AI. Linked or Hypertext manipulation systems (HMS) allow easy traversal of complex information networks that enables writers and authors to easily link passages and references [42,43].

3.6. Natural language processing

Natural Language Processing (NLP) is a subfield of Artificial Intelligence that is concerned with creating computational models that mimic the linguistic capabilities of human beings [44]. NLP has been applied in the fields of machine translation, natural language text processing and summarisation, user interfaces, multilingual and cross language information retrieval, speech recognition and expert systems [45]. Tasks involved in NLP include part-of-speech tagging, chunking, named entity recognition and semantic role labelling [46].

3.7. Optimisation

Optimisation is concerned with making decisions or choices that provides the best outcomes given a set of constraints. According to Boyd and Vandenberghe, L., [47]; an optimisation problem is a construct of the problem of making the best choice from a set of choices. Optimisation is a lifelong phenomenon, originally known as a mathematical discipline concerned with finding an optimal solution to any given problem. With the birth of AI in the 1950s, a new family of metaheuristic algorithms known as evolutionary algorithms (EA) was created [48]. Some of the recent algorithms belonging to the EA family include evolutionary strategies (ES), evolutionary programming (EP), genetic algorithms (GA), differential evolution (DE) and particle swarm optimisation (PSO) [48].

4. State-of-the-art and future opportunities of AI applications in the construction industry

4.1. Trends of AI application in the construction industry

Fig. 2 clearly highlights the trend of an increasing number of publications in the artificial intelligence domain from the 1960s decade onwards. In the 1960s, the use of artificial intelligence was still at its infancy with very few publications applying optimisation techniques. Over time, optimisation has been the foremost area of research interest in the application of AI subfields for the construction industry. This could be attributed to the agelong struggle of the industry with low productivity levels. Another insight from the research trends over the years is that machine learning has overtook knowledge-based systems as a subfield of interest in the construction industry in the last decade. This can be attributed to the increased need to meet up with labour and skill shortages. Furthermore, robotics has also come to the fore of AI applications in the construction industry in the introduction of 3D printing, exoskeletons, UAV technologies for construction processes (Toriz et al., 2017). However, natural language processing has been the least researched subfield in the construction industry.

Fig. 2

Fig. 2Over 60% of AI application research in construction was done in the last decade and has given rise or enhanced the emergence of advanced technologies including: (1) Quantum computing; (2) Internet of Things (IoT); (3) Cybersecurity, and; (4) Blockchain. Quantum computing has the capability to solve certain computational tasks more efficiently than classical (or traditional) computers [49,50]. As a consequence of the special nature of quantum information, quantum algorithms are more effective than classical (or traditional) algorithms. AI can leverage on the capabilities of Quantum computing to accelerate problem-solving and optimise its solutions.

The internet has evolved from just allowing humans to communicate with each other, to enabling communication between multiple objects and humans to create a smart environment [51]. This transformation has been made possible by recent advances in technology such as sensors, actuators, wireless technologies (e.g. RFID), cloud computing, faster and cheaper devices with increased processing capabilities. In the construction industry, IoT has been integrated with AI in many ways including: energy-saving on demand for intelligent building energy monitoring [52,53]; IoT-enabled building information modelling (BIM) platform to achieve real-time visibility and traceability in prefabricated construction [54]; and to generate early warnings and alarms as dynamical safety barriers for hazard energy on underground construction sites (Zhou & Ding, L.Y., 2017).

The numerous advantages precipitated by an increased access to the internet and interconnected systems all over the world is threatened by the challenge of ever-evolving cyber threats. Some examples of cyber threats that are common in the construction industry include malware, social engineering and phishing [55]. [56] established that although the construction industry does not figure much in findings about cybersecurity, the introduction of level 3 BIM with an increasing reliance on virtuality will increase exposure to cybercrime. The increasing integration of BIM with data from other external sources makes it particularly vulnerable to cyber-attacks. In fact, any digital technology used in the construction industry, AR/VR, IoT and even AI such as hard and soft robots are at risk of cyber-attacks if there is no proper network security and response plan [57].

Since the invention of Blockchain in 2008, there has been a rapid growth in its adoption, especially in the areas of cryptocurrency, risk management, IoT, public, social and financial services (Cearley, [58,59]. Blockchain technology helps to ensure the legitimacy of a transaction, prevents double-spending, and allows for high-value transactions in a distrustful environment using cryptography and a consensus mechanism for verification [59]. Some recent applications of blockchain in construction includes logistics of construction materials [60], integration with IoT and BIM to manage building lifecycle data [61] and to enhance manufacturing supply chains in the composite materials industry [62]. The applications of blockchain technology in the construction industry are non-trivial and it has the potential to solve most of the trust, communication and transparency issues in the industry. The applications of AI in construction could be integrated with blockchain technology to develop solutions that are secure, transparent and have a decentralised CDE.

4.2. Application of AI subfields in the construction industry

Table 1 presents the applications of the previously identified AI subfields within the construction industry as well as its advantages and limitations.

Table 1. Application of AI subfields in Construction.

| AI Subfields | Construction Application Areas | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Health and Safety | Scheduling | Cost Estimation | Legal (Contracts & Conflict Management) | Supply chain & Logistics | Site Monitoring & Performance Evaluation | Material Management | Offsite Assembly | Plant and Equipment Management | Project Planning | Knowledge Management | Design | Risk Management | Temporary Structures | Bids/Tenders | Energy Management | Sustainability | |

| Machine Learning | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Computer Vision | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Automated Planning & Scheduling | ✓ | ✓ | |||||||||||||||

| Robotics | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Knowledge-based Systems | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Natural Language Processing | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Optimisation | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

Table 2 shows some of the advantages and limitations of the subfields of AI in the construction industry. Similar advantages across all the subfields include increased cost and time savings, improved safety, better accuracy and overall increased productivity. Some of the limitations of AI subfields in construction includes incomplete data, high initial cost of deployment, data and knowledge acquisition issues.

Table 2. Advantages and limitations of AI subfields in construction.

| Subfield | Advantages in construction | Limitations in construction | References |

|---|---|---|---|

| Machine Learning |

|

|

[30,63] |

| Computer Vision |

|

|

[64] |

| Automated Planning and Scheduling |

|

|

[36] |

| Robotics |

|

|

[[65], [66], [67]] ) |

| Knowledge-based systems |

|

|

[68] |

| Natural Language processing |

|

|

[69] |

| Optimisation |

|

|

[70] |

4.3. Common application areas and future opportunities of AI in construction

Table 3 presents the identified areas of application of AI in the construction industry, state-of-the-art and the potential future opportunities for increased adoption of AI. From the table, fourteen (14) subdomains were identified with relevant state-of-the-art applications and potential opportunities for construction-specific issues. Some of the identified subdomains include resource and waste optimisation; value-driven services; supply chain management; health and safety, AI-driven construction contract analytics; voice user interfaces; and AI-driven audit system for construction financials. Under value-driven services, subdomains such as estimation and scheduling, construction site analytics, job creation, AI and BIM integrations with other industry 4.0 tools such as internet of things (IoT) are described.

Table 3. State-of-the-art and potential opportunities of AI in the construction industry.

| S/N | Construction industry sub-domain | State-of-the-art | Potential opportunities |

|---|---|---|---|

| Resource and waste optimisation |

Data analytics for waste management and collection [71] BIM-based 3D model for construction waste quantification [72] BIM-based construction waste minimzation framework [73] BIM for waste minimisation design [74] |

|

|

| Value-driven Services | |||

| 2a | Estimation and Scheduling | BIM for cost and time estimation [75] |

|

| 2b | Construction site analytics |

Project control on construction sites [76] Construction perfromance analytics [77] Site layout planning [78] |

|

| 2c | Job creation |

BIM jobs and competences [79] Green jobs [80] Effects of robot automation on Jobs [81] |

|

| 2d | AI and BIM with Industry 4.0 Tools | ||

| AI with Internet of Things (IoT) |

Intelligent building energy monitoring [52] IoT-enabled BIM platform for prefabricated construction [54] IoT for safety warning on construction sites (Zhou & Ding, L.Y., 2017) |

|

|

| AI with Smart Cities (SC) |

Smart home energy consumption management [82] smart city development and urban planning using sensors [83] Metadata schema for smart building infrastructure [84] Urban energy performance using BIM and CIS [85] |

|

|

| AI with Augmented Reality (AR) |

Defect management using BIM, AR and ontology-based data collection [86] mobile-based virtual reality and augmented reality for health and safety education [87] Application areas of AR in construction [88] |

|

|

| AI and Blockchain |

RFID combined with blockchain for materials logistics [60] Integrating IoT, blockchain and BIM for managing building lifecycle data [61] Blockchain-driven manufacturing supply chains in composite materials industry |

|

|

| AI and Quantum Computing (QC) | Quantum computing [50] |

|

|

| Supply chain management |

Risk monitoring system [89] Mobile supply chain [90] Process specification language for improving supply chain communication [91] |

|

|

| Health and safety analytics |

BIM-based fall hazard identification and prevention [92] Design-for-safety knowledge library for BIM-integrated safety risk reviews Wearable technology for personalised construction safety and monitoring [93] Integration of sensor technologies with BIM to improve safety [94,95] |

|

|

| Construction contract management |

Construction contract management using value packaging systems [96] Blockchain technologies and cryptocurrencies for database management in construction engineering [97] |

|

|

| Voice user interfaces |

Voice-assisted key-in building quantities estimation system [98] Integrating voice recognition and gesture control for augmented reality interaction to enhance design practice [99] |

|

|

| Audit systems for construction financials |

5D BIM solutions for construction cost management [100] Blockchain-based big data model for BIM modification audit [101] |

|

|

4.3.1. Resource and waste optimisation

There is a growing amount of construction and demolition waste (C&DW) produced each year across the due to rapid continual development [102,103]. These construction activities have adverse effects on the environmental, natural and human resources globally [103]. [104] observed a paradigmatic change in the approaches to waste management from waste intelligence, which suggests measures to reduce waste only after it happens, to proactive data-driven approaches i.e. waste analytics (WA), which minimzes waste through design. There has been an increasing use of BIM as a virtual, less-expensive and computational enviroment to enable construction design with a view to minimize waste generation [72,74]. [71] highlights the potential of advanced data analytics techniuques to produce more detailed waste generation profiles. Therefore, the use of advanced data analytics could minimize waste extensivenly.

Waste analytics depends on a diverse data from different sources such as building design, material properties and construction strategies, which allows for high-performance computation and real-time processing [104,105]. The large amount of data requires advanced data analytics techniques to turn it into information relevant for waste minimzation. This calls for the adoption of artificial intelligence techniques for effective waste management [106,107]. Particularly, the use of advanced AI techniques with BIM to optimise design for offsite construction, materials selection, reuse and recovery, waste-efficient procurement, deconstruction and flexibility. Table 3 summarises the state-of-the-art and potential opportunities for this subdomain.

4.3.2. Value-driven services

This section discusses a broad range of non-core services, which can be benefitted from the emerging trend of AI in the construction industry.

4.3.2.1. Estimation and scheduling

AI-based estimation (or prediction) models have wide applicability in various domains of the construction industry. Particularly, these estimation models are instrumental in the early prediction of construction cost and duration, which are key project success factors (Sridarran, 2017). Unreliable project cost and time estimates could have huge economic and financial implications (Flyvbjerg et al., 2002).

BIM is the current state-of-art in the construction industry, which is used to enhance reliability of cost and time estimates in the construction industry [75,108]. The integration of time (4D) and cost (5D) to BIM enables better planning at the early design stage for project scheduling and cost estimation (Jrade & Lessard, 2015; McCuen, 2018). Nevertheless, in spite the huge benefits of BIM, evidences have also shown that the automation advantage brought about by BIM accounts for only the information in the model while disregarding external subjective factors, additional materials and resources respectively (Golaszewska & Salamak, 2017). Consequently, applying BIM for cost and time estimation still requires a lot of work for the cost estimator.

This calls for the integration of advanced AI techniques such as deep learning with BIM for cost and time prediction to take advantage of better accuracy. Consequently, deep learning techniques can also aid in better predictions of other relevant factors such as bankruptcy, success, energy, carbon efficiency and even waste. Table 3 summarises the state-of-the-art and potential opportunities for this subdomain.

4.3.2.2. Construction site analytics

Construction sites are rapidly being transformed to smart working environments due to the increasing pervasiveness of IoT sensors and other digital technologies [109]. Construction site analytics is concerned with the generation, collection, storage and analysis of construction site data to generate deep insights for visualisation [109]. A large volume of images, videos and other forms of data is generated on construction sites such as reports, real-time equipment and site monitoring, which are mostly unstructured. The data collected can be aggregated in BIM and analysed using advanced AI techniques to optimise site performance in all key areas such as planning, design, safety, quality, schedule and cost [110].

Lin & Golparvar-Fard [76] presented a theoretical foundation for visual data and predictive analytics for proactive project control on construction sites [77]. discussed the potential of big visual data and BIM for modeling construction performance analytics. Schwabe et al. [78] described the process of digitizing construction site layout planning process in BIM by applying rule-based model checking. There is a need for the development of a holistic site analytics tool using AI for real-time, cloud-powered analytics of data generated on the construction site. This will improve productivity, quality control and help to achieve set performance targets. A construction site AI chatbot to get real-time updates about site activities would prove to be very helpful for project managers and other relevant stakeholders.

4.3.2.3. Job creation

Construction jobs are the third highest jobs at risk of automation in the next decade [81], due to the increasing prevalence of automation technologies such as AI and IoT. Most construction jobs that require medium to low education are at a high risk (38–45%) of automation by mid 2030s [81]. However, the adoption of such technologies could also lead to the creation of entirely new roles to assimilate and reskill the displaced workers in the industry. For example, the advent of BIM has led to creation of new roles such as BIM project manager, director, coordinator and designer [79]. The adoption of digital technologies like AI in the construction industry will give rise to new types of jobs such as construction AI researcher, trainers and engineers. The researchers will be responsible for bringing construction industry to the frontier of AI adoption by continually carrying out research and bringing innovation into the sector. Construction AI engineers will focus on developing and deploying state-of-the-art AI solutions suited to the construction industry. Finally, trainers and testers will be needed to ensure these solutions such as robots and autonomous agents carry out designated goals effectively and efficiently. For example, low to medium skilled workers that will lose their job to automation could serve as trainers and testers for those systems replacing them.

4.3.2.4. AI and BIM with industry 4.0 tools

BIM is the current state-of-art in the architecture, engineering and construction (AEC) industry being adopted worldwide [111]. For example, the UK government mandated BIM level 2 for all publicly procured projects. However, despite attempts to make BIM as the de-facto standard globally, its rate of adoption is still very low [112]. Consequently, it is important to carry out relevant research on ways to improve the adoption of BIM. For example, some studies have combined BIM applications with AI subfields such as NLP to improve navigation of BIM interfaces. According to a study of construction project work carried out by Styhre et al. (2006), the authors argued that nature of construction practise is largely dependent on direct verbal and symbolic communication for sharing expertise and information. Perhaps, this may be because speech is undoubtedly, one of the oldest and most natural form of communication (Dutoit, 1997; Furui et al., 2004; Taylor, 2009). The integration of voice interaction with BIM will make it feel more natural and truer to the nature of construction. Other studies have also combined AI and BIM with other industry 4.0 tools such as Internet of Things (IoT) (Zhou & Ding, L.Y., 2017), smart cities [84], augmented reality [87], blockchain [60] and quantum computing [50] (Please see Table 3).

4.3.3. Supply chain management (SCM)

A recent study by Luo et al. [113], to explore factors affecting supply chain excellence and outcomes, revealed issues such as SCM knowledge education and supply chain culture. The major barriers found are lack of top-level buy-in and general understanding of supply chain. The literature also revealed that the high cost of advanced IT for SCM, lack of unique and regional specific performance measurement frameworks, lack of organisational trust and effective communication channels between partners had been a major hindering factor [114,115]. AI techniques can play a significant role in solving these issues that are hindering excellence in the supply chain.

Tsang et al. [89] developed an IoT-based real-time risk monitoring system for controlling product quality and occupational safety risks in cold chains using wireless sensors network, cloud database services, and fuzzy logic. According to Barata et al. [90]; real-time integration of in decentralised supply chains is at the top of the agenda for European institutions, industries and multinational consulting firms. Xiong et al. [91] developed a process specification language to improve supply chain communication for offsite construction.

This study calls for the development of a decentralised supply chain knowledge management and monitoring system. The advantages of blockchain to ensure transparency and legitimacy of transactions, combined with the advanced analytics powered by AI has the potential to solve the organisational trust and communication issues in construction supply chain. For example, Mondragon, et al. [62] explored the applicability of blockchain to enhance manufacturing supply chain and results show a tamper-proof history of product manufacturing and storage. AI can be used to manage the whole supply chain process to detect potential issues and ensure timely and quality project delivery. Also, the creation of AI chatbots for supply chain management system to harness relevant information in a simple manner.

4.3.4. Health and safety analytics

Health and Safety analytics (HSA) makes use of advanced data analytics techniques to predict and prevent occupational accidents in the workplace. The construction industry records a signifcantly higher rate of occupational injuries and deaths than other industries [116]. This is because construction work is highly risky due onsite dangers like working from heights, getting trapped, falling objects, equipments and tools, dust and toxic materials, and loss of hearing due to noise [110]. These dangers could result in longterm health issues, disability or even death for the workers [117]. For employers, this could mean loss of reputation, reduced productivity, increased insurance premiums, litigations and claim costs. Hence, the need to take a proactive approach by using digital technologies like AI to envisage accidents or health risks before they occur and to prevent them.

Some recent uses of AI in health and safety include BIM-based fall hazard identification and prevention [92]; integration of sensor-based technologies with BIM to improve construction safety [94,95]; and wearable technology used in construction safety monitoring [93].

Based on the aforementioned, it can be inferred that data from different digital technologies like IoT sensors, UAV and wearable devices are used in the different construction stages with BIM to prevent and mitiage safety risks. These inevitably calls for the application of advanced AI techniques (e.g. deep learning) to make relevant use of these data for predictive and proactive safety management. Winge et al. [116] identified seven most common factors causing construction accidents to include worker actions, risk management, immediate supervision, usability of materials or equipments, local hazards, worker capabilites and project management. All of these factors have the potential to be solved using AI technologies such as robotics, computer vision, advanced data analytics and optimisation techniques, especially when integrated with other digital technologies. Also, the health and safety management process will benefit from a more holistic system that integrates monitoring, visualisation, notification and action-taking.

4.3.5. AI-driven construction contract comprehension

Construction contract management can be very complex, involving bulky and multiple contracts where mistakes often have huge implications [96]. Some of these implications include litigation costs, claims, project delay and loss of reputation. A major challenge is that current contract management is heavily dependent on humans such as contract managers or legal team, which makes it prone to errors and mistakes. This calls for the automation of the contract management with AI to augment the efforts of contract managers or legal teams by ensuring processes are faster and more accurate [118]. This will allow for easy querying of contracts to retrieve relevant information, contract summarisation, contracts drafting, identification of dispute prone clauses, contract negotiation and dispute-resolution, contract-obligation-enforcement and closure.

One major challenge with developing an AI-driven tool for contract management is implementing text summarisation, which is required to retrieve succinct but important information from contracts. This is a difficult task that calls for the attention of researchers because construction contracts are different from general contracts, and as such requires construction-specific training. Another challenge is machine reading comprehension (MRC), which is the ability of computers to understand a given text, formulate questions against it and generate well-formed answers. MRC is a very challenging task that researchers are working on rigorously. There are several datasets specific to some domains have been made publicly available for benchmarking and training MRC models e.g. MS MARCO [119], NewsQA [120], SearchQA. However, there are no datasets unique to the construction industry, which are essential to train construction MRC models. This presents an opportunity for further research that could improve MRC in construction and ultimately, contract management.

4.3.6. Voice user interfaces

The hands-busy and eyes-busy nature of construction work makes voice-enabled user interfaces (VUI) a viable alternative to the current modes of communication with devices on construction sites [99]. Construction workers often have to communicate with software applications e.g., BIM on the construction site, but typing on devices to retrieve information could lead to safety hazards. This has led to considerations for other means of communication with digital tools such as speech. This is further amplified by the rising popularity of speech-enabled user interfaces sometimes employed as automated assistants e.g. Alexa, Siri, Cortana [121]. The findings in this study reveal that speech in construction research has not garnered much attention by researchers.

Even though there has been a lot of recent improvements in VUIs, its use is still hindered by some challenges, especially those specific to the construction industry. One major challenge is that construction sites are usually very noisy [122], which puts unwanted information in the speech signal. This could generate too many errors which may frustrate the users and eventually lead to discontinuity of use. Other challenges include speaker variability, voice enhancement, homophones, ambiguity, amount of data and search space. Solving these challenges could potentially lead to the seamless use of VUIs in the construction industry. To this end, development of a robust dataset of common voice commands in different situations on the construction site needs to be collected. This can be used to train construction voice application models.

4.3.7. AI-driven audit system for construction financials

Despite the huge economic outputs generated by the construction industry, the rate of insolvency of firms in still is very high [123]. This may be partly because most construction businesses find it hard to manage their finances due to the uniqueness and long duration of projects, which is critical for project success [124]. Construction firms often have multiple projects running simultaneously involving the movement of employees and equipment between projects [125], with thin profit margins due to competitive bidding and overhead costs that are not properly accounted for [126]. Hence, it is important to ensure projects and general overhead costs are effectively tracked [127]. The focus should not only be on delivering quality work, but proactive management of financial resources [128]. Currently, there are no AI-driven financial audit tools to effectively track project costs and predict potential financial problems before they arise [129]. Accordingly, financial managers can proactively respond when a project is overspending or underspending and measure its overall effect on other projects and the entire business in real-time. This will guide the decisions of the firm's stakeholders and save the firm from bankruptcy.