1. Introduction

Ultra high molecular weight polyethylene (UHMWPE) represents the gold standard as an articulating counterface for arthroplasties, since it combines superior wear resistance along with high fracture toughness and biocompatibility compared to other polymers [1]. Initially, high density polyethylene (HDPE) was used as a material in biological application [2]. The HDPE compared with ultra high molecular weight polyethylene (UHMWPE) has essentially the same chemical structure, comparable mechanical properties, relatively low cost, excellent creep resistance, good processability and biocompatibility [3]. However, the UHMWPE has been preferred as the matrix because of its high rigidity, impact resistance and wear resistance unlikely the HDPE [4].

UHMWPE has superior wear resistance and low-friction surface properties and has been applied successfully in artificial implant, such as knee and hip joint replacements [5]. Its application is associated with its biological inertness, high levels of strength, wear, creep resistance and low friction coefficient [6]. However, the wear debris generated during the joint motions could cause osteolysis and loosening of the implant, contributing to the main cause for joint revision [7].

Attempts have been made to improve the wear resistance, hardness and Young's modulus of UHMWPE in order to extend the material's service life. The attempts include irradiated crosslinking technique [8], [9], [10], [11], simultaneous reinforcement [12], [13] and filling modifications using inorganic material [14], [15], [16]. Several inorganic materials has been explored with fillers in UHMWPE composite, such as carbon [17], [18], kaolin [19], quartz [20], montmorillonite [21], [22], [23], [24], aluminum oxide [25] and hydroxyapatite (HA) [26]. For biomedical applications, the HA is very interesting filler because is one of the bioceramics with good bioactivity [15] and is a major mineral constituent of the bone matrix [27].

Currently, many attempts was achieved on UHMWPE/HA composite [15], [26], [28], [29], [30], [31], [32], [33]. Combining wet ball milling, swelling, twin-screw extrusion composite UHMWPE/HA was obtained with a significant improvement in mechanical properties and bioactivity.

This review discusses the state of the art of UHMWPE/HA composites for biomedical applications. So, properties of HA and UHMWPE, processing methods of UHMWPE/HA, mechanical and tribological properties and commons biocompatibility are discussed.

2. Developments

2.1. Ultra high molecular weight polyethylene

Ultra high molecular weight polyethylene (UHMWPE) is a unique polymer with excellent physical, chemical and mechanical properties [35]. Most notable are its chemical inertness, lubricity, impact resistance and abrasion resistance [35]. These characteristics properties have been exploited since 1950 in wide range medical applications, such as, orthopedic implants.

This material has been used in orthopedics as a bearing in artificial joints. Two properties determine the priority in research and application of this polymer as biomaterials, particularly orthopedic implants. The first is the modulus of elasticity (Table 2), which is closest to the bone [35]. The second is the friction coefficient (Table 1). The UHMWPE has the lowest coefficient of friction among the polymers exhibited lower wear of the implant and risk to the patient (each year about 1.4 million joints replacements are performed around the world). Despite the success of this restorative procedure, UHMWPE have only a finite lifetime. Wear and the damage of the UHMWPE components is the one of the factors implant longevity [34].

| Polymer | Tensile strength (MPa) | Elastic modulus (GPa) | Impact Strength (J/m) | Elongation |

|---|---|---|---|---|

| UHMWPE | 39–48 | 0.5–0.8 | Not break | 350–525 |

| HDPE | 22–31 | 0.4–4.0 | 21–214 | 10–1200 |

| PMMA | 2.55 | 59 | – | – |

| PEEK | 110 | 3.3 | – | – |

Table 2. Dynamic friction coefficients of some polymers generally used in synthesis of composites for total join replacement (adapted from Park et al. [36]).

| Polymer | Dynamic friction coefficient | ||

|---|---|---|---|

| Dry | Water | Oil | |

| UHMWPE | 0.10–0.22 | 0.05–0.10 | 0.05–0.08 |

| NYLON 6,6 | 0.15–0.40 | 0.14–0.19 | 0.02–0.11 |

| PA | 0.12–0.20 | 0.10–0.12 | 0.08–0.10 |

| Polytetrafluoroethylene | 0.01–0.25 | 0.04–0.08 | 0.04–0.05 |

Table 3. Thermal properties of UHMWPE and others polyethylenes. High-density polyethylene-HDPE, Medium-density polyethyleneMDPE, Low-density polyethylene-LDPE (adapted from Martienssen and Warlimont [141]).

| Thermal properties | HDPE | MDPE | LDPE | LLDPE | UHMWPE |

|---|---|---|---|---|---|

| Melt temperature (Tm) (°C) | 126–135 | 120–125 | 105–118 | 126 | 130–135 |

| Glass transition temperature (Tg) (°C) | –110 | –110 | –110 | –110 | –120 |

| Heat capacity cp (KJ/KgK) | 2.1–2.7 | 2.1–2.5 | 1.7–1.8 | ||

| Thermal conductivity (W/m·K) | 0.38–0.51 | 0.32–0.40 | 0.41 | ||

| Enthalpy of fusion (KJ/mol) | 3.9–4.1 | 3.9–4.1 | |||

| Entropy of fusion (J/(K·mol)) | 9.6–9.9 | 9.6–0.9 |

Table 4. Processing methods of UHMWPE/HA composites.

| HA(%) | Compositea | Processing methods | Modulus (GPa) | Yield strength | Hardness |

|---|---|---|---|---|---|

| 30 | UHMWPE/HA [28] | Combining wet ball milling and swelling | 1.63 | 12.00 | |

| 23 | UHMWPE/HA [26] | Twin-screw extrusion compression molding | 6.80 | 26.60 | |

| 30 | UHMWPE/BHA (bovine hydroxyaopatite) [85] | Ball compression molded on (15 MB and 190C) | 1.25 | 120.00 | |

| 0,5 | HA/UHMWPE [29] | Swelling/twin-screw extrusion, compression molding, and then hot drawing | 4.10 | 100.0 ± 22 | |

| 1.5 | HA/UHMWPE [82] | Compression molded | 1.45 | 39.10 | |

| 5.0 | HA/UHMWPE [83] | Employing compression mold process | 0.34 | 9.40 | |

| 31,5 | HA/UHMWPE [15] | Sol − gel method | 1.73 | ||

| 0.5 | UHMWPE/HA [32] | Planetary ball milling | 32.40 | ||

| 50 | UHMWPE/HA [33] | Laboratory scale melting mixer (Brabender plastic-corder) internal mixer at 180C | 3.70 | 0.12 | |

| UHMWPE/HA [54] | Brabender internal mixer (D-47055 model, Germany) | 1.20 | 24.34 | ||

| 20 | UHMWPE/HA [31] | Mechano activation compaction via thermal pressing. Fritsch pulverisette 5 planetaryball mill. | 0.60 | 25.80 |

- a

-

Nanoparticles.

The structure of UHMWPE is formed by C C covalent bond and are arranged in both ordered and disordered regions, i.e., crystalline and amorphousrespectively. The crystalline phase contains chains folded into highly oriented lamellae, with the crystals being orthorhombic in structure [37]. The lamellae are 10–50 nm thick and 10–50 m long [35] and oriented randomly within the amorphous phase with molecules linking individual lamellae to one another [38].

C covalent bond and are arranged in both ordered and disordered regions, i.e., crystalline and amorphousrespectively. The crystalline phase contains chains folded into highly oriented lamellae, with the crystals being orthorhombic in structure [37]. The lamellae are 10–50 nm thick and 10–50 m long [35] and oriented randomly within the amorphous phase with molecules linking individual lamellae to one another [38].

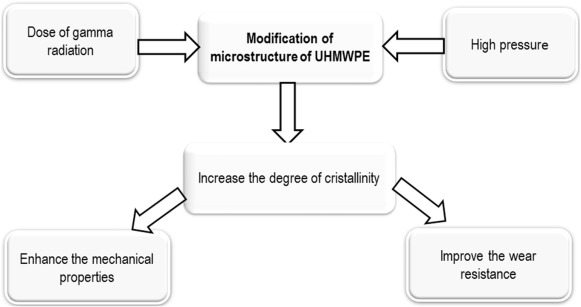

It's important to enhance that the degree of crystallinity of UHMWPE and theirs composites can be affected by the integral dose of gamma radiation [39], [40]and high pressure of crystallization [41]. At integral doses of 150 KGy UHMWPE shows a dependence on dose rate, as shown by both that the alteration of crystallinity affect the lamellar thickness distribution [39]. These results showed that the UHMWPE shows a strong crystallite thickness dependence on both gamma integral dose and depth into to the sample. Martinez-Morlaneses et al. [40] evaluated the effect of gamma irradiation in UHMWPE/multiwalled carbon nanotubes (MWCNT) composite and observed an increase in crystallinity after treatment with gamma radiation.

The mechanical and physical properties of UHMWPE are influenced by its crystallinity, which is related to the atomic or molecular arrangement, conforming a specific crystal structure. Higher degree of crystallinity results in the harder, stiffer and less ductile behaviors [42]. Karrupiah et al. [43] showed that the higher degree of crystallinity in the UHMWPE (medical grade-GUR 1050 resin) resulted in lower friction force and an increase in scratch resistance at the micro- and nanoscales. On the nanoscale, the lamellar structure appeared to affect the observed wear resistance, and showed that an increase in crystallinity also resulted in lower wear depth and width [43]. This finds corroborate the study of Simis et al. [44] that linked the mechanical properties in terms of crystalline mass fraction, lamellae size and distribution (Fig. 1).

Fig. 1. Relations between microstructure, crystallinity and mechanical properties and tribological properties.

Fig. 1. Relations between microstructure, crystallinity and mechanical properties and tribological properties.Others factors to consider in polymer materials are the thermal transitions. Generally, many polymers show three types of thermal transitions that are the glass transition temperature, the melting temperature and the flow temperature. In UHMWPE, the glass transition temperature occurs around -120 °C and the melt temperature around 137 °C. The flow temperature is dependent on the molecular weight of the polymer. Polyethylenes with molecular weight below of 500.000 g/mol can be observed the flow temperature. On the other hand, the molecular weights above of 500.000 g/mol the immense entanglement of the polymer chains acts by inhibiting the polymer flows. For this reason, the UHMWPE does not exhibit the flow temperature. Other thermal properties of UHMWPE and other polyethylenes are summarized in the Table 3 [35].

UHMWPE can be synthetized from ethylene gas (C2H4) using the traditional heterogeneous Ziegler-Natta process in a solvent using titanium tetra chloride (TiCl4) as a catalyst (Fig. 2) [45], [46]. Basically, the Ziegler-Natta catalyst is composed of a combination of transition metal and alkyl aluminum compounds [47]. There was proposed various mechanism for polymerization of ethylene gas, however, the Cosse mechanism (Fig. 3) has been generally accepted. According to the mechanism, Ti species reacts with co catalyst and produces vacant site. The π electron of carbon-carbon double bond in monomer coordinates the vacant site. In the subsequent step a four membered ring is formed as transition state, the Ti-carbon σ bond is broken and then an insertion of monomer occurs at the point [47]

Fig. 2. Synthesis of UHMWPE from ethylene gas.

Fig. 2. Synthesis of UHMWPE from ethylene gas. Fig. 3. Ziegler-Natta polymerization mechanism proposed by Cosse.

Fig. 3. Ziegler-Natta polymerization mechanism proposed by Cosse.Medical grade UHMWPE is categorized into three grades: type 1, 2 or 3 depending on the molecular weight and manufacturer [48].

In manufacturing of UHMWPE based components, due to the high melt viscosity of UHMWPE, conventional processing techniques such as injection molding, screw extrusion and blow molding are not suitable [48].

UHMWPE based composite synthesis is more challenging than other polymers, techniques such as melt-mixing is nearly impossible without help of solvents or addition of high density polyethylene (HDPE) [49], [50]. However, only a few solvents are known to dissolve UHMWPE. These solvents include paraffin oil, xylene, and decalin [29], [51], [52], [53], [54].

2.2. Hydroxyapatite

Hydroxyapatite (HA) is a calcium orthophosphate containing water with a chemical composition of Ca10(PO4)6(OH)2 (Fig. 4), which is also composed of carbonate (CO32 −) impurities incorporated into or attached surface of the crystals [55], [56]. The presence of the carbonate ion can be confirmed by the presence of characteristic peak in the EDS spectra (Fig. 5).

Fig. 4. Chemical structure of hydroxyapatite.

Fig. 4. Chemical structure of hydroxyapatite. Fig. 5. SEM micrograph (A) and EDS spectra (B) of hydroxyapatite produced by wet chemical precipitation.

Fig. 5. SEM micrograph (A) and EDS spectra (B) of hydroxyapatite produced by wet chemical precipitation.Although the HA exhibits poor mechanical properties, like low fatigue resistance, brittleness, low strength and toughness [57], [58]. However, it shows a high biocompatibility with different human tissues, therefore is widely used in the medical field, especially in bone implants [56]. Therefore, it is important customize its properties such as bioactivity, mechanical properties, homogeneity and sinterability by controlling its composition, morphology and particle size and adherence of coatings [59], [60], [61]. To this end, different methods are used, including the synthesis and extraction from natural products.

Synthetic HA has higher degree of crystallinity and consequently higher structural stability [60], [62]. However, some synthesis methods lead to presence of some toxic chemicals which is adsorbed on the surface that may have adverse effects in the medical applications [57] and therefore the choice of the method is important to ensure safe use. The most frequently synthesis methods of HA include dry methods (mechano-chemical and solid-state synthesis) and wet methods (sol–gel, chemical precipitation, hydrothermal, and microemulsion) [60], [63], [64]. Wet methods are most commonly used to produce hydroxyapatite when compared to dry methods. Applying the wet methods it is possible to obtain nano-HA with a regular morphology adjusting some synthesis parameters. But using dry methods the particles are generally larger and with irregular morphology. In any case, wet methods usually use solvents (sometimes toxics) which takes a step towards elimination of the solvent which sometimes its elimination is not complete [60].

Natural HA is generally recognized as the biologic mineral component of vertebrate hard tissue, such as, bone and teeth (≅ 70%) [54], [55], [58], [63]. Due to the high percentage of this material found in human and animal organism, an alternative method for the preparation of HA is extraction from natural resources [66]. Some examples of materials that HA are isolated are: corals, eggshell, bovine bone, seashells and fish [67], [68]. Extraction of HA from vertebrate hard tissue and sources can be performed using subcritical water process and alkaline hydrothermal hydrolyses. Both methods are suitable to extract the HA because preserve the carbonate content present in biological apatite. While the thermal treatments produce almost free HA carbonate-free [68]. Extraction process of HA from the natural materials is a biologically safe (no toxic chemicals are utilized) and economically desirable process [68]. The challenge of this method is the difficult to obtain a HA with nanosized particles.

2.3. Hydroxyapatite polymer based composites

HA as reinforcement in polymer composites was first introduced by Bonfield et al. [69] in 1980. The same authors [69] reported that the effect of HA on the mechanical properties of the composite HDPE/HA in order to bone replacement. The authors demonstrated that HA is effectively to reinforce the HDPE, resulting in a considerable increase in Young's modulus.

Hydroxyapatite- reinforced polymer composites offer interesting properties for biomedical applications because of the presence of HA improves the biological properties of the material. Conversely, the polymer provides enhanced mechanical properties which allow their application in bone tissue engineering [70].

Currently the application of HA with nanometric dimensions has attracted much attention in materials engineering because the interfacial area between the nano-reinforcement and polymer matrix is typically much larger than that for conventional composites. Thus, a relatively small amount of nano-scale reinforcements could lead to observable effects on the macro-scale properties of the composite [71]. Generally, nanocomposites differ from conventional composites due to the exceptionally high surface to volume ratios of the nano-fillers, or their high aspect ratios in the cases of fibrous nano-fillers [71], [72].

There are two groups of polymers that are used to produce polymeric composites reinforced with hydroxyapatite, the non-biodegradable and biodegradable polymers. Biodegradable polymer includes PLGA, PCL, PHB among others. Another group is the non-biodegradable; which stands out the HDPE, PMMA, PA, UHMWPE and among others.

Hydroxyapatite biodegradable polymer based composites for biomedical applications had been investigated [73], [74], [75], [76], [77]. For example, nanocomposite of PLGA microspheres reinforced with amorphous calcium phosphate nanoparticles was developed with the aim of optimizing the structure of the sintered microsphere matrix. The heating of microspheres improves the mechanical properties of traction. On the other hand, a nanocomposite allowed a good osteoblast proliferation [73], [74]. Moreover, Zhang et al. [75] developed a pioneer PLGA composite and HA grafted with PLA (g-HA). They noted that the graphitization influence the rate of in vivomineralization. The composite GHA/PLGA showed a rapid and robust digestion and a good osteoconductive compared to PLGA/HA. Besides PLGA other biodegradable polymers are used for producing reinforced composites with HA. For example, Luklinskla and Schluckwerder [78] developed the composite polyhydroxybutyrate (PHB)/HA. The in vivo tests showed that a bone layer formed at the interface after deployment. Furthermore, they found that bone grew layer 130 μm at 1 month and 6 months after the layer was already 700 μm. Luklinskla and Schluckwerder [78] suggested that the composite produced can be used in bone replacement therapies. Additionally, the addition of HA nanoparticles in PHB matrix and influences the biological properties of the composite can also improve the rheological and thermal characteristics [76].

Sadat-Shodajai et al. [77] produced hybrid scaffolds PHB/HA hydrogel combined with proteins. The hybrid composite, besides having excellent biological properties, was mechanically stable. This result is a major advance, as the biggest problem in the scaffolds produced with biodegradable polymers is their limited mechanical properties. Interestingly, the authors used a spinning technique-electrospun gel, which is a technique often produces materials with low mechanical performance and low bioactivity. However, the results show otherwise, it achieved excellent results both for and bioactivity for mechanical performance. The authors believe that the use of protein hydrogel was responsible for improving these properties.

Non-biodegradable polymers are also used in biomedical applications both in the form of composites and as pure consolidated resin without reinforcement. For example, Parra et al. [79] produced a high density polyethylene composite HA/applying a method using a decalin of processing steps. They observed that infrared data showed a lack of interaction between the polymer and HA. However, this interaction was observed when the high-density polyethylene was replaced with PMMA. On the other way, the high-density polyethylene/HA was developed using a twin screw extruder and then an injection molding. The authors concluded that the addition of HA particles with nanometric dimensions into high density polyethylene results in a composite with good mechanical and tribological properties compared to unreinforced high density polyethylene [80]. These results corroborate strongly with Li and Tijong [81], who observed a decrease in wear rates of the nanocomposite, as well as improved impact resistance of high density polyethylene/HA when compared with non- reinforced HDPE. It is assumed that this decrease in wear rate is due to the load-bearing effect of HA nanoparticles engaged and also by forming a continuous film on the transfer counterface [81].

The use of compatibilizers have been an alternative to improve the interface between polymer and HA. It is important to note that the mechanical and tribological properties are directly related to the microstructures and interfacial properties. It was in this perspective that Balakrishnan et al. [82] investigated the high-density polyethylene grafted with maleic anhydride as compatibilizer of high density polyethylene/HA composite for biomedical applications. The compatibilizer improved mechanical properties of HDPE/HA composite and did not affect the properties of biocompatibility because this induced growth apatite when it was immersed in SBF solution. Recently, composites of high density polyethylene/HA have been developed via in situ polymerization. Good dispersion in the polymer matrix of HA and without forming agglomerates was achieved. On the other hand, the osteoblasts showed good adhesion and proliferation, which are good indicative of good cytocompatibility [83].

Polyamide is another biostable polymer which is generally used in the production of composite HA is. This polymer arouses attention because in its structure has  CONH groups, which are the same groups that collagen present in its structure. For example, Wang et al. [84], produced scaffolds reinforced polyamide HA nanoparticles (PA/n-HA) using the technique of thermally induced phase inversion. They observed that PA/n-HA is biocompatible and no toxic effect on the mesenchymal stem cell was observed (MSCs) in vitro. However, the incorporation of MSCs in the scaffold dramatically improved the efficiency of the formation of new bone in the rabbit in vivo test, especially in the early stages after implantation. Similar results were observed by Xiong et al. [85]. However, these authors also tested the materials in humans and observed that the incorporation of the implant was completed after 1.5 years. As demonstrated above, composite PA/HA are biocompatible. In vitro assays and in vivo confirm this assertion. Nevertheless, for a material to be really ideal not just be biocompatible; It must also improves the mechanical properties. Therefore, Qiao et al. [86] developed a PA/HA/glass fiber composite. The addition of GF reduced stiffness and increased strength of the composite. In addition, the composite PA/HA/GF did not have any negative effect on MSCs, as they adhered and proliferated normally. Another similar study was developed by Su et al. [87], which studied the mechanical and biological properties (in vitro and in vivo) of the composite PA/HA/GF. They concluded that the composite was biocompatible and showed good biomechanical strength and quickly induced the formation and growth of new bone.

CONH groups, which are the same groups that collagen present in its structure. For example, Wang et al. [84], produced scaffolds reinforced polyamide HA nanoparticles (PA/n-HA) using the technique of thermally induced phase inversion. They observed that PA/n-HA is biocompatible and no toxic effect on the mesenchymal stem cell was observed (MSCs) in vitro. However, the incorporation of MSCs in the scaffold dramatically improved the efficiency of the formation of new bone in the rabbit in vivo test, especially in the early stages after implantation. Similar results were observed by Xiong et al. [85]. However, these authors also tested the materials in humans and observed that the incorporation of the implant was completed after 1.5 years. As demonstrated above, composite PA/HA are biocompatible. In vitro assays and in vivo confirm this assertion. Nevertheless, for a material to be really ideal not just be biocompatible; It must also improves the mechanical properties. Therefore, Qiao et al. [86] developed a PA/HA/glass fiber composite. The addition of GF reduced stiffness and increased strength of the composite. In addition, the composite PA/HA/GF did not have any negative effect on MSCs, as they adhered and proliferated normally. Another similar study was developed by Su et al. [87], which studied the mechanical and biological properties (in vitro and in vivo) of the composite PA/HA/GF. They concluded that the composite was biocompatible and showed good biomechanical strength and quickly induced the formation and growth of new bone.

Biodegradable and non-biodegradable polymers in the form of composites reinforced with HA are used in total or partial joint replacement or as a material that can allow bone regeneration. For circumstances where bone tissue damage is irreversible, non-biodegradable materials are used for partial or total replacement of bone/joint affected. Among the polymeric materials used, the UHMWPE is the most preferred because of their superior tribological and mechanical properties compared to other polymers like HDPE, PA and PMMA. So, the next topic will focus specifically UHMWPE composites reinforced with hydroxyapatite from the processing and its relation to some properties, and finally the biocompatibility of UHMWPE/HA and other polymer composites of the same application.

2.4. UHMWPE/HA composites

The composites of UHMWPE/HA are very interesting in view of biomedical application because they combine the improved mechanical, tribological and biological properties. It is important to emphasize that any material whatever its application must always be characterized in order to have an idea of its morphology as well as its chemical composition. Therefore, the SEM micrograph and EDS spectra of UHMWPE/HA composite is shown below. (Fig. 6).

Fig. 6. SEM micrograph (A) and EDS spectra (B) of UHMWPE/HA composite processed by melting mixing.

Fig. 6. SEM micrograph (A) and EDS spectra (B) of UHMWPE/HA composite processed by melting mixing.2.5. Processing of UHMWPE/HA composites

There are several studies and various specific processing methods are used in the development of UHMWPE/HA composites [15], [26], [30], [31], [32], [33], [71], [88], [89], [90], [91], [92], [93]. The more commons methods to synthetize the UHWPE/HA composites are twin-screw extrusion [26], sol-gel [15], planetary ball milling and hot pressing [34], [32], melting blending technique-Single screw extrusion [49], rotatory ball milling-compression molding [93], biomimetic process [30] were successful developed.

Conventional twin screw extrusion of UHMWPE composites was difficult due to the ultrahigh viscosity of UHMWPE melt [94]. However, the viscosity can be reduced by swelling UHMWPE in a solvent [48], [95], [96], [97]. Fang et al. [26]compounded the UHMWPE/HA composite in paraffin oil through twin-screw extrusion followed by compression molding at elevated temperature. As result the mechanical properties have been improved. They believed that the application of the swelling treatment enhanced UHMWPE chain mobility allowing HA particles to penetrate the fibril interspaces during twin-screw extrusion. In addition, Fang et al. synthetized the UHMWPE/HA combining swelling/twin-screw extrusion compression molding, (Fig. 7) [29]. The results showed an increase of tensile strength and the global dispersion of nano-HA in UHMWPE matrix [29]. The increasing of strength was attributed to high the highly oriented UHMWPE fibrils as consequence of hot drown process [29].

Fig. 7. Processing methods of UHMWPE composites: (A) Swelling agent and (B) Polyethylene glycol (PEG) as processing aid.

Fig. 7. Processing methods of UHMWPE composites: (A) Swelling agent and (B) Polyethylene glycol (PEG) as processing aid.Ball milling is a common technique for grinding minerals, ceramics and paints into fine powder, as well as a technique for mechanical alloying. It is a good alternative for composite manufacturing where melting or dissolution of the matrix is not possible, as it mixes the constituents in the solid state. Fang et al. [28] produced the UHMWPE/HA composite combining wet ball milling and swelling, as a result some mechanical properties was enhanced but the dispersion of HA in UHMWPE matrix was weak. In this work, they developed a novel method by wet ball-mill compounding and swelling in a non-toxic solvent. Ball milling in ethanol not only remarkably reduced HA particles to nanometric dimensions and also effectively compounded UHMWPE/HA mixture uniformly. Preliminary results of this novel processing indicate a promising direction for the future development of UHMWPE/HA processing for biomedical applications.

Recently, Gupta et al. [98] synthesized UHMWPE based polymer composites reinforcing of bioactive HA, bioinert aluminum oxide (Al2O3), and carbon nanotubes (CNTs) using compression molding. Process parameters cause the movement of  CH2

CH2 CH2

CH2 chains of UMWPE to the (100) plane. Addition of HA and CNTs led to decrease of hardness and modulus while the addition of Al2O3 increase the hardness and modulus in comparison of pristine UHMWPE. This positive effect of alumina addition may be linked with substantial increment of total work works of composite. However, empirical constants shows weak interfacial bonding of UHMWPE matrix with HA and CNT fillers elicits a poor mechanical due to absence of chemical bond of HA and CNT containing composites [98] Utilization of coupling agents (for example PEG) can modify the interfacial properties as consequence mechanical properties can be enhanced.

chains of UMWPE to the (100) plane. Addition of HA and CNTs led to decrease of hardness and modulus while the addition of Al2O3 increase the hardness and modulus in comparison of pristine UHMWPE. This positive effect of alumina addition may be linked with substantial increment of total work works of composite. However, empirical constants shows weak interfacial bonding of UHMWPE matrix with HA and CNT fillers elicits a poor mechanical due to absence of chemical bond of HA and CNT containing composites [98] Utilization of coupling agents (for example PEG) can modify the interfacial properties as consequence mechanical properties can be enhanced.

Crowley and Chalivendra [99] studied UHMWPE/HA nanocomposites for the purpose of joint, prosthesis were investigated under quasi-static and dynamic loading conditions. By employing compression mold process, five different volume fractions of HA nanoparticle reinforced nanocomposites are made. The results of the fabricated nanocomposites are compared with currently employed UHMWPE in the joint implants. The agglomeration of nano-HA particles increases as the volume fraction of the particle increases. For comparison purposes, separate sets of tests are performed on currently employed UHMWPE. This comparison provides a valid measure to identify the optimum volume fraction of HA that can be used without compromising the integrity of the UHMPWPE in joint prosthesis. Recently, Panin et al. [34]compared the influence of nano and micro hydroxyapatite fillers on tribotechnical property of UHMWPE nanocomposites, and was found that nanofilling of UHMWPE by 0.1–0.5 wt% HA increases its wear resistance in 3.5 folds compared to the pure polymer. Adding of 20 wt% HA micron size particles provides the similar wear resistance. Similar effect of nano and micro hydroxyapatite on tribological properties of composites was found by Panin et al. [32].

Xiong et al. [12], processed the UHMWPE/nano-hydroxyapatite (n-HA) composite using ball mill and the blended materials were put into the self-made mold to hot press in vacuum using a vacuum furnace for hot forming. The products of nanocomposites were irradiated by gamma rays. They found that, the wear behaviors of original UHMWPE are abrasive and adhesive without irradiation while abrasive wear was the main wear behaviors for 1% n-HA filled UHMWPE. However, after the irradiation of unfilled and n-HA filled UHMWPE adhesive and abrasive wear was significantly reduced and the fatigue wear behavior was dominant after irradiation. These results can be correlated with structural modification (cross linked structure) of UHMWPE after irradiation. The cross-linked structure increases the entanglement density of molecular chain so that pulling force between macromolecules is increased [12].

As can be seen in Table 4 the mechanical properties have an intrinsic relationship with the processing method and also by the particle size of hydroxyapatite used. It is important in the development of UHMWPE/HA composite to observe some criteria such as particle size of HA and the processing method in order to obtain a composite with desirable properties for biomedical applications.

2.6. Wear, toughness and creep properties

The wear rate is one of the main factors to be taken into account when designing materials for use as bone implants [100]. Polyethylene is a polymer with interesting properties for applications in total or partial replacement of bone therefore, the problem is aware debris after long time l. It is estimated that most of prosthesis revision is directly linked to wear of materials. The reinforcement of UHMWPE by inorganic/organic fillers had showed promising results [101]. Various kinds of inorganic/organic fillers had interesting results in reduction of wear rate. However, most of them have poor or have not bioactivity. So HA is an interesting bioceramics for this purpose because it can form a real bond with the surrounding bone tissue. Therefore, increasing its wear resistance or bioactivity will be useful in order to obtain high quality artificial joints.

Liu et al. [100] studied UHMWPE composites filled with the bovine bone hydroxyapatite (BHA). A ball-on-disc wear test was carried out with a Universal Micro-Tribometer to investigate the friction and wear behavior of a Si3N4ceramic ball, cross-sliding against the UHMWPE/BHA composites with human plasma lubrication. They observed that the addition of HA in UHMWPE reduces the wear rate but an increase which exceeds 30% of HA in the composite tends to increase the wear rate but, this increase did not reach the value of the pure polymer. These results corroborate strongly with the findings by Wang et al. [102] and Wang et al. [103], which found that when the content of BHA powders is lower than 30 wt%, the wear rate of the composites reduces rapidly. However, when the BHA powders increases from 30 wt% to 40 wt%, the wear rate only reduces by about 3% [102]. The abrasive and fatigue wear are the main wear mechanisms for coralline hydroxyapatite (CHA)/UHMWPE composite cups. The sizes of the wear particles become larger with the increase of CHA powders [103].

Polymer wear rate is inversely proportional to the strength of its surface. Therefore, authors observed a strong correlation between the wear rate and hardness; from wear and creep modulus and both the sound consistent Archard equilibrium [102], [104], [105]. Consequently, with the increases in hardness and creep strength, the hardened surfaces increase the ploughing resistance and reduce the shear stress of UHMWPE composite against hard asperities on CoCrMo head surface, which results in lower wear rate of UHMWPE/BHA [102].

Furthermore, Wang et al. [102] investigated the effect of increasing the BHA in the size of the generated wear particles. They observed that addition of BHA increases the size of wear particles. This result is beneficial in application point of view because particles smaller than 10 μm are phagocytosed by the macrophages; but, the large wear particles are surrounded by the macrophages [104]. Consequently, an increase in size of wear particles of UHMWPE/BHA composites is beneficial to reduce the probability of phagocytosis by the macrophages [102]. Moreover, improved wear resistance were observed at concentrations near 60% of hydroxyapatite [32]. Additionally, Shi et al. [15], evaluated the wear rates of UHMWE/HA composites prepared by sol-gel method. The sliding wear of the samples was measured by using friction and wear experimental machine (M-2000 A) under dry station. They found that the UHMWPE/HA wear rate increases with increasing quantity of HA. But low wear rate values were observed in the composite with 13.5% of HA, however, they consider interesting composite with 31.5% of HA. The effect of processing was also investigated and observed that the frictional coefficient, wear rate and bending properties prepared by gelation/crystallization were higher with those prepared by the kneading method [15]. This difference in wear resistance can be attached to an unusual planar orientation of UHMWPE in the plane (110) when it is molded at 150 °C. It is important that this unusual orientation provides a good dispersion of HA in the polymer matrix and thereby improving the crystallinity of material [15].

Gu et al. [106], developed a novel strontium-doped calcium polyphosphate/ultrahigh molecular weight polyethylene (SCPP/UHMWPE) composites. They concluded that the composite exhibited good wear resistance when compared to the pure polymer. Interestingly, the composite wear rate increased timidly with SCPP concentrations above 20%. It is important to notice that similar results were observed by others works using another phosphate, HA [102], [103], [15]. Additionally, they observed that the SCPP/UHMWPE composites-wear particles promote the production of osteoprotegerin (OPG) by osteoblasts and decrease the production of ligand activator of nuclear factor KAPPA B receptor (RANKL) by osteoblasts, and then increase the OPG/RANKL ratio [106].

Other factor that affects the wear resistance of UHMWPE/HA composites are the conditions in which the tests are performed. Sonjaitham and Puangmalee [107]evaluated the tribotechnical properties of UHMWPE based composite filled with HA microparticles under dry sliding lubrication of distilled water and plasma blood wear investigated with block-on-ring. They found that, under lubrication conditions, wear intensity of pure UHMWPE and microcomposite are decreased up 50–70% as compared with dry sliding. This phenomenon may be related to the fact that lubrication reduces the coefficient of friction between the specimen and roller couterface [107].

It was previously mentioned that the use of nanometric reinforcements and gamma radiation significantly alter the mechanical and tribological properties of the composite [33], [108]. In this order, Xiong et al. [108] observed the synergistic wear reduction for irradiated UHMWPE/7% nano-HA. They attributed this phenomenon to the more prominent supporting function and the increased modulus [108]. Similar results were obtained by Panin et al. [32], when they evaluated the effect of s HA size and the irradiation by nitrogen ion beam. An introduction of 0.1–0.5 wt% HA a nanoparticle into UHMWPE is shown to result in a threefold increase in its wear resistance. A similar effect is observed in the case where 20 wt% of HA microparticles is used (Fig. 8). Treatment of the surface of nano- and microcomposites, with a nitrogen ion beam, increases the wear resistance by an additional by10–30% (Fig. 9). It was observed that UHMWPE composites reinforced with micro and nano HA 15% and 10% respectively, showed good wear resistance and low friction coefficients [109]. According to Kang et al. [109], friction and wear mechanism is furrow and scratch when the content of micro- and nano-HA under 15 and 10 wt%, but there are surface rupture and delamination on the worn surface of HA/UHMWPE composites when the content of micro and nano-HA particles is more than 15 and 10 wt%, and the wear debris increases with increasing content of HA particles.