1. Introduction

Biomaterials with well-defined structures and tailor-made properties significantly impact on human health, the economy, and many interdisciplinary scientific fields, including biology, chemistry, physics, and materials engineering. They are now commonly used as prostheses in dental, orthopedic, cardiovascular, and reconstructive surgery, and in other sophisticated interventions such as bioadhesives, surgical sutures, and controlled drug delivery/release devices. With an increasing standard of living, especially in developing countries, and aging populations, the biomaterials sector has noted rapid growth since the first medical materials made their way into human usage in the late 1940s and early 1950s [1]. In the 1950s the first generation of biomaterials was successfully applied in tissue engineering. They belonged to a group of inert materials, whose sole role was to replace damaged fragments. Such implants did not interact in any way with natural healthy tissues and were non-toxic to the human body. Second-generation biomaterials were developed in the 1980s. During that period, materials which interacted with the surrounding environment were intensively investigated. In the case of such biomaterials, it was required that the biochemical reactions occurring at the implant/human tissue interface should be harmless to the patient's health. A great revolution and significant technological progress was brought about at the end of the 20th and the beginning of the 21st century by third-generation biomaterials, namely biomimetic (mimetic, bionic) systems, imitating solutions that occur in natural living organisms. In fact, the concept of “bionics” was first (theoretically) used in the 1960s at the Living Prototypes of Artificial Organs conference held in Dayton, USA. The role of third-generation biomaterials is not only to replace damaged parts of the body but, thanks to their appropriate morphology and composition, to stimulate living cells to grow and regenerate directly in the organism. Biomimetic materials are the result of an analysis of ready-made solutions/concepts which have evolved over millions of years during the evolution of life on the earth [2].

The diversity and versatility of biomaterials used in a great variety of implants, diagnostic assays, drug delivery systems, smart sensors, mucosal and dermal devices and treatments, implants, and extracorporeal medical devices is impressively large. This wide pallet of materials currently used in medicine and related areas constitutes testimony to significant scientific advances that have occurred since World War II. In fact, the driving force for this incredible technological step forward was constituted by various dramatic failures mainly related to the poor choice or improper fabrication of the biomaterial components. Finally, that led to multidisciplinary collaborations with the aid of biologists, physicists, materials scientists, surgeons, and engineers, intensively cultivated in the 1970s and 1980s. As a result, many proposals were made in this field based on polymers (e.g. polyurethanes, silicones, acrylics, etc.), metals and alloys (e.g. titanium, stainless steels, etc.), ceramics and glasses (e.g. alumina, silica, natural and synthetic hydroxyapatites), and materials derived from solutions seen in nature (with special attention to collagen, polyhydroxyalkanoates, polysaccharides, biopolymers, etc.). It is worth emphasizing that special attention also focused at that time on organic–inorganic hybrid biomaterials.

When at least two different materials are combined, for instance binary glass/calcium phosphates [3], strontium-doped polymeric composites [4], or hydroxyapatite and binary oxide particles spread on methacrylate-based network, they form non-covalent composite materials [5,6]. From the chemical point of view, covalently bound hybrid materials are of great interest. Among the rich diversity of such synthetic compounds, an extraordinary place has been taken by polyhedral oligomeric silsesquioxanes (abbreviated as POSS) of the general formula (RSiO3/2)n (where: R = H, alkyl, aryl, halogen, alkenyl group and derivatives thereof; n = 6, 8, 10, 12, 14, 16, 18), and this review is devoted to these remarkable hybrid materials and their various applications in the field of tailor-made and well-defined biosystems [7,8].

This review is composed of two major parts. The first one is a tutorial guide to the chemistry of silicon (Section 2, where differences and similarities between Si- and C-based analogues are emphasized) with definitions and structures regarding spherosilicates (Section 3). This part should be helpful for readers from areas that are more biological than chemical. The second part, in turn, (Section 4) is devoted to selected biomaterials based on spherosilicate hybrids in the field of tissue engineering, including selected topics concerning (i) spherosilicates modified by functionalized methacrylates, (ii) spherosilicate hybrids containing degradable arms/networks, and (iii) spherosilicates containing polyurethanes and their derivatives. For many years, biomaterials based on silicon compounds and their organic derivatives have constituted a promising group of systems for medical applications. Currently, interest in this type of biomaterials experiences a peculiar renaissance, evidenced by numerous literature reports published in prestigious scientific periodicals concerning the interdisciplinary profile on the border of chemistry, biology, and related fields.

2. Carbon- versus silicon-containing compounds

Although silicon is located in group 14 of the periodic table, its compounds differ in their nature from their typical carbon analogues. Thermodynamically stable bonds typical of silicon compounds include siloxane bridges –Si–O–Si–, while –Si–Si–Si– moieties form non–durable connections. For carbon species in the series of alkanes, the situation is reversed, because –C–C–C– chains are thermodynamically stable, whereas –C–O–C– bonds in most cases exhibit lower stability (diethyl ether, for instance, can be an exception here). Similarly, in the case of cyclic structures, those with the Si O building fragments and carbon-based rings are particularly thermodynamically stable; tetrahydrofuran, for instance, is an example of a stable ring with a combination of the –C–O–C– moiety. Among silicon compounds, both covalent polarized and ionic bonds are preferred. On the other hand, in the midst of carbon species, there are covalent, low polarized σ bonds resulting from the imposition of specific atomic orbitals. In the group of Si compounds, the unrefined silicone 3d atomic orbital is involved in Si

O building fragments and carbon-based rings are particularly thermodynamically stable; tetrahydrofuran, for instance, is an example of a stable ring with a combination of the –C–O–C– moiety. Among silicon compounds, both covalent polarized and ionic bonds are preferred. On the other hand, in the midst of carbon species, there are covalent, low polarized σ bonds resulting from the imposition of specific atomic orbitals. In the group of Si compounds, the unrefined silicone 3d atomic orbital is involved in Si O bond formation. In turn, the formation of multiple bonds between carbon atoms is also involved in π molecular orbitals resulting from the overlapping of specific atomic orbitals. In addition, the Si

O bond formation. In turn, the formation of multiple bonds between carbon atoms is also involved in π molecular orbitals resulting from the overlapping of specific atomic orbitals. In addition, the Si H bond is extremely reactive and susceptible to hydrolysis, while the hybridized C

H bond is extremely reactive and susceptible to hydrolysis, while the hybridized C H bond in the alkane group shows a high degree of stability. At the same time, it is impossible to disregard the similarities of carbon- and silicon-containing compounds, which are as follows: (i) the creation of a rich variety of connections associated with straight, branched, or closed rings based on –C–C–C– and –Si–O–Si– sequences; (ii) the tetrahedral geometry of silicon and carbon atoms; (iii) the ability to form oligo and polymeric systems; (iv) the tendency to spontaneous transformations under changing external conditions; and (v) the natural occurrence of numerous compounds of these elements in nature [9].

H bond in the alkane group shows a high degree of stability. At the same time, it is impossible to disregard the similarities of carbon- and silicon-containing compounds, which are as follows: (i) the creation of a rich variety of connections associated with straight, branched, or closed rings based on –C–C–C– and –Si–O–Si– sequences; (ii) the tetrahedral geometry of silicon and carbon atoms; (iii) the ability to form oligo and polymeric systems; (iv) the tendency to spontaneous transformations under changing external conditions; and (v) the natural occurrence of numerous compounds of these elements in nature [9].

3. Polyhedral oligomeric silsesquioxanes: definition, chemical structures, and cage rearrangements

Polyhedral oligomeric silsesquioxanes constitute a unique family of organic–inorganic hybrid systems. They belong to a group of organosilicon compounds of the general formula (RSiO3/2)n (where R is H or any organic substituent; even numbers n = 6–18), in which the R substituents can be arbitrarily modified to form so-called side chains (arms) [10]. Thanks to this structure, these species are referred to as core/shell organic–inorganic hybrid systems, where the inorganic core is formed by a siloxane cage, and the organic part is composed of various organic arms which may constitute a reactive part of the compound.

Moreover, their structure fulfills requirements for the construction of multifunctional uncommon three-dimensional nanobuilding blocks for supramolecular hybrid materials [11]. Their complete functionalization can be, inter alia, achieved by Heck, hydrosilylation, and cross-metathesis approaches [[12], [13], [14]], and this field has been the topic of some interesting papers [15,16].

Cage-like silsesquioxanes have a number of interesting properties that distinguish them from conventional oligo and polymeric systems. They are hybrid materials combining the properties of inorganic compounds (e.g. silica, SiO2) as well as organic ones. Furthermore, they are distinguished by their nanometer size, which determines their use, for instance as additives to polymeric materials, composites, biomaterials, etc. In turn, the presence of three Si O bonds together imparts superior mechanical, thermal, and chemical stability, improving them by making attractive exploration objects in the area of prospective basic and industrial research, which constantly increases their application potential [17,18].

O bonds together imparts superior mechanical, thermal, and chemical stability, improving them by making attractive exploration objects in the area of prospective basic and industrial research, which constantly increases their application potential [17,18].

There are a number of silsesquioxane structures. These compounds are able to create random structures, ladder-like species, open-cage structures containing a partially condensed core with hydroxyl groups attached to Si nuclei, and closed cages with varying amounts of silicon atoms forming an inorganic core (Fig. 1). From the practical point of view, T8-type silsesquioxanes are the most attractive due to their high solubility in numerous organic solvents, allowing simple purification and making them useful covalent or non-covalent building blocks (depending on the nature of the side chains) for the construction of well-defined and tailor-made hybrid structures for, inter alia, biomedical applications [7].

Fig. 1. Known structural motifs of silsesquioxanes: (a) random structure, (b) ladder–like structure, (c) open cage structures of T8 type, and (d) cage–like structures of T8, T10 and T12 types.

Fig. 1. Known structural motifs of silsesquioxanes: (a) random structure, (b) ladder–like structure, (c) open cage structures of T8 type, and (d) cage–like structures of T8, T10 and T12 types.One of the drawbacks, which in many cases constitutes a real challenge during the synthesis of cage-like silsesquioxanes, is the spontaneous formation of higher analogues such as T10 and T12. The appearance of these forms in the reaction mixture is the result of cage rearrangement that occurs on the hexahedral siloxane core and the formation in solution of thermodynamically more stable cages [19]. In our studies on the cage-rearrangement process of T8species, we demonstrated a useful synthetic approach that made it possible to obtain various intermediates that could be trapped during the hexahedral-to-heptahedral (T8 → T10) transformation [20]. In this investigation, we explained the influence of the catalyst on the formation of cages with lower symmetries. In this case, trifluoromethanesulfonic acid (triflate, CF3SO3H) in DMSO was added to a solution of chloride salt of octakis(3-aminopropyl)octasilsesquioxane (1): several attempts were made in various stoichiometric ratios of 1: CF3SO3H = 1: 1, 1: 4, 1: 8, 1: 12, and 1: 16 (Scheme 1).

Scheme 1. Proposed pathway of T8 → T10 cage rearrangement.

Modified from ref. 20.Tracking the pathway drawn on Scheme 1, it can be seen that triflate acid attacks the siloxane cage in the first step causing simultaneous cage opening and the formation of the Si–OSO2CF3 moiety that leads to intermediate II. During replacement caused by a weaker nucleophilic substitution, inversion at silicon nuclei occurs [21]. Further attack leads to the T6(OH)2 compound (III) and siloxane dimer (IV). Since the reaction takes place under aqueous conditions, the T8(OH)4 (V) species is also formed; its appearance is forced by hydrolysis. In such an established system, the intermediate IV seems the natural partner of V for further reaction. In this manner, the abstraction of the CF3SO3−anion and siloxane cage closure are possible, leading to the formation of a higher T10 analogue (2). Although the formation of 2 is thermodynamically unfavorable, its existence is induced by the formation of a new Si4O4 core from the less energetically stable transition compounds IV and V. A similar study on reaction pathways leading to the formation of decaphenylsilsesquioxane [PhSiO3/2]10 via F− catalyzed rearrangement of [PhSiO3/2]n (where: n = 8, 12) has also been reported [22].

The formation of T10 and T12 analogues is the result of the spontaneous transformation of hexahedral silsesquioxanes (T8) and the construction of thermodynamically much more stable siloxane cage-like cores [20]. This phenomenon has been intensively studied by some research groups but there is little information available regarding pure, isolated species bigger than T8 [21,[23], [24], [25]]. There are two major facts that should be noted here: (i) solubility differences among T8, T10, and T12 derivatives, especially when both T10 and T12 species possess similar physical and chemical properties [26]; and (ii) difficult separation of derivatives which even possess different numbers of organic side arms, because they exhibit the same retention times during chromatographic purification [27]. The above-noted facts indicate that these compounds can simply be regarded as oligomers rather than discrete molecular species, even though the distinction may seem unnoticed [21].

4. Biomaterials based on spherosilicate hybrids and tissue engineering

Silicone-based biomaterials have been widely used in medicine for over 70 years. They have unique chemical and physical properties that manifest excellent biocompatibility and biodurability in many bioapplications. As was stated in the introduction, polyhedral oligomeric silsesquioxanes are able to attach miscellaneous organic side arms. However, in this review, biomaterials based on modified methacrylates, cyclic esters, and urethanes are discussed, and selected developments are shown regarding these materials (since 2006). They are considered the most promising solutions for innovative medical applications in the next-generation tissue engineering.

4.1. Spherosilicates modified by functionalized methacrylates

Functionalized methacrylate compounds such as 2-hydroxyethyl methacrylate (HEMA), 3-(trimethoxysilyl)propyl methacrylate (TMSPMA), and ethylene glycol dimethacrylate (EGDMA) (Fig. 2) constitute alternative monomers with improved properties and reactivity that can be used in various applications including well-defined tailor-made biomaterials. From the chemical point of view, these monomers constitute valuable agents for cross-linking connections, because they contain hydroxyl –OH and terminal vinyl C C groups, and, additionally, TMSPMA can be used in sol–gel processes, thanks to the silanol ≡Si

C groups, and, additionally, TMSPMA can be used in sol–gel processes, thanks to the silanol ≡Si OH groups; here, condensed silanols easily form siloxane (–Si–O–Si–) moieties that have an influence on the formation of strong connections between polymer chains.

OH groups; here, condensed silanols easily form siloxane (–Si–O–Si–) moieties that have an influence on the formation of strong connections between polymer chains.

Fig. 2. Selected functionalized methacrylate monomers.

Fig. 2. Selected functionalized methacrylate monomers.Recently, investigations of methacrylate-based materials have been reborn and are of interest to many scientists working in the field of tissue engineering. These materials, such as polymers and copolymers, possess various advantages, including biocompatibility, hydrophilicity, hardness similar to that observed for human soft and hard tissues, and the ability to be used as bone or teeth defect fillings [[28], [29], [30], [31], [32], [33]]. Table 1 summarizes potential applications of polymeric materials derived from these monomers.

Table 1. Selected applications of polymeric materials derived from functionalized methacrylates.

| Methacrylate | Selected applications in medicine | Refs. |

|---|---|---|

| HEMA | Contact or intraocular lenses, soft tissue replacements, vascular prostheses, increases the immobilization of cells, bioactive molecules (e.g. enzymes) or pharmacological compounds | 34 |

| TMSPMA | Dental restorative materials, contact lenses, drug release systems, artificial skin | 35 |

| EGDMA | Photocurable dental materials, systems directed toward reduced oxidative stress and co–stimulatory factors expression in human monocyclic cells, porous hydrogel device for the implantable delivery of insulin | [36], [37], [38] |

POSS modified by methacrylate side chains is one of the first examples of organic–inorganic hybrid material that has been synthesized by various methods [[39], [40], [41], [42]]. In our group, we have developed a simple and easy-to-scale-up method for the construction of T8 spherosilicate for bone-tissue engineering based on a macroporous scaffold modified by 3-(trimethoxysilyl)propyl methacrylate (Fig. 3).

Fig. 3. Synthesis of 2 and its use in macroporous scaffold formation.

Fig. 3. Synthesis of 2 and its use in macroporous scaffold formation.The synthetic approach includes the substitution reaction on 1 by the TMSPMA monomer giving hybrid 2. The advantage of this system is that, due to the presence of methoxy groups at the ends of the side chains, it is possible to use it in the sol–gel method. In this manner, we obtained a pre-matrix for the construction of the macroporous scaffold for potential applications in hard-tissue engineering [43]. The literature reports various known protocols for preparing such structures, e.g. surfactant-based foaming, gas foaming, the foam replica technique, solvent casting with particulate leaching (PCPL), highly internal phase emulsions (HIPE), thermally induced phase separation (TIPS), electrospinning, the self-assembly technique, solid freeform fabrication (SFF), etc., but it should be emphasized that these approaches do not allow for the construction of scaffolds with completely interconnected pores with a highly regular and reproducible morphology. These drawbacks can be omitted using much more sophisticated methods such as 3D printing, multiphase jet solidification, shape deposition manufacturing, etc., but these techniques are expensive and always require the use of complex devices [3,[44], [45], [46], [47], [48]]. A three-dimensional scaffold can be easily prepared using water-leachable agents; for instance scaffolds derived from 2 have been prepared using granulated white sugar as the porogen [43]. It should be noted that during the construction of the 3D macroporous scaffold, the shape (hexagonal, spherical, or cuboidal) and size (150–800 μm) of the pores can be easily controlled by using different types of water-leachable porogens as shown in Fig. 4a–c, and, therefore, macropores can be arbitrarily tailored in this sort of 3D materials [6]. Ideally, artificial tissue scaffolds should be biocompatible to prevent inflammation or toxicity effects in vivo, and they should also be highly porous to allow for cellular infiltration and nutrition supply via diffusion, convection, and directed fluid flow during the culture. It should be noticed that it is advantageous when three-dimensional scaffolds have a structure similar to the extracellular matrix for cell-matrix interactions and cell guidance to facilitate tissue development [49].

Fig. 4. Different sizes and geometries of pores depending on the kind of porogens: (a) sugar, (b) ammonium chloride and (c) sodium chloride. Sugar-based scaffolds derived from 4 (d) and 5 (e) biohybrids.

Modified from refs. 6 and 52.A series of microstructural analyses were also performed for the 2-derived scaffold to determine its geometrical and mechanical parameters that can be considered to predict its possible uses as a bone implant.

These studies were compared with parameters determined for polymerized TMSPMA (3) as a reference sample. Hybrid 2 exhibits greater porosity than polymer 3, but both materials have constant porosity through volume. The pore size distribution of 2 stays in the 300–800 μm range with a maximum at about 500 μm, which fulfills the requirements for mass transport, pore penetration by osteogenic cells, vascularization, and new bone formation [50]. The hybrid macroporous scaffold 2 has a larger Young's modulus (4.36 ± 0.57 GPa) and hardness (0.57 ± 0.13 GPa) than the polymeric reference sample 3 (here these values are as follows: 3.91 ± 0.34 and 0.46 ± 0.08 GPa, respectively). In turn, 3 has a higher compressive strength (0.82 ± 0.22 MPa; for 2–0.21 ± 0.03 MPa). In the case of monoliths, the situation is reversed, where the hybrid system 2 has a higher compressive strength (1.8 ± 0.05 and 1.2 ± 0.16 MPa for 2 and 3, respectively) [43]. The combination of the elasticity module and other designated mechanical parameters of the organic–inorganic hybrid 2 obtained with other materials described in the literature and parameters determined for human tissues show the great potential of the developed system in terms of potential applications in hard-tissue engineering [47,51]. We have also reported on the efficient synthetic approach to hexahedral cage-like silsesquioxanes containing side arms fully substituted by ethylene glycol dimethacrylate (4) and 2-hydroxyethyl methacrylate (5) (Fig. 5). These species have been obtained upon the treatment of 1 with EGDMA and HEMA monomers. During highly efficient synthesis (yields ca. 100%), no other undesirable processes like cage rearrangements or cage-opening reactions were observed. In these hybrids, functionalized side arms can be bound together via polymerization (4 and 5 containing EGDMA and HEMA arms, respectively) and polycondensation (in the case of 5); they can be used for the construction of macroporous scaffolds (Fig. 4d and e) [52]. The resulting compounds can be used as versatile building blocks for the efficient preparation of highly functionalized polyhedral oligomeric silsesquioxane frameworks toward specific bioapplications.

Fig. 5. Spherosilicates 4 and 5 containing EGDMA and HEMA as side chains.

Fig. 5. Spherosilicates 4 and 5 containing EGDMA and HEMA as side chains.It has also been reported that honeycomb-like scaffolds with ordered pores (ranging from about 0.52 to 1.24 μm) can be obtained with water droplet arrays as templates based on star hybrid fluorinated polymers with polyhedral oligomeric silsesquioxane cores POSS-(PTFEMA)8 (6) and POSS-(PMMA-PTFEMA)8 (7) (where: TFEMA = trifluoroethyl methacrylate; MMA = methyl methacrylate).

These two different star hybrid fluorinated acrylate polymers were synthesized via the standard ATRP protocol. Resulting hybrid spherosilicates possess excellent surface properties (hydrophobicity and acid-base resistance) which is promising for specific uses such as cell culture, filtration, marine antifouling, and tissue engineering [53].

4.2. Spherosilicate hybrids containing degradable arms/networks

Various natural and synthetic polymeric materials have been applied both in vitro and in vivo, but none have reached widespread clinical use. Biomedical applications often require artificial devices that must serve a temporary rather than a permanent purpose. Such degradable biomaterials have found some applications, and implants made of them do not need to be surgically removed. It is important to have controlled degradation rates to provide the required support for tissue formation, allowing degradation to start as neotissue forms, especially tissue engineered around a 3D scaffold; the products of degradation should be biocompatible to ensure that there is no (cyto)toxicity [54]. Polycaprolactone (PCL) and poly(lactic acid) (PLA) and their copolymers constitute biomaterials which currently possess a lot of useful applications; (i) PCL: long-term drug delivery, implantable drug devices, orthopedic applications, staples, stents, and (ii) PLA: barrier membranes, drug delivery, hormone delivery, guided tissue regeneration, orthopedic applications, vascular/urological stents, staples, sutures, injectable fillers, skin replacement materials, scaffolds for diverse tissue engineering [1]. Such polymers can be obtained from renewable sources using ring-opening polymerization with Sn(Oct)2 as a catalyst or much more sophisticated initiators based on biometals, e.g. zinc complexes [[55], [56], [57]].

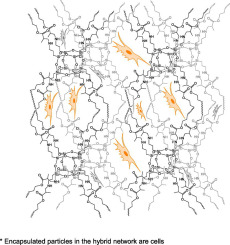

To engineer PCL and PLA physical properties for bone regeneration, these polymers and their various copolymers can be used as platforms of polyhedral oligomeric silsesquioxanes. For instance, poly(ε-caprolactone) triacrylate (PCLTA), which constitutes a photo-crosslinkable and injectable biopolymer for tissue engineering applications, can be incorporated with fully functionalized photo-reactive methacryl isobuthyl spherosilicate. Resulting PCLTA-POSS nanohybrid network (8) with improved osteoconductivity and mechanical properties has potential as scaffolding material for bone repair and regeneration (third-generation biomaterial). Among such factors as rheological, thermal, and mechanical properties, and surface characteristics (inter alia hydrophilicity, roughness, etc.), the obtained 8 and its various derivatives with different amounts of the amorphous PCLTA network have been found to be significantly enhanced by the crystalline domains of PCL and the presence of tethered POSS nanoparticles. Such a system serves not only as a good scaffold for osteogenic cells but also as a simple platform for the promotion of osteoconductivity that effectively affects fostering hard-tissue repair and its efficient regeneration [58]. Tissue scaffolds can also be obtained by anionic ring-opening polymerization of ε-caprolactone on POSS building blocks. A hybrid polymer with a higher amount of spherosilicates spread into a PCL network improved mechanical properties, thermal and biological stability including biocompatibility [59]. Biodegradable multi-arm polymers attached to a siloxane cage-like core can be obtained through other synthetic approaches creating degradable materials toward hard-tissue engineering applications [60].

Star-branched building blocks based on spherosilicate cores containing eight degradable poly(D,L-lactide) side chains upon reaction with a diisocyanate covalent crosslinker can create POSS-SMPs shape-memory tissue scaffolds (9). The degradation of 9 elicited a mild foreign-body-type immune response upon subcutaneous implantation in rats. Both in vitro and in vivo degradation rates inversely correlated with the length of PLA chains. The resulting system with its chemical functionalizability and tunable mechanical properties can be used for a wide range of bioapplications, for instance as vascular stents, orthopedic implants, or other tissue scaffolds, and constitutes a promising candidate for a scaffold-assisted tissue repair agent. Due to the controlled degradation of 9, the obtained scaffold is expected to achieve optimal long- or short-lasting clinical outcomes [61]. It has also been reported that the incorporation of spherosilicates into the poly(caprolactone/carbonate)urethane/urea system has resulted in the construction of a degradable polymer which preserves its mechanical properties during hydrolysis, oxidation, or degradation by plasma protein fractions [62].

Multi-arm star-like spherosilicates modified by polycaprolactone side chains can also be synthesized by the so-called core-first approach or by the arm-first strategy based on the functionalization of spherosilicate anhydrides with hydroxyl polymers. The arm lengths of polymeric arms attached to the siloxane core could be controlled by tailoring the quantity of ε-caprolactone and, thus, could precisely design the properties of hybrid core/shell systems. Preliminary cytotoxicity studies conducted on the above-mentioned biohybrids have shown that they have no toxic influence on C2C12 rat muscle myoblast or on MG63 human osteoblast cell lines. Such biomaterials can be used as soft- and hard-tissue scaffolds [63]. It has also been reported that porous scaffolds based on the POSS-PCL composite can be fabricated using the simple and inexpensive technique of solvent casting and particulate leaching. Such systems carry chemical and physical properties that are able to fulfill the requirements for intestinal cells. Alternatively, instead of PCL, PGA and PLA biopolymers can be used. Moreover, both porosity and pore size can be tailor-made depending on cells used in experiments (the type and size of the cell source) [64].