1. Introductions

One of the biggest problems that the world is facing at present is the energy crisis because traditional energy sources are consumed largely and continuously, which threatens to run out during the next fifty years [1]. Currently, fossil fuels such as oil, gas, and coal are used in a wide range, where the continued utilization of fossil-fuels interfaces many troubles, namely: global warming, and environmental pollution, in addition to the ongoing increase in fuel prices, and also, the expense of extracting and transporting [2]. The use of fossil fuels causes significant climate change on Earth as a result of the warming of the atmosphere [3]. Because of these factors, conventional energy sources now available could not be enough to gather the growing future power needs [4]. Scientists and engineers must therefore make great efforts to explore the potential of energy harnessing in many renewable energy sources [5]. That is seen as a probable resolution to the increasing energy confrontation. From the face of view of experts in the field of energy can be that renewable energy resources may be used to produce electricity, a topic that is gaining a lot of attention [6]. Due to its many advantages, it is clean and environmentally friendly, significant in the economic and social spheres, and creates a large number of work opportunities [7]. Renewable energy is divided into several types, the most important of which are: Wind energy, Bioenergy, Hydropower, Solar energy, and other types [8]. Solar energy represents the main source of life on Earth and human progress in particular, and it is one of the extremely important renewable energy sources due to its availability for free and is an ecologically cordial source [9]. There are several advantages to solar energy that promote reliance on it and its use, and the most significant of these advantages are [10].

-

•

Solar energy can't deplete and are present all over the world, so they are a renewable resource.

-

•

The technology used in this type of energy is simple and uncomplicated when compared to the technologies used in other energy sources, such as wind.

-

•

Low maintenance costs of solar energy devices, despite the high costs of their construction.

-

•

Solar energy is considered to be ecologically beneficial because it is a safe resource for the environment and doesn't produce any air pollution [11]. The main drawback of solar energy systems is the urgent need for equipment to store energy at night times and on cloudy days [12]. Solar energy systems are divided into several types, such as solar collectors [13], solar cells [14], solar stills [15], solar ponds [16], solar chimneys [17], and Trombe walls [18].

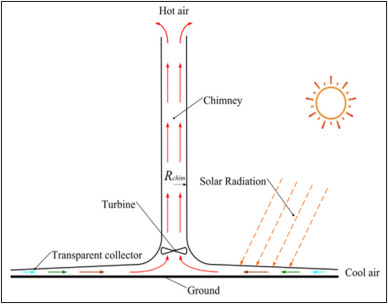

The solar chimney power plant is one of the promising technologies for generating electricity using solar energy. Figure (1) shows the simple diagram of this system. It is a solar–energy electric generating station that converts solar energy to electric power by utilizing a complex heat transfer mechanism [67]. The execution of this enterprise is crucial for the creation of a new power source, and the getting of energy generation systems of this nature will also aid growth nations in fostering the quick advancement of solar power generation[68]. The sun serves as the renewable energy source used by the solar chimney power plant. It's suitable for use in many nations throughout the world that have flat ground and a lot of solar radiation.

Fig. 1. The basic structure of the conventional SCPP [69].

Fig. 1. The basic structure of the conventional SCPP [69].A solar chimney power plant can operate under widespread sun radiation, can be durable and requires little upkeep. The concept of the SCPP consists of heating the air between the tower chimney's transparent cover and its base [70]. The hot air trapped between the glass cover and the absorbent floor as a result of its high temperature and low efficiency will move upwards, and due to the airflow, the wind turbines installed in the lower part of the tower chimney will rotate. The concept of the SCPP was presented for the first time in the world in 1931 in the book written by the author, Hans Gunther. The idea was implemented through cooperation between the German government and a Spanish company [71]. Schlaich designed the initial SCPP model in 1982 in Manzanares, Spain. In 1982, it was referred to as the Spanish model initial for determining energy production. The dimensions of this model are the collector radius tower chimney (122 m), its length (194.6 m), and collector diameter (5.08 m), in addition to one turbine system rotating with four blades (Fig. 2). This model was operated from 1982 to 1989 and was able to run for a median of 150 kW of electricity [72].

Fig. 2. Prototype Manzanaris plant, Spain [73].

Fig. 2. Prototype Manzanaris plant, Spain [73].Solar chimney power plant performance is also influenced by system design and environmental conditions [74]. Much research has been conducted to increase the effectiveness of SCPP systems and examine how environmental factors and design elements may affect their performance. One method explored by researchers to boost the performance of SCPP is to combine them with traditional power sources or renewable, like solar ponds, solar panels (Fig. 3), and geothermal power stations. The solar chimney that combines the most than one technology to improve its performance is called the hybrid solar chimney [75]. The solar chimney is made up of three major ingredients (Fig. 1); collector, tower, and turbine. The collector is the area where hot air is generated as a result of global warming, and it is made out of a floor and a diaphanous cover comprised of plastic, glass, or another material (Fig. 4) [76].

Fig. 3. The hybrid SCPP.

Fig. 3. The hybrid SCPP. Fig. 4. The chimney collector [77].

Fig. 4. The chimney collector [77].The solar collector produces more energy when the surface area is large. The height increase under the glass ceiling gradually from the outside to the centre to reduce the loss of friction [78]. The second part of the system is the tower which is considered an essential item of the system, as shown in Figure (5). When air flows from the collector to the tower chimney tower, it is propelled up the tower chimney due to the variation in pressure between the heated air and the outside air. The tower chimney must be built to improve the pressure difference in the tower, and its higher must be increased because the compression variation in the tower is proportionate to its higher [79]. The third part of the system is the turbine which is a device that produces electrical energy and changes the kinetic energy of air into mechanical energy (Fig. 6). For ease of maintenance and connection to generating equipment, the turbines are positioned near the tower's base in the tower chimney, one turbine is mounted on the vertical axis, and more turbines can be added either inside the tower chimney or in the space between the collector and the tower chimney.

Fig. 5. The solar chimney tower [80].

Fig. 5. The solar chimney tower [80]. Fig. 6. The tower chimney turbine [81].

Fig. 6. The tower chimney turbine [81].Solar chimney power plants have many advantages, including [82].

-

•

The tower chimney is manufactured from building materials that are widely available in the market, especially glass and concrete, in addition to steel.

-

•

Direct and diffuse radiation are both absorbed by the solar collector.

-

•

Free from pollution during operation.

-

•

The SCPP is characterized by its low operating cost in terms of maintenance and the lack of need for fuel, and the only moving parts that need periodic maintenance are the generator and the wind turbine.

-

•

The abundance of materials that go into the construction of the tower chimney and its presence in abundance in all countries, including of which concrete and glass, can be manufactured at the construction site.

Although there are some advantages to the SCPP, it also has some disadvantages, including [83].

-

•

The dynamic efficiency is low.

-

•

Not suitable in areas or countries where earthquakes occur.

-

•

It requires a very large space and suitable and specific sunny areas such as desert areas.

-

•

It requires the use of a very high tower chimney tower to produce high electrical energy.

-

•

The initial investment cost is high.

According to a review of earlier papers, researchers are keen to find new applications for solar energy due it is a renewable resource that isn't depleted and doesn't have the same negative environmental effects as traditional sources of fuel. Due to the poor performance of a solar system and the low production of power generated from it, researchers have focused on finding ways to enhance its efficiency. Therefore, the current goal is to review previously published articles and research related to the study of ways to improve previous efficiency and to suggest new ways to improve the performance of these systems.

2. Method to improve the efficiency of a solar chimney power plant

The main objectives of this study are divided into several axes: first, the basic components of an SCPP, and second, the integration of the SCPP with heat storage and with other technologies to improve its performance. In addition, previous research showed that geometric dimensions are considered the basic parameters for improving the performance of the tower chimney. The techniques for improving the thermal performance of the SCPP will include the following sections.

-

•

Integration of the SCPP with heat storage materials.

-

•

SCPP with the external source.

-

•

Enhance the absorber surface of the SCPP.

-

•

The impact of design parameters on the work of the SCPP.

-

•

Integration of the SCPP with other technologies.

The most important previous studies published will be reviewed as follows.

2.1. Integration of the SCPP with heat storage materials

When solar radiation is present, the SCPP works, that is, during the day only, but at night the solar radiation is absent, which leads to stopping the tower chimney's work [84]. For this reason, benefits from solar radiation are used in the day for the operation of the SCPP by using a variety of heat storage techniques. Previous articles and studies presented the integration of the SCPP with exothermic materials such as PCM [85] and porous materials [86]. Zhou et al. [19] presented a numerical analysis of SC, and the usage of paraffin–wax as a heat storage medium was given. According to the study, the output energy was 122 W, and the air velocity was 1.24 m/s at 12 h. As the output energy rose to roughly 1.3 W at night, the PCM was having an impact. Al-Abadi et al. [20] developed a theoretical model to assess how well an SCPP with a black concrete base would absorb and store more heat at night. The findings indicated that the black concrete led to heat storage more at night, which improved the energy output. Chaichan [21] suggested an experimental model of SC, and they used three various types of flooring, which are (black-coated gravel, black-coated concrete, and concrete). The result showed that the best floor used for the chimney was pebbles coated with black colour, as this floor produced the best SCPP efficiency of 49.7%, and the highest collector air temperature was approximately 49 °C. Amori & Mohammed [22] suggested a numerical and experimental model of a SCPP to obtain natural ventilation. Its thermal behaviour was studied by combining it with paraffin wax. The results led to an increase in the ventilation period after sunset. The amount of stored energy was approximately (5016 W) extending from 9 a.m. to 1:00 p.m. As for the energy that was discharged (4954.4 W), it extended from 1:00 p.m. to 10:00 in the evening. Amori & Hmood [23] presented a numerical analysis of a SCPP. The heat-absorbing surface was placed in different locations on both the front and back sides and in the centre of the air gap. The results showed that better ventilation and thermal performance were obtained for the absorptive surface in the centre of the gap, and the better efficiency was for an absorber surface on the backside. Li & Liu [24] worked on an experimental investigation using three distinct heat flows (500 W/m2, 600 W/m2, and 700 W/m2) to evaluate the thermal efficiency of a SCPP incorporating PCM. The case with 700 W/m2 had a higher air flow rate equal to 0.04 kg/s. The case is 500 W/m2, which has an efficiency of 80% and the highest average air outlet temperature of 20.5 °C. Li [25] studied a comprehensive analysis examination of the thermal efficiency of (SCPP) with PCM. They found that increasing the latent heat from 70 to 170 kJ/kg resulted in a 103% increase in melting time and a 60% in solidification time. The melting time is reduced by 36.4% when the heat flux is increased by 33%. Cao et al. [26] conducted a numerical study of a SCPP using the (TRANSYS) program and a study of six types of tower chimney floors to generate electric power(limestone, water, flint, sandstone, wet soil, sand), and the results were that the sand material gives the best heat storage in day and night the best electric capacity. Fadaei et al. [27] investigated the impact of latent heat storage(LHS) on an experimental tower chimney. The findings of two different types of experiments-one with and one without a PCM-showed that the maximum absorption surface temperature of the tower chimney with a PCM is 72 °C, while the LHS system boosts mass flow rate by 8.33%, as shown in the figure (7).

Fig. 7. The experimental design proposed by Fadaei et al. [27].

Fig. 7. The experimental design proposed by Fadaei et al. [27].Li et al. [28] suggested a numerical analysis to evaluate the thermal efficiency of the SCPP integrated with PCM. The finding showed that the temperature of the PCM had an impact on the thermal performance of the SC and that the thermal conductivity of the (PCM) was increased from 0.2 to 0.6 W/m.oC. The airflow rate and temperature difference rose from (0.033–0.038 kg/s) and (1.5–2 °C). Bashirnezhad et al. [29] presented a study to enhance the performance of an experimental SC by incorporating it with PCM (Fig. 8), and they use three different soils, water, and paraffin as heat stockpiling materials. The finding was the best heat stockpiling material is paraffin, which led to an increase in time by 20% and an increase in electrical energy production by 22%, with a limit of 11.5 kWh/day. Jamali et al. [30] suggested a theoretical study of cooling a semi-transparent STPV/SCPP using EES software. The slab was laid as a roof for the collector. They found that the user of the tower chimney for cooling improved the energy generation of the ST- PV panels by up to 29% as shown in Figure (9).

Fig. 8. The experimental work by Bashirnezhad et al. [29].

Fig. 8. The experimental work by Bashirnezhad et al. [29]. Fig. 9. The system suggested by Jamali et al. [30].

Fig. 9. The system suggested by Jamali et al. [30].2.2. Performance of the SCPP with an external source

The biggest problem facing the SCPP is that it stops working at night and during cloudy weather, which makes it difficult for it to produce electricity [87]. Combining the solar chimney with an outside heat source to utilize the waste heat can enhance the performance of the solar chimney. Several researchers enhanced the tower chimney's efficiency by using an external heat source. Aurybi et al. [88] presented a novel method by combining the SCPP with an external heat source. Installing thermal improvement channels between the collector's surface and floor will integrate the system by increasing the kinetic energy of the air inside the collector, allowing the tower chimney to operate at night. Al-Kayiem et al. [31] suggested a hybrid system using the SCPP and an external heat source to supplement solar energy for continuous electric energy generation, where they used flue gas ducts to supply air to the collector corridor. The study demonstrated that the proposed technology resulted in energy production throughout the weekdays. The proposed design is shown in Figure (10).

Fig. 10. The model suggested by Al-Kayiem et al. [31].

Fig. 10. The model suggested by Al-Kayiem et al. [31].Li et al. [32] developed a hybrid system they named the " Solar chimney power plant -aided dry cooling system", which heated the air entreating the SCPP collector using waste heat supplied by a coal-fired power plant's condenser. This led to an increase in power output and a decrease in fan energy consumption. Fathi et al. [33] worked on incorporating the SC with the nuclear power plant to increase the tower chimney's efficiency by using waste hate from the nuclear power plant. They used CFD software to analyze the proposed design, and they found that the nuclear power plant's integrated tower chimney's thermal efficiency increased by 42%. The proposed design is shown in Figure (11).

Fig. 11. A SCPP integrated with a shape diagram of a nuclear power plantproposed by Fathi et al. [33].

Fig. 11. A SCPP integrated with a shape diagram of a nuclear power plantproposed by Fathi et al. [33].2.3. Effect of the absorber surface on the performance of the SCPP

The flat plate solar collector is part of solar thermal collectors and is typically used to fever air and water at lower temperatures (less than 150 °C) [89]. The absorption surface, which is the primary component of the solar thermal collector with flat panels, has characteristics that have a significant impact on the efficiency of the solar thermal conversion system. It works to absorb the majority of the incoming solar radiation (high absorption) while minimizing the loss of thermal energy through re-radiation from the hot surface (low emission), to obtain the desired wavelength selectivity, it is imperative to enhance the properties of a surface's optical and structural qualities through the use of a variety of materials, the modification of the endothermic surface, or synthesis, which are called solar selective surfaces (absorption surfaces) [90]. The absorbent surface is a component of the SCPP [91]. The SCPP experimental investigation confirmed that the permeability of the glass is crucial for the SCPP and that a high value can both improve performance and raise the output temperature, as explained by Lee et al. [34]. Also, it was discovered that the effect of tower chimney vilification's permeability on the temperature increase was more pronounced than its effects from absorbance and reflectivity individually. Chaichan et al. [35] studied the effect of pollutants and dust deposition on the performance of the SCPP. They achieved that cleaning the solar collectors that absorb heat from pollutants and dust has a major participation in enhancing the performance of the tower chimney. Cleaning the collectors cause greater efficiency, as shown in Figure (12).

Fig. 12. The proposed tower chimney suggested by Chaichan [35].

Fig. 12. The proposed tower chimney suggested by Chaichan [35].One of the biggest problems facing researchers is the traditional SCPP system's lower efficiency. Studies and research are still being conducted to improve this system's overall performance. As a result of these studies, they developed the intelligible PV/Solar chimney power plant; it's an SCPP that combines the technology of PV solar panels and the conventional SC [92]. This type of tower chimney does not depend only on the kinetic energy of the hot air from a solar collector heating but also on else depends on resources, like the use of groundwater energy to warm the solar collector's floor or the integration and addition of solar photovoltaic panels to the solar collector surface, centre, or floor, to boost the overall efficiency of the tower chimney system PV solar, as in fig.(13) [93]. The concept of PV/SCPP is based on using photovoltaic panels as a heat-absorbing surface instead of the typical SCPP floor pained black. Air flowing above and bottom of solar panels will; therefore, cold them boost their electric performance. Additionally, electrical power is produced by wind turbines that are mounted at the base of the tower chimney [94]. Haghighat et al. [36] suggested a hybrid design for the SCPP integrated with PV panels and investigated the impact of each PV panel's width and position for four various situations, and they used three different widths, which (30 cm, 50 cm, 70 cm) for all conditions, According to their finding, the hybrid design gives the best results at widths of 50 cm rather than a glazed collector, and the rated temperature of the PV panels is 5o lower than that of the other model.

Fig. 13. The photovoltaic SCPP [95].

Fig. 13. The photovoltaic SCPP [95].Fig.(14) shows the proposed model by Martí-Herrero and Heras-Celemin [37]. They have proposed a new model of a SCPP where they replaced the outer surface with PV panels. They obtained an airflow rate of approximately 0.02 kg/s as well as the maximum temperature of the plates was 321 K.

Fig. 14. PV panels in SC with four various designs proposed by Haghighat et al. [96].

Fig. 14. PV panels in SC with four various designs proposed by Haghighat et al. [96].Biswas et al. [38] presented a new design to enhance the SCPP using a stair-shaped ground surface. In comparison to a flat ground absorber surface, the analysis shows that the suggested stair-shaped absorber can increase power generation by up to 80%. A traditional SCPP's power can be increased by 51–92 kW using a stair-shaped ground surface. Also, the results demonstrate that raising the absorber's step height or the number of steps increases plant productivity.

Mandal et al. [39] replaced the flat black absorbed surface with multiple triangular wavy peaks (n) at different amplitudes (h) and analyzes the performance of SCPP as shown in Fig.(15). Discrete ordinates (DO) and a solar ray-tracing model are used to undertake a three-dimensional investigation for this design of SCPP using Fluent software. The results confirmed that an increase in wavy wall amplitude significantly improves SCPP's ability to generate power. A single triangular wavy wall with larger amplitudes shows the greatest increase in power output and efficiency (increased power by 58.61% and augmented efficiency by 61.83%).

Fig.(15). The absorbent plate shapes of the system, which were studied by Mandal et al. [39].

Fig.(15). The absorbent plate shapes of the system, which were studied by Mandal et al. [39].