1. Introduction

India is the top spice producing, consuming, and exporting country in the world, accounting for 50% of the global trade (Board, 2019). Indian spices are known for their elegant aroma, flavor, and therapeutic value. About 80–85% of the total spices produced in the country are consumed at the domestic level (Singh and Solanki, 2015). The quality of any spice can be determined by its intrinsic and extrinsic traits. The unique characteristic of any spices is mainly because of a specific volatile oil or a compound that it contains. These compounds are embodied in the plant cell matrix and can be easily made available after grinding (Zachariah et al., 2012). For this reason, major spice crops such as red chili, coriander, turmeric, etc., are preferably consumed in powder form. The ground powder shows enormous export and local market potential. Hence, grinding becomes a critical unit operation in spice processing.

Grinding is an age-old technique of particle size reduction to produce powders that can be used as intermediate or end products. Grinding aims to reduce the size of the particle by mechanical means such as impact, compression, shear, and cutting (Sahay and Singh, 1996). Hammer mill, plate mill, ball mill, pin mill, roller mill are commonly used grinding equipment for spice (Balasubramanian et al., 2016). The schematic diagram, principle, and application of different size reduction equipment are presented in Table 1. Grinding is an energy-intensive process in which only 1% of the total input energy is utilized to reduce particle size and rest of the energy is dissipated as heat (Jung et al., 2018). Consequently, the grinding process is accompanied by a substantial rise in the temperature of the ground product, ambient air, and grinding mill (Balasubramanian et al., 2012). As the aromatic, flavoring and therapeutic components present in spices are heat liable in nature, an increase in temperature during grinding significantly lowers the quality of ground spices (Liu et al., 2013). Product temperatures of up to 90 °C in ambient grinding (Bera et al., 2001), 40 °C in wet grinding (Jung et al., 2018), and 26 °C in freeze grinding (Mathew and Sreenarayanan, 2007) were observed. Temperature-induced quality loss to the tune of 40% was reported in the conventional grinding process (Bera et al., 2001). Besides quality loss, temperature also results in clogging, higher oxidation of the product, higher energy consumption, and also induces tensile residual stress, reducing tool life (Meghwal and Goswami, 2014). Therefore, minimizing heat generation and quick removal of heat during grinding becomes crucial to maintaining the end product's quality.

Table 1. Size reduction equipment.

| Type | Schematic | Principle | Application |

|---|---|---|---|

| Roller mill |

|

Compression and shear | Sugar cane, chocolate, rye, oats, wheat, oilseed |

| Knife mill |

|

Cutting | Tea leaves, rubber bales, cheese, leaf, bark, and root of drugs |

| Turbo Mill |

|

Impact, shearing, and Cutting | cacao beans, fat, flax meal, milk powder, salt |

| Ball mill |

|

Impact and Shear | Coal, pigment, felspar |

| Hammer mill |

|

Impact | Fibrous solid, Sugar, tapioca, dry vegetables, Spices, food grains, hard rock |

| Pin mill |

|

Impact | Sugar, caffeine, fiber, flake, yeast, wax, milk powder, spices |

| Plate/Burr mill |

|

Crushing and shear | Wheat, coffee beans, salt peppercorns, spices, poppy seeds |

| Colloid mill |

|

Shear | Toothpaste, Cream, Fruit jam, honey, butter, corn and soybean milk, Dyestuff, Fish oil |

| Fluid energy mill (Ultrafine) |

|

Impact and attrition | Moderately hard and friable material |

The type of mill influences the rate and amount of heat generated during grinding, the principle of grinding, the degree of grinding (Meghwal and Goswami, 2014), and the properties of the material (Jung et al., 2018). Several techniques and technologies have been developed to remove heat generated during grinding. Circulation of cold water (Bandara et al., 2015b) or low-temperature air around the grinding chamber (Shelake and Dabhi, 2019) lowers heat generated to some extent. Mixing dry ice and prechilling material significantly decreased grinding zone temperature and improved final product quality (Mathew and Sreenarayanan, 2007). However, these techniques are inefficient in removing the quantum of heat generated during grinding. Cryogenic grinding (Fig. 1), a method in which liquid nitrogen (boiling point of −195.6 °C) is being used to pre-freeze the material before grinding (Balasubramanian et al., 2012) and removing heat during grinding, is the advanced and effective method to maintain the quality of spices during grinding (Saxena et al., 2015). Besides low-temperature grinding, cryogenic grinding has several advantages: reducing grinding force, lower specific energy requirement, no sieve clogging, etc. (Singh and Goswami, 1999). Very high initial investment and operational cost, scarce in the availability of liquid nitrogen and high ratio of liquid nitrogen to material hindering the adaptability of this technology (Wilczek et al., 2004).

Fig. 1

Fig. 1Retaining heat-sensitive ingredients of the food during sustainable and cleaner grinding process is a dynamic challenge for a food processor. The heat generation during grinding is influenced by several products and process parameters and principles. Temperature plays an important technological problem, particularly with heat-sensitive products, high-fat content, and thermoplastic substances (Gao et al., 2020). This article represents a comprehensive view of spice grinding techniques, focusing on critical quality control pregrinding and grinding process parameters to identify the most influential parameters and understand their cause-effect relationship. This work also intends to guide food processors and engineers in understanding the cause-effect relationship of one process parameter over another to select, design, and develop spice grinding technology for energy-efficient and quality grinding.

2. Literature review

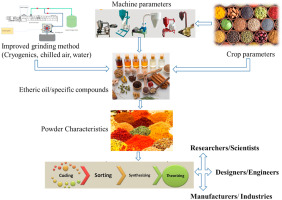

This segment consists of paper highlights in the area of spice grinding. Existing literature on spice grinding was thoroughly reviewed and categorized (Fig. 2) to identify critical factors influencing the quality of the final product. Further, identified factors and quality/performance indices were grouped and presented as cause-effect relationships (Fig. 3).

Fig. 2

Fig. 2 Fig. 3

Fig. 32.1. Crop parameters

Crop parameter includes attributes like variety, moisture content, hardness, and other engineering properties. Growing conditions have been reported to significantly impact thousand kernel weight, ash content, and physical and chemical properties of grains (Singh et al., 2012). Crop moisture content is a key factor defining the particle size distribution of ground product (Saxena, 2013) and grinding energy (Meghwal and Goswami, 2017). Further, there is a linear relationship between moisture and the mechanical properties of biological materials (Balasubramanian et al., 2017). Several studies have pointed out the relations between kernel hardness and the size reduction process. In general, brittleness reduces with increased moisture content, consequently increasing the energy required for grinding. Brittleness and tempering conditions affects the particle size, starch damage, milling yield, and functional properties of the powder (Dziki and Laskowski, 2005). Besides hardness, kernel weight, size, shape, and virtuousness affect the grinding process (Symons et al., 2003). Among these, shape and size are essential that define operational conditions and machines for grinding (Posner, 2000).

2.2. Machine parameters

Machine parameters include rotor/grinding tool speed, feed rate, grinding time, grinding zone temperature, and energy requirements. Selection of the grinding mechanism is the first and most crucial step, as it greatly impacts particle size distribution. Various grinding machines like a hammer, ultrafine, plate, roller, pin, ball mill and hand-pounding methods are being used for different spices (Balasubramanian et al., 2012). The efficiency of the grinding process is influenced by the design, operational and functional parameters of the mill. These parameters include the rollers' arrangement (Zawislak et al., 2007), speed, rotor type and number, distance between the rollers/plates, flutes profile, diameter of the plate, size of opening or clearance between grinding components, etc. (Meghwal and Goswami, 2014). Specific energy consumption and powder characteristics are affected by the grinding method or principle employed. For instance, a hammer mill is more energy-efficient than a knife mill and produces finer particles (Paraschiv et al., 2021). Comminution laws describe the relationship between the specific energy consumption and distribution of particle size. Different strategies were used when targeting small aperture sizes with the help of intermediate screens (Temmerman et al., 2013). These parameters were affected either individually or in combination and correlated in terms of rittinger’s constant, kick’s constant, bond’s index, total surface area, average particle size, grinding effectiveness, and yield (Balasubramanian et al., 2013).

2.3. Improved grinding methods

To protect heat-sensitive and volatile components, grinding should be performed under reduced temperature. For this, mills equipped with a cooling system or cryogenic milling are required (Saxena et al., 2018). Improved grinding methods were developed to minimize or extract the heat generated during grinding process. Air (Shelake and Dabhi, 2019), water (Bandara et al., 2015b), liquid nitrogen (Balasubramanian et al., 2016), dry ice (Mathew and Sreenarayanan, 2007), dual-stage grinding (Choudhary et al., 2015), superfine jet milling (Muttakin et al., 2015) were used to retain the quality of the spices and herbs.

2.4. Multicriteria decision approach

Multicriteria decision approach tools such as DEMATEL, attribute coding, fuzzy analytic hierarchy process, analytical hierarchy process (AHP), SWOT, etc., are being successfully used in agriculture and allied science research. For instance, analytic hierarchy process for banana warehouse site location (García et al., 2014), SWOT analysis for prospects of biogas plant (Brudermann et al., 2015), and fuzzy analytic hierarchy process for the thermal process (Do et al., 2014). Kohli et al. (2015) studied the factors involved in cotton harvesting mechanization in India using the attribute coding approach. Chavez et al. (2012) define important criteria involved in post-harvest activities.

3. Research methodology

The present study used two approaches: attribute coding (Kohli et al., 2015) and DEMATEL (Gardas et al., 2018). The conceptual framework for developing an attribute-based model is presented in Fig. 4.

Fig. 4

Fig. 43.1. Attribute identification

Attribute is a specification that defines the property of an object or element. Attribute Coding provides essential data information for future use (Onwuegbuzie et al., 2016). For this purpose, the cause and effect analysis diagram (Fig. 3) is drawn to identify all the different attributes and other parameters of the spices grinding process that require attention from researchers, engineers, industrialists, and manufacturers in the subject area. The attributes identified under four categories: crop parameters, machine parameters, improved methods on product characteristics, and grinding performance indicator are shown in Fig. 3.

Step 1

Matrix Identification

The importance of attributes and relevance in the research publication are expressed in matrix form and given in Table 2, Table 3. For each publication, grading was done based on the importance of a specific attribute considered in that study.

Step 2

Identification and construction of matrix based on a linguistic scale

Table 2. Matrix for various attributes of the crop, machine, and improved grinding methods.

| Attribute-based coding of the crop, machine, and improved grinding methods | |||||||

|---|---|---|---|---|---|---|---|

| Attribute (Category A) | Research publication | ||||||

| P1 | P2 | P3 | P4 | … … … … … … … … … …. . | Pn | ∑A | |

| A1 | a11 | a12 | a13 | a14 | … … … … … … … … … …. . | a1n | ∑A1 |

| A2 | a21 | a22 | a23 | a24 | … … … … … … … … … …. . | a2n | ∑A2 |

| A3 | a31 | a32 | a33 | a34 | … … … … … … … … … …. . | a3n | ∑A3 |

|

. . |

. . |

. . |

. . |

. . |

… … … … … … … … … …. .… … … … … … … … … …. . |

. . |

. . |

| (Category B) | |||||||

| B7 | b71 | b72 | b73 | b74 | … … … … … … … … … …. . | b7n | ∑B7 |

|

. . . |

. . . |

. . . |

. . . |

. . . |

… … … … … … … … … …. . … … … … … … … … … …. . … … … … … … … … … …. . |

. . . |

. . . |

| (Category C) | |||||||

| Cm | cm1 | cm2 | cm3 | cm4 | … … … … … … … … … …. . | can | ∑Cm |

| ∑P | ∑P1 | ∑P2 | ∑P3 | ∑P4 | … … … … … … … … … …. . | ∑P7 | ∑P = ∑A |

Table 3. Matrix for effects of A, B, and C attributes on powder characteristics and grinding performance indicator.

| Attribute-based coding of powder characteristics and grinding performance indicator | |||||||

|---|---|---|---|---|---|---|---|

| (Category D) | Research publication | ||||||

| P1 | P2 | P3 | P4 | … … … … … … … … … …. . | Pn | ∑D | |

| D1 | d11 | d12 | d13 | d14 | … … … … … … … … … …. . | d1n | ∑d1 |

| D2 | d21 | d22 | d23 | d24 | … … … … … … … … … …. . | d2n | ∑d2 |

|

. . . |

. . . |

. . . |

. . . |

. . . |

… … … … … … … … … …. . … … … … … … … … … …. . … … … … … … … … … …. . |

. . . |

. . . |

| Dm | dm1 | dm2 | dm3 | dm4 | … … … … … … … … … …. . | dmn | ∑d7 |

| ∑P | ∑P1 | ∑P2 | ∑P3 | ∑P4 | … … … … … … … … … …. . | ∑P26 | ∑P = ∑D |

The attribute ratings were given on 5 points numeric scale, with 5 for the most important and 1 for the least important attribute.

3.1.1. Rank distribution

Rank distribution is given as per attribute importance and narrated thoroughly; the highest-grade points were decided by the degree of closeness described in the research publication. Based on the degree of closeness, grade points were allocated to that attribute. To find the importance of each attribute, the attributes are required to be evaluated and coded for a range of values. It is desirable to assess the attributes on one interval scale of 1–5 for uniformity. Table 4 indicates the proposed coding scheme individually and in combination with research publications. The attribute assigned with 5-grade points was ranked excellent given through discussion in the research paper with the help of a graph showing the relation between variable quantities, table, and text narrative. Attribute awarded with 4 points was considered under the outstanding category. Attributes with 4-grade points represented the table information with the help of text, data observation, and simultaneous effect on other parameters. Three grade points were expressed as good rank and presenting text with data form showing little information, but its effect was not discussed in the study. Two grade points considered under average level were discussed and examined in the text form without physical data. Attributes carried 1-grade point with poor rank (Kohli et al., 2015).

Step 3

Calculation of total influence and inner dependency matrix (DEMATEL approach)

Table 4. Rank distribution of attribute coding.

| S.N | Attribute coding | Rank |

|---|---|---|

| 1. | 5 | Excellent |

| 2. | 4 | Very good |

| 3. | 3 | Good |

| 4. | 2 | Average |

| 5. | 1 | Poor |

Di and Rj represent the sum of ith row and jth column of matrix T. ‘D–R’ represents the centrality factors and their influence between elements, and positive values mean that a criterion is a causal factor and a negative value implies a criterion is the effect factor. ‘D + R’ represents the causality factor and their degree of relationship. Higher values of ‘D + R’ mean stronger the influence of the parameter under consideration.

Step 4

Summation of grading points (Attribute based coding approach)

The summation of grading points gives the idea of each attribute in individual publications for the comprehensive view of spice grinding.

4. Results

The values of ‘D–R’ and ‘D + R’ along with the inner dependency of the matrix, are presented in Table 5. In the inner dependency matrix, the threshold (α) value of 0.4 was considered, obtained by averaging the total relation matrix. The values lower than 0.40 were omitted from the tables. This indicates that the high significance factors were depicted in Table 5. Based on the calculated values of ‘D + R’, grinding methods have the maximum value (15.74) followed by cryogenic grinding (15.04) and moisture content (11.42). These values reflect that the grinding method, along with cryogenic pretreatment influences the final product quality. The relative weights of attributes and their rank are presented in Table 6. Selected parameters were categorized as cause and effect along with their ranks. The matrix calculation to identify factors and cause-effect relationships by using the DEMATEL approach and attribute coding approach presents similar results.

Table 5. Inner dependency and influence matrix.

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D + R | D-R | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.56 | 0.56 | 0.63 | 0.65 | 0.65 | 0.57 | 9.4 | −3.37 | |||||||

| A2 | 0.40 | 0.53 | 0.53 | 0.50 | 0.68 | 0.66 | 0.63 | 11.42 | −3.06 | ||||||

| A3 | 0.72 | 0.7 | 0.66 | 9.26 | −2.87 | ||||||||||

| B1 | 0.75 | 0.66 | 0.7 | 0.47 | 0.7 | 0.68 | 0.64 | 15.74 | −2.87 | ||||||

| B2 | 0.72 | 0.68 | 0.51 | 0.69 | 0.69 | 0.57 | 0.67 | 0.63 | 7.69 | −2.75 | |||||

| B3 | 0.69 | 0.68 | 0.68 | 0.66 | 0.62 | 8.13 | −1.85 | ||||||||

| B4 | 0.68 | 0.63 | 0.51 | 0.51 | 0.5 | 0.47 | 10.25 | −1.08 | |||||||

| B5 | 0.45 | 0.63 | 0.63 | 0.61 | 0.57 | 11.11 | −0.87 | ||||||||

| C1 | 0.55 | 0.5 | 0.63 | 0.69 | 0.69 | 0.5 | 0.69 | 0.68 | 0.65 | 7.68 | −0.75 | ||||

| C2 | 0.75 | 0.69 | 0.65 | 0.62 | 0.62 | 0.65 | 0.62 | 0.61 | 0.69 | 15.04 | −0.58 | ||||

| C3 | 0.62 | 0.63 | 0.69 | 0.61 | 0.61 | 0.6 | 0.61 | 0.6 | 0.67 | 7.14 | −0.25 | ||||

| C4 | 0.61 | 0.57 | 0.67 | 0.55 | 0.55 | 0.56 | 0.55 | 0.62 | 0.66 | 8.65 | −0.21 | ||||

| D-R | −3.37 | −0.87 | −3.06 | −2.87 | −2.75 | −0.75 | −0.58 | −0.2 | −1.08 | −1.85 | −0.21 | −0.25 | −2.87 | −0.2 |

Table 6. Relative weights of selected parameters.

| Cause-Effect group criteria | D-R | Rank | Cause-Effect group criteria | D-R | Rank | |||

|---|---|---|---|---|---|---|---|---|

| Crop variety (A1) | 3.24 | Cause | Particle size distribution | −3.37 | 1 | Effect | ||

| Moisture content (A2) | 6.12 | 3 | Cause | Color | −0.87 | 3 | Effect | |

| Engineering properties (A3) | 4.02 | Cause | Volatile oil content | −3.06 | 2 | Effect | ||

| Grinding types (B1) | 7.37 | 1 | Cause | Volatile compounds | −2.87 | 5 | Effect | |

| Grinding stages (B2) | 2.89 | Cause | Moisture content | −2.75 | Effect | |||

| RPM/speed (B3) | 1.18 | 6 | Cause | Engineering properties | −0.75 | Effect | ||

| Sieve size/Clearance (B4) | 4.23 | 5 | Cause | Antioxidant properties | −0.58 | Effect | ||

| Feed rate (B5) | 5.47 | 4 | Cause | Proximate composition | −0.2 | Effect | ||

| water (C1) | 2.29 | Cause | Thermal properties | −1.08 | Effect | |||

| Cryogenic (C2) | 7.06 | 2 | Cause | Energy requirement | −1.85 | 6 | Effect | |

| Dry ice (C3) | 3.89 | Cause | Grinding time | −0.21 | Effect | |||

| Chilling (C4) | 3.47 | Cause | Grinding loss | −0.25 | Effect | |||

| Grinding zone Temperature | −2.88 | 4 | Effect | 4 | ||||

In the Attribute coding approach, the summation of coding as per their importance in the research paper was calculated and presented in Table 7. It is observed from the table that the majority of researchers had discussed grinding methods. Machine and its related parameter are considered important with highest score (95) as the performance of grinding operation predominantly depends on the grinding mechanism (impact, attrition, shear, or compression). In improved grinding, water-cooling, pre-cooling of product/machine andr using cryogenics such as liquid nitrogen or dry ice (cryo-milling) were used to retain the quality of the spices. Among these attributes, cryogenic has the highest score (80) points and is discussed in depth. Most of the researcher had addressed the effect of cryogrinding on product quality as against ambient grinding. Cryogenic grinding provides higher retention of volatile oils per unit mass of spices maintaining the flavor. It leads to finer grinding with uniform particle distribution and without heat generation, which is suitable for spices and provides an inert atmosphere eliminating the oxidation process.

Table 7. Paper wise coding for different attributes of crop, machines & its performance and treatment.

| Attribute-based coding of the crop, machine parameter, and improved grinding method | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Attribute (Category A) | Attributes | Research publication | |||||||||||||||||||||||||||

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P 10 | P 11 | P 12 | P 13 | P 14 | P 15 | P 16 | P 17 | P 18 | P 19 | P 20 | P 21 | P 22 | P 23 | P 24 | P 25 | P 26 | ∑A | |||

| Crop Parameter | |||||||||||||||||||||||||||||

| A1 | Crop variety | 0 | 0 | 1 | 0 | 4 | 0 | 1 | 1 | 0 | 1 | 3 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 3 | 0 | 2 | 0 | 0 | 1 | 18 | |

| A2 | Moisture content | 2 | 2 | 0 | 0 | 0 | 0 | 5 | 5 | 2 | 0 | 1 | 1 | 5 | 1 | 0 | 2 | 2 | 0 | 5 | 5 | 1 | 0 | 5 | 1 | 0 | 0 | 45 | |

| A3 | Engineering properties | 0 | 0 | 3 | 0 | 0 | 2 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 2 | 0 | 0 | 4 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 17 | |

| ∑Px | 2 | 2 | 4 | 0 | 4 | 2 | 6 | 9 | 2 | 1 | 4 | 1 | 5 | 3 | 0 | 5 | 2 | 0 | 9 | 6 | 4 | 0 | 7 | 1 | 0 | 1 | 80 | ||

| Machine parameter | |||||||||||||||||||||||||||||

| B1 | Grinding type | 2 | 2 | 5 | 3 | 4 | 4 | 4 | 5 | 5 | 5 | 2 | 3 | 3 | 5 | 5 | 4 | 5 | 3 | 3 | 1 | 2 | 5 | 4 | 3 | 5 | 3 | 95 | |

| B2 | Grinding stages | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | |

| B3 | RPM, speed | 0 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 0 | 0 | 0 | 2 | 2 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 5 | 1 | 0 | 27 | |

| B4 | Sieve size/Clearance | 4 | 2 | 0 | 2 | 1 | 2 | 5 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 2 | 0 | 5 | 0 | 0 | 31 | |

| B5 | Feed rate | 3 | 1 | 1 | 1 | 2 | 1 | 4 | 0 | 1 | 0 | 0 | 5 | 2 | 0 | 0 | 0 | 4 | 1 | 0 | 5 | 1 | 1 | 1 | 5 | 0 | 0 | 39 | |

| ∑Py | 9 | 7 | 7 | 6 | 9 | 9 | 15 | 7 | 7 | 7 | 2 | 10 | 7 | 5 | 5 | 5 | 9 | 5 | 9 | 12 | 4 | 8 | 6 | 18 | 6 | 3 | 197 | ||

| Improved grinding method | |||||||||||||||||||||||||||||

| C1 | Water | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6 | |

| C2 | Cryogenic | 0 | 0 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 0 | 5 | 5 | 5 | 0 | 0 | 80 | ||

| C3 | Dry ice | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | |

| C4 | Chilling | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 7 | |

| ∑Pz | 8 | 2 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 0 | 0 | 5 | 4 | 5 | 5 | 0 | 0 | 98 | ||

| ∑P = ∑Px+∑Py+∑Pz | 19 | 11 | 16 | 11 | 18 | 16 | 26 | 16 | 9 | 13 | 11 | 16 | 17 | 13 | 10 | 15 | 16 | 9 | 18 | 18 | 13 | 12 | 18 | 24 | 6 | 4 | 375 | ||

| In Table 7, notations P1, P2, P3, …., P26 represent the research publications and can be mentioned as | |||||

|---|---|---|---|---|---|

| P1 | – | Mathew and Sreenarayanan (2007) | P14 | – | Singh et al. (2018) |

| P2 | – | Bandara et al. (2015a) | P15 | – | Liu et al. (2018) |

| P3 | – | Mallappa et al. (2015) | P16 | – | Barnwal et al. (2014a) |

| P4 | – | Pesek et al. (1985) | P17 | – | Meghwal and Goswami (2014) |

| P5 | – | Saxena al. (2014; 2015) | P18 | – | Shanmugasundaram et al. (2018) |

| P6 | – | Manohar and Sridhar (2001) | P19 | – | Choudhary et al. (2015) |

| P7 | – | Meghwal and Goswami (2013) | P20 | – | Balasubramanian et al. (2013) |

| P8 | – | Barnwal et al. (2015) | P21 | – | Balasubramanian et al. (2016) |

| P9 | – | Bandara et al. (2015b) | P22 | – | McKee et al. (1993) |

| P10 | – | Liu et al. (2013) | P23 | – | Barnwal et al. (2014b) |

| P11 | – | Sharma et al. (2014) | P24 | – | Singh and Goswami (2000) |

| P12 | – | Goswami and Singh (2003). | P25 | – | Murthy et al. (1996) |

| P13 | – | Barnwal et al. (2016) | P26 | – | Kuang et al. (2011) |

Moisture content was discussed most and given higher significance by most studies. The higher-grade points (45) for this attribute reflect its impact on spice grinding. It was observed that moisture substatinally influencing the grinding process, machine performance, and powder characteristics. As far as the performance of milling is concerned, various parameters like rpm, feed rate, sieve size, and grinding time were discussed in different studies. Among these attributes are feed rate, sieve size, and rpm/speed, with 39, 31, and 27-grade points. Only one researcher has shown the effect of grinding stages on product quality. These attributes strongly impact energy consumption, grinding losses, grinding capacity, and temperature of the grinding zone. Though the influence of crop variety (18) has been studied by limited researchers, the importance of this parameter is not analyzed in detail concerning flour characteristics and machine performance. However, crop variety/genotypes are the foremost consideration in volatile oil's yield, quantity, and quality.

Engineering properties with 17-grade points are considered essential for food processing methods and equipment design, which depends on moisture content. It is used to assess other properties and also used for product quality determination. Other parameters like hardness and kernel mass are concerned; none of the authors have given importance to these attributes and not considered these parameters in their studies.

4.1. Publication-wise attribute coding

The coding matrix of all publications is presented in Table 7. Two publications (P7 and P24) received grade points higher than 20, 4 publications (P9, P18, P25, and P26) received less than ten, and the rest of the publications were between 10 and 20 grade points. Publication P7 (Meghwal and Goswami, 2013) received higher grade points, i.e., 26 followed by P24 (Singh and Goswami, 2000) with 22-grade points, emphasizing improved method, feed rate, speed and sieve size. Grinding time, rotor speed, and energy requirement was high in ambient grinding and low specific surface area compared to cryogenic grinding. These parameters were directly related to moisture content, but feed rate was inversely correlated with moisture for both regular and cryogenic grinding (Meghwal and Goswami, 2013). Singh and Goswami (2000) reported that the feed rate, speed, sieve size, and grinding temperature significantly affected the volatile oil content, particle size, and specific energy consumption for clove grinding. P1 received the third rank with 19 points and the study includes the different sieve sizes, ambient and low (refrigerated sample) and ultra-low (dry ice) temperature conditions on product quality, grinding zone temperature, energy consumption, and particle size distribution. Ultra-low temperature (−3.33 to −1.25 °C) has a significant effect on the retention of volatile oil and oleoresin content with a 2–3% increase in moisture content of the powder.

Publications P5 (Saxena et al., 2014a; 2015), P19 (Choudhary et al., 2015), P20 (Balasubramanian et al., 2013), and P23 (Barnwal, P et al., 2014b) received 18 points. Saxena et al. (2014, 2015) studied the effect of grinding methods in retaining different properties regarding coriander genotype. Choudhary et al. (2015) emphasized grinding stages (single- and double-stage grinding). They reported that double-stage grinding contained more volatile oil, active compounds of oleoresin and curcumin, and fine turmeric powder than single-stage. P20 Balasubramanian et al. (2013) evaluated the effect of moisture content, screen aperture size, and feed rate at constant rotor speed on specific energy consumption and particle size distribution. Barnwal et al. (2014b) studied the effect of moisture content, turmeric grades, and improved grinding method (cryo vs. ambient) on physicomechanical characteristics of turmeric rhizome. P13 (reference) with 17 points discussed the impact of product moisture content and cryogenic grinding on thermochemical and antioxidant properties of turmeric powder. Cryogrinding retained 80–95% of chemical properties regardless of sample moisture. P3 (Mallappa et al., 2015), P6 (Manohar and Sridhar, 2001), P8 (Barnwal, P et al., 2015), P12 (Goswami and Singh, 2003.) and P17 (Meghwal and Goswami, 2014) received 16 points. P3 discussed the milling methods in combination with temperature on the quality of chili powder. Capsaicin content and nutrient retention are more in cryogrinding followed by low-temperature pulverizer and simple pulverizer. Similarly, P6 discussed the comparison of ambient and cryo grinding on the size and shape of particles. P8 emphasized sample moisture content and grinding method (hammer and pin mills) on quality parameters of coriander powder. Compared to pin mill, hammer mill yields more fine coriander. There was no significant difference in essential oil content observed in both mills with different moisture content. A significant difference in total flavonoid content and DPPH content was observed in the grinding method and total phenolic content was reduced with moisture content regardless of the grinding process.

P12 publication studied the feed rate and improved grinding method on energy consumption and bonds index. An optimized feed rate of 24 kg/h resulted in lower specific energy consumption and minimum work index with appropriate particle size distribution and size reduction ratio. The low feed temperature also had an important role in reducing the energy consumption per kilogram of material fed into the grinder. Meghwal and Goswami (2014) reported that rotor, pin, and hammer mills were suitable for grinding at a feed rate of 1.35 kg/h under ambient conditions and 1.47 kg/h under cryogenic grinding. Ball mill could be used for a feed rate of 0.0936 kg/h and 0.1248 kg/h under ambient and cryogenic grinding. Time is taken for a fixed amount of sample in order of ball mill followed by rotor mill, pin mill, and hammer mill. Similarly, for feed rate, decrease in hammer mill followed by rotor mill, pin mill, and ball mill. Rotor mill was found to be the most suitable among all grinders for fenugreek and black pepper grinding. P16 with 15 points studied the effect of cryogenic and ambient grinding on coriander, fenugreek, and black pepper. P10, P14, and P21 received 13-grade points. Studied the effect of cryogenic grinding for king chili (P14) and pepper (P10) on the other hand P21 coriander crop genotypes. P22 received 12-grade points and discussed the effect of ambient, chilled, and liquid nitrogen grinding on nutmeg properties. P2, P4, and P11 received 11-grade points. Bandara et al. (2015a) discussed the mill types, i.e., four types of pin mills and three types’ plate mills according to the capacity. Combination of operation in pin mill and plate mill, single pass without the screen and two passes, produce superior quality chili powder. Pesek et al. (1985) showed the effect of cryogrinding over ambient grinding for nutmeg, cinnamon, cumin, white pepper, and oregano. Other publications, P9, P15, P18, P25, and P26 received grade points less than 10. Among the above, P26 received only 4-grade points with simple fine grinding. In improved grinding methods, Mathew and Sreenarayanan (2007) have emphasized the dry ice treatment. Bandara et al. (2015b) discussed evaporative water-cooling treatment and Shanmugasundaram et al. (2018) examined pre-cooling using a deep freezer.

4.2. Category-wise and publication-wise attribute coding

Among 13 dependent attributes, particle size distribution is the most discussed parameter presented in Table 8. Particle size distribution obtained maximum grade points (79) followed by volatile oil content (73). Color of powder is an essential quality for consumer acceptance which received 65-grade points. Grinding zone temperature was considered necessary with grade point 64 followed by volatile compound (60). Energy requirement received 48-grade points. Some publications considered powder's antioxidant properties and thermal properties important and received 29 and 25-grade points. Some researcher includes grinding time, grinding loss but the impact is not observed in their studies. Moisture content, engineering properties, and proximate powder composition were less concerned, but 4–5 studies discussed the importance of these attributes getting grade points less than 20.

Table 8. Paper wise coding of powder characteristics.

| Attribute-based coding of powder characteristics and grinding performance indicator | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Attribute (Category A) | Attributes | Research publication | ||||||||||||||||||||||||||

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 | P11 | P12 | P13 | P14 | P15 | P16 | P17 | P18 | P19 | P20 | P21 | P22 | P23 | P24 | P25 | P26 | ∑D | ||

| D1 | particle size distribution | 5 | 0 | 0 | 0 | 0 | 5 | 5 | 4 | 5 | 1 | 1 | 4 | 0 | 5 | 0 | 5 | 5 | 5 | 5 | 5 | 0 | 5 | 0 | 5 | 4 | 5 | 79 |

| D2 | color | 0 | 4 | 5 | 0 | 0 | 0 | 0 | 5 | 5 | 5 | 0 | 0 | 5 | 5 | 0 | 5 | 5 | 5 | 5 | 0 | 0 | 5 | 5 | 1 | 0 | 0 | 65 |

| D3 | Volatile oil content | 5 | 4 | 2 | 5 | 5 | 0 | 2 | 4 | 0 | 5 | 5 | 0 | 5 | 0 | 5 | 0 | 2 | 5 | 5 | 0 | 0 | 4 | 0 | 5 | 5 | 0 | 73 |

| D4 | volatile compounds | 5 | 4 | 4 | 5 | 5 | 0 | 0 | 1 | 0 | 5 | 5 | 0 | 5 | 0 | 5 | 0 | 0 | 2 | 4 | 0 | 0 | 4 | 0 | 1 | 5 | 0 | 60 |

| D5 | Moisture content | 3 | 3 | 3 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 19 | |

| D6 | Engineering properties | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 3 | 3 | 0 | 5 | 0 | 0 | 0 | 20 |

| D7 | antioxidant properties | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 5 | 0 | 0 | 5 | 0 | 5 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 29 |

| D8 | proximate composition | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 4 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 18 |

| D9 | Thermal properties | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 5 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 5 | 0 | 0 | 0 | 25 |

| D10 | Energy requirement | 3 | 0 | 2 | 0 | 0 | 0 | 5 | 1 | 4 | 0 | 0 | 5 | 0 | 0 | 0 | 4 | 5 | 5 | 0 | 5 | 0 | 0 | 0 | 5 | 4 | 0 | 48 |

| D11 | Grinding time | 2 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 3 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 5 | 17 |

| D12 | Grinding loss | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 8 |

| D13 | Grinding zone Temperature | 5 | 4 | 2 | 4 | 0 | 0 | 2 | 2 | 3 | 2 | 2 | 5 | 1 | 2 | 2 | 3 | 5 | 5 | 4 | 3 | 0 | 0 | 2 | 5 | 1 | 0 | 64 |

| ∑Pd | 28 | 19 | 24 | 14 | 15 | 5 | 21 | 27 | 24 | 18 | 18 | 14 | 26 | 21 | 30 | 17 | 26 | 30 | 23 | 23 | 8 | 26 | 17 | 22 | 19 | 10 | 591 | |

P15 (Liu et al., 2018) and P18 received the same grade points i.e., 30, which emphasizes particle size distribution, color, oil content, volatile compound, volume and surface area, thermal properties, proximate composition, and antioxidant activities. Liu et al. (2018) reported that essential oil, piperine, unsaturated fatty acids, and monoterpenes content were reduced. In contrast, insignificant changes were found in starch, lipid, amino acid, protein, and thermal properties after six months of storage at 4 °C despite the grinding technique. P1 (Mathew and Sreenarayanan, 2007) received 28-grade points and discussed specific energy, grinding time, and zone temperature. P8 (Barnwal et al., 2015) received 27-grade points and examined the particle size distribution, color, volume and surface area, thermal properties, and antioxidant activities. Particle size, surface, and volume mean diameter increased significantly with moisture content (6.4–13.6% Dry basis). Color and antioxidant values varied with the grinding method. Thermal conductivity linearly varied with temperature and moisture. Coriander powder ground using hammer mill had lower specific heat and higher thermal conductivity than that of pin mill.

P13, P17, and P22 received the same grade points, i.e., 26. Barnwal et al. (2016) discussed the chemical, thermal and antioxidant properties of turmeric powder. Meghwal and Goswami (2014), discussed the grinding method in ambient and cryogenic conditions on different properties of fenugreek and pepper. The specific surface area was observed high in rotor mill followed by hammer mill, pin mill, and ball mill. Power consumption is high in pin mill followed by hammer mill, rotor mill, and ball mill. Temperature rise in ambient and cryogrinding is high in pin followed by hammer, rotor, and ball mill. On the other hand, McKee et al. (1993) emphasized volatile oil, percentage of oleoresin, particle size distribution, moisture content, and antioxidant capacity of nutmeg ground under ambient, chilled, and liquid nitrogen. The temperature had no significant effect on particle size, uniformity, and moisture content. Volatile oil and oleoresin were significantly different from ambient to chilled and nitrogen but not significant from chilled to nitrogen. Overall, color and oleoresin across batch-wise were more consistent and better results were obtained in the nitrogen grinding method.

P3 and P9 received 24-grade points. P3 discussed the cryogenic effect on color, proximate composition, and capsaicin content of byadagi chilli. In a cryogenic pulverizer, the retention of nutrients, color, and capsaicin content was more than a low-temperature pulverizer and simple pulverizer. P9 emphasized the effect of a different combination of machines on particle size, energy, color, moisture, fat, and fiber content of ground chili. A combination of pin mill (one pass without screen) and plate mill (two passes) gives the best color chill powder with lower particle and energy consumption and higher fat content and fiber. P19 and P20 received 23-grade points. Double-stage grinding gives better color, temperature reduction, volatile oil, oleoresin, and curcumin compounds than single-stage grinding. Further, volume and surface mean diameter was higher in single-stage grinding and increased with increased moisture content for both grinding (Choudhary et al., 2015). Balasubramanian et al. (2013) discussed particle size distribution with bond’s index and kick’s constant. Particle size, bonds work index, and kicks constant increase with moisture content and sieve size opening and varied from 0.21 mm to 0.29 mm, 0.086–0.312 kWh/kg, and 0.68 to 20.33 kWh/kg, respectively. Conversely, size reduction ratio (25.42–14.57) and grinding effectiveness (0.077–0.008) decrease with moisture content. P24 (Singh and Goswami, 2000) received 22-grade points and discussed clove grinding at a temperature below −50 °C shows no clogging of sieve, more volatile oil, and lower specific energy consumption. P7 and P14 received 21-grade points. Goswami and Singh (2003) reported that grinding time and power consumption increased as the moisture content increased from 10% to 20% for both grinding (cryogenic and ambient grinding). Singh et al. (2018) discussed bulk powder properties such as flowability bulk density and tapped density, Hausner ratio, particle size distribution, compressibility index, color, microstructural and mineral content. Publication P2, P4, P5, P10, P11, P12, P16, P23, P25, and P26 received between 10 and 20 grade points. Evaporative water-cooling grinding of chill significantly reduces temperature, retained capsicum, oleoresin, and color of grounded chili (Bandara et al., 2015a, Bandara et al., 2015b). Pesek et al. (1985) reported that cryo grinding has high volatile oil content and volatile compound in nutmeg, cinnamon, cumin, white pepper, and oregano compared to ambient grinding. Saxena et al. (2014) discussed the volatile oil, antioxidant properties, and flavor for different diverse coriander genotypes. Liu et al. (2013) showed that the concentration and percentage of aroma compounds are retained in cryogenic grounded pepper compared to ambient hammer grinding, which induces browning and oxidative decomposition due to high temperature. Two genotypes of cumin ground in ambient and cryogenic and compare the volatile oil, oleoresin, total phenolic, flavonoid content, and antioxidant properties. Results showed that these characteristics were higher in cryo-grounded powder for both genotypes. The finer powder was observed in the case of cryogenic grinding compared to that in ambient grinding (Sharma et al., 2014). Goswami and Singh (2003), discussed the effect of cryogrinding of cumin on grinding temperature, specific energy consumption, particle size, and bond work index. Barnwal et al. (2014b) reported that the thermal conductivity of the cryo-ground samples was higher than that of the ambient ground samples. Kuang et al. (2011) discussed the effect of ultra-fine grinding of cinnamon and clove in a ball mill on powder particle size and antibacterial properties of the powder and results depicted that ultra-fine grinding powder had strong antimicrobial activity activities.