1. Introduction

Despite rapid advancements in the biotechnology field, metabolic engineering for commercial small-molecule production still constitutes a challenging optimization problem. A major component of the task is identification of a genotype that confers improved strain performance (i.e. titers, productivities, and yields). However, phenotype is also heavily influenced by environment. Thus, every fermentative manufacturing process is wrought from the simultaneous development of strain and culture conditions. This poses an intractable problem for engineers: if the physiology of every strain is dependent on culture conditions, how can a screening scheme be designed that most efficiently converges on a strain and process that meet specifications? A successful strategy must address two issues: (1) effectively sampling a massive space of genetic and process variables while maintaining high measurement quality and (2) achieving a controlled small-scale fermentation model that can identify strains with key physiological advantages.

To illustrate the first point, consider a hypothetical strain engineering problem: balancing flux through a biosynthetic pathway consisting of n sequential enzymatic steps (Fig. 1A). Without knowing any other information, an engineer could quickly learn a great deal about engineering this pathway by combinatorially adjusting the expression strengths of all the enzymes and quantifying the final product. The size of a library including all possible constructs grows exponentially with the length of the pathway, or with the inclusion of relevant off-pathway genes: the library size is pn, where p is the number of promoters available and n is the number of genes included. As the throughput of a screening platform increases, so does the complexity of the system one can feasibly explore in a single experiment (Fig. 1C). Since a cycle of strain construction and evaluation can be time-intensive (e.g., 3–6 weeks for Saccharomyces cerevisiae), the time savings accrued by increasing throughput can amount to a reduction of many months on the timeline to reach a consumer market. Moreover, such combinatorial exploration can avoid the problem of optimizing strains into local performance maxima without identifying a strong set of high-potential strains.

Fig. 1

Fig. 1An analogous point can be made with respect to protein engineering. As pioneers of directed evolution have pointed out, it can be difficult or impossible to predict influential amino acids to mutate for improvement of enzymatic activity, and improvements resulting from mutations to different residues often combine in a non-additive manner (Arnold, 2018). It would therefore be advantageous to routinely explore libraries of single point-mutants, as well as double- or even triple-mutants (Fig. 1B). However, the sizes of such libraries quickly explode with increased numbers of target residues: for a protein with n variable positions, a complete single-, double-, or triple-mutant library contains 19n, 361n (n-1)/2, or 6859n (n-1) (n-2)/6 variants, respectively. This places such strategies out of reach if millions of variants cannot be rapidly screened (Fig. 1D). These principles have been concretely demonstrated at Amyris during the construction of strains for production of rebaudioside M. During this campaign, the adoption of high-throughput mass spectrometry (HTP MS) led to marked acceleration in progress after months of initial screening with lower-throughput chromatographic analytical methods (Fig. 1E) (Wichmann et al., 2019; Zhao et al., 2019).

Achieving such exponential increases in throughput requires miniaturization and experiment parallelization, prompting efforts to develop multiple fermentation models that span a range of volumes and conditions (Table 1). Optimized manufacturing processes often incorporate feedback regulation of culture conditions, dependent on monitoring and adapting to real-time performance of the strain during the run. Table 1 summarizes some of the logistical challenges in modeling such a process when many miniature fermentations are executed in parallel. It is challenging for any high-throughput (HTP) culture model to exactly replicate the chemical environment of an individually monitored large-scale fermentation. Even if this were possible, manufacturing processes are tailored around the physiology of one strain; for this reason, the scale-down of a specific manufacturing process might not be the best approach to strain screening. Instead, a useful model system needs flexibility to accommodate strains with different physiologies. Culture conditions for screening must be selected that allow the engineer to identify strains bearing a physiological advantage in the aspects that limit performance during a scaled fermentation process, often without yet knowing exactly which conditions will be used for manufacturing. Screening conditions that can challenge these physiological limitations permit identification of high-performing strains at small scales with improved probability to translate into high performers at commercial manufacturing scale.

Table 1. Overview of model systems for screening production strains.

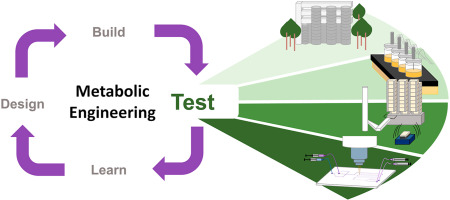

This review presents an overview of screening techniques and strategies that have supported progress in metabolic engineering, focusing primarily on aerobic fermentation. Because performance at manufacturing scale is paramount, the next section introduces some key elements of a commercial fermentation process as context for design choices in scaled-down culture models. Many of these elements can be closely recapitulated by bioreactors with volumes in the range 0.25–30 L, which serve as the final gate for strain selection. The subsequent section discusses best practices and considerations for the design of miniaturized culture models (i.e. those smaller than 1 mL) and their application in HTP workflows. Emphasis is placed on efforts to improve the predictive power of the screen through the control of culture conditions, as well as innovations that have improved the generalizability, specificity, speed, and quality of sample analysis. The penultimate section then highlights some of the recent successes and promising advances in microfluidic culture and screening. Once this field has reached maturity, a research group of any size should be able to generate strains with outstanding potential for development into manufacturing strains using much less infrastructure than currently required. The review concludes with several remarks on the successful coordination of these technologies in the experience of the authors and a brief perspective on the future promise of the field.

2. Fermentation processes and strain physiology at manufacturing scale guide design of lab-scale models

Thanks to integrated instrumentation, bioreactors can provide fine monitoring and control of culture conditions, ensuring the optimal performance of a strain. Many process variables are read in real time using signals from in-situ probes, off-gas analysis, and other measurements, providing feedback to a control system that can modulate inputs so that the strain environment is tightly regulated (Table 2). In this review, a fermentation vessel or process controlled in this style at the volume range 0.25–30 L is referred to using the descriptor “lab-scale.” Other sources also use the terms “bench-scale” or “scale-down.”

Table 2. Measurements and control measures used in lab-scale bioreactors.

This section outlines the complexity of common fermentative production processes, the key variables influencing strain physiology, and the metrics used to assess performance correlation between scales. It is intended to give context for the remaining sections, which discuss how HTP screening platforms have addressed parallel challenges.

2.1. Common manufacturing process strategies

Although a range of fermentation strategies are used at manufacturing scale, some common approaches are widely used across the industry. Typical variable process elements include feeding schemes, separation of growth and production phases, and the use of extractive fermentation.

Feed control has a major impact on overall fermentation performance. A well-controlled feeding strategy directs carbon flux towards desired product and biomass while minimizing by-product formation. The two general modes of fermentation most applied in manufacturing are (1) batch mode, the simultaneous introduction of all non-gaseous components at the start of the fermentation, and (2) fed-batch mode, the controlled introduction of media components over time. Although batch mode is usually preferred for production due to its simplicity, many operational variations of fed-batch mode have also been used in industry to produce biomolecules (Yamanè and Shimizu, 1984). The advantages of fed-batch fermentation were historically demonstrated in an experiment wherein a culture intermittently fed with glucose reached a titer more than four-fold higher than that attained in a simple batch fermentation (Soltero and Johnson, 1953). The fed-batch mode allows maintenance of residual nutrients in the broth at moderate levels, thereby avoiding issues caused by high substrate concentrations; these include high viscosity, substrate inhibition of growth, osmotic stress, overflow metabolism, and catabolite repression (Yamanè and Shimizu, 1984). Other benefits include access to high cell density and extended operating times (Yamanè and Shimizu, 1984). In contrast, batch fermentation for many organisms includes a period in which sugar consumption exceeds the rate of respiration, which can cause accumulation of undesired products from overflow metabolism (Xu et al., 1999). This is the case for S. cerevisiae, which can switch between oxidative and fermentative metabolism under aerobic conditions in the presence of excess sugar (Frick and Wittmann, 2005).

Another common strategy to increase productivity at manufacturing scale is to decouple growth from molecule production (Burg et al., 2016). This approach comprises two phases: (1) a growth phase marked by rapid biomass accumulation and minimal product formation, and (2) a production phase, where a different metabolic state is targeted, prioritizing production of the target molecule. When a predefined target metric has been reached (e.g., biomass density, oxygen uptake rate (OUR), or quantity of substrate fed), a control mechanism, or “switch”, is applied to transition the culture from growth to production phase. The control mechanism itself can be a nutritional limitation, a chemical addition or depletion, or a process change in the bioreactor to induce a metabolic shift towards product formation. For example, a temperature switch was applied for L-lactate production in E. coli by selecting an L-lactate dehydrogenase with optimal activity at 42 °C, well above the ideal growth temperature for the host (Niu et al., 2014). In another case, a neutral pH was used for optimal growth, followed by acidification in the production phase to favor enzyme activity for generation of 2-ketogluconic acid (Y. Sun et al., 2014). Other processes have exploited an inducer compound, for example, a shift from glycerol (for biomass) to methanol (for product) to produce malarial vaccine candidates in Pichia pastoris (Kastilan et al., 2017). In a final example, Amyris used pantothenate as a switch for increased strain stability in farnesene production (Sandoval et al., 2014). Excluding pantothenate from the growth-phase media slowed production of farnesene during this time, eliminating a growth advantage for undesired mutants with poor productivity. For control mechanisms with significant impact on central metabolism, the process must be transferrable to a lab-scale model to maintain correlation.

An emerging approach to boost productivity of many hydrophobic molecules is the in-situ use of an inert extractive organic phase. This second phase, which sequesters the product from the aqueous fermentation broth, can be especially impactful for production of molecules that are toxic to the host (S. Kumar and Babu, 2008). By mitigating toxic effects, the cell physiology can be maintained longer in a productive state and increase the efficiency of manufacturing. This strategy has also been used to reduce evaporative product loss, as demonstrated in E. coli fermentations using dodecane to capture amorpha-4,11-diene (Newman et al., 2006).

2.2. Key variables used to drive scaled-down model development

When designing lab-scale models of commercial bioreactors, it is instructive to consider the process design, target values for environmental variables, and the controls available to meet these targets. While commercial and lab-scale bioreactors may be designed to be geometrically similar, some process characteristics are difficult to replicate across scales. As discussed by Junker (2004), increases in fermentation scale result in:

-

•

increases in the number of cell divisions of the host, which increases the chance of random mutations that impact production;

-

•

decreases in surface area-to-volume ratio, leading to reduced heat transfer capacity;

-

•

increased hydrostatic pressure at the bottom of the vessel, and thus heightened dissolved CO2 concentration;

-

•

less efficient bulk mixing, causing gradients in the concentrations of dissolved O2 and nutrients.

Although not perfect models, lab-scale bioreactors can be operated under conditions that prioritize variables with a significant impact in the commercial fermentation environment (Hill et al., in press). Matching the physiological state of the host between scales can improve the likelihood of success in scaling up and reduce the risk of unexpected performance. A few key process variables are crucial to maintaining predictive power. The most important of these include oxygen transfer rate (OTR), pH, and media composition.

The oxygen available in the micro-environment of an organism during a fermentation process can have a dramatic influence on its physiology. Because oxygen has low aqueous solubility, OTR is a key control parameter for aerobic fermentation processes (Islam et al., 2008). In a bioreactor, OTR characterizes the transfer of gaseous oxygen into the liquid phase. It is directly proportional to the oxygen concentration gradient between these phases, with a proportionality constant between the two terms known as the volumetric mass transfer coefficient (kLa). Both OTR and kLa are dependent on the specific bioreactor configuration and set of operating conditions. The kLa is affected by multiple variables including vessel shape, impeller design, agitation rate, aeration rate, and broth matrix. Additionally, gassing composition and headspace pressure contribute to differences in OTR. Hardware controlling these variables differs in bioreactors at the manufacturing and lab scales and must be empirically tested to maintain roughly equivalent OTR across vessel sizes.

Another critical parameter to consider when developing lab-scale processes is pH. In bioreactors, pH can be maintained at a set value via a control loop. Without pH control, microbial cultures may acidify due to carbon dioxide or organic acid accumulation, or uptake of ammonium ions (Roos and Luckner, 1984); basification may also occur when organic acids serve as a carbon source (Wolfe, 2005). Change in pH can strongly affect microbial physiology, triggering secondary metabolite pathways or inhibiting growth. For example, the oleaginous yeast Rhodotorula glutinis has an optimum growth pH of 5.5 and acidic deviation from this setpoint triggers lipid accumulation; acidic pH is also reported to cause changes in lipid profile and ergosterol content (Johnson et al., 1992).

While it is ideal that all media components are identical across scales, this is not always the most practical choice. At manufacturing scale, material supply and cost are the major drivers in the selection of media components, motivating use of less-pure components and complex, inexpensive materials like molasses (Hahn-Hägerdal et al., 2005). However, at lab scale it may be advantageous to choose more well-defined media components to minimize lot-to-lot variation and ensure greater process consistency for improved comparison across the genotypic space being screened.

2.3. Metrics to assess fermentation performance

Although lab-scale bioreactors may not be able to perfectly replicate commercial-scale conditions, they are able to evaluate strains on the same key metrics: yield, volumetric productivity, titer, oxygen efficiency, and product profile. Time-course data provide other important metrics such as maximum growth rate and stability of strain performance throughout the fermentation. These metrics, together with reasonable estimates of downstream recovery yield, allow predictions of final cost of production. Such cost models can guide strain promotion decisions as well as prioritization of research and development efforts for the most efficient use of resources (Benjamin et al., 2016). In lab-scale bioreactors, non-product-based metrics can also be used for evaluating performance by taking specialized measurements (e.g., proteomics and metabolomics) to better understand the strain response to process conditions and identify metabolic bottlenecks (Wehrs et al., 2019).

2.4. Miniaturization and motivation for smaller volume screening

Lab-scale bioreactors are the final gate of laboratory strain testing because they provide fine control and precise measurements of process variables, leading to results that usually correspond quite well with manufacturing scale. However, a modern metabolic engineering group often screens millions of strains or more per year; screening even 1% of this throughput level in bioreactors would demand enormous fermentation infrastructure with a prohibitive capital outlay. There have been many technological advances to miniaturize and automate bioreactors at a middle ground between lab-scale fermenters and microplate culture models. Notable examples include the commercial BioLector (Funke et al., 2010) and 15-mL ambr (Sandner et al., 2019) platforms, which have become valuable tools in synthetic biology. These systems enable several key real-time process measurements (pH, pO2) and process controls (e.g., fed-batch mode capability) to bridge the major differences between microplates and lab-scale bioreactors. While these systems can provide higher throughput than traditional lab-scale models, they do not provide the orders-of-magnitude increase needed for analysis of large genetic diversity screens (Fig. 1).

3. High-precision screening at the milliliter scale

As discussed in the previous section, manufacturing process conditions can rarely be exactly reproduced at lab scale; it is typically even more difficult to control environmental conditions when cultures are further miniaturized, for example, in microplates (0.1–1.0 mL). To manage this challenge, the same guiding principles that are used when designing bench-scale models of manufacturing bioreactors should also be applied when creating microplate culture models – strain improvements are most likely to translate from microplate performance to manufacturing performance when the key physiological limitations determining their manufacturing performance are challenged during the screen. However, an additional consideration is introduced when many experiments are run in parallel: detecting small improvements in performance requires highly reproducible processes.

This section addresses HTP screening at the milliliter scale in two parts: (1) microplate cell culture with target molecule production and (2) sample preparation and assays. This review defines an HTP screening process as one that can sustain at least ∼104-105 cultures and analyses per week. For effective screening in this paradigm, precision must be prioritized in both the maintenance of culture conditions and the sample analysis. Although it is not essential that absolute titers and volumetric productivities align exactly with larger-scale fermentations, strain performance will ideally rank the same in the HTP screen as in a bioreactor. Assuming that this ranking is not affected, accuracy of analytical measurements can be de-emphasized in HTP screening in favor of precision, which is more important for identification of improved strains with high statistical confidence.

Both the throughput and reproducibility of a screening operation at this scale can depend critically on the automation infrastructure of the laboratory, so a short section is first devoted to some of the standard automation equipment that enables strain improvement in industrial environments.

3.1. Automation

HTP culture and sample preparation in microplates can be extremely labor-intensive and represent a serious bottleneck for strain improvement. In order to meet the physical and data quality needs of HTP screening, it is essential to automate some of the key steps of routine processes. Tasks like media plate preparation, sub-culturing, cryopreservation, and sample dilution can be greatly facilitated by automated liquid transfer. Many commercial vendors offer liquid handling solutions for volumes in the μL-mL range (Lorenz, 2004). Advancements have mainly been incremental in the last two decades (Kong et al., 2012). In any sample preparation involving a series of steps, the variability in a measurement is usually driven by the least precise transfer; notably, many commercially available bulk reagent dispensers cannot attain precisions of <5% coefficient of variation (CV) for volumes below 10 μL or with solvents other than water, and so it is sometimes necessary to perform some reagent additions using multichannel pipetting modules. One significant advancement in liquid transfer has been the Labcyte Echo acoustic liquid handler, which allows volume reduction in molecular biology steps required for strain engineering by up to 100-fold (Shapland et al., 2015). If volatile organic solvents are frequently used in sample extractions, chemically resistant positive-displacement liquid handlers may be considered. These instruments avoid error introduced by vapor pressure in the headspace of a standard pipetting head. More sophisticated instruments, such as the pressure-sensing liquid handlers available from Hamilton, can improve precision by detecting inaccurate dispense volumes and automatically performing error correction before proceeding. However, liquid volatility and viscosity may still impact the ability of the instrument to accurately employ the pressure sensing mechanism.

A range of options exists for automating complex workflows. For straightforward operations like serial dilution or full-plate stamping, Opentrons offers a simple robot with a small footprint and open-source scripting (May, 2019). These instruments require minimal capital expenditure and little automation experience. The Beckman Biomek systems are a biotech industry standard that can handle larger sample volumes, incorporating plate positioning and integration with some peripherals like plate hotels, shakers, and barcode scanners. For groups wishing to pursue routine screens consisting of 40 or more plates per day, it is highly recommended to invest in a custom-built integrated system that suits the specific needs of the lab (Banks et al., 1997). Modular systems can integrate multiple stackers, plate shakers, centrifuges, plate readers, bulk dispensers, multichannel pipettors, plate peelers, plate sealers, and other equipment for virtually any unit operation (Ma et al., 2008), as long as the rate-limiting step in the process does not preclude the desired throughput. The benefits of this investment include minimizing human intervention, reducing the risk of repetitive stress injuries, elevating the precision of most processes, and facilitating process troubleshooting. Because of the large cost required to build, maintain, and operate such infrastructure, many research institutions have recently coordinated efforts to establish an international Global Biofoundry Alliance (Hillson et al., 2019). This consortium is designed to support collaborative public and private endeavors that benefit from pooling resources toward automating HTP strain construction (Si et al., 2017a) as well as the culture and analysis components described here.

The microplate is the workhorse of the HTP lab and is broadly compatible with HTP robotics because of widely adopted ANSI/SLAS standards (Astle, 1997). However, culture and assay plates must be selected with the downstream sample preparation steps and analysis in mind; some plastics, like polystyrene, are susceptible to damage by certain solvents, and others, like polypropylene, introduce significant optical background in UV spectrophotometric assays (Thermo Fisher Scientific, Inc. 2016). For processes requiring minimal surface-binding or solvent resistance, inert glass-coated polypropylene 96-well plates can provide a sustainable solution that is compatible with standard robotics (Thermo Fisher Scientific, Inc. 2016).

A significant gap in commercial automation is the integration of high-speed, high-capacity shaking incubators with liquid handling instrumentation. The few integrated culture/assay systems designed for microplates (such as those available from Hamilton and BioTek) are designed for processes requiring lower throughput, lower oxygen demand, or less complex sample preparation. Note that this gap is addressed at the ultrahigh-throughput (UHTP) sub-microliter scale (>106 samples per week), in which step-change improvements in automation are occurring; examples are discussed in Section 4.

3.2. Microplate culture models

An ideal screening culture model gives a strong correlation to manufacturing scale across diverse strain genotypes and reliably predicts strain ranking at lab scale; to achieve this, it is important to add as much control to the microplate format as possible. In this review, the phrase “microplate culture model” or simply “plate model” is used to refer to the set of culture conditions used during an HTP screen. Key process variables discussed in Section 2 that influence strain performance are summarized in Table 3, along with a comparison of how these variables are controlled in lab-scale bioreactors and in plate models. The number of parallel cultures required in an HTP screen precludes the measurement-driven feedback for each well that can be achieved in larger bioreactors. Instead, self-regulating or blanket environmental conditions are typically employed that allow identification of strains with statistically improved performance.

Table 3. Control measures used in lab-scale bioreactors and plate models.

3.2.1. Media composition

To maintain long-term precision in HTP processes, screening groups often select highly defined culture media with minimal lot-to-lot variability. Some basal media have consisted of defined mixtures of amino acids along with essential enzyme cofactors and trace metals (Postma et al., 1989); other media simply leave the strain to produce its own amino acids from a nitrogen source such as ammonium or urea (Ponomarova et al., 2017). If amino acid biosynthesis is heavily challenged in a manufacturing process due to minimal media or high nitrogen flux to product, it is advisable to consider these factors during screening media selection. It is also wise to consider the scalability of media components while designing a plate model. If strains are iteratively engineered in media containing a reagent that is expensive, environmentally unfriendly, or otherwise not scalable, the performance of the resulting strain could depend critically on a process that cannot be commercialized.

Maintenance of pH is critical to ensure consistency in the chemical environment of cultures; large drifts in pH can affect the performance of engineered strains as well as the stability and solubility of products. In contrast to lab-scale bioreactors, it is not feasible to control pH in individual wells by way of an acidic or basic feed, as the measurement of pH in each well and reagent additions necessary for pH adjustment pose major challenges. Many plate models therefore take advantage of buffering media components, such as succinate (Westfall et al., 2012), 2-(N-morpholino)ethanesulfonic acid (MES) (Nandy et al., 2015), and (3-(N-morpholino)propanesulfonic acid) (MOPS) (Neidhardt et al., 1974). A caveat with the use of succinate is that it may itself serve as a carbon source for some microbes, which can impact the physiology of the strain and deplete the buffer over time. Buffers can be added in relatively high molar concentrations, on the same order of magnitude as the carbon source, to reduce the risk of acid or base generation in excess of the buffering capacity. Alternatively, slow-release polymer discs containing alkaline compounds have also been used to control pH in some shake-flask fermentations, allowing a significant reduction in the buffer required (Scheidle et al., 2011). A similar strategy could theoretically be applied in a plate model.

3.2.2. Subculturing for multistage process simulation and biomass normalization

“Switch”-controlled fermentation processes used in manufacturing and in lab-scale models can significantly impact the strain metabolic state, potentially interacting with designed or random genetic modifications in engineered strains. However, this process typically involves media exchange, which is not easily accomplished in plate models. To induce physiological shifts that recapitulate the transition made during switch activation at manufacturing scale, strains in plate models can be subcultured, diluting into secondary media that triggers the switch (Chua et al., 2016).

Subculturing also provides an opportunity to standardize the inoculum for each well of the microplates. Although automation can enable picking of up to 20,000 colonies per day (Anzai et al., 2017), even the most advanced robotics will inoculate a variable number of viable cells, which can negatively impact precision among biological replicates. To address this, relatively uniform cell densities can be achieved in parallel “precultures” using common practices for protein overexpression: cells are grown in batch culture to stationary phase, which then allows precise inoculation of production culture from an aliquot of the preculture (Berrow et al., 2006). More sophisticated fed-batch precultures have been shown to give even more uniform performance by eliminating stationary-phase incubation and the associated growth lag following subculture (Keil et al., 2019b).

3.2.3. Feeding strategies

Because of its operational simplicity, batch mode is the most used feeding scheme for plate models. As discussed in Section 2.1, carbon sources, nutrients, and buffers available in the culture are added to the growth medium before inoculation (Jones and Kompala, 1999). A consequence of running cultures in batch mode is the risk of activating overflow metabolism, which occurs for many microbes when high concentrations of feedstock are readily available (Xu et al., 1999; Keil et al., 2019a). Batch cultures may also lead to oxygen limitation (Vasala et al., 2006; see also Section 3.2.4) or substrate inhibition (Minihane and Brown, 1986) that are not observed in lab- or manufacturing-scale fermentation process. These phenomena can cause strain behavior in fed-batch or lab-scale models to sometimes be poorly modeled by plate models that are run in batch mode.

Some limitations of batch feeding can be circumvented with “pseudo-fed-batch” systems that use controlled-release technologies (Schultz and Gerhardt, 1969; Lübbe et al., 1985). In these strategies, all media components are still added at the outset, but a limiting nutrient is released over time from within the culture. This allows for fed-batch-like conditions in standard microplates incubated in common shakers.

There are two main approaches used in pseudo-fed-batch plate models: diffusion and enzymatic-release systems. The former embeds a nutrient inside a polymer matrix with the polymer either suspended within the culture or affixed to the bottom of the vessel (Jeude et al., 2006; Huber et al., 2009). The nutrient then diffuses into the bulk medium over the course of the culture. Commercial versions of such diffusion feeding systems are available from Kuhner AG (Switzerland). The enzymatic approach uses an inaccessible form of a substrate, usually a sugar polymer, which is converted into a consumable form by a supplemented enzyme (Panula-Perälä et al., 2008; Krause et al., 2010). A glucose-releasing product is available from Enpresso GmbH (Germany) and a similar system can be achieved with maltodextrin and amyloglucosidase (Nagy et al., 1992). Both pseudo-batch-fed methods can have their release rates tuned to some extent by modifying substrate and enzyme loading, respectively.

3.2.4. Oxygenation control

As previously emphasized in Section 2.2, oxygen availability is one of the most important considerations in aerobic culture. It has been shown that when lab- and pilot-scale E. coli fermentations are adjusted such that their measured kLa values match those observed in plate models, near-equivalent biomass and protein production can be achieved (Islam et al., 2008). Unfortunately, kLa for an optimal manufacturing process is often too high to be achievable in microplates (Doig et al., 2005). Despite this limitation, a plate model can still attempt to match the physiology of the strain to that in a lab-scale process by targeting the same cell-specific OUR, sometimes called qO2, with units of mmol O2 consumed per gram of dry cell weight per hour. Because the cell density reached in microplates can sometimes be up to 10-fold lower than in larger bioreactors, equivalent qO2 may be attainable even with a smaller maximum kLa. Nevertheless, it is usually desirable to maximize OTRs in microplates to avoid oxygen limitation of flux through overexpressed pathways unless it is expected that this limitation occurs at manufacturing scale.

Incubator design is a key factor in attaining a desired OTR and in maintaining consistent OTRs across plates. Incubator chambers should promote circulation of gases to distribute oxygen evenly and will ideally allow feedback regulation of CO2 and O2 content. Monitoring dissolved O2 within plate media can also be helpful in determining whether proper oxygenation is achieved in a plate model (A. Kumar 2004). Several sensors have been published based on oxygen-sensitive phosphorescent or fluorescent materials (O'Riordan et al., 2000; Stitt et al., 2002; John et al., 2003; Deshpande and Heinzle, 2004). Changes in dissolved oxygen can then be tracked to obtain estimates of OTR and OUR.

Increasing air-liquid interfacial area within a microplate well is the most practical and effective way to increase kLa, and therefore OTR (Duetz et al., 2000). This can be achieved by shaking at high frequencies (i.e. ∼1000 rpm) and with large throw (diameter of the circle described by the motion of the shaker), which cause the liquid to spread vertically up the well wall (Hermann et al., 2003; Islam et al., 2007). In practice, most microplates are shaken with a smaller throw because it allows higher shaking frequency without culture broth spilling out of the plate or wetting the plate seal; the liquid spreads more radially on the well wall with a smaller throw (Kensy et al., 2005). Air-permeable seals or covers can be used to avoid spillage and cross-contamination but do affect oxygen availability to some extent. Despite this, it has been demonstrated that most commercially available seals are not rate limiting in oxygen transfer to cultures (Sieben et al., 2016).

Microplate well geometry can also significantly affect oxygen transfer, especially at lower shaking speeds (Hermann et al., 2003; Funke et al., 2009). Angular well edges can act as baffles, increasing turbulence and leading to higher air-liquid interfacial area (Lattermann et al., 2014). However, this effect is less pronounced relative to round wells at very high shaking speeds. For plates with round wells, lowering the surface tension also increases liquid spreading, leading to higher OTR (Hermann et al., 2003). It has also been shown that surface tension can be decreased with more hydrophilic plate material (Doig et al., 2005), which circumvents the need to adjust the composition of the culture. The authors are unaware of commercially available well geometries in an ANSI/SBS plate format besides round and square wells.

A final factor influencing OTR is the fill volume of the well; lower liquid volumes lead to higher OTRs because the air-liquid interface (and therefore mass of oxygen transferred over time) stays roughly constant as the volume is changed, but OTR is a volume-normalized metric (Hermann et al., 2003). It is important to note that, for most conditions, the evaporation rate also increases along with higher air-liquid interfacial area (Doig et al., 2005); the starting culture volume should therefore be selected with this eventual liquid loss in mind.

3.2.5. Temperature and humidity control

Because of the exothermic nature of aerobic fermentation processes and the low surface area-to-volume ratio of lab-scale bioreactors, temperature must often be feedback-regulated with a surrounding water jacket or immersed heat-transfer element (Table 2). Fortunately, plate models can achieve more efficient heat transfer in the absence of these control elements, especially when vigorous shaking is used (Schäpper et al., 2009). It is therefore feasible to globally control temperature and reduce evaporation in minibioreactors or microplates within large shaker-incubators such as Infors AG (Switzerland) laboratory shakers or humidity-regulated rooms (Sieben et al., 2016). These approaches can allow much higher throughput than smaller benchtop heater-shakers.

Vigorous shaking to increase OTR can result in high rates of evaporation, even when incubators are humidity controlled. Significant evaporation can increase concentrations of broth and cause osmotic stress (Silk et al., 2010), and generally introduces an uncontrolled variable into the culture model. In one study, spongy silicone mats with 1.5-mm venting holes over each well were able to reduce evaporation to less than 10 μL per well per day at all volumes tested (Duetz et al., 2000). There are also numerous commercially available breathable seals for microplates, the permeabilities of which have been compared under conditions relevant to fermentative culture (Sieben et al., 2016). Ultimately, the results revealed an unresolved tradeoff between oxygen availability and evaporation rate (Sieben et al., 2016). As a next-best approach to eliminating evaporative loss, Amyris has investigated the impacts of culture conditions and liquid volumes on evaporation in these systems over time, yielding useful correction factors when time-course comparisons are required (Schmidt, unpublished results).

3.2.6. Product capture

Subcellular localization of products and intermediates is often the subject of engineering efforts, as intracellular accumulation can be detrimental to production and create challenges for product recovery at scale. Localization can be driven by factors including (1) the localization of pathway enzymes, (2) the chemical properties and size of the product or intermediate, and (3) mechanisms of membrane transport. In designing a high-throughput screen for strain improvement, it is essential to consider these factors along with the immediate goals of engineering. For instance, potential improvements in pathway flux by an enzyme engineering effort could be obscured in the absence of expression of a transporter protein if the enzyme suffers inhibition from accumulation of a downstream product (Alberstein et al., 2012) or if the product results in cytotoxicity (Mukhopadhyay, 2015). It can therefore be advantageous to adjust culture models in a way that influences metabolite and/or product localization.

As a common example, additives to the culture can help to draw products out of the cell in the absence of strong active transport. In some cases, these may be water-soluble (e.g., Triton X, Tween-80, or cyclodextrins) and aid in solubilization or dissociation from cells (Dufosse et al., 1999; Dhamole et al., 2012). Other additives are immiscible with water, forming a separate phase (a layer or emulsion) that can sequester and better dissolve or suspend the product (Gu et al., 1999). Note that while the latter usage has been very common for extractive fermentations in lab-scale and larger bioreactors, there are few literature examples of use in HTP plate models. Several industrial patents and applications do, however, outline claims over their use in plate-based screening workflows, with commonly used organic additives including dodecane, isopropyl myristate, and methyl oleate (Tsuruta et al., 2009; Ridley et al., 2019). Amyris has also reported the use of isopropyl myristate and mineral oil in lower-throughput shake-flask-based screens for artemisinin precursor production in S. cerevisiae (Westfall et al., 2012; Paddon et al., 2013).

3.3. Microplate assays

Following the selection of a culture model, the second component of a high-throughput screen is the set of assays that support strain evaluation. Most often these assays measure the titer of final product(s); however, they can also identify bottlenecks in biosynthetic pathways or undesired side-reactions, monitor feedstock consumption, and/or measure cell density, vitality, and viability. Together, these data can be used to construct multivariate models that are more predictive than a single readout. To be suitable for a high-throughput screen, measurements should meet the following criteria:

-

•

Speed: Able to accommodate large library sizes (ideally less than 1 s per sample)

-

•

Automatability: Uses robotics-friendly operations; designed with as few steps as possible

-

•

Precision: Minimal variation due to sample preparation or measurement system

-

•

Robustness: Requires minimal tuning as strains improve (e.g., wide linear range, small matrix effects); capable of large sample numbers without performance decrease or excessive maintenance

3.3.1. Product localization and analyte extraction

Products synthesized within a cell partition between the extracellular and intracellular spaces over time, depending on the properties of the molecule. Passive diffusion is a common route of membrane transport for smaller and more hydrophobic molecules but occurs only to a very small extent for larger, uncharged, polar molecules (N. J. Yang and Hinner, 2015). Complete extraction of the whole-cell broth and subsequent sample analysis will reflect the sum of the extracellular and intracellular product concentrations. This is the standard method of analysis and is often the least technically challenging. However, when considering optimization of manufacturing potential, independent analysis of these two fractions can give insight into whether intracellular product recovery (which can be quite costly at manufacturing scale) will be necessary. As an example, recovery of fatty acids from intracellular pools can increase manufacturing cost by 40–80% (Ledesma-Amaro et al., 2016). This type of analysis is particularly useful when screening for strains with improved product export (Wagner et al., 2018).

Cell membrane permeabilization or disruption is often necessary to quantify intracellular product. Many techniques can be used to mechanically disrupt cell membranes, including bead-beating, ultrasonication (Stipetic et al., 2016), lyophilization (Jayatilaka et al., 2011), and freeze/thaw cycling (Canelas et al., 2009); these are semi-automated at best and are a poor match for HTP-sample preparation (Table 4). However these methods can serve to generate a reliable reference point for the total content of a sample. Chemical permeabilization methods are a better match for HTP workflows, since they are more compatible with automated liquid handlers. Chemical permeabilization can be achieved via enzymatic or surfactant lysis buffers, or via solvent treatment. For example, lysozyme and two other commercial enzymatic lysis agents have been compared against sonication as an automation-compatible method for releasing proteins from dried cell pellets of E. coli (Listwan et al., 2010) and found to be comparable in efficiency. In another study, combinations of lysis enzymes, surfactants, detergents, chaotropic agents, antibiotics, and chelating agents were tested in a design-of-experiment study to release proteins from E. coli that laid out a framework for selecting effective cell lysis buffers (Glauche et al., 2017). This approach resulted in a cell lysis buffer whose performance was equivalent to a commercially available product. Methanol, ethanol, and chloroform are widely cited as permeabilizing for some bacteria (especially E. coli) and yeast (Faijes et al., 2007; Mashego et al., 2007). In particular, cold methanol has been described as an ideal sample treatment for global analysis of metabolites in E. coli at native concentrations (Maharjan and Ferenci, 2003); extraction procedures for targeted quantitation of a particular metabolite should, however, be optimized for that purpose. Combining multiple methods can also be advantageous. For example, amorpha-4,11-diene has been extracted from S. cerevisiae fermentation broth using a combination of strong acid, a commercially available detergent-based protein extraction reagent, and ethyl acetate (Westfall et al., 2012).

Table 4. Sample preparation techniques for microplate culture models.

Once released from the cell, traditional liquid-liquid extraction or solubilization methods can be used to isolate analytes from the surrounding matrix and ensure that they are amenable for analysis. As previously mentioned, pipetting, agitation, and centrifugation are all commonly employed on robotics platforms and can be readily used in HTP sample preparation (Ma et al., 2008). Organic solvents are commonly used and, depending on the chemical characteristics of the target compounds and downstream analytical method, may be miscible or immiscible with the culture media. Predictions for effective extraction and solubilization systems may be made in advance based on physical characteristics of the target compound(s) such as hydrogen bonding, acidity/basicity, and octanol-water partitioning coefficient; however, due to the complex makeup of biological samples, several options should always be empirically tested on well-studied strains to optimize the sample preparation (Tshepelevitsh et al., 2017). Multi-component systems with a mixture of solvents or salt additives may be helpful, especially in extracting polar analytes from aqueous matrices (Hyde et al., 2017). As an example of a sample preparation that would be straightforward from both an automation and extraction perspective, antibacterial metabolites have been extracted from aqueous supernatant of marine actinomycete cultures using ethyl acetate (Rajan and Kannabiran, 2014).

Solid-phase extraction (SPE) has also been used with commercially available SPE cartridges in 96-well plates. These are most used for cleanup of tissue or fluid samples for bioanalysis, and integrated systems are available to automate or semi-automate the extractions in 96-well formats. As a typical example, carboxylic acid-based metalloprotease inhibitor compounds have been extracted from mammalian plasma samples using diatomaceous earth-packed extraction plates, and washed with organic solvents before elution (Peng et al., 2001). Application to microbial sample preparation has also been reported; in one study, secondary metabolites were separated from Streptomyces coelicolor culture supernatant using a hydrophilic-lipophilic balanced sorbent SPE packing (Čihák et al., 2017). Filter plates are also commonly used for sample cleanup, whether in the form of molecular weight cut-off filters or membrane-based filters. Even in 96-well plate format and with automation compatibility, the time needed for SPE or filter plate sample preparation pushes these sample techniques into the medium throughput range (∼103-104 samples per week) and they are thus generally not suitable for large libraries. Regardless of the process used, attention should be paid to the resulting sample matrix to ensure that it is compatible with the analysis platform and optimized for accuracy, precision, selectivity, and robustness.

3.3.2. Detection of products, pathway intermediates, and by-products

Analytical instrumentation has traditionally been developed to support the chemical and pharmaceutical industries, and more recently the biopharmaceutical industry. The metabolic engineering (synthetic biology) industry is relatively new; thus, instruments designed for the specific challenges related to desired throughputs are still being developed. Instrumentation development in the last decade has been especially rapid in the field of mass spectrometry (MS) and this pace of development is likely to continue into the next 10 years as well. Large step-changes in sensitivity and selectivity of commercial instrumentation are also expected for Raman-based spectroscopic techniques, which will be discussed in the context of microfluidic platforms in Section 4.3.4. This section focuses on analytical technologies that are most practical for analysis of plate model samples (Table 5).

Table 5. Analytical technologies used for analysis of microplate culture model samples.

3.3.2.1. Traditional analytical technologies and reference assays

Chromatography-based analytical techniques combine separation and detection technology, and offer high accuracy, precision, and chemical specificity. These techniques can accommodate a wide variety of molecule properties, including a large range of molecular weights and polarities. Although some chromatography instruments are equipped with microplate-compatible autosamplers, analysis times can run from minutes to hours per sample, making it difficult to use them for HTP screening applications. Instead, these methods can be used as reference assays to validate and periodically reassess the accuracy, precision, and specificity of HTP screens during an engineering campaign. They are also often used in “second tier” screens to increase confidence in the performance of strains identified in a preliminary HTP screen.

There are several technologies in liquid and gas chromatography that can be deployed on modern instrumentation that can be used to reduce analysis times. Ultra-performance liquid chromatography (UPLC), replacing HPLC, uses smaller particle sizes and higher pressures to increase throughput by between 3- and 10-fold (Dong and Zhang, 2014), allowing analysis to be completed in a few minutes or less per sample. Further gains can be made by operating liquid chromatographs in constant pressure mode, which allows higher flow rates as the percentage of organic solvent is increased; this adaptation can decrease analysis times by 20–30% without sacrificing peak resolution (Broeckhoven et al., 2011; Verstraeten et al., 2011). For volatile, non-polar molecules, gas chromatography is still the standard technology. Limited thermal mass ovens (LTMs) with reduced volumes allow faster heating, cooling, and equilibration than traditional GC ovens. When coupled with narrow-bore columns, these improvements can decrease the time required for separation of complex mixtures by 60-fold compared to standard bore columns (Bicchi et al., 2004).

3.3.2.2. Spectroscopic assays

HTP assays have traditionally relied on spectroscopic readouts (i.e. UV–Vis absorbance or fluorescence measurements from microplate spectrophotometers) due to their speed, relatively low cost, and ease of implementation. Detection is quick, with a throughput on the order of one well per second, and spectroscopy is thus easily amenable to direct integration in automated systems for increased throughput and precision. Assays based on UV–Vis absorbance or fluorescence can rely on the intrinsic spectral characteristics of the target molecule or can involve addition of enzymes (Hutchinson et al., 2012; Liaud et al., 2014), dyes, and/or derivatization reagents. For compounds with strong intrinsic spectra, there is often little to no sample preparation required. However, UV–Vis absorbance assays can often be vulnerable to sample matrix interference and lack sensitivity and chemical specificity. Fluorescence assays can offer greater specificity and sensitivity than absorbance assays, but few molecules are intrinsically fluorescent.

When developing fluorescence assays, it is important to identify the extent of the linear range for each analyte, as high concentrations can result in difficulty exciting the entire sample, accelerated quenching of excited electronic states, and other phenomena that cause nonlinear signal. Signal from some fluorescent molecules can also suffer interference by the presence of other fluorophores in the sample, such as tryptophan found in biomass. In these cases, a separate biomass measurement and background subtraction can sometimes be required to provide useful data (Y. Yang et al., 2015). Biosensors (covered in greater detail in Section 4.2) have also been used for measurement at multiple culturing scales, and often use fluorescence as a readout (Lin et al., 2017).

There are many examples of strain engineering efforts that utilize the UV–Vis absorbance or fluorescence of target molecules. For example, farnesene production by S. cerevisiae has been quantitated in plate models using the UV absorbance of the conjugated diene in the product (Meadows et al., 2016); and lycopene overproduction has been assayed colorimetrically (i.e. by visible light absorbance) from extracted E. coli cell pellets (Alper et al., 2005). Examples using enzymatic or chemical reagents include colorimetric detection of microbially produced lactic acid via its oxidation and a subsequent coupled horseradish peroxidase-mediated oxidation of a chromogenic reagent (Liaud et al., 2014); and Nile Red, a common dye that exhibits increased fluorescence in a hydrophobic environment, which has been used to detect lipids in the microalgae Chlorella vulgaris (Morschett et al., 2016).

3.3.2.3. Mass spectrometry assays

In recent years, MS has become more prevalent as a screening platform due to its ability to detect a wide variety of analytes, label-free, with specificity and sensitivity in complex mixtures. A full survey of HTP MS platforms has been thoroughly covered in reviews elsewhere (Kempa et al., 2019). Of specific interest are two commercially available platforms, the Agilent RapidFire-MS and the Sciex Echo-MS. Both technologies use tandem-MS to separate targets by mass and fragmentation pattern, improving assay selectivity over other detection methods. RapidFire-MS, which uses an SPE-like cartridge to trap and then elute targets of interest into an electrospray ionization (ESI) or atmospheric-pressure chemical ionization (APCI) source, has a run time of 7–30 s per sample. The platform has proven popular for screening in pharmaceutical and other biotechnology-related industries and has been used to screen in vitro enzyme inhibition libraries with human health applications (Hutchinson et al., 2012; Asano et al., 2019). The option of using either ESI or APCI sources widens the range of molecules that can be ionized, making the technique amenable to both highly polar and less-polar molecules at a range of molecular weights (Awad et al., 2015). Echo-MS interfaces a Beckman Coulter acoustic liquid handler with a mass spectrometer. The liquid handler ejects nanoliter droplets of sample into an open-port probe (Van Berkel and Kertesz, 2015) that directs the sample into an ESI source and has a run time of 0.5–2 s per sample (H. Zhang et al., 2020). Another version of Echo-MS used an Echo interface to eject a fine mist into a heated transfer line. That technology is no longer being commercially developed but has nonetheless been successfully used in enzyme inhibition assays (Sinclair et al., 2016, 2019). Another commercially available platform for MS analysis from plates, the Triversa NanoMate from Advion, uses disposable single-use conductive tips and a disposable nano-ESI chip. The system aspirates 1–10 μL of sample from 96- or 384-well plates and ionizes it in a single-use inlet nozzle on the ESI chip, with the ion plume directed into an MS (Van Pelt et al., 2003). While this platform has been used for a range of applications, including bioanalysis in pharmacokinetic studies (Zhang et al., 2004), lipidomics (Chen et al., 2014; Matyash et al., 2008), and enzyme inhibition studies (Zheng et al., 2020), sample analysis time is 45 s per sample, and can be expanded up to 2 min per sample depending on the application. It is therefore considered slow for an HTP MS application and may instead be considered medium throughput.

To achieve the desired measurement precision or dynamic range, mass spectrometry may require internal standards (either isotopomers or close analogs of analytes) to combat ion suppression and sample matrix effects. The RapidFire-MS uses μL-dwell-volume SPE cartridges to desalt samples and minimize matrix effects (Sawyer et al., 2020), while Echo-MS relies on greater than 1000-fold dilution of sample into the solvent flow path to avoid matrix effects (H. Zhang et al., 2020). Multiple analytes may be measured in one MS method, which can provide an advantage for strain screening by allowing for detection of pathway intermediates as well as the final product.

Flow-injection, a technique where samples are infused directly into the flow-path of the source of an MS without chromatographic separation, has been applied to rapid untargeted metabolite screening of extracts from E. coli by using a commercially available liquid chromatograph (LC) to inject samples into a quadrupole time-of-flight (QTOF) mass spectrometer with a throughput of 1 min per sample (Fuhrer et al., 2011). While faster than conventional LC-MS methods, and with the advantage of high data density from untargeted metabolite detection (as opposed to the 5 to 20 analytes simultaneously detectable by Echo-MS or RapidFire-MS), the requirement of 1 min per analyzed sample moves the technique into the realm of medium throughput. Another implementation of flow-injection MS has been described that uses a non-commercially available microfluidic sampling platform to draw a segmented flow of aqueous nanoliter droplets from a 384-well plate (S. Sun and Kennedy, 2014). The continuous phase in this setup is drawn from an immiscible supernatant phase composed of fluorinated ethylene propylene oil. The entire segmented flow is then directed into the ESI-source of a tandem-MS. Sample throughput, which is dictated by the duty cycle of the MS and carryover in the ESI needle, is on the order of 1–5 samples per second, depending on the number of compounds monitored. A key constraint on the compound type in this is the need for the analyte to remain encapsulated within the aqueous droplets in the segmented flow; this technique may therefore be most suitable for polar analytes with a low affinity for the fluorinated oil. The platform has been used to monitor product peptide abundance in an in-vitro cathepsin B enzyme inhibition study and is of interest due to its high throughput and minimal sample preparation required prior to analysis (S. Sun and Kennedy, 2014).

Surface-based MS is another MS-based detection modality that has been applied to the area of HTP screening for metabolic engineering. Although many different platforms have been developed for surface-based MS, this section will focus on matrix-assisted laser desorption/ionization (MALDI). Other desorption ionization techniques like self-assembling monolayer desorption/ionization mass spectrometry (SAMDI-MS), though highly relevant to in vitro enzyme engineering (Patel et al., 2015; O'Kane et al., 2019), have been covered in other reviews (L.-H. Li, Hsieh, and Hsu, 2017). Similarly, ambient desorption ionization techniques that in the field of synthetic biology have mostly been used in colony surface imaging or qualitative organism fingerprinting such as desorption electrospray ionization-MS (DESI) will be further discussed in Section 4.2.2. In MALDI, nanoliter or microliter volumes of liquid samples are spotted onto a target plate and then co-crystallized with a matrix solution such as succinic acid, α-cyano-4-hydroxycinnamic acid, 2,5-dihydroxybenzoic acid, or 3-hydroxy-picolinic acid (Awad et al., 2015). A pulsed laser is used to photoionize the matrix crystal, which in turn ionizes the analyte; the ion stream is then electrostatically directed into the mass analyzer. Once the target plate has been prepared, analysis is rapid, on the order of 1 s per sample, making it suitable for high throughput screening. It has been demonstrated to be a compatible readout for in vitro enzyme inhibition assays with targets of both low (approximately 100 Da) and high (approximately 1000 Da) molecular weight. The lower limit of quantitation, however, was not as low as the RapidFire-MS reference assay and some molecular species exhibited lower ionization efficiency than others (Haslam et al., 2016). Hurdles in the application of MALDI include the need for co-crystal sample preparation and inherent compound-dependent variation in ionization efficiency. The matrix compounds can also interfere with measurement of low-molecular weight compounds of less than 500 Da (S. Zhang et al., 2010). Additionally, MALDI can be vulnerable to ion suppression from salts, such as sodium chloride. Use of an internal standard has been shown necessary to reduce the assay CV from 40% down to 5% (Winter et al., 2018).

3.3.3. Alternative response variables

Although endpoint titer measurements of products and intermediates are the most typical benchmarks for strain improvement in an HTP screen, there are occasionally other readouts that can be exploited, such as measurements of cell health, metabolic state, growth, protein expression, and kinetics of product formation. Many of these readouts are generalizable across different strain development efforts, making their implementation cost effective.

Cell density measurements are ubiquitously used to obtain relative biomass yields and monitor growth. Growth rates, which can be determined from repeated biomass measurements, are often used as indicators of strain metabolic activity and cell health. Absolute cell density can be acquired using flow cytometry or simplified automatic cell counters. However, for strains with similar cell morphologies and sizes, biomass and cell density are roughly proportional and can be more quickly estimated with absorbance measurements, usually at 600 nm. Due to the narrow linear range of the absorbance assay measurements, dilution of culture can often be required in such assays. A 96-well adaptation of the BioLector has demonstrated that measurement of light scattered from the culture (rather than that transmitted) can give a broader linear range without dilution (Kensy et al., 2009), although this is not a readout available for most plate readers.

In some cases, a strain can be utilized as a whole-cell biosensor and included in samples to allow simple OD measurements to be used as a surrogate for direct detection of product. For instance, some groups have engineered sensor strains that are auxotrophic for the desired product; the result of this can be that the sensor strain only grows in the presence of an engineered strain that provides the product at the necessary level (Saleski et al., 2019).

Direct measurements of membrane integrity (Edwards et al., 2007) and redox-equivalent generation (Nandy et al., 2015) have also been widely used for assessing product tolerance and metabolic state and can give a more nuanced illustration of strain health. While flow cytometry readouts can give the most data-rich analysis of culture samples, they are somewhat throughput-limited (∼30 s per sample). Cruder but still broadly informative alternatives have been demonstrated using spectrophotometers, providing throughputs of more than one sample per second (Kwolek-Mirek and Zadrag-Tecza, 2014).

Because sugars are common feed sources, it can be valuable to develop a high-throughput readout that can assess the residual sugar content in a plate model. Such assays can help with the development of culture models when rate of sugar consumption is a concern and can also be used in estimates of yield when sugar is only partially consumed. Absorbance assays based on the detection of NADH production through coupled enzymatic reactions that consume sugar have widely been used for this purpose (Badotti et al., 2008).

Yield is a very important factor in the final cost of production at manufacturing scale when feedstock is the major contributor to cost. When all carbon sources in a plate model are completely consumed, yield can usually be assumed proportional to endpoint titer, making relative titer the most convenient metric for strain ranking. However, if time-dependent factors like facility rental or labor dominate cost models, volumetric productivity can become a critical factor as well (Benjamin et al., 2016). A challenge in determination of volumetric productivity in plate models is that multiple measurements of titer for each sample are required to allow an estimate to be calculated. Methods to accomplish this have been used at Amyris (Sandoval et al., 2014) and elsewhere but are typically not used as primary screens because of increased operational burden. Moreover, the limited sample volume in plate models imposes a constraint on the number of assays that can be run on each plate; this means that several replicate plates must sometimes be cultured to acquire productivity data, which introduces additional error into the measurement. An interesting example of how a microfluidic screening platform can circumvent the need for multiple measurements is introduced in Section 4.2.2.

There are many literature examples demonstrating the power of metabolomic, transcriptomic, and proteomic analysis to understand the bottlenecks and feedback mechanisms in cell factories (Jewett et al., 2005; Redding-Johanson et al., 2011; Petzold et al., 2015). These techniques generate complex multivariate datasets that, together with other readouts described above, may be integrated to improve prediction of performance at lab scale. Machine learning algorithms have been successfully implemented to analyze similar datasets for applications in oncology research, personalized medicine, and neuroscience (Grapov et al., 2018) and are now beginning to demonstrate their promise in metabolic engineering as well (Serber et al., 2017; Opgenorth et al., 2019; Presnell and Alper, 2019). There is little precedent for application of multi-omics to HTP mL-scale strain screening as it is defined in this review (analysis of >104-105 cultures per week). However, there is strong potential especially for targeted proteomics and metabolomics accelerated by HTP MS, and they should be considered as possible readouts for engineering libraries.

4. Screening for production at micron scale

The recent rapid development of microfluidic applications for biotechnology offers an extremely promising opportunity for metabolic engineering. However, such systems have not been widely developed into commercial platforms for the purposes of screening for small-molecule producing microbes; this is likely because of the relatively small size of the research market compared with other testing applications, such as point-of-care diagnostics. However, there have been exciting examples both in academic groups and in industry that have demonstrated strong potential.

Microfluidic systems most typically consist of custom-designed polymer devices containing networks of narrow (∼1–100 μm) channels. The channels can be used for the precise manipulation of liquids and suspended particles with the aid of hydrodynamic, electrostatic, and other forces. By miniaturizing the culture volume for each strain down to 0.01–100 nL, these technologies could make it possible to scale screening throughput by several orders of magnitude (up to 107 strains per day per device) without linearly increasing the physical footprint of the lab.

Most of the challenges associated with strain screening in microplate culture models translate when systems are scaled to even smaller volumes. As with plate-based screening systems:

-

•

Independently monitoring and controlling the environment within each droplet, cell, or chamber is infeasible.

-

•

High-precision analytics and liquid handling is of critical importance to ensure the ability to distinguish strains based on performance.

However, scaling to microfluidics introduces some additional challenges:

-

•

Analyte availability (total mass per sample) is extremely limited, constraining readout sensitivity.

-

•

As the number of cells in a sample decreases, biological stochasticity (e.g., from time-dependent fluctuations in gene expression levels in single cells) can cause increased phenotypic heterogeneity even among samples with uniform genotypes (Ansel et al., 2008; Ackermann, 2015).

-

•

The linkage of genotype to phenotype becomes more challenging.

Regarding the last point, microfluidic screens must be designed carefully so that the cells with the successful genotypes can be recovered or can be faithfully reproduced. This is a trivial matter at the microplate scale, where culture material from each well is abundant, contained in a defined compartment, and easily retrieved. In contrast, microfluidic systems use tiny culture volumes with relatively few cells per strain; hits must be selectively flushed out of the device or otherwise tracked after detection. If real-time sorting of hits as they are identified is not an option, then a barcoding strategy allowing unambiguous identification of the genotype (such as introduction of known unique DNA sequences for each strain) is needed.

This section addresses how demonstrations of microfluidic platforms have addressed (or failed to address) these fundamental problems. There have been many insightful reviews that span topics touched on here, including aspects of droplet microfluidics (P. Zhu and Wang, 2016; Dressler, Casadevall i Solvas, and deMello, 2017; Bowman and Alper, 2020), various analytical techniques (McNay et al., 2011; Wei and Min, 2018; Kempa et al., 2019), enzyme engineering (Chen and Arnold, 2020), biosensor applications (Lin et al., 2017), and single-cell analysis (Vasdekis and Stephanopoulos, 2015). The scope of this review is limited to some of the most promising strategies and their likely future paths, directing the reader to deeper discussions of each field as necessary.

As with microtiter plate-based screening approaches, microfluidic screens comprise two parts – (1) the culture model and (2) detection and sorting. This section discusses efforts toward development of solutions for both modules, with key aspects for each approach summarized in Table 6.

Table 6. Summary of micron-scale culture and screening options for metabolic engineering.