1. Introduction

According to the generation mechanism, the vehicle noises may be generally classified into five categories: mechanical noise, electromagnetic noise, aerodynamic noise, frictional noise and their coupling noises. In the past decades, the mechanical, electromagnetic and aerodynamic noises have been widely studied and effectively suppressed. However, the friction related noises, such as brake noise, clutch noise, wiper-windshield noise, window-glass lifting noise and tire noise, have not yet been solved due to their complex mechanisms [1,2]. With the rapid development of electric vehicles, the noise level of vehicles has been greatly reduced, thus these friction-induced noises are becoming more prominent [3]. The annoying wiper-windshield noise caused by the friction between the rubber blade and the windshield glass has a significant effect on the vehicle interior sound quality. From the end of nineteenth century, the wiper-windshield friction noise entered people's research vision. As researching deeply, it has been gradually recognized that the wiper-windshield friction noise is a typical nonlinear noise, and its generation mechanism is closely related to the working state of the wiper system. The extreme annoyance is caused by the friction-induced wiper noises [4], such as squeal [[5], [6], [7]], chattering [8] and reversal noises [[9], [10], [11]], which are usually accompanied by bifurcation [12,13] and chaos [[14], [15], [16], [17]] phenomena. Due to the complex generation mechanism, peculiar acoustical characteristics, randomicity and instability [18,19], the suppression of wiper-windshield friction noise has been a pending issue in the international academic community.

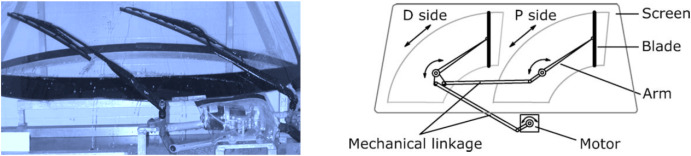

The automatic wiper system of a vehicle is composed of four main parts: two wipers, a mechanical linkage, an electric motor, and an electronic control unit (ECU). There are three types of wiper: conventional frame-style, beam-style and hybrid wipers [12,20,21]. The conventional frame-style wiper is the most common one. The beam-style wiper is manufactured from double rubber or silicone material. The hybrid wiper, which is a combined by the conventional and beam-style wipers, boasts aerodynamic design, ideal to all-seasons, and has specific pressure points for uniform application. Each windshield wiper consists of an arm and a rubber blade. The typical structure of a wiper system is shown in Fig. 1 [12,17]. The rubber blades are pressed against the windshield by the arms. The electric motor provides the torque for the mechanical linkage which generates the left and right reciprocating motions of the wiper arms and rubber blades to remove water and/or dust on the windshield. As a vulnerable component, the wiper system that is essential for every vehicle has been used in large amounts on vehicles. Due to the usual environmental situation in many rainy, windy and dusty days, the requirements for the wiper's function and reliability are very high. As one of the important factors affecting on the interior sound quality, the “unique” noises caused by the wiper-windshield friction cannot be ignored in vehicle engineering.

Fig. 1. The typical structure of a vehicle wiper system [12,17].

Fig. 1. The typical structure of a vehicle wiper system [12,17].To improve sound quality of the “unique” noises, one needs to study the dynamic characteristics of the wiper system, the adhesion mechanism between the blade and windshield surfaces, the auditory perception behavior with respect to frictional noise, the generation mechanism of friction-induced vibration and noise and their optimization and control methods. Therefore, many experimentally and theoretically studies have been carried out, and obtained some instructive results, which are helpful for reducing the wiper-windshield friction noise. However, most of the achievements are still confined to the descriptions of experimental phenomena and the preliminary discussions of theory. The essential characteristics of the wiper-windshield friction vibration and noise have not been thoroughly revealed. There are still some residual scientific problems need to be broken through in the aspects of generation mechanisms and control methods. To completely eliminate the wiper noise, more recently, some alternative technologies have been suggested to replace the vehicle wiper system for water and/or dust removal, such as the ultrasonic cleaning [22,23] and the solar panel cleaning [24,25]. Due to the high cost in industrialization, these new technologies are too far from being applied in vehicle industry. Currently, it is still an important research topic to reduce the friction-induced vibration and noise of the existing wiper-windshield systems, and thereby improving the interior sound quality of vehicles.

2. Fundamental frictional noise theory vs. wiper-windshield noise

The friction-induced vibration and noise has been listed as one of the important scientific issues in the field of mechanical engineering [26]. The research on friction noise can be traced back to 1930s. A large amount of effort has been made to study the generation mechanism of frictional vibration and noise, and some valuable results were obtained [[27], [28], [29], [30], [31], [32]]. The discomfort and annoyance caused by friction-induced vibration and noise is a very common problem encountered in many mechanical systems. Typical frictional noises in vehicle engineering are those generated by the friction pairs, such as brake disc-caliper, clutch disc-disc, wheel-rail in curve, lifting glass on window seal rubber, wiper-windshield, and driving belt-pulley, etc. The resulting noises with a wide frequency bandwidth are generally referenced as low-frequency chattering (200–500 Hz), and high-frequency squeak and/or squeal (1–15 kHz). Due to the characteristics of extremely annoying and serious damage of the high-frequency squeal to the human auditory system, these noises have always paid attention in the field of noise control engineering.

According to the property of contact materials, the friction pairs of a mechanical system can be divided into rigid-on-rigid and flexible-on-rigid frictions. The generation mechanism of friction noise is different due to the different materials and contact forms [33]. A lot of studies have been carried out by experimental analysis and theoretical modeling, but these works mainly focused on the friction noise of vehicle brake [[34], [35], [36], [37], [38], [39], [40]]. In view of the system dynamics and tribology, some theories for frictional vibration and noise, such as the modal coupling and splitting, energy feed-in, excitation-structure coupling, stick-slip, negative slope of frictional force vs. relative velocity, sprag-slip, and hammering, were put forward successively. The simulation method for friction noise has developed from single degree-of-freedom (SDOF), multiple degrees-of-freedom (DOFs) to finite-element modeling [41,42]. These theories and methods have laid a good foundation for studying friction behavior, but are not sufficient to reveal the mechanism of wiper-windshield friction noise. Compared with the brake noise, the wiper-windshield noise as a typical flexible-on-rigid friction noise generated by a soft elastomer sliding on a solid surface is more complex. The in-situ studies on frictional noise of the wiper system have preliminarily presented the noise generation mechanism and some feasible noise reduction methods. The friction noise is produced by a combination of forcing or self-excited nonlinear oscillations of the wiper system in the presence of a friction force. The coupling of the friction force and the resulting motion induces a loss of stability which leads to self-excited oscillations [27,43,44]. It has been realized that the generation mechanism of wiper-windshield friction noise is related to the surface features of rubber blade, the operation state of wiper system, the lubrication conditions, the wiping velocity of blade, the coupling of the normal and frictional forces acting on the windshield and other influencing factors [3,45].

Due to the characteristics of time-varying, random and high annoyance of the friction noise, it is difficult to obtain a desired sound quality only from the generation mechanism researches. One should also consider the characteristics of human auditory perception and reasonably reduce the noise according to people's subjective psychological expectations. This has been called “people-oriented” design in a modern mechanical system. The changed concept of noise reduction brings new challenges to friction noise control methods. For a wiper-windshield system, how to reasonably take into account the dynamics of the system, the friction behavior and surface characteristics of the blade, and realize optimization and control of friction noise based on multiple psychoacoustic indices has become a new research hotspot.

From the above discussions, the contents of the previous researches on wiper-windshield friction noise include the experimental analysis for friction vibration and noise, the dynamic modeling and simulation of wiper system, the adhesion characteristics of contact surface, the generation mechanism of frictional vibration, and the optimization and active control of frictional noise. These achievements are summarized in the following text, respectively.

3. Experimental studies on wiper-windshield friction noise

Experiment is the traditional method for studying friction noise, which is helpful to understand the physical characteristics of the noise. The measurements for the wiper-windshield friction noise have been implemented by using real vehicle, rotational test-bed and translational test-bed [5,6,9,12]. To observe the behavior in a friction process, some non-contact apparatuses, such as laser Doppler vibrometer, laser speckle interferometer, high-speed camera and microscope, are used to measure the dynamic deformation and surface microstructure changing of the wiper blade when the friction noise occurs [6,9,13,46].

By using the rotational test system shown in Fig. 2, the experimental investigations on mechanism of friction-induced noise and vibration under reciprocating sliding were conducted [6,47]. It is found that the wiper-windshield friction noise includes squeal (above 1000 Hz), chattering (below 100 Hz) and reversal noise (below 500 Hz), which are respectively related to the high-, low-frequency vibrations and reversal impact of the wiper system. And the varying time of static friction coefficient, the sliding velocity, and the friction coefficient are the main factors governing the friction-induced vibration. By using the translational test-bed shown in Fig. 3, the wiper-windshield friction noises in three contact states (dry, wet and tacky) under different temperatures [48] and the frictional force and noise at the specimen and system levels [12,49] were studied. The tested data were qualitatively analyzed by using Greenwood Williamson law and Persson contact theory. The variation rules of friction coefficient were obtained. The experimental results show that the wiper-windshield friction noise is related to the ambient temperature, the contact state, the lubricating and operating conditions, the rubber adhesion, the normal force and wiping velocity of the blade, the material properties of the blade, the morphologies of the contact surfaces. In view of the noise frequency, a series of experiments for the correlation between the contact resonance and friction-induced noise were carried out [50]. The results indicate that the mechanism for the contact resonance frequency being close to the frequency of friction-induced noise may be attributed to the interactions between the contacting asperities. Through some real vehicle tests, the frictional vibration and noise and the influence of windshield waviness on the squeal noise of the wiper systems were investigated [6,51]. The vibration and noise signals measured at different wiper gears in dry and wet states were analyzed in time-, frequency- and time-frequency domains, and the reasons of wiper-windshield friction noise were obtained. Furthermore, the interior noises at high- and low-speed wiper gears and the vibrations of vehicle parts at high-speed gear were experimentally analyzed [52].

Fig. 2. Rotary test-bed for wiper friction noise [6].

Fig. 2. Rotary test-bed for wiper friction noise [6]. Fig. 3. Translational test-bed for wiper friction noise [13].

Fig. 3. Translational test-bed for wiper friction noise [13].Using a contact imaging method, Audry [53] investigated the stick-slip motions at a contact interface between a smooth rubber and a patterned glass, and found that the stick-slip motions involve in the localized propagation of shear cracks. The propagating velocity is independent on the moving velocity. By means of experimental modal analysis and spatial matrix identification, Rusli [54] proposed a prediction method of squeal noise occurrence possibility, which can be used to calculate the possibility of a squeal noise incident and its frequency within the range of friction coefficient and contact stiffness in actual structures with relative sliding friction surfaces.

Generally say, the in-situ experimental studies are limited to the qualitative analysis of some critical factors influencing on the wiper-windshield friction noise, which cannot essentially illustrate the frictional behavior and noise generation mechanism. Therefore, it is necessary to develop some alternative theoretical methods and/or new specific test platforms and measurement methods for further experimental studying of the frictional vibration and noise of wiper-windshield systems.

4. Dynamic system modeling for wiper-windshield noise

Theoretically, the study of wiper-windshield friction noise involves the fundamental principles of frictional vibration, such as the stick-slip, sprag-slip sliding, modal coupling, negative slope friction coefficient, energy feed-in, modal coupling and splitting and excitation-structure coupling, etc [[55], [56], [57]]. In contrast to the braking noise [[34], [35], [36], [37], [38], [39], [40],42], the theoretical research on wiper-windshield friction noise is relatively lagging behind. In recent years, many studies have been carried out from theoretical modeling and numerical simulation, and obtained some valuable results. The wiper-windshield systems have been regarded as mass-stiffness-damping dynamic systems with different degrees of freedom (DOFs). Some dynamic system models with the number DOFs up to 4 have been developed.

The dynamic models with SDOF of the wiper systems were established for predicting the wiper-windshield friction vibration and noise [7,13,[58], [59], [60]]. The results show that the squeal noise comes from the self-excited vibration caused by the friction, and assuming that the friction satisfies the Stribeck's law, the wiper shows instability when the negative slope curve of frictional coefficient vs. velocity increases [7]. The SDOF model with linear viscous damper and dry friction can be solved by the phenomenological macro-slip described by the signum function and the physically correct stick-slip, respectively. The comparison results indicate that the latter is better than the former in description of a friction phenomenon [[58], [59], [60]]. Based on a SDOF sliding system, a criterion for fundamental design of robust-stable systems with regard to the stick-slip was proposed [61]. Typically, based on the Coulomb friction hypothesis, Sugita [13] derived the SDOF dynamic equation with respect to the wiper blade angle. Through the observation test of wiper motion, the change rule of normal force in reversal process of the blade and the bifurcation and chaos of the frictional vibration and noise were discussed, as shown in Fig. 4.

Fig. 4. The bifurcation phenomena in a wiper-windshield friction process, where (a) and (b) are the real and imaginary parts of friction coefficient [12], and (c) is the instability range of blade angle, θ is the angle of the blade, and δ is the compressed value of the blade [13].

Fig. 4. The bifurcation phenomena in a wiper-windshield friction process, where (a) and (b) are the real and imaginary parts of friction coefficient [12], and (c) is the instability range of blade angle, θ is the angle of the blade, and δ is the compressed value of the blade [13].Some dynamic system models with 2DOFs for wiper-windshield friction vibration and noise were established [4,9,[62], [63], [64]]. The sliding system with an elastomer in contact zone was modeled as a 2DOFs system with tangential contact compliance to study the stick-slip characteristics [62], and the criteria for avoiding stick-slip of the system were put forward. To improve the accuracy of the model, the nonlinearity of blade stiffness is introduced into the 2DOFs model of the wiper system [4]. The results show that, because the contact of the rubber blade and glass surface is restricted by the Stribeck's friction law and the Poisson's impact law, the induced instable vibrations in friction process lead to the squeal, chattering and reversal noise. Based on an analytical link model with 2DOFs, the dynamic and static friction behaviors and noises during reversals of a wiper blade under two states (stick and slip) were theoretically analyzed and experimentally verified [9]. It was found that the vibration frequency during transitions is close to the natural frequency of the blade neck. The effect of the varying friction coefficient on the dynamic performance of the wiper-windshield system was investigated by using a 2DOFs model subjected to elastic, gravitational and viscous forces constrained by frictional surfaces [58]. The 2DOFs models of a self-excited friction pair with different friction coefficients and normal forces acting on the sliding body [63] and a vibration system with friction pairs of a lumped parameter mass and a rigid mass [64] were built, And the conditions of mode coupling instability were investigated. It is found that the energy feed-in depending on mode coupling theory cannot be regarded as another generation mechanism of friction squeal.

Base on the 2DOFs models, furthermore, the dynamic models with 3DOFs and 4DOFs of the wiper systems were established. The calculated results of a 3DOFs model for reversal behavior show that the reversal impact force can be reduced by modifying the maximum angle and the stiffness of the rubber neck rotation, and the reaction force at the reversal points can be changed by adjusting the twist angle of arm head [10]. The results of a 3DOFs self-excited vibration model for intermittent squeal noise suggested that the system stability is mainly dependent on the modal coupling of the system [11]. A mathematical two-link model with 4DOFs based on the Sprag-slip theory was built to simulate the behavior of a wiper blade during wiping motion [8], which pointed out the effects of the cross-section geometry and material property of the wiper blade on the instability of the system. The reason of frictional squeal was studied by the friction coefficient measurements and t the scar topography observations [65]. The squeal is firstly excited at a place closing to the largest friction coefficient and the most serious fluctuation of friction force. Integrating the negative slope formula of friction coefficient, the Coulomb's friction law and the fluid lubrication characteristics, more recently, the dynamic models with 2DOFs and 3DOFs for the frictional vibration and noise of a wiper system under dry and wet conditions were established [66,67]. The comparison results show that the 3DOFs model with good accuracy is useful for structural optimization and frictional noise research of the wiper-windshield system.

The typical dynamic models with SDOF, 2DOFs and 3DOFs of the wiper system are shown in Fig. 5, and their corresponding results are shown in Fig. 6, Fig. 7, Fig. 8. From these researches, it can be concluded that a reasonable combination of the discrete lumped-mass dynamic model with multiple DOFs and the theory of tribology is an effective way to study the friction vibration and noise of the wiper-windshield system.

Fig. 5. The classical dynamic models of the wiper systems with (a) SDOF [13], (b) 2DOFs [66] and (c) 3DOFs [67], where k and c are the stiffness and damping coefficients corresponding to the DOFs, d and hd are the translational displacements, θ and φ are the angular displacements of the second and third DOF, respectively, N and Fe, are the normal force acting on the windscreen surface and the external force from wiper arm, f and Ff are the frictional forces acting on the windscreen surface, M and m are the mass of the wiper head.

Fig. 5. The classical dynamic models of the wiper systems with (a) SDOF [13], (b) 2DOFs [66] and (c) 3DOFs [67], where k and c are the stiffness and damping coefficients corresponding to the DOFs, d and hd are the translational displacements, θ and φ are the angular displacements of the second and third DOF, respectively, N and Fe, are the normal force acting on the windscreen surface and the external force from wiper arm, f and Ff are the frictional forces acting on the windscreen surface, M and m are the mass of the wiper head. Fig. 6. The calculated results from the SDOF model [13]: variations of the angle of blade and the normal force acting on blade during reversal, where (a) and (b) are the relationships between the angle of blade θ and the normal force η with respect to the dimensionless t.

Fig. 6. The calculated results from the SDOF model [13]: variations of the angle of blade and the normal force acting on blade during reversal, where (a) and (b) are the relationships between the angle of blade θ and the normal force η with respect to the dimensionless t. Fig. 7. The calculated results from the 2DOFs model [66]: the variations of the blade angle under a wet condition in the reversal processes.

Fig. 7. The calculated results from the 2DOFs model [66]: the variations of the blade angle under a wet condition in the reversal processes. Fig. 8. The calculated results from the 3DOFs model [67]: the vibration accelerations of the wiper blade angle in the reversal processes, where aθ and aφ denote the angular vibration accelerations of the second and third DOF.

Fig. 8. The calculated results from the 3DOFs model [67]: the vibration accelerations of the wiper blade angle in the reversal processes, where aθ and aφ denote the angular vibration accelerations of the second and third DOF.5. Numerical simulation for friction vibration and noise

The dynamic models with multiple DOFs based on discrete lumped-mass can be used to preliminarily analyze generation mechanism of the frictional noise, but cannot completely reflect the natural characteristics such as the intrinsic frequency and modal shape of a system [68,69]. From the previous studies, one may found that the modal coupling method is effective for friction noise study. In the recent years, the multi-body dynamics theory and the complex eigenvalue analysis based on finite element method (FEM) were introduced into the studies of friction noise [5,20,[70], [71], [72], [73], [74], [75], [76]].

The stress analysis of wiper blade, vibration modes and motion equations of a wiper system were synthesized to reveal the frictional mechanism of squeal [5]. The minimal model for modal coupling mechanism and the elastic vibration model for squeal noise mechanism of the self-excited oscillations were proposed [70,71]. The results suggest that, the friction-induced cross-coupling forces balance the corresponding structural ones, the phase shifts among oscillations may cause the instability of the system, the system instability and vibration can be excited by the time delay between the normal and friction forces, and the time delay increases with increasing of normal excitation frequency. Physically, this phenomenon could be explained by the modal coupling of a friction system, in which a time delay in the down stroke of reciprocating sliding is larger than that in the up stroke. In view of the reversal noise, especially, the dynamic and acoustic models under tacky condition were established by considering the blade deformation and the elastic contact [72]. The motions in the wiper system, the pressure distributions between the blade and windshield, the vibro-acoustic response and the interior sound pressure of a vehicle were successfully predicted and analyzed.

Based on the FEM, the methods of nonlinear contact analysis and transient dynamic analysis were used to investigate the structural behavior of a wiper-windshield system and the dynamic behavior of its rubber blade [20]. The results suggest that the contact force distribution is very sensitive to the curvature change of the primary beam, the rotational angle of the yoke and the thickness of the steel beam. The normal force and friction coefficient affect the blade vibration significantly. A proper combination of these variables may obtain a uniform contact force distribution with less vibration and noise. A Newtonian-based mathematical method was developed to simulate the friction noise of a wiper system [73], and the influence of groove-textured surfaces on frictional noise at a flat-on-flat contact was investigated. The results suggest that a reasonable combination of the normal force, frictional coefficient and contact angle can improve the noise and vibration performances and thereby avoiding the passengers’ annoyance. The dry and wet frictions and their contact behaviors of a wiper system were simulated by using plain-strain FEM models [74]. A hybrid friction model was proposed to solve the steady-state elastohydrodynamic lubrication problem of wiper-windshield contact. The variations of the interference between blade and windshield, the contact pressure distribution, and the nominal contact area during a transition from wet to dry friction were simulated, ignoring the influences of cavitation flow field, surface roughness, micro-convex deformation and capillary adhesion. Based on the methods of complex eigenvalue analysis and dynamic transient analysis, the FEM models were established [75,76]. The simulated results show that the friction pair with groove-textured surfaces can reduce squeal noise. Different types of wiper may produce a uniform or non-uniformly contact force distribution between the blade and windshield, and the behavior of blade depends on the structural and environmental parameters, such as blade stiffness, humidity and temperature. As the examples, some simulation results obtained by the FEM models [20,73] for analyzing the mechanism of wiper-windshield frictional vibration and noise are shown in Fig. 9.

Fig. 9. The simulated results of a wiper-windshield system by using the FEM: (a) the vibrational characteristics of rubber blade depending on the normal load F[20], and (b) the contact pressure p distributions as a function of interference (s = 0.6 mm) and friction coefficient, where b is the width of nominal contact area and s is the actual interference value [74].

Fig. 9. The simulated results of a wiper-windshield system by using the FEM: (a) the vibrational characteristics of rubber blade depending on the normal load F[20], and (b) the contact pressure p distributions as a function of interference (s = 0.6 mm) and friction coefficient, where b is the width of nominal contact area and s is the actual interference value [74].From the discussions in section 5, it can be concluded that the numerical simulation methods based on the modal coupling and FEM methods can obtain the system dynamic characteristics, frictional and contact behaviors, and vibration and noise characteristics. Comparing with the discrete lumped-mass models, these simulation methods with the advantage of visualizing the frictional process have played an important role in the research of frictional noise of the wiper windshield systems.

6. Frictional behavior vs. surface quality and adhesion

In terms of the contact and adhesion characteristics between elastomer and solid surfaces, a lot of studies have conducted from the microscopic perspective [[77], [78], [79], [80], [81], [82], [83]]. Persson [[79], [80], [81]] successively put forward the theories of adhesive force and capillary adhesion for the contacts of solid-solid and two-elastomer surfaces with random roughness. The theory of adhesion between an elastic solid and a hard randomly rough substrate [79] suggest that the adhesion interaction strongly affect the sliding friction force, which is essentially determined by the area of real contact. From the theory of capillary adhesion between two elastic solids with random roughness surfaces [80], for the elastically hard and soft solids, the relative humidity have great effects on the contact area and adhesion work. For the sliding contact between two elastically soft solids such as the rubbers in water, a transition from boundary (at low sliding speed) to hydrodynamic (at high sliding speed) lubrications will occur [81]. Assuming a wiper system working under various wetting conditions, the friction behavior of the rubber/glass contact was studied by using a modified tribometer [82], and the results show that the frictional instability is correlated to the contact vibrations during the transitions between wet and dry regimes. The adhesion between the processed glass and filled bromobutyl rubber in dry air, in water, and in silicone oil was studied [83], which suggests that the viscoelastic energy dissipation and surface roughness strongly affects the adhesion work depending on loading force and contact time.

In terms of the surface roughness, coating treatment and blade material, some studies related to frictional behavior and noise have been carried out [11,[84], [85], [86], [87], [88], [89], [90], [91]]. The experimental results of the breakloose friction with lubricated elastomer contacts [84] show that different surface roughness and contact pressures lead to different time dependences of the breakloose friction, and the increase of breakloose friction is due to the increase of real contact area. The effects of surface roughness on the stability of wiper systems were investigated by numerical computation and experimental study [11,85]. The results show that, expect for the modal coupling, the system stability is also affected by the friction coefficient and surface roughness, and the surface roughness and the wear status of the friction pair are the main factors in triggering and evolution of squeal noise. The sliding friction behaviors of different contact surfaces with the SiOx-based coatings on glass and the nitrile rubber with hollow glass beads (HGB) were experimentally investigated by using the plasma jet system, microscope and high-speed camera [[86], [87], [88]]. The conclusions suggest that, the thickness and chemical composition of coatings can determine the friction behavior due to a change of friction coefficient, the Young modulus is a very important factor that governs the generation of detachment waves, and the HGB treatment can reduce the friction coefficient and enhance the anti-wear ability of the rubber. The frictional stress distribution on the sliding interfaces between a glass lens and a rubber substrate was discussed [89], which show that the high lateral strains are achieved at the periphery of sliding contacts, and the linearly sliding and the twisting contacts can be simulated by finite-element inversion. Some experimental investigations were carried out by considering the material property, normal load and water lubrication of a rubber-steel frictional contact[90]. The results show that the maximum static friction of the contact increase with the normal load in dry and wet conditions, and a significant reduction of friction can be obtained by using the seawater droplets as lubricating medium. The analysis results of changing patterns of friction force show that, under dry sliding conditions, the friction force changes steeply during the formation of a strong frictional noise [91].

In view of the wear status and the surface texturing, the acoustic measuring technique, scanning electron microscope observation and surface topographymeasurement were applied to investigate the friction-induced squeal noise occurred at a wear scar under reciprocating sliding [92]. Based on a modified wear rate formula, furthermore, the effects of contact wear on the squeal noise were studied by using the FEM-base complex eigenvalue analysis method [93]. Comparisons of the scar profiles under the silent and squeal conditions showed that the generated squeal is attributed to the material detachment of the contacts. More recently, some novel surface texturing approaches for improving tribological properties were introduced into the studies of wiper-windshield fraction vibration and noise [94,95]. The conclusions can be drawn that the groove-textured contacting surfaces with reasonable dimensions and distributions can greatly reduce the frictional squeal noise, which may be explained as that the collisions between the groove edges and their counterpart can suppress the self-excited vibrations and thereby the squeal noise. In the wet working condition, especially, the grooves with an orientation angle of 0° can essentially improve the tribological properties and reduce the wiper-windshield noise. The surface texturing approach might be a promising direction for frictional vibration and noise study of wiper-windshield system.

The above mentioned theories and techniques, which are related to the capillary adhesion, contact compliance, surface roughness, surface coating, surface sandblasting, wear status, surface texturing, effects of temperature and humidity, etc., have not yet been completely integrated into the studies of wiper-windshield friction noise. It might be expected to yield more effective results in the future studies of wiper-windshield friction vibration and noise, if one combines the capillary adhesion of elastomer-solid contact, the treatment of friction contact surface and the finite-element analysis of wiper systems. As examples, the influences of the capillary adhesion and surface roughness of the rubber and glass interfaces on sliding friction characteristics are taken from Refs. [79,83] and given in Fig. 10, where E and p denote the Young's elastic modulus and the squeezing pressure, respectively.

Fig. 10. The effects of capillary adhesion and surface roughness on rubber-glass sliding friction characteristics: (a) very rough surfaces without adhesion, (b) thin fluid film with slight adhesion, (c) fluid film with strong adhesion, (d) the macroscopic interfacial energy as a function of roughness, where E is the Young's elastic modulus [79], and (e) The interaction potential energy between a flat glass surface and a flat rubber surface in water as a function of the surface separation (in nanometer), (f) the logarithm of the interfacial separation as a function of the logarithm of time [83].

Fig. 10. The effects of capillary adhesion and surface roughness on rubber-glass sliding friction characteristics: (a) very rough surfaces without adhesion, (b) thin fluid film with slight adhesion, (c) fluid film with strong adhesion, (d) the macroscopic interfacial energy as a function of roughness, where E is the Young's elastic modulus [79], and (e) The interaction potential energy between a flat glass surface and a flat rubber surface in water as a function of the surface separation (in nanometer), (f) the logarithm of the interfacial separation as a function of the logarithm of time [83].