1. Introduction

Concrete is one of the most broadly utilized materials in the construction of buildings and other infrastructure owing to its excellent mechanical properties (Liu and Chen, 2014; Shoukry et al., 2011), durability (Afroughsabet and Ozbakkaloglu, 2015; Faried et al., 2021), and fire resistance (Haido et al., 2021; Kodur, 2014; Kodur et al., 2008). Every year, over 21 Giga tons of concrete are produced worldwide (Klee, 2004; Zhang et al., 2019). The expansion of various industries to meet the demand of a diverse population with unique needs forms continuous increase in construction business. The thriving construction industry has positively boosted the concrete trade. The annual increase in concrete consumption owing to the rising demand for this product has caused a significant strain on the supply of its essential mixing ingredients (Al-Jabri et al., 2009; Aprianti et al., 2015; Behera et al., 2014; Gallagher and Peduzzi, 2019). Cement as one of the utmost important constituents that functions as a binding agent to form solid hardened concrete, is also continuously being produced in increasing volume over the years. In 2020, the cement production reached 4.3 gigaton (IEA, 2021). Global cement production is forecasted to rise by 23% by 2050 (WBCSD, 2018). Cement production poses significant environmental, economic, and social challenges in attaining the United Nations Sustainable Development Goals settled by the United Nations. Goals for Sustainable, Resilient, and Inclusive Development (SDGs) have been adopted on a worldwide scale as a means to this end (Neshovski, 2018). One of the primary desires of the SDGs is to fight climate change and its impacts. Meanwhile, this industry accounts for up to 7% of global carbon dioxide emissions (Ahmed et al., 2021; Talaei et al., 2019). This industry is the third-largest emitter of CO2 (Andrew, 2018). The cement industry contributes 2.7 giga tons of CO2 to the atmosphere (Mainz, 2021). In addition, various pollutants such as sulphur dioxide (SO2), nitrogen oxides (NOx), and dust/fine particulate matter (PM) are emitted into the atmosphere due to the cement production (Isaiah et al., 2021; Tanash and Muthusamy, 2022). These pollutants have adverse effects on several environmental categories, including global warming, depletion of ozone layer, and acidification of water and soil. Non-renewable energy consumption of 3–5 MJ is required to dry, crush, and sinter 1 kg of carbonate minerals into "clinker," which is then grinded into cement powder and combined with other components (Bourtsalas et al., 2018; Hendriks et al., 1998; Venkatarama Reddy and Jagadish, 2003). The production of a sustainable, more environmentally friendly, and less expensive cement material is necessary in light of growing concerns about man-made global warming, and increasing energy shortages (Lasseuguette et al., 2019). Thus, the approach of transforming the available waste materials generated from any industries as ingredients in cement production would reduce the burden at landfill, create cleaner environment and contribute towards preservation of green environment for healthier lifestyle of the nation.

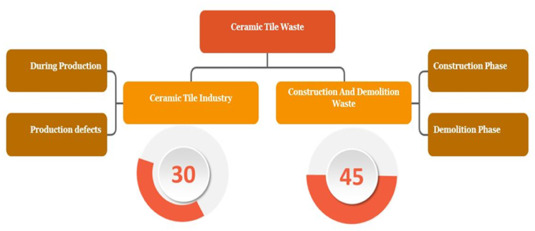

The flourishing construction projects to meet the demand of diverse industries also generates waste that need to be managed. Construction and remediation activities generate significant amounts of construction waste, which accounts for a substantial portion of man-made waste (Wu et al., 2023a). The improper disposal of this waste has significant adverse effects on the environment and society and causes great concern among professionals. Construction and demolition waste (CDW) are a significant waste stream (Tanash et al., 2023). In many regions of the world, CDW accounts for about 50% of landfilled waste. In the U.S. and Europe, municipal waste management has resulted in recycling rates of 70% and 90%, respectively (Villoria Sáez and Osmani, 2019). However, in many countries, municipal waste management has failed, and recycling rates are below 10% (Hoang et al., 2020; Nunes and Mahler, 2020). In relation to that, ceramic waste which is among the waste derived from construction and demolition activities, when disposed of at dumpsites, causes environmental pollution. Ceramic products are an essential part of the building fabric used in most structures. Clay, silica, metal oxides, carbides, and other earthy elements are the principal constituents of ceramics (Mustafi et al., 2011; Pacheco-Torgal and Jalali, 2010; Subedi, 2013). Floor tiles, wall tiles, sanitary ware and household ceramics are all examples of commonly manufactured ceramics (Awoyera et al., 2018; Juan et al., 2010; Monfort et al., 2014). In 2019, the world production size of ceramic tile was about 12.6 billion m2 (insights, 2021), which increased to 18.2 billion m2 in 2021 (Pompo, 2021). It has been predicted that up to 30% of all ceramic production will go to waste (Agrawal et al., 2020; Mohit et al., 2021; Tan et al., 2011; Umar et al., 2021). Although some of this waste can be recycled on site (e.g., to fill excavation pits), the vast majority is disposed of in disorganized piles and landfills (Horňáková et al., 2020; Lu et al., 2020; Raval et al., 2013). It has been predicted that more than 45% of CDW arinsights, 2021e ceramic (Reig et al., 2013; Zimbili et al., 2014). Ceramic materials are inherently brittle, so handling and fixing them at construction sites produces fragments that become waste. A considerable amount of CTW is generated from demolition material and production defects every year (Pitarch et al., 2021b). Fig. 1 shows the source of ceramic tile waste, mainly from the production phase, construction, and demolition phases. Additionally, throwing of CTW in landfills can lead to contamination of soil, air, and groundwater (Aly et al., 2018; Kanaan and EL-Dieb, 2016; Tabak et al., 2012). The undesirable negative effects of CTW on the environment have been pointed out by previous researchers (Bignozzi and Saccani, 2012; El-Dieb et al., 2018; Pitarch et al., 2021b). The fact that CTW is not decomposable has led to long-term problems such as illegal dumping, environmental pollution and health problems. Hence, it is necessary to explore effective management for CTW in order to avoid environmental problems that may arise from the improper disposal of CTW (Ray et al., 2021c; Singh and Srivastava, 2018; Suzuki et al., 2009). The environmental impact of cement and CTW can be minimized by reusing this waste in concrete, which is a fascinating and sustainable green solution. The approach of diverting the CTW from the dumpsite and channelling it for concrete production positively in line with circular economy that contributes towards saving space of the precious land for better use rather than waste disposal area and reduce the hassle of waste management by the building industry. Sustainable building materials that use CTW might cut down on construction expenses, energy usage, and pollution, all while reducing the amount of raw resources needed (Matias et al., 2014; Pacheco-Torgal and Jalali, 2010).

Fig. 1. Source of ceramic tile waste.

Fig. 1. Source of ceramic tile waste.The objective of this paper is to provide a comprehensive review of research published in various peer-reviewed sources on the extensive use of ceramic tile waste (CTW) as a substitute for natural aggregates (coarse and fine) and cement in cement-based composites. This paper provides a concise summary of a wide range of literature on the use of CTW. The literature addresses, among other topics, the evaluation of mechanical properties and durability, as well as microstructural characteristics. This review also provides a brief analysis of reported conflicting results. Therefore, this discussion focuses on the general trends, the impact of integrating CTW on various properties of concrete and mortar, potential areas for future research, and claims related to these factors in light of current developments. The goal is to promote the widespread use of CTW in the upcoming construction sector.

2. Keywords co-occurrence analysis.

1.1. Methodology

For bibliometric analysis, two databases are mainly recognized: Web of Science (WoS) and Scopus. In this study, the Scopus database was selected because it provides a broader content of summaries and citations of literature searches, mainly focused on scientific and technical disciplines. This database allows measuring the influence of research, among other research results, and establishing a relationship between fields. The documents that were found using search query are listed in Table 1. Quarry 1 means the use of ceramic waste in the cementitious composite, while Quarry 2 means the use of ceramic waste as a substitute for cement in the cementitious composite. The preliminary phase consisted in collecting the data in different steps. In order to create an appropriate framework for the study, representative keywords were chosen that formed two queries. Data refining techniques were used to eliminate unnecessary records. Table 2 shows the numerous choices made during the data retrieval from Scopus. The articles that were produced after applying these restrictions (as illustrated in Table 2) were then saved in comma-separated values (CSV) files for analysis.

Table 1. Several resulting data from database search (Scopus) as of (2003-end of September 2023).

| Query number | Article results | Article results after employing limits |

|---|---|---|

| 1 | 1064 | 640 |

| 2 | 302 | 162 |

Table 2. limits/filters used when obtaining data from the Scopus database.

| Option | Limits applied |

|---|---|

| Type of document | Article |

| Review | |

| Language | English |

| Source type | Journal |

| Subject area | Engineering |

| Material science | |

| Environmental science | |

| Years | 2003–2023 |

The VOS viewer (version: 1.6.19) was used to examine the data that had been gathered in more detail. Researchers strongly advise using the open-source software application VOS viewer, which is widely used in a variety of domains (Goulden et al., 2017; Van Eck and Waltman, 2010; Yang et al., 2022). The retrieved CSV files were imported into the VOS viewer, which analysed them in phases while guaranteeing the homogeneity and consistency of the data. During the VOS viewer evaluation, co-occurrence of keywords was examined.

1.2. Yearly publication trend

The annual publication trend for the searched keywords is shown in Fig. 2. The earliest article found is from 2000, and only 68 articles were published until 2013. Thereafter, the total number of publications increased slowly but steadily, reaching a total of 20 publications in 2013. However, from 2014 to September −2023, the number of publications increased significantly and reached 640. Regarding the utilize of ceramic waste as a cement substitute, the earliest article found is from 2007, and only 8 articles were published by 2015. After that, the total number of publications increased slowly but steadily, reaching a total of 34 publications in 2017. However, from 2017 to September −2023, the number of publications increased significantly and reached 162. It is interesting to note that recently, research has focused more on ceramic waste in concrete, one of the components of concrete. These findings suggested researchers are becoming more enthusiastic about green practices in the construction industry.

Fig. 2. Annual publication trend in the use of ceramic waste in concrete (2003-end of September 2023).

Fig. 2. Annual publication trend in the use of ceramic waste in concrete (2003-end of September 2023).1.3. Keywords co-occurrence of ceramic waste in concrete

Keywords are essential research instruments because they identify and denote the crucial subjects of a field of study. The VOS viewer analysis revealed that the five most frequently occurring keywords are compressive strength, ceramic materials, ceramic waste, aggregates, and recycling. Fig. 3 Displays the global map of the co-occurrence of the keywords used by the authors in query 1 (ceramic waste in concrete). Only terms with at least 30 occurrences are considered; 49 terms meet this criterion. The co-occurrence visualization in Fig. 3 shows keyword maps, their links, and the density associated with their co-occurrence. The size of the frame of a keyword in Fig. 3 represents the frequency of its occurrence, while its position represents the frequency of its occurrence with another term. It was found 16 keywords in cluster 1 (red), 15 keywords in cluster 2 (green), 11 keywords in cluster 3 (blue), and 7 keywords in cluster 4 (yellow). The first cluster refers to the use of ceramic waste as a binder in various types of concrete. Key terms in this cluster include "compressive strength," "ceramic waste," "Portland cement," "fly ash," and "slags". The second cluster could refer to the use of ceramic waste as an aggregate of concrete. This cluster contains expressions such as "ceramic materials," "recycled," "concrete," "aggregates," and "recycled aggregates”. The third cluster could refer to the various mechanical and durability properties of concrete. This cluster includes terms such as “concrete aggregate”, “water absorption”, “mechanical properties”, “durability” and “tensile strength”. Since sustainability comprises a smaller group of keywords, it is considered as one cluster, yellow coloured. In this case, cluster #4 has two closely tied keywords “sustainable development”, “sustainability”.

Fig. 3. Literature network of authors co-occurrence keywords for the utilize of ceramic waste in concrete (Network visualization).

Fig. 3. Literature network of authors co-occurrence keywords for the utilize of ceramic waste in concrete (Network visualization).Fig. 4 shows the world map of authors who used the same keywords in response to query 2 (ceramic powder in concrete). 41 terms meet the threshold for inclusion, which is set at 10 occurrences each. There were 17 keywords in group 1 (red), 10 in group 2 (green), 9 in group 3 (blue) and 5 in group 4 (yellow). In the first group, represented here by the colour red (Group 1), the terms "compressive strength", "ceramic," and "ceramic powder" predominate. Group 2, in green, includes terms such as "fly ash," "slags," "Portland cement," and "concrete," indicating a focus on the utilize of ceramic powder as a replacement for binders in a variety of concrete types. Terms such as "powder," "ceramic waste powder," and "mortar" appear in blue Group No. 3.Finally, the terms "ceramic materials", "durability" and "concrete" are appearing in the yellow group.

Fig. 4. Literature network of authors co-occurrence keywords for the utilize of ceramic powder in concrete (Network visualization).

Fig. 4. Literature network of authors co-occurrence keywords for the utilize of ceramic powder in concrete (Network visualization).2. Ceramic tile waste as aggregate replacement

2.1. Physical properties of ceramic waste aggregates

The physical, mechanical, and chemical properties of CTA play a critical role in increasing the strength and durability of concrete. The properties of the above materials are listed in Table 3. Compared to natural coarse aggregate (NCA), CTA have a lower bulk density and specific gravity. The CTA had a lower density compared to NCA and its porosity was greater, resulting in increased water absorption compared to NCA. As seen in the table, the bulk densities of the coarse CTA were within the range of 1280–1920 kg/m3 specified by the American Concrete Institute (ACI) for standard aggregates. The water absorption of CTA varies from 0.55% to 14.4%, and the porous nature of the CTA is the cause of the significant water absorption. The water absorption of CTA is higher than that of most NCA, i.e., less than 2% (Neville and Brooks, 1987). However, it had a lower absorption capacity compared to alternative waste materials. The differences in the physical properties of CTA are mainly due to the different firing temperatures and the different compositions of the tiles (Elçi, 2016).The angular shape of CTA is recognizable (as seen in Fig. 5), and its surface texture was found to be rougher compared to NCA. The observed cracks are a result of the crushing process (Sua-iam and Jamnam, 2023; Torkittikul and Chaipanich, 2010). As shown in Fig. 7, pores can be easily identified in both wall and floor tile aggregates, with the pore size of wall tile aggregates being significantly larger than that of floor tile aggregates (see Fig. 8) (see Fig. 6).

Table 3. The physical properties of CTA.

Fig. 5. The SEM image of fine CTA and natural sand. Adapted from (Meena et al., 2022d).

Fig. 5. The SEM image of fine CTA and natural sand. Adapted from (Meena et al., 2022d). Fig. 6. SEM results of coarse CTA. (Adapted from (Li, et al., 2023)).

Fig. 6. SEM results of coarse CTA. (Adapted from (Li, et al., 2023)). Fig. 7. The effect of CTA as a substitute for fine or coarse aggregates on the workability of cement-based composite. (Adapted from (Alves et al., 2014; Daniel and Sangeetha, 2021; Giridhar et al., 2015; Paul et al., 2023; Pitarch et al., 2019; Rashid et al., 2017; Roig-Flores et al., 2023; Sharba, 2020; Sivakumar et al., 2022; Torkittikul and Chaipanich, 2010)).

Fig. 7. The effect of CTA as a substitute for fine or coarse aggregates on the workability of cement-based composite. (Adapted from (Alves et al., 2014; Daniel and Sangeetha, 2021; Giridhar et al., 2015; Paul et al., 2023; Pitarch et al., 2019; Rashid et al., 2017; Roig-Flores et al., 2023; Sharba, 2020; Sivakumar et al., 2022; Torkittikul and Chaipanich, 2010)). Fig. 8. The effect of CTA as a substitute for coarse aggregates on the compressive strength of cement-based composite (Adapted from (Awoyera et al., 2018; Daniel and Sangeetha, 2021; Daniyal and Ahmad, 2015; Goyal et al., 2022; Meena et al., 2022a; Mohammed and Ahmed, 2020; Pitarch et al., 2019; Rashid et al., 2017; Roig-Flores et al., 2023; Sekar, 2017; Sivakumar et al., 2022a; Sua-iam and Jamnam, 2023; Subedi et al., 2020; Varma and Pravalli, 2022; Xu et al., 2022a; Zareei et al., 2019a; Zhang et al., 2023)).

Fig. 8. The effect of CTA as a substitute for coarse aggregates on the compressive strength of cement-based composite (Adapted from (Awoyera et al., 2018; Daniel and Sangeetha, 2021; Daniyal and Ahmad, 2015; Goyal et al., 2022; Meena et al., 2022a; Mohammed and Ahmed, 2020; Pitarch et al., 2019; Rashid et al., 2017; Roig-Flores et al., 2023; Sekar, 2017; Sivakumar et al., 2022a; Sua-iam and Jamnam, 2023; Subedi et al., 2020; Varma and Pravalli, 2022; Xu et al., 2022a; Zareei et al., 2019a; Zhang et al., 2023)).2.2. Workability

Fig. 7 shows the effect of CTA as coarse and fine aggregate on the workability of cement-based composite material.In general, the workability of cement-based composite with CTA decreases when the proportion of CTA substituting for natural aggregate (NA) increases (Al Bakri et al., 2013; Anderson et al., 2016; Awoyera et al., 2016; Awoyera et al., 2021; Azmi et al., 2017; Gharibi and Mostofinejad, 2023; Giridhar et al., 2015; Gour et al., 2022; Hilal et al., 2020; Jackiewicz-Rek et al., 2015; Johnson Daniel and Sangeetha, 2021; Martínez-Lage et al., 2012; Medina et al., 2012; Vilas Meena et al., 2022e; Mohammadhosseini et al., 2020a; Ramirez et al., 2023; Rashid et al., 2017; Ray et al., 2021a; Sivakumar et al., 2022a; Sua-iam and Jamnam, 2023; Tassew and Lubell, 2014; Torkittikul and Chaipanich, 2010; Yiosese et al., 2018; Zareei et al., 2019b; Zhang et al., 2023). The deterioration in workability can be attributed to the greater roughness and irregular shape of the CTA surface compared to NA. The workability of cement-based composites is reduced due to the interlocking of the CTA because of the increased frictional resistance (Meena et al., 2022d; Mohammadhosseini et al., 2020a; Torkittikul and Chaipanich, 2010; Zhang et al., 2023).In addition, the porous nature of CTA increases the ability of the mixture to absorb water (Anderson et al., 2016; Awoyera et al., 2021; Hilal et al., 2020; Zareei et al., 2019b; Zhang et al., 2023). According to Alves et al. (2014), increasing the water-cement ratio is an effective way to overcome the decrease in workability. In addition, the adverse effects on the workability of the cement-based composite can be mitigated by pre-soaking CTA with some of the appropriate water, thereby achieving saturation of CTA (Paul et al., 2023; Roig-Flores et al., 2023).

2.3. Fresh and dry densities

The collective results of several studies have revealed a consensus regarding the effects of increasing CTA content on the density of cement-based composites. It was found that with increasing CTA replacement, there is a corresponding linear decrease in fresh and dry density (Daniyal and Ahmad, 2015; Elçi, 2016; Gharibi and Mostofinejad, 2023; Hilal et al., 2020; Pitarch et al., 2019; Poon and Chan, 2007; Sharba, 2020; Subedi et al., 2020; Tabak et al., 2012; Zareei et al., 2019a). Density decreases as the substitution ratio of NA to CTA increases. This can be explained by the lower density of CTA compared to NA. In addition, the uneven and rough shape of CTA leads to a higher percentage of voids (Hilal et al., 2020; Kumar Goyal et al., 2022). A literature search showed a reduction in fresh density of 14%–20% when comparing CTA blends to a control blend (Elçi, 2016; Hilal et al., 2020). Similarly, when neutral coarse aggregate (NCA) is completely replaced by the coarse CTA, the dry density experiences a reduction from 2260 kg/m3 (for 0% replacement) to 1670 kg/m3 (Elçi, 2016). In addition, other studies reported a decreasing trend in dry density of cement-based composites when replaced by CTA (Goyal et al., 2022; Ikponmwosa and Ehikhuenmen, 2017; Poon and Chan, 2007).

2.4. Compressive strength

In studies using concrete with CTA, compressive strength was the most important mechanical behaviour investigated. The compressive strength of concrete often comparable or increase when coarse CTA are included (Anderson et al., 2016; Awoyera et al., 2018; Daniyal and Ahmad, 2015; Goyal et al., 2022; Manikandan et al., 2023; Rashid et al., 2017; Roig-Flores et al., 2023; Subedi et al., 2020; Varma and Pravalli, 2022; Xu et al., 2022a; Yiosese et al., 2018). Fig. 10illustrates the change in 28-day compressive strength of concrete including CTA as NCA replacement. Several studies have shown that the use of coarse CTA as a replacement for NCA in the range of 5%–30% results in a significant improvement in compressive strength from 5% to 25% (Awoyera et al., 2018; Daniyal and Ahmad, 2015; Goyal et al., 2022; Rashid et al., 2017; Subedi et al., 2020; Varma and Pravalli, 2022; Zareei et al., 2019a). The observed increase in 28 days compressive strength can be attributed to the irregular morphology and coarse texture of CTA, which allows more effective interlocking between the aggregates and the hardened cement paste (Awoyera et al., 2018; Zareei et al., 2019a). In addition, it should be noted that CTA, as a permeable substance, provides a moist environment for the hydration process of the cement paste. This property leads to a reduction in autogenous shrinkage, which ultimately leads to an increase in the compressive strength of the cement-based composite (Rashid et al., 2017; Suzuki et al., 2009a; Xu et al., 2022a; Yiosese et al., 2018).

Similarly, the optimal use of fine CTA increases the 28-day compressive strength of the cement-based composite. Fig. 9 illustrates the change in 28-day compressive strength of concrete including fine CTA as a function of the proportion of aggregate replaced. The use of fine CTA as a substitute for natural fine aggregate (NFA) at levels up to 60% generally results in higher compressive strength compared to conventional concrete, with compressive strength increasing by 5–30% after 28 days (Abadou et al., 2016; Guendouz and Boukhelkhal, 2019; Meena et al., 2022a, 2022d; Zhang et al., 2023). It could be that the increased compressive strength of cement-based composites with CTA is due to the irregular shape and rough surface of the particles (Gharibi and Mostofinejad, 2023; Vilas Meena et al., 2022b; Meena et al., 2022d). Another reason for the increase in compressive strength is the presence of water in the fine CTA. This allows sufficient hydration of the cement by internal curing, which leads to improved hydration of the cement and thus to better properties of the cement-based composite (Gonzalez-Corominas and Etxeberria, 2014; Suzuki et al., 2009; Zhang et al., 2023). The improvement in compressive strength can be attributed in part to the pozzolanic properties of fine CTA (Awoyera et al., 2021; Manikandan et al., 2023; Vilas Meena et al., 2022b). In addition, the mixture with fine CTA was better compacted due to the uniform particle size distribution and high content of very fine CTA particles, which improved particle packing (Evangelista et al., 2019b; Vilas Meena et al., 2022b; Vilas Meena et al., 2022e).

Fig. 9. The effect of CTA as a substitute for fine aggregates on the 28 days compressive strength of cement-based composite (Adapted from (Ambrose et al., 2023; Awoyera et al., 2018; Daniel and Sangeetha, 2021; Evangelista et al., 2019a; Gonzalez-Corominas and Etxeberria, 2014; Koech, 2017; Manikandan et al., 2023; Meena et al., 2022a; Meena et al., 2022c, d; Yahya et al., 2020; Zhang et al., 2023)).

Fig. 9. The effect of CTA as a substitute for fine aggregates on the 28 days compressive strength of cement-based composite (Adapted from (Ambrose et al., 2023; Awoyera et al., 2018; Daniel and Sangeetha, 2021; Evangelista et al., 2019a; Gonzalez-Corominas and Etxeberria, 2014; Koech, 2017; Manikandan et al., 2023; Meena et al., 2022a; Meena et al., 2022c, d; Yahya et al., 2020; Zhang et al., 2023)). Fig. 10. The effect of CTA as a substitute for coarse aggregates on the splitting tensile strength of cement-based composite. (Adapted from (Anderson et al., 2016; Arun and Ramaswamy, 2016; Awoyera et al., 2018; Bommisetty et al., 2019; Goyal et al., 2022; Hilal et al., 2020; Jagadeesh and Reddy, 2017; Kamala and Rao, 2012; Mohammed and Ahmed, 2020; Paul et al., 2023; Sivakumar et al., 2022a; Subedi et al., 2020; Verendra and Brunda, 2020; Younis et al., 2022; Zareei et al., 2019a)).

Fig. 10. The effect of CTA as a substitute for coarse aggregates on the splitting tensile strength of cement-based composite. (Adapted from (Anderson et al., 2016; Arun and Ramaswamy, 2016; Awoyera et al., 2018; Bommisetty et al., 2019; Goyal et al., 2022; Hilal et al., 2020; Jagadeesh and Reddy, 2017; Kamala and Rao, 2012; Mohammed and Ahmed, 2020; Paul et al., 2023; Sivakumar et al., 2022a; Subedi et al., 2020; Verendra and Brunda, 2020; Younis et al., 2022; Zareei et al., 2019a)).2.5. Splitting tensile strength

The change in 28-day splitting tensile strength of concrete with coarse CTA, as a function of the proportion of replaced aggregates, is shown in Fig. 10. Replacement of NCA with coarse CTA in the range of 5%–40% often results in higher 28-day splitting tensile strength compared to conventional concrete, with increases ranging from 3% to 21%.This increase in 28-day splitting tensile strength could be related to the same factors that influence the increase in compressive strength: 1) irregular morphology and coarse texture of CTA 2) CTA is a permeable substance that provides a moist environment. In addition, This may be attributed to the fact that incorporating coarse CTA refines the pore system, resulting in an increase in the volume of capillary pores and a decrease in the volume of macropores (Awoyera et al., 2018; Medina et al., 2012). On the other hand, the splitting tensile strength shows a comparable or slightly lower with an increasing replacement ratio of more than 50% (Anderson et al., 2016; Mohammed and Ahmed, 2020).

On the other hand, The change in 28-day splitting tensile strength of concrete with fine CTA, as a function of the proportion of replaced NFA, is shown in Fig. 11 several studies in the literature have documented a remarkable improvement in splitting tensile strength when CTA is incorporated as a fine aggregate (Awoyera et al., 2018; Boopathi, 2023; Meena et al., 2022a; Meena et al., 2022d; Ray et al., 2021a; Shareef et al., 2023). Several studies show that the use of 60% CTA as a substitute for NFA results in a significant increase in compressive strength, ranging from 5% to 30% (Boopathi, 2023; Vilas Meena et al., 2022b; Meena et al., 2022d). With increasing fine CTA content, the strength increase during the curing time also increases. It was found that the splitting tensile strength increased by up to 30% when 50% of the NFA was replaced by fine CTA (Awoyera et al., 2018; Boopathi, 2023; Evangelista et al., 2019b; Ray et al., 2021a). The optimum replacement level of NFA by CTA was found to be in the range of 20–60%, further than the compressive strength reduces gradually (Awoyera et al., 2018; Boopathi, 2023; Evangelista et al., 2019b; Vilas Meena et al., 2022b; Meena et al., 2022d; Ray et al., 2021c).It is worth mentioning that the fine CTA has a higher fineness modulus than the (NFA). This leads to a densification of the mixture and to a reduction of the macropores, ensuring a sufficient strength development.

Fig. 11. The effect of CTA as a substitute for fine aggregates on the splitting tensile strength of cement-based composite. (Adapted from (Awoyera et al., 2018; Awoyera et al., 2018; Boopathi, 2023; Evangelista et al., 2019a; Gonzalez-Corominas and Etxeberria, 2014; Meena et al., 2022a; Meena et al., 2022d; Ray et al., 2021c; Shareef et al., 2023)).

Fig. 11. The effect of CTA as a substitute for fine aggregates on the splitting tensile strength of cement-based composite. (Adapted from (Awoyera et al., 2018; Awoyera et al., 2018; Boopathi, 2023; Evangelista et al., 2019a; Gonzalez-Corominas and Etxeberria, 2014; Meena et al., 2022a; Meena et al., 2022d; Ray et al., 2021c; Shareef et al., 2023)).2.6. Flexural strength

The change in 28-day flexural strength of concrete with coarse CTA, as a function of the proportion of CTA, is shown in Fig. 12. Several studies have reported that the use of CTA as a 20% replacement for NCA has comparable or even higher flexural strength compared to conventional concrete (Agrawal et al., 2020; Anderson et al., 2016; Bommisetty et al., 2019; Chandel and Goyal, 2022; Goyal et al., 2022; Kamala and Rao, 2012; Mohammed and Ahmed, 2020; Sivakumar et al., 2022; Varma and Pravalli, 2022). In addition, it is found that the flexural strength to compressive strength ratio of ultra-high-performance concrete (UHPC) with CTA shows an increasing trend with increasing curing age. This indicates that the flexural strength of UHPC with CTA increases faster compared to its compressive strength. Consequently, the toughness of the material also increases steadily with time. When the CTA content is 80%, the ratio of flexural strength to compressive strength reaches a maximum value of 0.143, which corresponds to an increase of 20% compared to the control group (Zhang et al., 2023). The ratio of flexural strength to compressive strength increases progressively with increasing CTA content. This observation shows that CTA has a more favourable effect on flexural strength compared to compressive strength.

Fig. 12. The effect of CTA as a substitute for coarse aggregates on the 28 days flexural strength of cement-based composite (Adapted from (Anderson et al., 2016; Bommisetty et al., 2019; Chandel and Goyal, 2022; Goyal et al., 2022; Kamala and Rao, 2012; Mohammed and Ahmed, 2020; Rajprasad et al., 2020; Rinu isah, 2017; Sivakumar et al., 2022; Sua-iam and Jamnam, 2023a; Talaeitaba and Dehghani, 2023; Varma and Pravalli, 2022; Verendra and Brunda, 2020)).

Fig. 12. The effect of CTA as a substitute for coarse aggregates on the 28 days flexural strength of cement-based composite (Adapted from (Anderson et al., 2016; Bommisetty et al., 2019; Chandel and Goyal, 2022; Goyal et al., 2022; Kamala and Rao, 2012; Mohammed and Ahmed, 2020; Rajprasad et al., 2020; Rinu isah, 2017; Sivakumar et al., 2022; Sua-iam and Jamnam, 2023a; Talaeitaba and Dehghani, 2023; Varma and Pravalli, 2022; Verendra and Brunda, 2020)).Similarly, concrete containing fine CTA particles often exhibit better flexural strength after a 28-day curing period than concrete composed of natural fine aggregates. Fig. 13 shows the change in 28-day flexural strength of concrete with fine CTA as a function of the extent of NCA substitution. Replacing NFA with fine CTA in a proportion of 10%–60% typically leads to a boost in flexural strength when compared to standard concrete, resulting in an increase ranging from 14.2% to 45% (Boopathi, 2023; Guendouz and Boukhelkhal, 2019; Meena et al., 2022a; Meena et al., 2022d; Zhang et al., 2023).

Fig. 13. The effect of CTA as a substitute for fine aggregates on the flexural strength of cement-based composite (Adapted from (Abadou et al., 2016; Agrawal et al., 2020; Boopathi, 2023; Gautam et al., 2022a; Guendouz and Boukhelkhal, 2019; Meena et al., 2022a; Meena et al., 2022d; Shareef et al., 2023; Sivakumar et al., 2022; Yahya et al., 2020; Zhang et al., 2023)).

Fig. 13. The effect of CTA as a substitute for fine aggregates on the flexural strength of cement-based composite (Adapted from (Abadou et al., 2016; Agrawal et al., 2020; Boopathi, 2023; Gautam et al., 2022a; Guendouz and Boukhelkhal, 2019; Meena et al., 2022a; Meena et al., 2022d; Shareef et al., 2023; Sivakumar et al., 2022; Yahya et al., 2020; Zhang et al., 2023)).2.7. Modulus of elasticity

The substitution of natural coarse aggregates by CTA has a significant effect on the elastic behaviour of cement-based composites. Fig. 14 illustrates the relationship between the percentage of aggregate replaced and the corresponding change in the 28-day modulus of elasticity of concrete with coarse CTA. In general, the elastic modulus of concrete containing CTA increases with increasing CTA content. The complete replacement of natural coarse aggregates by CTA leads to a noticeable increase in the modulus of elasticity in concrete mixtures containing CTA (Anderson et al., 2016b; Meillyta et al., 2023; Younis et al., 2022). The modulus of elasticity shows an increase of up to 26.9% compared to the control concrete, with a total replacement of 100% (Anderson et al., 2016b). The significant rise in the modulus of elasticity can be ascribed to the elevated angular morphology and textured surface of CTA in comparison to natural coarse aggregate. This increase is proportional to the replacement ratio of the aggregate, indicating a clear correlation between the modulus of elasticity and the proportion of angular aggregate (Anderson et al., 2016b). On the contrary, alternative studies have shown that the use of coarse CTA as a substitute for NCA leads to a reduction in the elastic modulus of cement-based composites (Al-Azzawi and Al-Azzawi, 2020; Li et al., 2023a; Mohan et al., 2018; Peter et al., 2020; Tahwia, 2017). The observed discrepancies in the results of the different studies can be attributed to the different physical properties of the CTA used.

Fig. 14. The effect of CTA as a substitute for NCA on the Modulus of elasticity of cement-based composite (Adapted from (Anderson et al., 2016; Li et al., 2023; Meillyta et al., 2023; Mohan et al., 2018; Peter et al., 2020; Sua-iam and Jamnam, 2023a; Younis et al., 2022)).

Fig. 14. The effect of CTA as a substitute for NCA on the Modulus of elasticity of cement-based composite (Adapted from (Anderson et al., 2016; Li et al., 2023; Meillyta et al., 2023; Mohan et al., 2018; Peter et al., 2020; Sua-iam and Jamnam, 2023a; Younis et al., 2022)).3. Durability-related properties of CTA concrete

3.1. Water absorption

In this section, the water absorption properties of CTA-based cementitious composites are explained since the water absorption properties of concrete play a crucial role in determining its overall quality and strength. In several experiments it was found that increasing the proportion of CTA in the concrete increases the water absorption capacity of the concrete (Elçi, 2016; Hilal et al., 2020; Keshavarz and Mostofinejad, 2019a; Kumar Goyal et al., 2022; Paul et al., 2023; Subathra Devi et al., 2017). Using CTA as NCA replacement in concrete has been shown to dramatically increase absorption and porosity. Paul et al. (2023)reported that the absorption increases by approximately 130, 142, 150, 174, and 221% in concrete with CTA contents of 10, 20, 30, 50, and 100%, respectively, compared to the reference concrete after 28 days. The increased absorption coefficient of CTA can be attributed to its better absorption capacity compared to NCA. In addition, the increased percentage of voids in mixtures containing CTA serves as an empty vessel, which improves the ability of these mixtures to absorb a greater amount of water (Hilal et al., 2020). It is worth noting that, according to a study carried out by Amin et al. (2020), the use of mineral admixtures to replace cement effectively reduces the water absorption of ultra-high performance concrete made with coarse CTA. Furthermore, the capillary absorption of concretes made with coarse CTA showed significantly higher values compared to conventional concretes (Arun and Ramaswamy, 2016; Gonzalez-Corominas and Etxeberria, 2014). This increment is probably due to the improved interconnection of the pores in each grain of the coarse-grained aggregate mixture. On the other hand, other researchers have noted a gradual decrease in water absorption as the coarse CTA content increases, with a slight increase when the course CTA replacement level exceeds a certain threshold (Amin et al., 2021a; Nataraja et al., 2022; Roig-Flores et al., 2023; Sua-iam and Jamnam, 2023; Younis et al., 2022).Samples mixed with well-graded CTA increase filling capacity, reducing water absorption (Sivakumar et al., 2022a). Furthermore, the porous nature of CTA means that it maintains a high level of internal moisture, which in turn promotes gel formation and subsequent pore sealing (Younis et al., 2022).Therefore, the admixture of CTA as a substitute for NCA in concrete can lead to two different effects on the permeability of the cement-based composite. Fig. 15 shows the effect of CTA as a substitute for coarse aggregates on the water absorption of various types of cement-based composites.

Fig. 15. The effect of CTA as a substitute for NCA on the water absorption of various types of cement-based composites a) Normal concrete (Adapted from (Keshavarz and Mostofinejad, 2019a)) b) Self curing high performance concrete (Adapted from (Amin et al., 2021)) c)self-curing normal concrete (Adapted from (Younis et al., 2022)) d) self-compacting concrete (Adapted from (Sua-iam and Jamnam, 2023)).

Fig. 15. The effect of CTA as a substitute for NCA on the water absorption of various types of cement-based composites a) Normal concrete (Adapted from (Keshavarz and Mostofinejad, 2019a)) b) Self curing high performance concrete (Adapted from (Amin et al., 2021)) c)self-curing normal concrete (Adapted from (Younis et al., 2022)) d) self-compacting concrete (Adapted from (Sua-iam and Jamnam, 2023)).The water absorption decreases with an increased inclusion of fine CTA as a substitute for NFA until certain threshold (Boopathi, 2023; Gautam et al., 2022b; Kherraf et al., 2022; Vilas Meena et al., 2022b; Nayana. and Rakesh, 2018). In another research, Meena et al. (2022c) reported that the use of up to 60% fine CTA resulted in lower water absorption compared with other substitutes. The results indicate a decrease in water absorption to less than 2%. A similar result was observed by Boopathi (2023), the results showed that using 50% of fine CTA reduced the water absorption of self-compacting concrete to 1.9%, and further increasing the replacement ratio slightly increased the water absorption. Other researchers found that the use of up to 20% fine CTA as NFA reduced the water absorption of various cement-based composites and increased at higher replacement ratios. This could be due to the presence of tiny CTA particles has been seen to refine the pore size, leading in a drop in the water-to-cement ratio (w/c ratio). This reduction in w/c ratio subsequently leads to a decrease in both permeability and the thickness of the interfacial transition zone (Gautam et al., 2022b; Vilas Meena et al., 2022b). In contrast, other studies have shown that the use of fine CTA enhances the water absorption of cement-based composites (Ajamul et al., 2018; Azmi et al., 2017; Guendouz and Boukhelkhal, 2019; Ramirez et al., 2023; Yahya et al., 2020). The porosity of cement-based composites is shown to increase, mostly because to the porous nature of CTA and the higher absorption capacity of CTA in comparison to NFA (Guendouz and Boukhelkhal, 2019).It can be concluded that the use of fine CTA as a substitute for NFA in cement-based composites may have two opposing influences on water absorption. Therefore, the impact of CTA on the water absorption of concrete depends on the prevalence of one effect over the other. Fig. 16 shows the effect of CTA as a substitute for fine aggregates on the water absorption of various types of cement-based composites.

Fig. 16. The effect of CTA as a substitute for fine aggregates on the water absorption of various types of cement-based composites a) Mortar (Adapted from (Kherraf et al., 2022)) b) Flowable sand concrete (Adapted from (Guendouz and Boukhelkhal, 2019)) c) Normal concrete (Adapted from (Yahya et al., 2020)) d) self-compacting concrete (Adapted from (Meena et al., 2022a)).

Fig. 16. The effect of CTA as a substitute for fine aggregates on the water absorption of various types of cement-based composites a) Mortar (Adapted from (Kherraf et al., 2022)) b) Flowable sand concrete (Adapted from (Guendouz and Boukhelkhal, 2019)) c) Normal concrete (Adapted from (Yahya et al., 2020)) d) self-compacting concrete (Adapted from (Meena et al., 2022a)).3.2. Chloride diffusion

The durability of concrete structures is significantly affected by chloride-induced reinforcement corrosion. The chloride penetration resistance of concrete with coarse CTA is comparatively inferior to that of concrete with NCA (Gonzalez-Corominas and Etxeberria, 2014; Xu et al., 2023; Yasin Mousavi et al., 2020). The increase in CTA content leads to an increase in both the 'depth of critical chloride content' and the apparent chloride diffusion coefficient (Xu et al., 2023; Yasin Mousavi et al., 2020).However, it is worthy to mention that the chloride ion passed charges fall within low to moderate range as specified per ASTM. Xu et al. (2023) results indicate a significant increase in the transferred charge of the samples when coarse CTA is used as a substitute for NCA, by 10%, 20%, and 30%, with respective increases of 18.2%, 26.8%, and 53.2%.The observed phenomenon can be attributed to the increased permeability of the concrete due to high porosity coarse CTA (Xu et al., 2023; Yasin Mousavi et al., 2020). However, recent research has shown that supplementary cementitious materials (SCM)can mitigate the reduction in chloride ion resistance that results from replacing NCA with coarse CTA(Ngoc-Tra Lam et al., 2023). This observation could be attributed to the use of SCM, which led to a refinement of the pore structure of the concrete.On the other hand, alternative studies have shown that the substitution of NCA by coarse CTA leads to a reduction in chloride ion penetration (Amin et al., 2021a; Arun and Ramaswamy, 2016; Sivakumar et al., 2022a; Sundo et al., 2015). The observed phenomenon can be attributed to the use of coarse CTA under conditions characterized by a saturated and dried surface, which mitigates the adverse consequences of the pronounced water absorption properties of CTA. Furthermore, the reduced permeability to chloride ions may be associated with the high-water absorption of coarse CTA, which is enhanced by the retention of water required for the ongoing rehydration process. The addition of CTA helps maintain a high internal moisture content, which facilitates the completion of hydration processes and allows for the continued formation of gel and subsequent pore closure (Amin et al., 2021). Fig. 17 shows the charge passed through concrete with different replacement ratios with coarse CTA.

Fig. 17. The charge passed through concrete with different replacement ratios with coarse CTA (Adapted from (Amin et al., 2021a; Arun and Ramaswamy, 2016; Sivakumar et al., 2022a; Xu et al., 2023)).

Fig. 17. The charge passed through concrete with different replacement ratios with coarse CTA (Adapted from (Amin et al., 2021a; Arun and Ramaswamy, 2016; Sivakumar et al., 2022a; Xu et al., 2023)).The use of fine CTA as a replacement for NFA gives good results in terms of resistance to chloride ion penetration. In general, the diffusion coefficient of chloride ions decreases as the proportion of fine CTA as a fine aggregate in the concrete increases up to a certain threshold (Binici, 2007; Gonzalez-Corominas and Etxeberria, 2014; Mohammadhosseini et al., 2020a; Packrisamy and Jayakumar, 2022; Sundo et al., 2015). The 'depth to critical chloride content' and the apparent chloride diffusion coefficient are both reduced by an increase in fine CTA level (as shown in Fig. 20) (Packrisamy and Jayakumar, 2022; Sundo et al., 2015). The observed phenomenon can be attributed to the presence of adsorbed water in CTA may have contributed to increased hydration of the cement particles near the aggregates. This in turn could have led to the formation of a compact microstructure, reducing the permeability to chloride ions (Packrisamy and Jayakumar, 2022). In addition, the pozzolanic reactivity of fine CTA particles, which leads to a densification of the microstructure of cement-based composites and a reduction in the pore size within such composites (Mohammadhosseini et al., 2020a). The trend observed generally extends up to a replacement ratio of 40%, whereas a further increase in the replacement ratio results in an increase in the transportation of chloride ions (Packrisamy and Jayakumar, 2022). In addition, ageing of the concrete is accompanied by a decrease in chloride permeability within the CTA-based concrete. The values for total charge permeability fall below the "very low" range, indicating that the concrete is durable in terms of chloride permeability (Etxeberria and Gonzalez-Corominas, 2018; Gonzalez-Corominas and Etxeberria, 2014; Packrisamy and Jayakumar, 2022). The decrease in chloride penetration can be attributed to the impeded diffusion of chloride ions within the cement matrix around the fine CTA particles due to pozzolanic activity. Fig. 18 shows the influence of fine CTA as a substitute for natural fine aggregate on chloride diffusion behaviour.

Fig. 18. The influence of fine CTA as a substitute for NFA on chloride diffusion behaviour (Adapted from (Packrisamy and Jayakumar, 2022; Sundo et al., 2015)).

Fig. 18. The influence of fine CTA as a substitute for NFA on chloride diffusion behaviour (Adapted from (Packrisamy and Jayakumar, 2022; Sundo et al., 2015)).3.3. Resistance to sulphate attack

The correlation between the increase in the fine fraction of CTA and the resistance to expansion due to sulphate attack is noted (Ambrose et al., 2023; Meena et al., 2023; Samadi et al., 2020b). The pozzolanic reaction of a part of fine CTA leads to a decrease in the formation of surplus ettringite, which is generally produced by the reaction between sulphate and calcium hydroxide (Meena et al., 2023). The diminished occurrence of secondary ettringite in concrete based on fine CTA enhances its capacity to withstand expansion resulting from sodium sulphate. In addition, the presence of CTA particles with a coarse surface and angular morphology results in favourable interlocking with the cement paste, improving resistance to attack by sulfuric acid (Meena et al., 2023). It is important to highlight that the pozzolanic activity of fine CTA supersedes the effect of increased porosity in concrete mixtures that utilize CTA, thus increasing their resilience against sulphate attack.

3.4. Drying shrinkage

Elçi (2016) reported that the use of CTA as a substitute for NCA increased the drying shrinkage of concrete. The results showed that the shrinkage value of aggregates for floor tiles and wall tiles was 1.37 and 2.42 times higher than that of control specimens, respectively. This could be attributed to the high-water absorption of CTA. In another study, Younis et al. (2022) documented the occurrence of both early and late shrinkage. The admixture of CTA as a coarse aggregate in self-curing concrete results in a reduction of drying shrinkage. The porous CTA material exhibits a phenomenon known as the "reservoir effect" In this effect, the absorbed moisture is gradually released into the concrete mix during the drying process, resulting in a reduction in shrinkage at a constant water-cement ratio. On the other hand, the use of fine CTA as a substitute for NFA showed a reduction in drying shrinkage of cement-based composites (Batikha et al., 2021; Ghrieb et al., 2021; Vilas Meena et al., 2022e; Rodríguez-Álvaro et al., 2022). The decrease in shrinkage noted indicates that the aggregates played a part in partially reducing the process of self-desiccation, which happened concurrently with external drying over a certain period. This decrease in drying shrinkage could be due to the angular particle packing of fine CTA (Vilas Meena et al., 2022e).

4. Ceramic tile powder (CTP) as cement replacement

4.1. Physical aspects

Ceramic tile waste (CTW) is available in white and red colours. The existence of a significant amount of iron oxide (Fe2O3) is considered to be the cause of the red colour of CTW (Monteiro et al., 2008; Pacheco-Torgal and Jalali, 2010). After being subjected to fine grinding, the particles of CTP become more uniform and acquire a rounder appearance (Pereira-de-Oliveira et al., 2012b; Xu et al., 2021) as illustrated in Fig. 19. The specific gravity of CTP is between 2.30 and 2.80. The reported physical properties of the CTP vary from one research to another owing to the differences in the grinding process adopted, e.g., the amount of material in a ball mill and the duration of grinding. Scanning electron microscope findings show that the CTP consists of angular and irregular particles resembling cement (Aly et al., 2019; Chen et al., 2022; El-Dieb and Kanaan, 2018; Kannan et al., 2017; Mohit and Sharifi, 2019). As the grain size gradation of CTP is comparable to that of cement (as illustrated in Fig. 20) (Chen et al., 2022; Gautam et al., 2021; Ouyang et al., 2022a). Fig. 19 demonstrates the appearance of CTW. Table 4 exhibits the various physical properties of CTP.

Fig. 19. (a)Ceramic tile waste at dumping site (b) Ceramic tile powder (Adapted from (Xu et al., 2021)) (c) SEM Image of ceramic tile powder, enlarged with 20kx (Adapted from (Mohit and Sharifi, 2019)) (d) SEM Image of ceramic tile powder, enlarged with 40kx (Adapted from (Mohit and Sharifi, 2019)) (

Fig. 19. (a)Ceramic tile waste at dumping site (b) Ceramic tile powder (Adapted from (Xu et al., 2021)) (c) SEM Image of ceramic tile powder, enlarged with 20kx (Adapted from (Mohit and Sharifi, 2019)) (d) SEM Image of ceramic tile powder, enlarged with 40kx (Adapted from (Mohit and Sharifi, 2019)) (